Jcb 3155 fastrac service repair manual sn:00642001 00643010

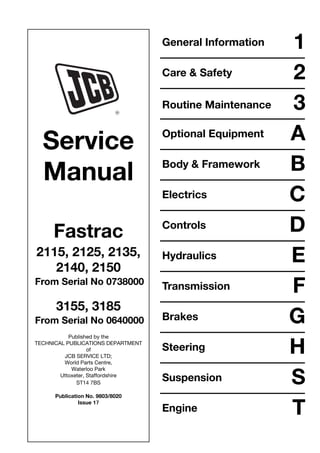

- 1. Service Manual Fastrac 2115, 2125, 2135, 2140, 2150 From Serial No 0738000 3155, 3185 From Serial No 0640000 Published by the TECHNICAL PUBLICATIONS DEPARTMENT of JCB SERVICE LTD; World Parts Centre, Waterloo Park Uttoxeter, Staffordshire ST14 7BS Publication No. 9803/8020 Issue 17 General Information 1 Care & Safety 2 3 Optional Equipment A Body & Framework B Electrics C Controls D Hydraulics E Transmission F Brakes G Steering H Suspension S Engine T Routine Maintenance

- 2. 9803/8020 Issue 1 Introduction This publication is designed for the benefit of JCB Distributor Service Engineers who are receiving, or have received, training by JCB Technical Training Department. These personnel should have a sound knowledge of workshop practice, safety procedures, and general techniques associated with the maintenance and repair of hydraulic earthmoving equipment. Renewal of oil seals, gaskets, etc., and any component showing obvious signs of wear or damage is expected as a matter of course. It is expected that components will be cleaned and lubricated where appropriate, and that any opened hose or pipe connections will be blanked to prevent excessive loss of hydraulic fluid and ingress of dirt. Finally, please remember above all else SAFETY MUST COME FIRST! The manual is compiled in sections, the first three are numbered and contain information as follows: 1 = General Information - includes torque settings and service tools. 2 = Care & Safety - includes warnings and cautions pertinent to aspects of workshop procedures etc. 3 = Routine Maintenance - includes service schedules and recommended lubricants for the whole machine. The remaining sections are alphabetically coded and deal with Dismantling, Overhaul etc. of specific components, for example: A = Optional Equipment B = Body & Framework ...etc The page numbering in each alphabetically coded section is not continuous. This allows for the insertion of new items in later issues of the manual. Section contents, technical data, circuit descriptions, operation descriptions etc. are inserted at the beginning of each alphabetically coded section. All sections are listed on the front cover; tabbed divider cards align directly with individual sections on the front cover for rapid reference. Page cross references are generally made by presenting the subject title printed in bold, followed by the title of the section containing the subject. For example: “24 If the axle is still on the machine, fit the brake calipers (see Brake Caliper Removal and Replacement, Section G).” Note: If only the subject title in bold is given, i.e. no section title, the cross reference is to another part of the same section. Use the contents list at the beginning of each section to find the exact page number. Where a torque setting is given as a single figure it may be varied by plus or minus 3%. Torque figures indicated are for dry threads, hence for lubricated threads may be reduced by one third. ‘Left Hand’ and ‘Right Hand’ are as viewed from the rear of the machine facing forwards.

- 3. i Section 1 General Information 9803/8020 Section 1 i Issue 4* Contents Page No. Machine Identification Plate 1 - 1 Typical Vehicle Identification Number (VIN) 1 - 1 Typical Engine Identification Number 1 - 1 Unit Identification 1 - 1 Torque Settings Introduction - Zinc Plated Fasteners and Dacromet Fasteners 2 - 1 Zinc Plated Fasteners 2 - 2 Dacromet Fasteners 2 - 3 to 2 - 6 Sealing and Retaining Compounds 3 - 1 Service Tools Numerical List 4 - 1 Service Tools Body and Framework 5 - 1 Electrics 6 - 1 Hydraulics 7 - 1 Transmission 8 - 1 Brakes 9 - 1 Steering 9 - 1 Suspension 9 - 2 Engine 9 - 2 Moving a Disabled Machine General 10 - 1 Preparation for Towing 10 - 1 Transporting the Machine 10 - 2 *

- 4. 1 - 1 Machine Identification Plate Each machine has an identification plate located at X. The Vehicle Identification Number (VIN), and the serial numbers of the engine and transmission are stamped on the plate. Typical Vehicle Identification No. (VIN) SLP FT 11 3 30 0738010 A B C D E F A = Manufacturing Code B = Machine Range C = Engine Code: 07 = 1006-6T4 10 = 6BTA 13 = New 1000 Series, Rating 1941/2300 (2115) 14 = New 1000 Series, Rating 1929/2300 (2125) 15 = New 1000 Series, Rating 1947/2300 (2135) 16 = New 1000 Series, Rating 1930/2200 (2150) 20 = Fastrac 2140 engine D = Transmission Speed Code: 3 = 30 km/h 4 = 40 km/h 5 = 55 km/h 6 = 65 km/h 7 = 75 km/h C = 40 km/h (Fastrac 2140 only E = Vehicle Max. Speed Code: 30 = 30 km/h 40 = 40 km/h 50 = 50 km/h 80 = 80 km/h F = Sequential Serial Number Typical Engine Identification Number YH 50532 U 123456 X G H J K L G = Engine Type:- YB = Turbocharged 1000 Series, 6 cylinder YD = Intercooled 1000 Series, 6 cylinder YH = Turbocharged New 1000 Series, 6 cylinder YK = Intercooled New 1000 Series, 6 cylinder H = Build List Number (see Engine Technical Data for details) J = Country of Origin K = Engine Serial Number L = Year of Manufacture Note: Fastrac 2140 and 3185 engines are identified by the model number and a separate engine serial number. Unit Identification The serial number of each major unit is also stamped on the unit itself as shown below. If a major unit is replaced by a new one, the serial number on the plate will be wrong. Either stamp the new number of the unit on the identification plate, or simply stamp out the old number. This will prevent the wrong unit number being quoted when replacement parts are ordered. Fastrac 2115, 2125, 2135, 2150 and 3155 Engines M Fastrac 2140 and 3185 Engines T Transmission (Assembly of all three gearboxes) N Speed Gearbox P Front Axle R Rear Axle S Section 1 General Information 9803/8020 Section 1 1 - 1 Issue 3* 194601 S P X R T M N * * * *

- 5. 2 - 1 Section 1 General Information 9803/8020 Section 1 2 - 1 Issue 3* Torque Settings Introduction - Zinc Plated Fasteners and Dacromet Fasteners The JCB Fastrac 3000 series from serial number 642494 and the Fastrac 2000 series from serial number 740276 are assembled using an improved type of corrosion resistant finish on the external fasteners. This type of finish is called Dacromet and replaces the original Zinc and Yellow plating used on earlier machines. The two types of fasteners can be readily identified by colour and part number suffix as follows: Fastener Type Colour Part Number Zinc and Yellow Golden finish ‘Z’ (e.g. 1315/3712Z) Dacromet Mottled silver finish ‘D’ (e.g. 1315/3712D) Note: As the Dacromet fasteners have a lower torque setting than the Zinc and Yellow fasteners, when servicing the Fastrac it is important that you are aware of this change of policy and that the information you are using is relevant to the type of fasteners that you have. Note: A Dacromet bolt should not be used in conjunction with a Zinc and Yellow plated nut, as this could change the torque characteristics of the torque settings further. For the same reason, a Dacromet nut should not be used in conjunction with a Zinc and Yellow plated bolt. Note: All bolts used on JCB machines are high tensile and must not be replaced by bolts of a lesser tensile specification. Note: Dacromet bolts, due to their high corrosion resistance are used areas where rust could occur. Dacromet bolts are only used for external applications. *

- 6. 2 - 2 Section 1 General Information 9803/8020 Section 1 2 - 2 Issue 1* Torque Settings Zinc Plated Fasteners (golden finish) Use only where no torque setting is specified in the text. Values are for dry threads and may be within three per cent of the figures stated. For lubricated threads the values should be REDUCED by one third. Metric Grade 8.8 Bolts Bolt size Torque Settings Dia. (mm) Hexagon Nm kgf m lbf ft (A/F) mm M5 (5) 8 7 0.7 5 M6 (6) 10 12 1.2 9 M8 (8) 13 28 3.0 21 M10 (10) 17 56 5.7 42 M12 (12) 19 98 10 72 M16 (16) 24 244 25 180 M18 (18) 27 350 36 258 M20 (20) 30 476 48 352 M24 (24) 36 822 84 607 M30 (30) 46 1633 166 1205 M36 (36) 55 2854 291 2105 Metric Grade 10.9 Bolts Bolt size Torque Settings Dia. (mm) Hexagon Nm kgf m lbf ft (A/F) mm M6 (6) 8 16 1.6 12 M8 (8) 13 39 4 29 M10 (10) 17 78 8 57 M12 (12) 19 137 14 101 M16 (16) 24 343 35 253 M20 (20) 30 657 67 485 M24 (24) 36 1157 118 853 Hydraulic Hose to Adapter Connections Hydraulic Adapter into Component Connections with bonded washers Torque Settings Torque Settings BSP Size Nm kgf m lbf ft BSP Size Nm kgf m lbf ft (inches) (inches) 1/8 14 1.4 10 1/8 20 2.1 15 1/4 24 2.5 18 1/4 34 3.4 25 3/8 33 3.3 24 3/8 75 7.6 55 1/2 44 4.8 35 1/2 102 10.3 75 5/8 58 6.0 43 5/8 122 12.4 90 3/4 84 8.6 62 3/4 183 18.7 135 1 115 11.8 85 1 203 20.7 150 11/2 244 24.9 180 11/2 305 31 225 Metric - All Internal Hexagon Headed Cap Screws Diameter Torque mm Nm kgf m lbf ft M3 2 0.2 1.5 M4 6 0.6 4.5 M5 11 1.1 8 M6 19 1.9 14 M8 46 4.7 34 M10 91 9.3 67 M12 159 16.2 117 M16 395 40 292 M18 550 56 406 M20 770 79 568 M24 1332 136 983 Verbus Ripp Bolts Torque settings for these bolts are determined by the application. Refer to the relevant procedure for the required settings. Note: In most cases Verbus Ripp bolts should not be re- used. If one is disturbed it should be removed and a new one fitted in its place. For details of exceptions to this general rule, see T.I.’s 10/140 (F161/N. Am) and 10/141 (F162 N. Am). A343780

