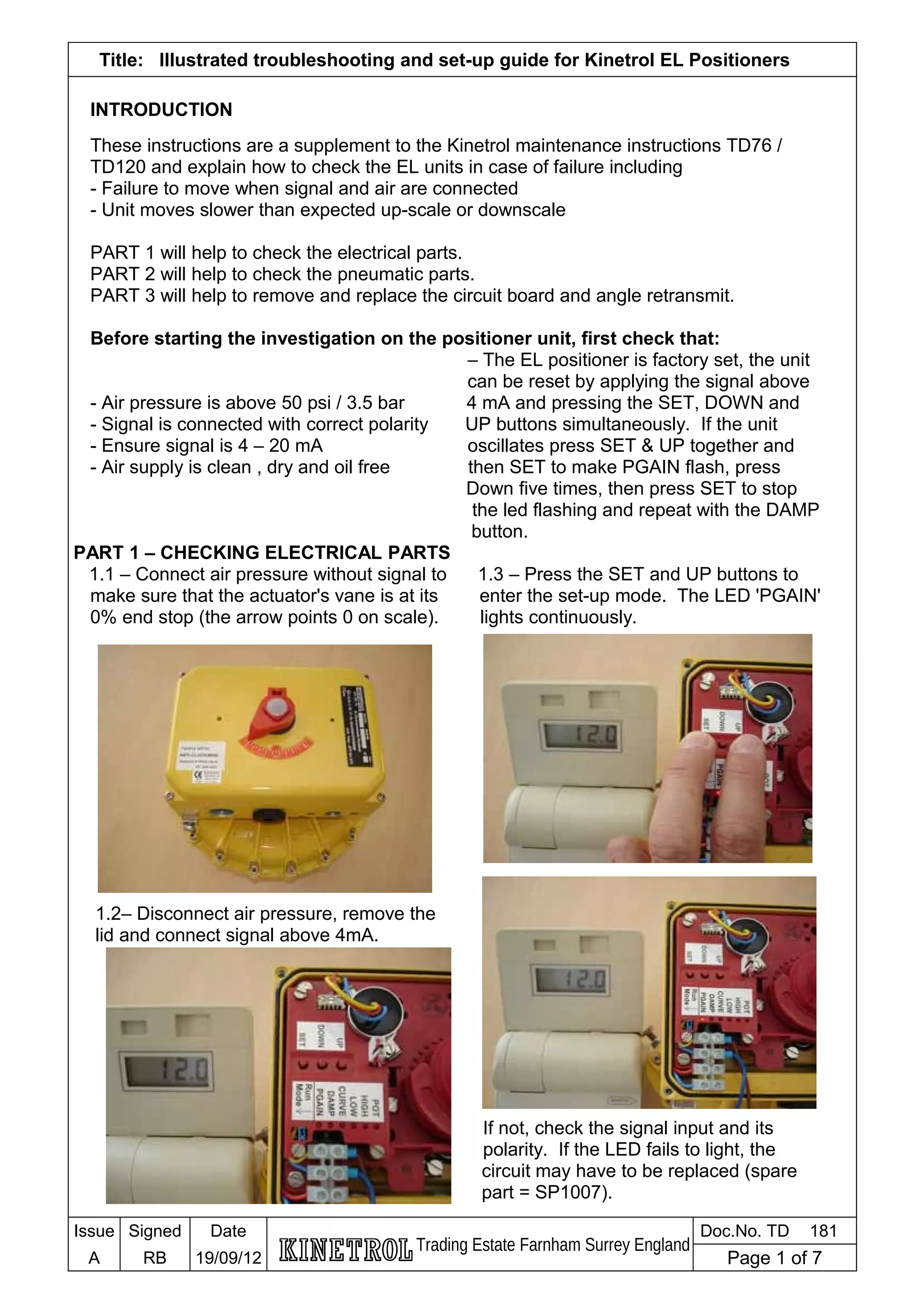