- 7. 2 - 3 Section 1 General Information 9803/8020 Section 1 2 - 3 Issue 1* Torque Settings Dacromet Fasteners (mottled silver finish) Use only where no torque setting is specified in the text. NOTE: DACROMET FASTENERS ARE LUBRICATED AS PART OF THE PLATING PROCESS: DO NOT LUBRICATE. Metric Grade 8.8 Bolts Bolt size Torque Settings Dia. Nm kgf m lbf ft M6 x 1.0 9 0.9 7 M8 x 1.25 22.5 2.3 17 M10 x 1.5 47.5 4.8 35 M12 x 1.75 80 8.2 59 M14 x 2 133 13.6 98 M16 x 2 200 20.4 148 M18 x 2.5 278 28.4 205 M20 x 2.5 392 40 289 M24 x 3 675 69 498 M30 x 3.5 1348 138 994 Metric Grade 10.9 Bolts Bolt size Torque Settings Dia. Nm kgf m lbf ft M6 x 1.0 13.5 1.4 10 M8 x 1.25 35 3.6 26 M10 x 1.5 62.5 6.4 46 M12 x 1.75 115 11.7 85 M14 x 2 175 17.9 129 M16 x 2 300 30.6 221 M18 x 2.5 395 40 291 M20 x 2.5 559 57 412 M24 x 3 962 98 710 M30 x 3.5 1920 196 1416 Metric Grade 12.9 Bolts Bolt size Torque Settings Dia. Nm kgf m lbf ft M6 x 1.0 15 1.5 11 M8 x 1.25 40 4.1 29 M10 x 1.5 80 8.2 59 M12 x 1.75 133 13.6 98 M14 x 2 225 23 166 M16 x 2 350 35.7 258 M18 x 2.5 463 47 342 M20 x 2.5 654 67 482 M24 x 3 1125 115 830 M30 x 3.5 2247 229 1657

- 8. 2 - 4 Section 1 General Information 9803/8020 Section 1 2 - 4 Issue 1* Torque Settings Dacromet Fasteners (mottled silver finish) - List of Torque Settings This list represents those fasteners which have been affected by the change from zinc-plated to Dacromet but are not mentioned in the service manual. The settings apply to 2000 and 3000 series machines unless otherwise stated. Location: Gearbox Crossmember Nm: 200 kgfm: 20 lbf ft: 148 Location: Rockinger Hitch Bolt Nm: 392 kgfm: 40 lbf ft: 289 A402030 Bolt: Rear Crossmember Nm: 392 kgf m: 40 lbf ft: 289 A402280 Bolt: Left Hand Pannier Step Nm: 47.5 kgf m: 4.8 lbf ft: 35 A402200 Bolt: Right Hand Pannier (rear) Nm: 80 kgf m: 8.2 lbf ft: 59 (2000 series machines only) A402190 Bolt: Right Hand Pannier (front) Nm: 47.5 kgf m: 4.8 lbf ft: 35 (2000 series machines only) A402160 Bolt: Front Wrapper (top/bottom) Nm: 392 kgf m: 40 lbf ft: 289 A402060 Bolt: Rear Lower Crossmember Nm: 80 kgf m: 8.2 lbf ft: 59 (2000 series machines only) A402050 Bolt: Lower Link Bolt (Hex Head) Nm: 392 kgf m: 40 lbf ft: 289 A402040

- 9. 2 - 5 Section 1 General Information 9803/8020 Section 1 2 - 5 Issue 2 Torque Settings Dacromet Fasteners (mottled silver finish) - List of Torque Settings (cont.) Location: Lower Link Bolt (capscrew) Nm: 654 kgf m: 67 lbf ft: 482 A402140 Location: Tower Casting to Axle Nm: 392 kgf m: 40 lbf ft: 289 A402010 Location: Front Lower Crossmember Nm: 115 kgf m: 12 lbf ft: 85 A401990 Location: Rear Lower Crossmember Nm: 200 kgf m: 20 lbf ft: 148 (3000 series machines only) A402260 Location: Fuel Tank Support Strap Nm: 47.5 kgf m: 4.8 lbf ft: 35 (2000 series machines only) A402090 Location: Front P.T.O. Box Nm: 200 kgf m: 20 lbf ft: 148 A402230 Location: Front Axle Upper Arm Mounting Bracket Nm: 200 kgf m: 20 lbf ft: 148 (3000 series machines only) A402270 Location: Steershaft Bearing Nm: 28 kgf m: 2.9 lbf ft: 21 (3000 series machines only) Location: Steershaft Intermediate UJ Nm: 38 kgf m: 3.9 lbf ft: 28 (3000 series machines only)

- 10. 2 - 6 Section 1 General Information 9803/8020 Section 1 2 - 6 Issue 2* Torque Settings Dacromet Fasteners (mottled silver finish) - List of Torque Settings (cont.) Location: Rear Anti-Roll bar mounting bracket Nm: 392 kgf m: 40 lbf ft: 289 (3000 series machines only) A402120 Location: Front Anti-Roll Bar Fasteners: Pivot Bolt Nm: 200 kgf m: 20 lbf ft: 148 (3000 series machines only) A402110 Location: Front Engine Mounting Nm: 200 kgf m: 20 lbf ft: 148 A402150 Location: Header Tank Clamp Plate Nm: 30 kgf m: 3 lbf ft: 22 (3000 series machines only) A402290 Location: Front Anti-Roll Bar Fasteners: Pivot Bolt Nm: 278 kgf m: 28 lbf ft: 205 (2000 series machines only) Location: 4.W.S. only rear anti-roll bar crossmember Nm: 80 kgf m: 8.2 lbf ft: 59 (2000 series machines only) A402130 A402080 * Location: Front Anti-Roll Bar Fasteners: Insulators Nm: 47.5 kgf m: 4.8 lbf ft: 35

- 11. 3 - 1 Section 1 General Information 9803/8020 Section 1 3 - 1 Issue 2* * Sealing and Retaining Compounds Gasketing - Loctite 509 To seal the joint faces between the PTO/splitter gearbox, the 4102/3202 50ml speed gearbox and the range gearbox. 4102/3240 315 ml JCB Multigasket A medium strength sealant suitable for all sizes of gasket flanges, and for hydraulic fittings of 25-65 mm diameter. 4102/1212 JCB High Strength Threadlocker A high strength locking fluid for use with threaded components. 4102/0551 Gasketing for all sizes of flange where the strength of the joint is important. JCB Retainer (High Strength) For all retaining parts which are unlikely to be dismantled. 4101/0651 JCB Threadlocker & Sealer A medium strength locking fluid for sealing and retaining nuts, bolts, and screws up to 50 mm diameter, and for hydraulic fittings up to 25 mm diameter. 4101/0251 JCB Threadlocker For threads of suction strainer. 4101/0451 50ml JCB Threadlocker & Sealer A medium to high strength locking fluid. 4101/0552 (High Strength) JCB Threadseal Medium strength thread sealant (for patch bolts that are re-used). 4102/1951 50 ml Clayton System Seal SC1251 A thread sealant used mainly on air brake system hose adapters. 4102/2210 2ml JCB Activator A cleaning primer which speeds the curing rate of anaerobic 4104/0251 Aerosol products. 4104/0253 Bottle JCB Cleaner/Degreaser For degreasing components prior to use of anaerobic adhesives and sealants. 4104/1557 Aerosol Direct Glazing Kit For one pane of glass, comprises items marked † below plus applicator nozzle etc. 993/55700 † Ultra Fast Adhesive For direct glazing 4103/2109 310 ml † Active Wipe 205 For direct glazing 4104/1203 250 g 4104/1206 30 ml † Black Primer 206J For direct glazing 4201/4906 30 ml JCB Clear Silicone Sealant To seal butt jointed glass. Also to seal hub planet gear carrier when no 'O' ring is fitted 4102/0901 Black Polyurethane Sealant To finish exposed edges of laminated glass 4102/2309 310 ml

- 12. * 4 - 1 Service Tools Numerical List Page No. 1370/0901Z Nut M24 9 - 1 1406/0021 Bonded Washer 7 - 1 1604/0006 Adapter 7 - 1 1604/0008 Adapter 7 - 1 1606/0012 Adapter 7 - 1 1606/0015 Adapter 7 - 1 1612/0006 Adapter 7 - 1 331/64246 Tool Kit for Non-return Valve 7 - 2 331/64265 etaining Bush for Valve spool 7 - 2 4101/0251 JCB Threadlocker and Sealer 3 - 1 4101/0451 JCB Threadlocker 3 - 1 4101/0552 JCB Threadlocker and Sealer (High Strength) 3 - 1 4101/0651 JCB Retainer (High Strength) 3 - 1 4102/0551 JCB High Strength Threadlocker 3 - 1 4102/0901 JCB Clear Silicone Sealant 3 - 1 4102/1212 JCB Multigasket 3 - 1 4102/1951 JCB Threadseal 3 - 1 4102/2210 Clayton System Seal SC1251 3 - 1 4102/2309 Black Polyurethane Sealant 3 - 1 4103/2109 Ultra Fast Adhesive 3 - 1 4104/0251 JCB Activator (Aerosol) 3 - 1 4104/0253 JCB Activator (Bottle) 3 - 1 4104/1557 JCB Cleaner/Degreaser 3 - 1 4104/1203 Active Wipe 205 (250 g) 3 - 1 4104/1206 Active Wipe 205 (30 ml) 3 - 1 4104/1310 Hand Cleaner 5 - 1 4201/4906 Black Primer 3 - 1 454/30056 Spacer 13.80 mm 8 - 4 477/00437 Gearbox Lifting Adapter 8 - 2 721/00664 Connecting Lead (Psion Workabout) 6 - 1 721/10885 Harness - Diagnostic (J1939) 6 - 2 816/15118 Test Adapter 7 - 1 816/20008 Adapter 7 - 1 816/20013 Adapter 7 - 1 816/55038 Adapter/Test Point 7 - 1 816/55040 Adapter/Test Point 7 - 1 892/00041 Deglazing Tool 9 - 2 892/00078 Connector 7 - 1 892/00137 Micro Bore Hose 7 - 2 892/00174 Measuring Cup 8 - 2 892/00179 Bearing Press 8 - 1 892/00180 Seal Fitting Tool 9 - 1 892/00181 Replacement Plastic Boss 9 - 1 892/00223 Hand Pump 7 - 2 892/00224 Impulse Extractor 8 - 2 892/00225 Adapter for Impulse Extractor 8 - 1 892/00253 Pressure Test Kit 7 - 1 892/00255 Adapter/Test Point 7 - 1 892/00256 Adapter/Test Point 7 - 1 892/00257 Adapter/Test Point 7 - 1 892/00258 Adapter/Test Point 7 - 1 892/00259 Adapter/Test Point 7 - 1 892/00260 Adapter/Test Point 7 - 1 892/00261 Adapter/Test Point 7 - 1 892/00262 Adapter/Test Point 7 - 1 & 7 - 2 892/00263 Adapter/Test Point 7 - 1 892/00264 Adapter/Test Point 7 - 1 892/00265 Adapter/Test Point 7 - 1 892/00268 Flow Monitoring Unit 7 - 1 892/00269 Sensor Head 7 - 1 892/00270 Load Valve 7 - 1 892/00271 Adapter 7 - 1 892/00272 Adapter 7 - 1 892/00273 Sensor Head 7 - 1 892/00274 Adapter 7 - 2 892/00275 Adapter 7 - 1 892/00276 Adapter 7 - 1 892/00277 Adapter 7 - 1 892/00278 Gauge 0 - 40 bar 7 - 2 892/00279 Gauge 0 - 400 bar 7 - 2 892/00281 Avo Meter 6 - 1 892/00282 Shunt 6 - 1 892/00283 Tool Kit Case 6 - 1 892/00284 Digital Tachometer 6 - 1 892/00285 Oil Temperature Probe 6 - 1 892/00286 Surface Temperature Probe 6 - 1 892/00293 Connector Pipe 7 - 1 892/00294 Connector Pipe 7 - 1 892/00298 Fluke Multimeter 6 - 1 892/00311 Brake Test Kit 8 - 4 892/00312 Dummy End Plate 8 - 2 892/00313 Clutch Alignment Tool 8 - 1 892/00314 Accumulator Adapter 9 - 1 892/00315 Engine Support Brackets 8 - 1 892/00318 Hose and Adapter Kit 7 - 2 892/00333 Heavy Duty Socket, 19 mm A/F 8 - 2 892/00334 Gland Seal Fitting Tool 7 - 2 892/00706 Test Probe 7 - 2 892/00800 Splitting Frame 8 - 1 892/00801 Clutch spanner 5 - 3 892/00802 Rotor puller set 5 - 3 892/00803 Rotor installer set 5 - 3 892/00807 Front plate puller 5 - 3 892/00808 Shaft protector 5 - 3 892/00812 Drive Coupling Spanner 8 - 1 892/00817 Heavy Duty Socket, 17 mm A/F 8 - 2 892/00818 Heavy Duty Socket, 22mm A/F 8 - 2 892/00819 Heavy Duty Socket, 15 mm A/F 8 - 2 892/00842 Glass Lifter 5 - 1 892/00843 Folding Stand 5 - 1 892/00844 Long Knife 5 - 2 892/00845 Cartridge Gun 5 - 1 892/00846 Glass Extractor Handles 5 - 2 892/00847 Nylon Spatula 5 - 3 892/00848 Wire Starter 5 - 2 892/00849 Braided Cutting Wire 5 - 2 892/00864 PD 90 Axle Locknut Spanner 8 - 4 892/00871 Frame (Puller Adapter Assembly) 9 - 1 892/00874 Brace (Puller Adapter Assembly) 9 - 1 892/00875 Bar M24 (Puller Adapter Assembly) 9 - 1 892/00876 Block (Puller Adapter Assembly) 9 - 1 892/00882 Socket 6 - 1 892/00883 Spanner (Steer Box Input Shaft Nuts) 9 - 1 892/00884 ‘C’ Spanner (Steer Box Input Shaft Nuts) 9 - 1 892/00892 Speed Gearbox Locking Tool 8 - 3 892/00916 Spring Compressor 8 - 3 892/00918 Setting Tool Kit 8 - 4 892/00945 Sleeve for M30 Pinion 8 - 4 892/00956 Timing Pin for Fuel Injection Pump 9 - 2 892/01033 Data Link Adapter Kit 6 - 2 892/01045 Peg Socket - Wet Clutch 8 - 5 892/01046 Mandrel - Wet Clutch 8 - 5 892/01047 Jig - Wet Clutch 8 - 5 Section 1 General Information 9803/8020 Section 1 4 - 1 Issue 8* *

- 13. * 4 - 2 Service Tools Numerical List (continued) Page No. 892/01048 Clutch Pack Retainer - Wet Clutch (2 required) 8 - 4 892/01049 Guide Rod - Wet Clutch (2 required) 8 - 4 892/01050 Mandrel - Wet Clutch 8 - 5 892/01051 Intermediate Gear Retaining Tool - Wet Clutch Transmission 8 - 4 892/01052 Locking Plate - Wet Clutch (2 required) 8 - 4 892/01053 Adapter for impulse extractor (PTO intermediate shaft, wet clutch transmission) 8 - 2 892/01092 Wheel Hub Service Kit 8 - 5 926/15500 Rubber Spacer Blocks 5 - 3 992/12300 Mobile Oven 5 - 1 992/12400 Static Oven 5 - 1 992/12600 Static Oven 5 - 1 992/12800 Cut-out Knife 5 - 2 992/12801 'L' Blades 5 - 2 993/45400 Torque Multiplier 8 - 2 993/55700 Direct Glazing Kit 3 - 1 993/59300 Pressure Test Adapter and Clamp 8 - 3 993/70111 Break-back Torque Wrench 8 - 4 993/85700 Battery Tester 6 - 1 997/11000 Drive Head Setting Bracket 8 - 4 997/11100 Adapter for M24 Pinion 8 - 4 The following parts are replacement items for kits and would normally be included in the relevant kit numbers. Replacement items for kit no. 892/00253 892/00201 Gauge 0 - 20 bar 7 - 1 892/00202 Gauge 0 - 40 bar 7 - 1 892/00203 Gauge 0 - 400 bar 7 - 1 892/00254 Hose 7 - 1 993/69800 Seal Kit 7 - 1 Replacement parts for kit no. 892/01092 1315/3414Z Bolt M10x60 8 - 5 1315/3731Z Bolt M16x220 8 - 5 1315/3835Z Bolt M20x300 8 - 5 1370/0301Z Nut M10 8 - 5 1370/0401Z Nut M12 8 - 5 1370/0601Z Nut M16 8 - 5 1370/0701Z Nut M20 8 - 5 1420/0009Z Washer M12 8 - 5 1420/0012Z Washer M20 8 - 5 445/12303 Washer 8 - 5 892/00891 Dolly 8 - 5 917/02800 Bearing 8 - 5 998/10606 Bearing Fitting Tube 8 - 5 998/10607 Inner Bearing Plate 8 - 5 998/10608 Bearing Centre Puller 8 - 5 998/10610 Puller Rod 8 - 5 998/10614 Reaction Tube 8 - 5 998/10615 Wheel Bearing Carrier Puller 8 - 5 998/10616 Puller Handle Nut 8 - 5 998/10623 Puller Beam 8 - 5 998/10624 Modified Wheel Stud 8 - 5 Section 1 General Information 9803/8020 Section 1 4 - 2 Issue 6* * *

- 14. 5 - 1 Section 1 General Information 9803/8020 Section 1 5 - 1 Issue 1 Service Tools Section B - Body and Framework S186240 Hand Cleaner - special blend for the removal of polyurethane adhesives. JCB part number - 4104/1310 (454g; 1lb tub) S186250 12V Mobile Oven - 1 cartridge capacity - required to pre-heat adhesive prior to use. It is fitted with a male plug (703/23201) which fits into a female socket (715/04300). JCB part number - 992/12300 S186260 240V Static Oven - available with 2 or 6 cartridge capacity - required to pre-heat adhesive prior to use. No plug supplied. Note: 110V models available upon request - contact JCB Technical Service JCB part number: 992/12400 - 2 cartridge x 240V 992/12600 - 6 cartridge x 240V S186270 Cartridge Gun - hand operated - essential for the application of sealants, polyurethane materials etc. JCB part number - 892/00845 ' S186280 Folding Stand for Holding Glass - essential for preparing new glass prior to installation. JCB part number - 892/00843 S186300 Glass Lifter - minimum 2 off - essential for glass installation, 2 required to handle large panes of glass. Ensure suction cups are protected from damage during storage. JCB part number - 892/00842

- 15. Service Tools (continued) Section B - Body and Framework (continued) S186310 Wire Starter - used to access braided cutting wire (below) through original polyurethane seal. JCB part number - 892/00848 S186320 Glass Extractor (Handles) - used with braided cutting wire (below) to cut out broken glass. JCB part number - 892/00846 S186330 Braided Cutting Wire - consumable heavy duty cut-out wire used with the glass extraction tool (above). JCB part number - 892/00849 (approx 25m length) S186340 Cut-out Knife - used to remove broken glass. JCB part number - 992/12800 ' S186350 'L' Blades - 25mm (1in.) cut - replacement blades for cut-out knife (above). JCB part number - 992/12801 (unit quantity = 5 off) S186360 Long Knife - used to give extended reach for normally inaccessible areas. JCB part number - 892/00844 5 - 2 Section 1 General Information 9803/8020 Section 1 5 - 2 Issue 1

- 16. Service Tools (continued) Section B - Body and Framework (continued) S186470 Nylon Spatula - general tool used for smoothing sealants - also used to re-install glass in rubber glazing because metal tools will chip the glass edge. JCB part number - 892/00847 892/00801 Clutch spanner S200940 for air conditioning compressor 892/00802 Rotor puller set S200950 for air conditioning compressor 892/00803 Rotor installer set S200960 for air conditioning compressor S186550 Rubber Spacer Blocks - used to provide the correct set clearance between glass edge and cab frame. JCB part number - 926/15500 (unit quantity = 500 off) 892/00807 Front plate puller S200970 for air conditioning compressor 892/00808 Shaft protector S200980 for air conditioning compressor 5 - 3 Section 1 General Information 9803/8020 Section 1 5 - 3 Issue 1

- 17. 6 - 1 Section 1 General Information 9803/8020 Section 1 6 - 1 Issue 2* 188230 239510 S216770 Electrical Test Equipment 1 892/00283 Tool Kit Case 2 892/00281 AVO Meter 3 892/00286 Surface Temperature Probe 4 892/00284 Microtach Digital Tachometer 5 892/00282 100 Amp Shunt - open type 6 892/00285 Hydraulic Oil Temperature Probe 7 892/00298 Fluke 85 Multimeter Service Tools Section C - Electrics 993/85700 Battery Tester 892/00882 Socket for Pulley Nut on Magneti Marelli Alternator. Psion Workabout 1Mb/RS232 † Docking Holster † Software - Psion Link, Version 1.1 † 721/00664 Connecting Lead 2 x CD ROM †† † These items to be obtained from your nearest Psion agent as listed on M.I.’s 569/H, 525 HA and 516E. †† As detailed on the same M.I.’s as above.

- 18. 6 - 2 Service Tools Section C - Electrics Section 1 General Information 9803/8020 Section 1 6 - 2 Issue 1 A360250 892/01033 Data Link Adapter Kit Note: Item A of the Data Link Adapter Kit is unsuitable for use with the Fastrac and must be replaced by the ‘Harness - Diagnostic (J1939)’ shown below. 8 1514131211109 7654321 D FAB C H J E G A386040 721/10885 Harness - Diagnostic (J1939) AA

- 19. 7 - 1 Section 1 General Information 9803/8020 Section 1 7 - 1 Issue 1 Pressure Test Adapters 892/00255 1/4 in BSP x Test Point 892/00256 3/8 in BSP x Test Point 892/00257 1/2 in BSP x Test Point 892/00258 5/8 in BSP x Test Point 816/15118 3/4 in BSP x Test Point 892/00259 1 in BSP x Test Point 892/00260 1.1/4 in BSP x Test Point 892/00261 5/8 in UNF x Test Point Pressure Test 'T' Adapters 892/00262 1/4 in M BSP x 1/4 in F BSP x Test Point 816/55038 3/8 in M BSP x 3/8 in F BSP x Test Point 816/55040 1/2 in M BSP x 1/2 in F BSP x Test Point 892/00263 5/8 in M BSP x 5/8 in F BSP x Test Point 892/00264 3/4 in M BSP x 3/4 in F BSP x Test Point 892/00265 1 in M BSP x 1 in F BSP x Test Point Hydraulic Circuit Pressure Test Kit 892/00253 Pressure Test Kit 892/00201 Replacement Gauge 0-20 bar (0-300 lbf/in2 ) 892/00202 Replacement Gauge 0-40 bar (0-600 lbf/in2 ) 892/00203 Replacement Gauge 0-400 bar (0-6000 lbf/in2 ) 892/00254 Replacement Hose :993/69800 Seal Kit for 892/00254 (can also be used with probe 892/00706) S188130 S188120 S200140 Service Tools Section E - Hydraulics Flow Test Equipment 892/00268 Flow Monitoring Unit 892/00269 Sensor Head 0 - 100 l/min (0 - 22 UK gal/min) 892/00293 Connector Pipe 892/00270 Load Valve 1406/0021 Bonded Washer 1604/0006 Adapter 3/4 in M x 3/4 in M BSP 1612/0006 Adapter 3/4 in F x 3/4 in M BSP 892/00271 Adapter 3/4 in F x 5/8 in M BSP 892/00272 Adapter 5/8 in F x 3/4 in M BSP 816/20008 Adapter 3/4 in F x 1/2 in M BSP 892/00275 Adapter 1/2 in F x 3/4 in M BSP 892/00276 Adapter 3/4 in F x 3/8 in M BSP 892/00277 Adapter 3/8 in F x 3/4 in M BSP 892/00273 Sensor Head 0 - 380 l/min 892/00294 Connector Pipe 1606/0015 Adapter 1.1/4 in M BSP x 1 in M BSP 892/00078 Connector 1 in F x 1 in F BSP 1604/0008 Adapter 1 in M x 1 in M BSP 1606/0012 Adapter 1 in M x 3/4 in M BSP 816/20013 Adapter 3/4 in F x 1 in M BSP S188150