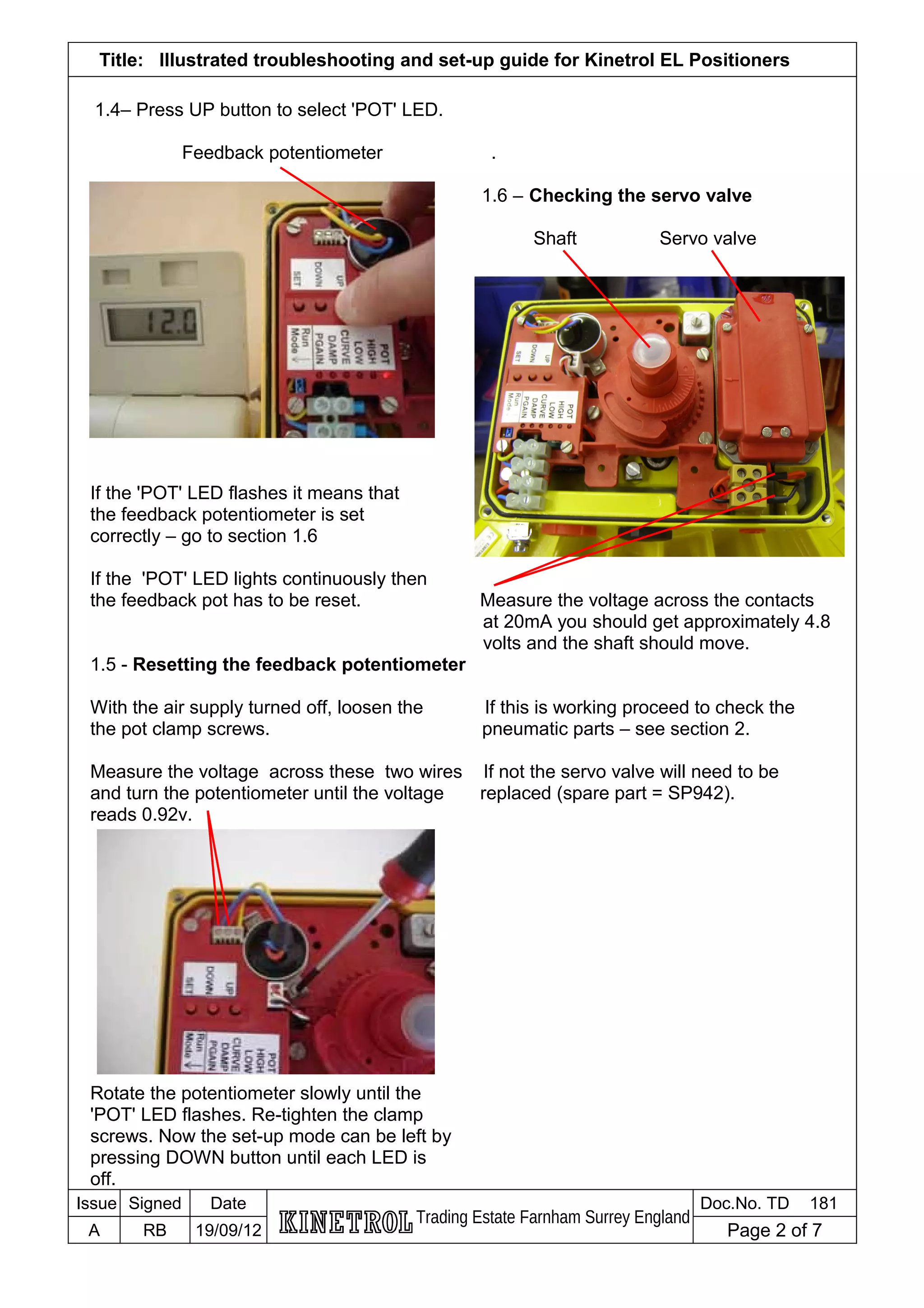