- 20. Service Tools (continued) Section E - Hydraulics (continued) Hand Pump Equipment 892/00223 Hand Pump 892/00137 Micro-bore Hose 1/4 in BSP x 5 metres 892/00274 Adapter 1/4 in BSP male x 3/8 BSPT male 892/00262 Test Point on 1/4 in BSP male x 1/4 BSP female adapter 892/00706 Test Probe 892/00278 Gauge 0-40 bar (0-600 lbf/in2 ) 892/00279 Gauge 0-400 bar (0-6000 lbf/in2 ) 892/00334 Gland Seal Fitting Tool 331/64265 Retaining Bush for Valve Spool 892/00318 Hose And Adapter Kit To enable flow and pressure test equipment to be connected to adapters fitted with 'O' ringface seals. 331/64246 Tool Kit for Non-return Valve 7 - 2 Section 1 General Information 9803/8020 Section 1 7 - 2 Issue 2 S193850 197210 197220

- 21. 8 - 1 Section 1 General Information 9803/8020 Section 1 8 - 1 Issue 2 892/00315 Engine Support Bracket 892/00812 Drive Coupling Spanner for yoke couplings 892/00225 Adapter - Impulse Extractor Small 17mm to 25mm Medium 25mm to 45mm Large 45mm to 80mm Service Tools Section F - Transmission 892/00800 Splitting Frame (complete with ratchet hoist) 892/00179 Bearing Press 892/00313 Clutch Alignment Tool 197260 188200 197280 107750 197270 197080

- 22. 8 - 2 Service Tools (continued) Section F - Transmission (continued) Heavy Duty Sockets 892/00817 17 mm A/F x 3/4in. square drive 892/00818 22 mm A/F x 3/4in. square drive 892/00819 15 mm A/F x 1/2in. square drive 892/00333 19 mm A/F x 3/4in. square drive 892/00224 Impulse Extractor Set for Hub Bearing Seals * 892/01053 Adapter for impulse extractor (PTO intermediate shaft, wet clutch transmission) 477/00437 Gearbox Lifting Adapter 993/45400 Torque Multiplier (use in conjunction with a torque wrench to give a 5 : 1 multiplication) 892/00174 Measuring Cup - Pinion Head Bearing 892/00312 Dummy End Plate for Range Gearbox Rear Differential Setting Key Cut from 5 mm plate to dimensions shown. Fabricate handle to suit. Section 1 General Information 9803/8020 Section 1 8 - 2 Issue 3* 110 15 40 25 25 S197030 197250 S197070 197200 A197180 S197240 S190770

- 23. 8 - 3 Section 1 General Information 9803/8020 Section 1 8 - 3 Issue 3 S196750 S226300 S267310 993/59300 2/4 WD Pressure Test Adaptor & Clamp 892/00892 Speed Gearbox Locking Tool 892/00916 Spring Compressor for Splitter and PTO Clutches Service Tools (continued) Section F - Transmission (continued)

- 24. 8 - 4 Service Tools (continued) Section F - Transmission (continued) Section 1 General Information 9803/8020 Section 1 8 - 4 Issue 6* Solid Spacer Setting Tools 1 892/00918 Setting Tool Kit. Contains the following: A Sleeve for M24 Pinion B Adapter for M30 Pinion C Fork (suitable for all axles) The following setting tools must be purchased seperately: 892/00945 A Sleeve for M30 Pinion 997/11100 B Adapter for M24 Pinion 2 997/11000 Drive Head Setting Bracket 3 993/70111 Break-back Torque Wrench 4 - Solid spacer (see parts CD or michrofiche for part numbers) A270851 4 3 A B 2 1 C S234120 892/00864 PD 90 Axle Locknut Spanner A361710 A361730 892/01051 Intermediate Gear Retaining Tool - wet clutch transmission 892/01052 (x2) Locking Plate for locking wet clutch drum to housing A361740 892/01049 (x2) Guide Rod - wet clutch A361720 892/01048 (x2) Clutch Pack Retainer - wet clutch

- 25. 8 - 5 Service Tools (continued) Section F - Transmission (continued) Section 1 General Information 9803/8020 Section 1 8 - 5 Issue 1 A361750 892/01045 Peg Socket - wet clutch A361770 892/01046 Mandrel - for bush assembly - wet clutch A361760 892/01047 Jig, for use when dismantling and assembling of PTO input gear - wet clutch A361780 892/01050 Mandrel, for hub seal renewal - wet clutch. Note: Protective plastic cap A to be removed before use. A

- 26. 8 - 6 Section 1 9803/8020 Section 1 8 - 6 Issue 1 General Information Service Tools (continued) Section F - Transmission (continued) Item Description Part No. Qty A Hub Service Kit 892/01092 1 comprises: 1 Puller Beam 998/10623 1 2 Inner Bearing Plate 998/10607 1 3 Bolt M16x220 1315/3731Z 2 4 Nut M16 1370/0601Z 2 5 Reaction Tube 998/10614 1 6 Modified Wheel Stud 998/10624 2 7 Wheel Bearing Carrier Puller 998/10615 2 8 Nut M20 1370/0701Z 4 9 Washer M20 1420/0012Z 2 10 Puller Rod 998/10610 2 11 Nut M12 1370/0401Z 2 12 Washer M12 1420/0009Z 2 13 Bearing Centre Puller 998/10608 1 14 Bolt M10x60 1315/3414Z 1 15 Nut M10 1370/0301Z 1 16 Bearing Fitting Tube 998/10606 1 17 Puller Handle Nut 998/10616 1 18 Bolt M20x300 1315/3835Z 2 19 Washer 445/12303 2 20 Bearing 917/02800 1 21 Dolly 892/00891 1 1 A 2 3 4 5 6 7 8,9 10 11,12 8 14 15 21 13 16 17 18 19, 20

- 27. Service Tools (continued) Section H - Steering 9 - 1 Section 1 General Information 9803/8020 Section 1 9 - 1 Issue 3* 222490 AA BB DD CC EE Puller adapter assembly for removal of drop arm from steering box (3000 Series machines). Comprises: A 892/00871 Frame 1 off B 892/00874 Brace 1 off C 892/00875 Bar M24 2 off D 892/00876 Block 2 off E 1370/0901Z Nut M24 2 off Use in conjunction with a 20 tonne hydraulic ram as obtainable from Sykes Pickavant to suit puller bars at 185 mm centres. 220130 GG FF Spanners for input shaft nuts on steering box (3000 Series machines with serial nos. 640001 to 640053 and 640056 to 640058). F 892/00883 Spanner G 892/00884 ‘C’ Spanner Section G - Brakes S199470 892/00311 Brake Test Kit 3 x Calibrated Test Gauges - 0-20 bar (0 - 290 lbf/in2 ) 3 x 5 Metre Hoses with Quick Release Adapters 3 x ISO Test Point Adapters 229270 892/00180 Seal Fitting Tool for fitting ‘O’ ring and back-up ring to Danfoss Orbitrol Unit 892/00181 Replacement Plastic Boss

- 28. 9 - 2 Section T - Engine Note: For other engine tools refer to the relevant Engine Service Manual. Section 1 General Information 9803/8020 Section 1 9 - 2 Issue 2* S192390 892/00041 De-glazing Tool for Cylinder Bores (to assist bedding-in of new piston rings) A314530 892/00956 Timing pin for fuel injection pumps (Fastrac 2115, 2125, 2135, 2150 only). Service Tools (continued) S199480 892/00314 Accumulator and Gas Spring Pressure Test Adapter Section S - Suspension *

- 29. 10- 1 General Do not tow a machine unless there is no alternative. Remember that more damage might be caused to the machine by towing it. If at all possible repair the machine where it stands. Note: It is not possible to tow-start or push-start the Fastrac due to the design of the transmission. Make sure you will be obeying all pertinent laws and regulations before towing the machine on public roads. ! DANGER If the engine is not running, there will not be enough air to apply the service brakes or release the parking brake. Carefully follow the precautions in this section before moving the machine or there may be a serious accident. 13-2-2-6/1 ! CAUTION Towing a machine too far or too fast can damage the transmission. Do not tow the machine further than one mile. Use a trailer for greater distances. When towing do not travel faster than 25 km/h (15 mph). Use a rigid drawbar. If you must use towing chains, then use two towing vehicles. One towing vehicle should be coupled to the front of the disabled machine. The other towing vehicle should be coupled to the rear of the disabled machine, to provide braking power. The towing vehicle(s) must have enough pulling and braking power to move and stop the machine. 2-2-7-3 Preparation for Towing 1 Connect the towing vehicle. a Apply the parking brakes on the towing vehicle and securely chock the wheels on the Fastrac. b Fit the drawbar between towing vehicle and Fastrac. 2 Prepare the machine. a Make sure that the range and speed gearboxes are both in neutral. b If the gearbox has failed, disconnect both propshafts (see Section F). c If an axle has failed, remove the sun gears (see Section F). 3 Release the Fastrac parking brake. Note: The Schrader valve X shown below on the right hand side of the machine is that for Fastrac 2115, 2125 and 2135 machines. On 2150, 3155 and 3185 machines the valve is on the left hand side of the machine. If there is not enough air pressure to release the brake, start the engine to charge up the air system. If the engine cannot be run but the brake air system is serviceable, charge the system to 120 psi (8 bar) through Schrader valve X. This job must be done by a qualified mechanic, using the correct equipment. ! DANGER Ensure that the chocks and towing vehicle will prevent the Fastrac from moving as it is necessary to work under the machine to release the parking brake. When the parking brake has been manually released as described below, it will be impossible to apply the brake until plate A has been removed. 13-2-2-11 Alternatively, position plate A (if provided with the machine) as shown. Keeping nut B tight against clevis C, turn nut D against the plate so that rod E is drawn out of the actuator body and the parking brake is released. Note: If the parking brake cannot be released, remove both propshafts (see Section F). The machine is now ready for towing. If you will be steering the Fastrac, make sure you understand what the towing driver will be doing. Obey his instructions and all relevant regulations. Remember that the steering will be much heavier if the engine is not running. Section 1 General Information 9803/8020 Section 1 10 - 1 Issue 3* Moving a Disabled Machine S261600 S160392 X C E A D B A286550 *

- 30. 10 - 2 Transporting the Machine The safe transit of the load is the responsibility of the transport contractor and driver. Any machine, attachments or parts that may move during transit must be adequately secured. 5-2-5-9 Note: Before transporting the machine make sure you will be obeying the rules and laws of all the areas that the machine will be carried through. Make sure that the transporting vehicle is suitable. See Static Dimensions (SPECIFICATIONS section in the machine handbook) for the dimensions of the machine. ! WARNING Before moving the machine onto the trailer, make sure that the trailer and ramp are free from oil, grease and ice. Remove oil, grease and ice from the machine tyres. Make sure the machine will not foul on the ramp angle. See Static Dimensions in SPECIFICATIONS section for the minimum ground clearance of your machine. 2-2-7-5/1 1 Place blocks at the front and rear of the trailer wheels. 2 Move the machine on to the trailer as follows: a Make sure the ramps are correctly in place and secure. b Carefully drive the machine onto the trailer. c Set the drive to neutral and engage the parking brake. d Switch off the engine. e Ensure that the overall height of the load is within regulations. f Secure the cab. 3 Anchor the machine to the trailer with chains or suitable webbing straps. The preferred fixing is to use webbing straps individually fixing all four wheels to the deck of the trailer as at A. If chains are used they should be connected to a suitable part of the drawbar at the rear of the machine. At the front, use the tie down points. Avoid chaining any part of the machine where the chains may damage critical componentry. For example, chaining around either axle provides the possibility of damaging the steel brake pipes running along their length. 4 Measure the maximum height of the machine from the ground. Try to make sure the truck driver knows the clearance height before he drives away. Section 1 General Information 9803/8020 Section 1 10 - 2 Issue 1 A288080 AA

- 31. i Section 2 Care & Safety 9803/8020 Section 2 i Issue 1 Contents Page No. Safety Notices 1 - 1 General Safety 2 - 1 Operating Safety 3 - 1 Maintenance Safety 4 - 1

- 32. 1 - 1 In this publication and on the machine, there are safety notices. Each notice starts with a signal word. The signal word meanings are given below. !! DANGER Denotes an extreme hazard exists. If proper precautions are not taken, it is highly probable that the operator (or others) could be killed or seriously injured. INT-1-2-1 !! WARNING Denotes a hazard exists. If proper precautions are not taken, the operator (or others) could be killed or seriously injured. INT-1-2-2 !! CAUTION Denotes a reminder of safety practices. Failure to follow these safety practices could result in injury to the operator (or others) and possible damage to the machine. INT-1-2-3 Section 2 Care & Safety 9803/8020 Section 2 1 - 1 Issue 1

- 33. 2 - 1 Section 2 Care & Safety 9803/8020 Section 2 2 - 1 Issue 1 All construction and agricultural equipment can be hazardous. When a JCB Fastrac is correctly operated and properly maintained, it is a safe machine to work with. But when it is carelessly operated or poorly maintained it can become a danger to you (the operator) and others. Do not work with the machine until you are sure that you can control it. Do not start any job until you are sure that you and those around you will be safe. If you are unsure of anything, about the machine or the job, ask someone who knows. Do not assume anything. Remember BE CAREFUL BE ALERT BE SAFE GEN-1-6 As well as the warnings in the following pages, specific warnings are given throughout the book. This section is designed to give a safety code for use of the machine generally and for operation and maintenance practices. General Safety !! WARNING Lifting Equipment You can be injured if you use faulty lifting equipment. Make sure that lifting equipment is in good condition. Make sure that lifting tackle complies with all local regulations and is suitable for the job. Make sure that lifting equipment is strong enough for the job. INT-1-3-7 !! WARNING Clothing You can be injured if you do not wear the proper clothing. Loose clothing can get caught in the machinery. Wear protective clothing to suit the job. Examples of protective clothing are: a hard hat, safety shoes, safety glasses, a well fitting overall, ear-protectors and industrial gloves. Keep cuffs fastened. Do not wear a necktie or scarf. Keep long hair restrained. INT-1-3-6 !! WARNING Alcohol and Drugs It is extremely dangerous to operate machinery when under the influence of alcohol or drugs. Do not consume alcoholic drinks or take drugs before or whilst operating the machine or attachments. Be aware of medicines which can cause drowsiness. INT-1-3-9 Note: This section includes a certain amount of operating safety information. But remember that whenever you drive the machine or operate its controls you are in effect a machine operator. Therefore you should read and understand the information given in the Operator Handbook before driving the machine or operating its controls. !! WARNING Care and Alertness All the time you are working with or on the machine, take care and stay alert. Always be careful. Always be alert for hazards. INT-1-3-5 !! WARNING Raised Equipment Raised equipment can fall and injure you. Do not walk or work under raised equipment unless safely supported. 13-1-1-6 !! WARNING Machine Modifications This machine is manufactured in compliance with legislative and other requirements. It should not be altered in any way which could affect or invalidate any of these requirements. For advice consult your JCB Distributor. Reference should also be made to Optional Attachments section where appropriate. INT-1-3-10

- 34. 3 - 1 Operating Safety !! DANGER Parking Leaving the machine in gear will not prevent it running away. Do not leave the driving seat under any circumstances unless the parking brake is on. 13-2-1-10 !! WARNING Roll Over Protection Structure (ROPS) The machine is fitted with a Roll Over Protection Structure (ROPS). You could be killed or seriously injured if you operate the machine with a damaged or missing ROPS. If the ROPS has been in an accident, do not use the machine until the structure has been renewed. Modifications and repairs that are not approved by the manufacturer may be dangerous and will invalidate the ROPS certification. 13-1-1-8/1 !! WARNING Entering/Leaving Always face the machine when entering and leaving the cab. Use the step(s) and handrails. Make sure the step(s), handrails and your boot soles are clean and dry. Do not jump from the machine. Do not use the machine controls as handholds, use the handrails. INT-2-1-7 !! WARNING Seat Position the seat so that you can comfortably reach the machine controls. You could have an accident if you operate the machine with the seat in the wrong position. INT-3-3-5 !! WARNING Seat Belt Operating the machine without a seat belt can be dangerous. Before starting the engine, make sure your seat belt is fastened. Check the tightness and condition of the seat belt securing bolts regularly (see maintenance schedules). INT 2 -1-8/1 !! WARNING Passengers Ensure that passengers use the seat provided in the cab. Passengers must not be carried on the rear deck of the vehicle under any circumstances. 13-1-1-1/1 !! WARNING Reversing Reversing at high speeds can cause accidents. Always drive at a safe speed to suit working conditions 13-1-1-3 !! WARNING Visibility Accidents can be caused by working in poor visibility. Keep windows clean and use your lights to improve visibility. Do not operate the machine if you cannot see properly. INT-2-1-11 !! WARNING Practice You or others can be killed or seriously injured if you do unfamiliar operations without first practising them. Practise away from the work site on a clear area. Keep other people away. Do not perform new operations until you are sure you can do them safely. INT-2-1-1 !! WARNING Machine Limits Operating the machine beyond its design limits can damage the machine, it can also be dangerous. Do not operate the machine outside its limits. Do not try to upgrade the machine performance with unapproved modifications. INT-2-1-4 !! WARNING Brakes Do not coast the machine with the engine stopped as the main brakes will only operate for a limited number of applications and hydraulic trailer brakes will not function at all. Also the steering will become very heavy. 13-1-1-5/2 !! CAUTION Hydraulic Trailer Brakes Trailers with single line hydraulic brakes used in the United Kingdom are subject to a maximum speed of 20 mph (32 kph). 13-2-2-8 !! CAUTION Trailer Brakes Trailers with single line air brakes used in the Republic of Germany are subject to a maximum speed of 25 km/h (15 mph). 13-2-2-13 !! WARNING Engine The engine has rotating parts. Do not open the engine cover while the engine is running. Do not use the machine with the cover open. INT-2-1-6 Section 2 Care & Safety 9803/8020 Section 2 3 - 1 Issue 1

- 35. 3 - 2 Operating Safety (cont'd) !! WARNING Banks and Trenches Banked material and trenches can collapse. Do not work or drive too close to banks and trenches where there is danger of collapse. INT-2-2-5 !! WARNING Ramps and Trailers Water, mud, ice, grease and oil on ramps or trailers can cause serious accidents. Make sure ramps and trailers are clean before driving onto them. Use extreme caution when driving onto ramps and trailers. INT-2-2-6 !! WARNING Communications Bad communications can cause accidents. Keep people around you informed of what you will be doing. If you will be working with other people, make sure any hand signals that may be used are understood by everybody. Work sites can be noisy, do not rely on spoken commands. INT-2-2-3 !! WARNING Engine/Steering Failure If the engine or steering fails, stop the machine as quickly as possible. Do not operate the machine until the fault has been corrected. INT-2-1-5 !! DANGER Sparks Explosions and fire can be caused by sparks from the exhaust or the electrical system. Do not use the machine in closed areas where there is flammable material, vapour or dust. INT-2-2-10 !! WARNING Controls Keep the machine controls clean and dry. Your hands and feet could slide off slippery controls. If that happens you will lose control of the machine. 2-2-3-6 !! WARNING Exhaust Gases Breathing the machine exhaust gases can harm and possibly kill you. Do not operate the machine in closed spaces without making sure there is good ventilation. If possible, fit an exhaust extension. If you begin to feel drowsy, stop the machine at once. Get out of the cab into fresh air. INT-2-1-10 !! WARNING Power Take-off Operation When operating PTO equipment, always observe the following safety precautions: Follow the instructions in the implement operator's handbook. Rotating equipment is dangerous. Do not wear loose fitting clothing when working close to rotating shafts. Always disengage the PTO, stop the engine and wait until the equipment stops, before: 1 Leaving the cab 2 Attempting to attach or detach an implement to or from a PTO shaft or 3 Working on or cleaning an implement connected to the machine via a PTO shaft. Always ensure that the PTO shaft and driveline are fully guarded before use. When using stationary PTO equipment, ensure that the parking brake is applied. 13-2-1-6 !! WARNING Power Take-off Jamming If the PTO becomes jammed, disengage the PTO, stop the engine and clear the blockage. Wait until the PTO shaft stops before working on the equipment. If the PTO clutch slips, immediately disengage the PTO and stop the engine. 13-2-2-2 !! WARNING Hitching Trailers and Equipment When the vehicle is approaching a trailer or equipment to be hitched, make sure that no persons are present between vehicle and trailer or equipment. When mounting equipment at the rear of the vehicle, you must ensure that proper steering control is maintained. The machine must never be loaded such that less than 20% of the vehicle weight is carried on the front axle. 13-1-1-13/1 Section 2 Care & Safety 9803/8020 Section 2 3 - 2 Issue 2* *

- 36. 3 - 3 Operating Safety (cont'd) !! WARNING Tyres - General You could be killed or injured if a machine tyre bursts. Do not use the machine with damaged, incorrectly inflated or excessively worn tyres. Recognize the speed limitation of the tyres fitted and do not operate at more than their recommended maximum speed. 13-2-1-2 !! WARNING Certain tyres fitted as after-market equipment may have maximum permitted speeds below the maximum speed of the vehicle. Brake efficiency is slightly reduced and stopping distance is increased when these tyres are fitted. They will suffer damage if operated at speeds higher than those recommended and may endanger life. 13-3-2-5 !! WARNING Tyre Speed Limitations Running tyres outside recommended guidelines may result in failure of the tyres which at high speeds may endanger life. BE WARNED. 13-3-1-6 !! WARNING Rear Deck Passengers must not be carried on the rear deck of the vehicle. Ensure that loads carried on the rear deck are secured adequately to prevent them rolling about, falling off or toppling over. 13-1-1-12/1 !! WARNING Weight Distribution The machine must never be loaded such that less than 20% of the vehicle weight is carried on the front axle. 13-1-1-11/1 !! CAUTION Weight Distribution The Fastrac has to comply with certain braking regulations which in some countries control weight distribution between front and rear axles. Travelling on the road with implements or weights carried on the front when no implement is on the rear may break the law. In this case you should transfer the front mounted equipment to the rear linkage. It is the operator's responsibility to know and observe the laws in the country concerned. 13-2-2-5 !! WARNING Travel Speed Be aware of the load the machine is carrying or towing and the speed at which you are travelling. Do not corner fast when carrying heavy mounted implements or towing trailers. Reduce speed when towing non-suspended implements on rough ground. 13-2-2-1 !! WARNING Stability In the event of the machine becoming unstable, keep firm hold of the steering wheel and do not try to leave the cab. 13-2-2-10 !! WARNING Audible Warnings When you hear an audible warning, stop the machine as soon as possible. Get the fault put right before using the machine again. 13-2-1-9 !! WARNING Controls When driving the machine on the road, use the accelerator pedal and not the hand throttle to control the engine speed. Always set the hand throttle to ‘idle’ before using the accelerator pedal. 13-2-1-8/1 !! WARNING Safe Working Loads Overloading the machine can damage it and make it unstable. Study the specifications before loading, towing or using implements. 13-1-1-4/1 !! DANGER The JCB Fastrac is capable of operating at high speeds. Implements or trailers you tow behind the Fastrac may not be designed for high speed operation. BE AWARE of the manufacturers specified maximum speed rating for any trailers or implements that you tow behind the Fastrac. DO NOT EXCEED THE MAXIMUM DESIGN SPEED OF TRAILERS OR IMPLEMENTS AS INJURY OR DEATH MAY RESULT. 13-2-3-5 !! WARNING Cab Air Filter The cab air filter is designed to remove dirt from the outside air. When using chemicals (e.g. for crop spraying) follow the chemical manufacturer’s recommendations for protection from dangerous chemicals. 13-2-3-6 !! WARNING Hazardous Atmospheres This machine is designed for use in normal out door atmospheric conditions. It should not be used in an enclosed area without adequate ventilation. Do not use the machine in a potentially explosive atmosphere, i.e. combustible vapours, gas or dust, without first consulting your JCB Distributor. INT-2-1-14 Section 2 Care & Safety 9803/8020 Section 2 3 - 3 Issue 2* * * *

- 37. 4 - 1 Maintenance Safety !! WARNING Working Under the Machine Make the machine safe before getting beneath it. Do the following: Park on level ground. Engage the parking brake. Lower any mounted implements to the ground. Stop the engine, remove the starter key, disconnect the battery. Chock the wheels. 13-3-1-1 !! WARNING Soft Ground A machine can sink into soft ground. Never work under a machine on soft ground. INT-3-2-4 !! WARNING Jacking A machine can roll off jacks and crush you unless the wheels have been chocked. Always chock the wheels at the opposite end of the machine to that which is to be jacked. Do not work underneath a machine supported only by jacks. Always support a jacked-up machine on axle stands before working underneath it. INT-3-2-8 !! WARNING Transmission Testing The transmission is in 4 wheel drive until de-selected by hydraulic pressure to 2 wheel drive. If the machine is to be raised and the engine/transmission run, make sure all four wheels are off the ground and supported by axle stands as if only the rear wheels were raised, the machine could still drive through the front axle. Note that when a NoSpin differential is fitted, both front wheels will be driven even if one is jacked up and the other is on the ground. TRAN 8-1/2 !! WARNING Diesel Fuel Diesel fuel is flammable; keep naked flames away from the machine. Do not smoke while refuelling the machine or working on the engine. Do not refuel with the engine running. There could be a fire and injury if you do not follow these precautions. INT-3-2-2 !! WARNING Petrol Do not use petrol in this machine. Do not mix petrol with the diesel fuel; in storage tanks the petrol will rise to the top and form flammable vapours. INT-3-1-6 !! WARNING Battery A battery with frozen electrolyte can explode if it is used or charged. Do not use a machine with a frozen battery. To help prevent the battery from freezing, keep the battery fully charged. INT-3-1-7 !! WARNING Battery Gases Batteries give off explosive gases. Keep flames and sparks away from the battery. Do not smoke close to the battery. Make sure there is good ventilation in closed areas where batteries are being used or charged. Do not check the battery charge by shorting the terminals with metal; use a hydrometer or voltmeter. INT-3-1-8 !! WARNING Battery Terminals The machine is negatively earthed. Always connect the negative pole of the battery to earth. When connecting the battery, connect the earth (-) lead last. When disconnecting the battery, disconnect the earth (-) lead first. INT-3-1-9 !! WARNING Electrical Circuits Understand the electrical circuit before connecting or disconnecting an electrical component. A wrong connection can cause injury and/or damage. INT-3-1-4 !! WARNING Hydraulic Hoses Damaged hoses can cause fatal accidents. Inspect the hoses regularly for: Damaged end fittings Chafed outer covers Ballooned outer covers Kinked or crushed hoses Embedded armouring in outer covers Displaced end fittings. INT-3-3-2 !! WARNING Rams The efficiency of the rams will be affected if they are not kept free of solidified dirt. Clean dirt from around the rams regularly. When leaving or parking the machine, close all rams if possible to reduce the risk of weather corrosion. INT-3-2-10 Section 2 Care & Safety 9803/8020 Section 2 4 - 1 Issue 1

- 38. 4 - 2 Maintenance Safety (cont'd) !! WARNING Hydraulic Pressure Hydraulic fluid at system pressure can injure you. Before disconnecting or connecting hydraulic hoses, stop the engine and operate the controls to release pressure trapped in the hoses. Make sure the engine cannot be started while the hoses are open. INT-3-1-11/2 !! WARNING Hydraulic Fluid Fine jets of hydraulic fluid at high pressure can penetrate the skin. Do not use your fingers to check for hydraulic fluid leaks. Do not put your face close to suspected leaks. Hold a piece of cardboard close to suspected leaks and then inspect the cardboard for signs of hydraulic fluid. If hydraulic fluid penetrates your skin, get medical help immediately. INT-3-1-10/1 !! WARNING Oil Oil is toxic. If you swallow any oil, do not induce vomiting, seek medical advice. Used engine oil contains harmful contaminants which can cause skin cancer. Do not handle used engine oil more than necessary. Always use barrier cream or wear gloves to prevent skin contact. Wash skin contaminated with oil thoroughly in warm soapy water. Do not use petrol, diesel fuel or paraffin to clean your skin. INT-3-2-3 !! WARNING Hot Coolant The cooling system is pressurised when the engine is hot. Hot coolant can spray out when you remove the radiator cap. Let the system cool before removing the radiator cap. To remove the cap; turn it to the first notch and let the system pressure escape, then remove the cap. INT-3-2-9 !! WARNING Wheels Wheels are heavy. Handle and store with care to ensure that they cannot fall and cause injury. 13-3-1-7 !! WARNING Metal Splinters You can be injured by flying metal splinters when driving metal pins in or out. Use a soft faced hammer or drift to remove and fit metal pins. Always wear safety glasses. INT-3-1-3 !! WARNING Always wear safety glasses when dismantling assemblies containing components under pressure from springs. This will protect against eye injury from components accidentally flying out. GEN 6-2 !! WARNING Communications Bad communications can cause accidents. If two or more people are working on the machine, make sure each is aware of what the others are doing. Before starting the engine make sure the others are clear of the danger areas; examples of danger areas are: the rotating blades and belt on the engine, the attachments and linkages, and anywhere beneath or behind the machine. People can be killed or injured if these precautions are not taken. INT-3-1-5 !! WARNING Cleaning Cleaning metal parts with incorrect solvents can cause corrosion. Use only recommended cleaning agents and solvents. INT-3-2-11 !! WARNING 'O' rings, Seals and Gaskets Badly fitted, damaged or rotted 'O' rings, seals and gaskets can cause leakages and possible accidents. Renew whenever disturbed unless otherwise instructed. Do not use Trichloroethane or paint thinners near 'O' rings and seals. INT-3-2-12 !! WARNING Clutch Fluid Do not use ordinary hydraulic fluid in the clutch system. 13-3-2-4 !! WARNING Welding and Modifications To prevent the possibility of damage to electronic components, disconnect the battery and withdraw the plug from the electronic draft control unit before arc-welding on the machine or attached implements. Parts of the machine are made from cast iron; welds on cast iron can weaken the structure and break. Do not weld cast iron. On no account weld or drill the chassis structure. Non- approved modifications can cause injury and damage. Contact JCB before modifying the machine. GEN 8-1 !! WARNING Protect your eyes when grinding metal. Wear safety glasses or goggles. Remove or protect any combustible materials from the area which could be ignited by sparks. GEN-1-12 !! WARNING Radar Speed Sensor (if fitted) To avoid possible eye damage from microwave signals, do not look directly into the sensor face. 13-1-1-15 Note: The radar speed sensor is located underneath the machine. Section 2 Care & Safety 9803/8020 Section 2 4 - 2 Issue 2* *

- 39. 4 - 3 Maintenance Safety (cont'd) !! WARNING Fluoroelastomeric Materials Certain seals and gaskets (e.g. crankshaft oil seal) on JCB machines contain fluoroelastomeric materials such as Viton, Fluorel and Technoflon. Fluoroelastomeric materials subjected to high temperatures can produce highly corrosive hydrofluoric acid. THIS ACID CAN SEVERELY BURN. New fluoroelastomeric components at ambient temperature require no special safety precautions. Used fluoroelastomeric components whose temperatures have not exceeded 300°C require no special safety precautions. If evidence of decomposition (e.g. charring) is found, refer to the next paragraph for safety instructions DO NOT TOUCH COMPONENT OR SURROUNDING AREA. Used fluoroelastomeric components subjected to temperatures greater than 300°C (e.g. engine fire) must be treated using the following safety procedure. Make sure that heavy duty gloves and special safety glasses are worn: 1 Ensure that components have cooled then remove and place material in plastic bags. 2 Thoroughly wash contaminated area with 10% calcium hydroxide or other suitable alkali solution, if necessary use wire wool to remove burnt remains. 3 Thoroughly wash contaminated area with detergent and water. 4 Contain all removed material, gloves etc used in this operation in sealed plastic bags and dispose of in accordance with Local Authority Regulations. DO NOT BURN FLUOROELASTOMERIC MATERIALS. If contamination of skin or eyes occurs, wash the affected area with a continuous supply of clean water or with calcium hydroxide solution for 16-60 minutes. Get medical attention immediately. INT - 3 - 3 - 5/1 !! WARNING Brake Pads Always renew brake pads and locating pins in complete axle sets, using genuine JCB parts, otherwise braking will be unsafe. 13-3-1-10 !! WARNING Cleaning Agents When using cleaning agents, solvents or other chemicals, you must adhere to the manufacturer's instructions and safety precautions. GEN-1-9 !! WARNING ABS Upon completion of any work done on the brake system of machines fitted with ABS, the ABS test within Servicemaster must be run satisfactorily before the machine is driven. It is not sufficient to rely on the ABS self-check which can only check for presence of components, not that they are correctly installed. 0091 Section 2 Care & Safety 9803/8020 Section 2 4 - 3 Issue 2* *

- 40. i Section 3 Routine Maintenance 9803/8020 Section 3 i Issue 7* Contents Page No. Engine Oil - (All Machines) 1 - 1 Lubricants & Capacities (2000 Series Machines) 1 - 2 Lubricants & Capacities (3155) 1 - 4 Lubricants & Capacities (3185) 1 - 6 Lubricants - Health and Safety 1 - 8 Service Schedules (Dry Clutch Transmission †) 2 - 1 Service Schedules (Wet Clutch Transmission ††) 2 - 4 Cleaning the Machine and Checking for Damage 2 - 8 Checking Seat Belt Condition and Security 2 - 8 Opening/Closing the Bonnet (2000 Series Machines) 2 - 9 Opening/Closing the Bonnet (3000 Series Machines) 2 - 9 Greasing General 3 - 1 Propshafts and PTO Driveshafts 3 - 1 Steering Swivels (2000 Series Machines) 3 - 2 Front Axle Steering Swivels (3000 Series Machines) 3 - 3 Hydraulic Lift & 3 point Linkage (2000 Series Machines) 3 - 4 Rear PTO Driveshaft Bearings (2000 Series Machines) 3 - 4 Rear Suspension Cylinder Pivots (2000 Series Machines) 3 - 4 Hydraulic Lift & 3 point Linkage (3000 Series Machines) 3 - 5 Rear PTO Driveshaft Bearings (3000 Series Machines) 3 - 5 Rear Suspension Cylinder Pivots (3000 Series Machines) 3 - 5 Rear Anti-roll Bar Ball Joints (2000 Series Machines) 3 - 6 Steering Box Input Shaft Seal (3000 Series Machines) 3 - 7 Rear Anti-roll Bar Ball Joints (3000 Series Machines) 3 - 7 Automatic Trailer Coupling (if fitted) 3 - 8 Cab Checking the ROPS Structure 4 - 1 Checking the Windscreen Washer Fluid Level 4 - 2 Air Conditioning Cleaning the Filter (2000 Series Machines) 5 - 1 Adjusting the Compressor Belt (2115, 2125, 2135, 2150) 5 - 1 Cleaning the Filter (3000 Series Machines) 5 - 2 Adjusting the Compressor Belt (2140 and 3000 Series) 5 - 3 Electrics Battery Warning Symbols 6 - 1 First Aid - Electrolyte 6 - 1 Checking the Battery Electrolyte Level 6 - 2 Checking the Headlight Beam Alignment 6 - 3 Fuses See Section C Hydraulics Checking the Fluid Level 7 - 1 Changing the Filter Element 7 - 1 Changing the Hydraulic Fluid and Cleaning the Suction Strainer 7 - 2 Emptying the Hydraulic Coupling Drain Reservoir (if fitted) 7 - 3 Dry Clutch Hydraulic System † Checking the Fluid Level 8 - 1 † 2000 Series to S/N 739999, 3000 Series to S/N 641999 †† 2000 Series from S/N 740000, 3000 Series from S/N 642000 * * *

- 41. ii Section 3 Routine Maintenance 9803/8020 Section 3 ii Issue 10* Contents Page No. PTO, Speed and Range Gearboxes Checking the Oil Level 9 - 1 Changing the Oil and Cleaning the Strainer - (Dry Clutch Transmission) † 9 - 2 Changing the Oil and Cleaning the Strainer - (Wet Clutch Transmission) †† 9 - 2A Changing the Transmission Oil Filter 9 - 3 Checking the Front PTO Gearbox Oil Level (if fitted) 9 - 4 Front Axle Checking the Differential Oil Level 10 - 1 Changing the Differential Oil 10 - 1 Checking the Hub Oil Levels 10 - 2 Changing the Hub Oil 10 - 2 Rear Axle (2WS) Checking the Oil Level 11 - 1 Changing the Oil 11 - 2 Rear Axle (4WS) Checking the Differential Oil Level 11 - 3 Changing the Differential Oil 11 - 3 Checking the Hub Oil Levels 11 - 4 Changing the Hub Oil 11 - 4 Front and Rear Axle Steering Swivels (4WS) Checking 4WS Right Side Trunnion Seals 11 - 5 Tyres and Wheels General 12 - 1 Tyre Inflation 12 - 1 Pressures, Speeds and Loads See Operator Handbook Checking and Adjusting Wheel Alignment 12 - 4 Track Width 12 - 5 Checking Wheel Nut Torques 12 - 5 Lock Stops 12 - 6 Fender Adjustment 12 - 7 Brakes Checking and Renewing Foot Brake Pads 13 - 1 Checking and Renewing the Parking Brake Pads 13 - 3 Checking the Foot Brake Fluid Level (2000 Series Machines) 13 - 4 Draining the Air System Tank (2000 Series Machines) 13 - 6 Checking the Foot Brake Fluid Level (3000 Series Machines) 13 - 7 Draining the Air System Tank (3000 Series Machines) 13 - 8 Exhaust Brake (if fitted) (3185 Machines only) 13 - 9 Cleaning the Trailer Brake Control Line Air Filter See Section G † 2000 Series to S/N 739999, 3000 Series to S/N 641999 †† 2000 Series from S/N 740000, 3000 Series from S/N 642000 *

- 42. iii Section 3 Routine Maintenance 9803/8020 Section 3 iii Issue 4* Contents Page No. Engine Checking the Oil Level 14 - 1 Changing the Oil and Filter 14 - 2 Draining/Cleaning the Fuel Sediment Bowl 15 - 1 Draining/Renewing Fuel Pre-Filter (when fitted) 15 - 2 Draining the Fuel Filters 15 - 3 Changing the Fuel Filter Elements 15 - 3 Cleaning the Fuel Lift Pump (2115, 2125, 2135, 2150 and 3155) 15 - 4 Bleeding the Fuel System (2115, 2125, 2135, 2150 and 3155) 15 - 5 Bleeding the Fuel System (2140) 15 - 5A Bleeding the Fuel System (3185) 15 - 6 Cleaning the Fuel Tank Strainer (Early machines only) 15 - 7 Checking the Coolant Level 16 - 1 Draining the Coolant (2115, 2125, 2135 and 2150 Machines) 16 - 2 Filling the Cooling System (2115, 2125, 2135 & 2150 Machines) 16 - 3 Coolant Mixtures 16 - 3 Draining & Refilling the Coolant (3155 Machines) 16 - 4 Draining & Refilling the Coolant (2140 and 3185 Machines) 16 - 5 Cleaning the Radiator (2000 Series Machines) 16 - 6 Cleaning the Radiator (3000 Series Machines) 16 - 7 Cleaning the Pre-Cleaner (optional) 17 - 1 Adjusting the Fan Belts (Machines Except 3185) 17 - 1 Adjusting the Fan Belt (2140) 17 - 2 Adjusting the Fan Belt (3185) 17 - 3 Changing the Air Filter Elements (Early 2000 Series) 18 - 1 Changing the Air Filter Elements (Later 2000 Series) 18 - 2 Changing the Air Filter Elements (3000 Series) 18 - 2 * * * * * * * * * * * *

- 43. 1 - 1 Section 3 Routine Maintenance 9803/8020 Section 3 1 - 1 Issue 7* New Engines New engines DO NOT require a running-in period. The engine/machine should be used in a normal work cycle immediately. DO NOT use a special running-in oil but use the oil recommended below from new. Engine Oil Specification Recommended Oil JCB Extreme Performance Engine Oil SAE 15W/40 API CH-4 or ACEA E3/B3A3 IMPORTANT NOTE: IF SAE 15W/40, API CH-4 OR ACEA E3/B3A3 ENGINE OIL IS NOT AVAILABLE, THEN THE ENGINE OIL MUST BE CHANGED AT 250 HOURS. Alternative Oil If the oil recommended above is not available then the alternatives listed below should be used according to the ambient temperature. Note: (2140 and 3185 machines only). While 15W/40 oil is recommended for most climates, limited use of low viscosity oils such as 10W/30 is permitted to provide easier starting and sufficient oil flow at ambient temperatures below -5 °C (23 °F). Continued use of low viscosity oils can decrease engine life. JCB Super Multigrade 15W/40 SAE15W/40, API CF4/SG -10 °C to 50 °C (14 °F to 122 °F) JCB Super Multigrade 10W/30 SAE10W/30, API CF4/SG † -15 °C to 40 °C (5 °F to 104 °F) † The temperature range for 2140 and 3185 machines is - 20 °C to 20 °C (-4 °C to 68 °F). Engine Oil Specification (N. America) Recommended Oil JCB Genuine Engine Oil SAE 15W/40, Grade CH-4/SJ IMPORTANT NOTICE: IF SAE 15W/40, GRADE CH-4/SJ ENGINE OIL IS NOT AVAILABLE, THEN THE ENGINE OIL MUST BE CHANGED AT 250 HOURS. Alternative Oil If the oil recommended above is not available then the alternatives listed below should be used according to the ambient temperature. Notice: (2140 and 3185 machines only). While 15W/40 oil is recommended for most climates, limited use of low viscosity oils such as 10W/30 is permitted to provide easier starting and sufficient oil flow at ambient temperatures below -5 °C (23 °F). Continued use of low viscosity oils can decrease engine life. JCB 15W/40 Engine Oil SAE15W/40, API CF4/SG -10 °C to 50 °C (14 °F to 122 °F) JCB Engine Oil 10W/30 SAE10W/30, API CE/SF † -15 °C to 40 °C (5 °F to 104 °F) † The temperature range for 2140 and 3185 machines is -4 °C to 68 °F (- 20 °C to 20 °C). * Engine Oil (All Machines)

- 44. 1 - 2 Section 3 Routine Maintenance 9803/8020 Section 3 1 - 2 Issue 9* Lubricants & Capacities (2000 Series Machines) ITEM CAPACITY FLUID/LUBRICANT MINIMUM INTERNATIONAL Litres (UK Gal) SPECIFICATION Fuel 2115, 2125, 2135, 2140 220 (48) Diesel Oil (See Types of Fuel) ASTM D975-66T Nos. 1D, 2D 2150 350 (77) Engine (Oil) 2115, 2125, 2135, 2150 16.5 (3.6) See Engine Oil (All Machines) at the 2140 15 (3.3) beginning of this section Engine (Coolant) 2115, 2125, 2135, 2150 34 (7.5) JCB Four Seasons Antifreeze & ASTM D3306, BS6580 2140 33 (7.3) Summer Coolant/water (See Coolant Mixtures) PTO, Speed and Range Boxes 38 (8.4) † JCB Super Universal Agricultural API-GL-4, MIL-L-2105 (combined) 42 (9.3) †† Front Axle Housing 7 (1.56) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Hubs (x2) 1.9 (0.4) Rear Axle (2WS) 23 (5.0) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Rear Axle (4WS) Housing 17 (3.7) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Hubs (x2) 2.0 (0.4) Brake System JCB Universal Brake Fluid SAE J1703 DOT 4 Front 0.75 (0.17) Rear 0.75 (0.17) !! CAUTION Do not use ordinary hydraulic fluid in the brake system. 13-3-2-6 † Clutch System - JCB Light Hydraulic Fluid - see Note 2 ISO VG15 Hydraulic System JCB High Performance Hydraulic Oil ISO VG46 - see Note 1 82 (18.0) † (Above 38 °C, 100 °F) 120 (26.4) †† JCB Hydraulic Fluid HP32 ISO VG32 (Below 38 °C, 100 °F) Grease Points --- JCB HP Grease Lithium complex NLGI No. 2 consistency including extreme pressure additives Air Conditioning System - Refrigerant 0.98 kg (2.16 lb) HFC R134a CH2 FC F3 - Compressor Lubricant 0.24 (0.05) Polyalkalineglycol PAG SP20 Front PTO Transfer Box (optional) 3.0 (0.67) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Note 1: The total hydraulic system capacity depends on the equipment being used. Watch level indicator on hydraulic tank. Note 2: It is esssential that the correct specification fluid is used. Contact your JCB Dealer for further information. † 2000 Series to S/N 739999 †† 2000 Series from S/N 740000 * * *

- 45. 1 - 3 Section 3 Routine Maintenance 9803/8020 Section 3 1 - 3 Issue 9* Lubricants & Capacities (N. America) (2000 Series Machines) ITEM CAPACITY FLUID/LUBRICANT MINIMUM INTERNATIONAL US Gal (Liters) SPECIFICATION Fuel 2115, 2125, 2135, 2140 57.6 (220) Diesel Oil (See Types of Fuel) ASTM D975-66T Nos. 1D, 2D 2150 92.5 (350) Engine (Oil) 2115, 2125, 2135, 2150 4.3 (16.5) See Engine Oil (All Machines) at the 2140 4 (15) beginning of this section Engine (Coolant) JCB PermanentAntifreeze/water ASTM D3306-74 2115, 2125, 2135, 2150 9.0 (34.0) (See Coolant Mixtures) 2140 8.77 (33) PTO, Speed and Range Boxes 10 (38.0) † JCB AG Transmission Fluid API-GL-4, MIL-L-2105 (combined) 11.2 (42.0) †† Front Axle Housing 1.8 (7.0) JCB GL5 80W/90 Gear Oil API-GL-5, MIL-L-2105C Hubs (x2) 0.5 (1.9) Rear Axle (2WS) 6.1 (23.0) JCB GL5 80W/90 Gear Oil API-GL-5, MIL-L-2105C Rear Axle (4WS) Housing 4.5 (17.0) JCB GL5 80W/90 Gear Oil API-GL-5, MIL-L-2105C Hubs (x2) 0.5 (2.0) Brake System JCB Universal Brake Fluid SAE J1703 DOT 4 Front 0.2 (0.75) Rear 0.2 (0.75) !! CAUTION Do not use ordinary hydraulic oil in the brake system. 13-3-2-6 † Clutch System - JCB Light Hydraulic Fluid - see Notice 2 ISO VG15 Hydraulic System 21.7 (82.0) † JCB High Performance Hydraulic Oil ISO VG46 - see Notice 1 31.7 (120) †† Grease Points --- JCB HP Grease Lithium complex NLGI No. 2 consistency including extreme pressure additives Air Conditioning System - Refrigerant 2.16 lb (0.98 kg) HFC R134a CH2 FC F3 - Compressor Lubricant 0.06 (0.24) Polyalkalineglycol PAG SP20 Front PTO Transfer Box (optional) 0.8 (3.0) JCB GL5 80W/90 Gear Oil API-GL-5, MIL-L-2105C Notice 1: The total hydraulic system capacity depends on the equipment being used. Watch level indicator on hydraulic tank. Notice 2: It is esssential that the correct specification fluid is used. Contact your JCB Dealer for further information. † 2000 Series to S/N 739999 †† 2000 Series from S/N 740000 * * *

- 46. ITEM CAPACITY FLUID/LUBRICANT MINIMUM INTERNATIONAL Litres (UK Gal) SPECIFICATION Fuel 350 (77) Diesel Oil (See Types of Fuel) ASTM D975-66T Nos. 1D, 2D Engine (Oil) 16.5 (3.6) See Engine Oil (All Machines) at the beginning of this section Engine (Coolant) 34 (7.5) JCB Four Seasons Antifreeze & ASTM D3306, BS6580 Summer Coolant/water (See Coolant Mixtures) PTO, Speed and Range Boxes 38 (8.4) † JCB Super Universal Agricultural API-GL-4, MIL-L-2105 (combined) 42 (9.3) †† Front Axle Housing 20 (4.4) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Hubs (x2) 2.5 (0.55) Rear Axle 21 (4.6) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Brake System JCB Universal Brake Fluid SAE J1703 DOT 4 Front 0.75 (0.17) Rear 0.75 (0.17) !! CAUTION Do not use ordinary hydraulic fluid in the brake system. 13-3-2-6 † Clutch System - JCB Light Hydraulic Fluid - see Note 2 ISO VG15 Hydraulic System 82 (18.0) † JCB High Performance Hydraulic Oil ISO VG46 - see Note 1 120 (26.4) †† (Above 38 °C, 100 °F) JCB Hydraulic Fluid HP32 ISO VG32 (Below 38 °C, 100 °F) Grease Points --- JCB HP Grease Lithium complex NLGI No. 2 consistency including extreme pressure additives Air Conditioning System - Refrigerant 1.41 kg (3.11 lb) HFC R134a CH2 FC F3 - Compressor Lubricant 0.24 (0.05) Polyalkalineglycol PAG SP20 Front PTO Transfer Box (optional) 3.0 (0.67) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Note 1: The total hydraulic system capacity depends on the equipment being used. Watch level indicator on hydraulic tank. Note 2: It is essential that the correct specification fluid is used. Contact your JCB Distributor for further information. † 3000 Series to S/N 641999 †† 3000 Series from S/N 642000 1 - 4 Section 3 Routine Maintenance 9803/8020 Section 3 1 - 4 Issue 7* Lubricants & Capacities (Fastrac 3155) *

- 47. 1 - 5 Section 3 Routine Maintenance 9803/8020 Section 3 1 - 5 Issue 7* Lubricants & Capacities (N. America) (Fastrac 3155) ITEM CAPACITY FLUID/LUBRICANT MINIMUM INTERNATIONAL US Gal (Liters) SPECIFICATION Fuel 92.5 (350) Diesel Oil (See Types of Fuel) ASTM D975-66T Nos. 1D, 2D Engine (Oil) 4.3 (16.5) See Engine Oil (All 2000, 3000 Series Machines) on page 60-00-01/11 Engine (Coolant) 9 (34.0) JCB Permanent Antifreeze/water ASTM D3306-74 (See Coolant Mixtures) PTO, Speed and Range Boxes 10.1 (38.0) † JCB AG Transmission Fluid API-GL-4, MIL-L-2105 (combined) 11.2 (42.0) †† Front Axle Housing 5.3 (20.0) JCB GL5 80W/90 Gear Oil API-GL-5, MIL-L-2105C Hubs (x2) 0.66 (2.5) Rear Axle (2WS) 7.1 (27.0) JCB GL5 80W/90 Gear Oil API-GL-5, MIL-L-2105C Brake System JCB Universal Brake Fluid SAE J1703 DOT 4 Front 0.2 (0.75) Rear 0.2 (0.75) !! CAUTION Do not use ordinary hydraulic oil in the brake system. 13-3-2-6 † Clutch System --- JCB Light Hydraulic Fluid - see Notice 2 ISO VG15 Hydraulic System 21.7 (82.0) † JCB High Performance Hydraulic Oil ISO VG46 - see Notice 1 31.7 (120) †† Grease Points --- JCB HP Grease Lithium complex NLGI No. 2 consistency including extreme pressure additives Air Conditioning System - Refrigerant 3.11 lb (1.41 kg) HFC R134a CH2 FC F3 - Compressor Lubricant 0.06 (0.24) Polyalkalineglycol PAG SP20 Front PTO Transfer Box (optional) 0.8 (3.0) JCB GL5 80W/90 Gear Oil API-GL-5, MIL-L-2105C Notice 1: The total hydraulic system capacity depends on the equipment being used. Watch level indicator on hydraulic tank. Notice 2: It is essential that the correct specification fluid is used. Contact your JCB Dealer for further information. † 3000 Series to S/N 641999 †† 3000 Series from S/N 642000 *

- 48. 1 - 6 Section 3 Routine Maintenance 9803/8020 Section 3 1 - 6 Issue 7* Lubricants & Capacities (Fastrac 3185) ITEM CAPACITY FLUID/LUBRICANT MINIMUM NTERNATIONAL Litres (UK Gal) SPECIFICATION Fuel 350 (77) Diesel Oil (See Types of Fuel) ASTM D975-66T Nos. 1D, 2D Engine (Oil) 15 (3.3) See Engine Oil (All Machines) at the beginning of this section Engine (Coolant) 33 (7.3) JCB Four Seasons Antifreeze & ASTM D3306, BS6580 Summer Coolant/water (See Coolant Mixtures) PTO, Speed and Range Boxes 38 (8.4) † JCB Super Universal Agricultural API-GL-4, MIL-L-2105 (combined) 42 (9.3) †† Front Axle Housing 20 (4.4) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Hubs (x2) 2.5 (0.55) Rear Axle 27 (6.0) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Brake System JCB Universal Brake Fluid SAE J1703 DOT 4 Front 0.75 (0.17) Rear 0.75 (0.17) !! CAUTION Do not use ordinary hydraulic fluid in the brake system. 13-3-2-6 † Clutch System - JCB Light Hydraulic Fluid - see Note 2 ISO VG15 Hydraulic System 82 (18.0) † JCB High Performance Hydraulic Oil ISO VG46 - see Note 1 120 (26.4) †† (Above 38 °C, 100 °F) JCB Hydraulic Fluid HP32 ISO VG32 (Below 38 °C, 100 °F) Grease Points --- JCB HP Grease Lithium complex NLGI No. 2 consistency including extreme pressure additives Air Conditioning System - Refrigerant 1.41 kg (3.11 lb) HFC R134a CH2 FC F3 - Compressor Lubricant 0.24 (0.05) Polyalkalineglycol PAG SP20 Front PTO Transfer Box (optional) 3.0 (0.67) JCB HD90 Gear Oil API-GL-5, MIL-L-2105C Note 1: The total hydraulic system capacity depends on the equipment being used. Watch level indicator on hydraulic tank. Note 2: It is essential that the correct specification fluid is used. Contact your JCB Distributor for further information. † 3000 Series to S/N 641999 †† 3000 Series from S/N 642000 *