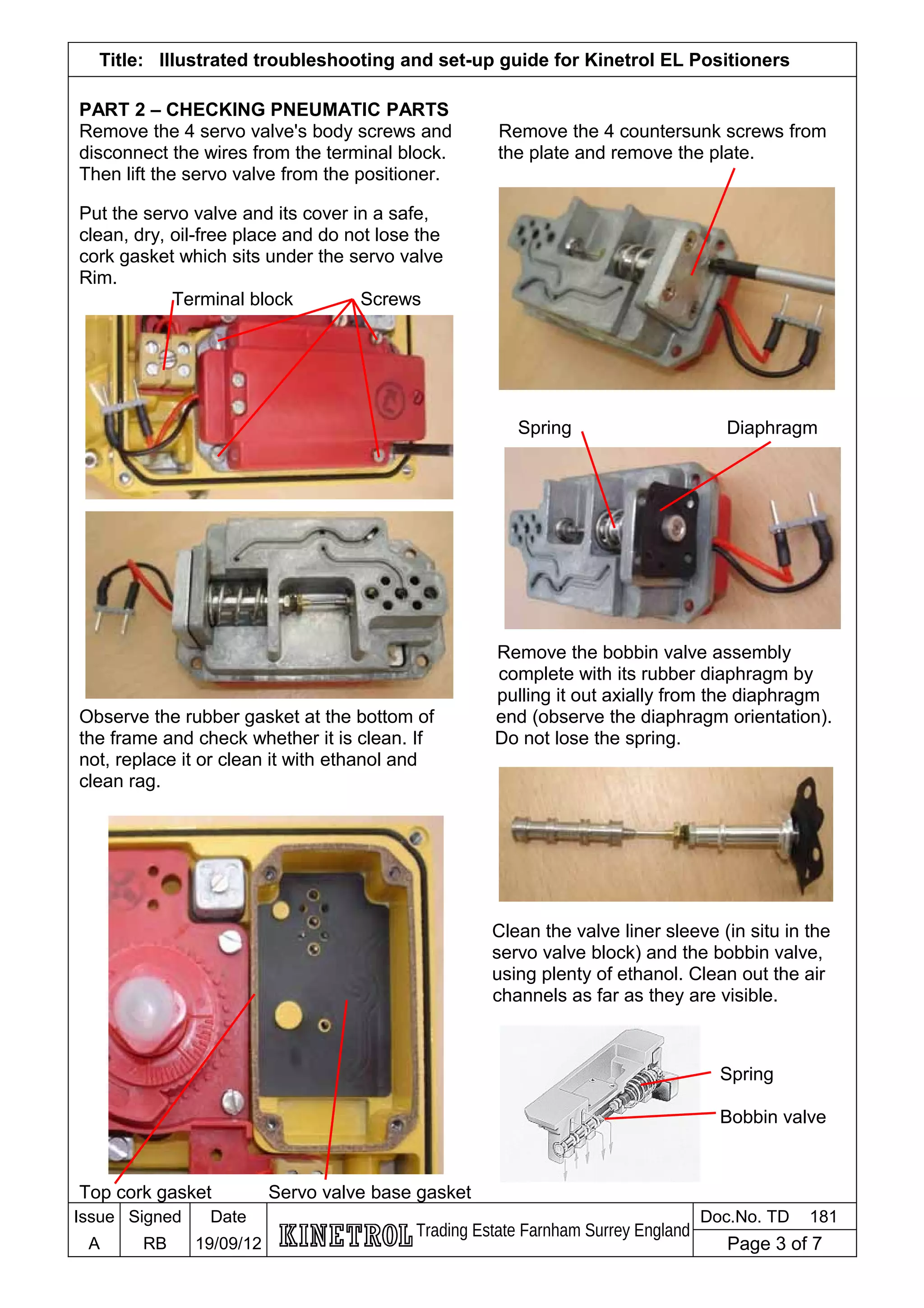

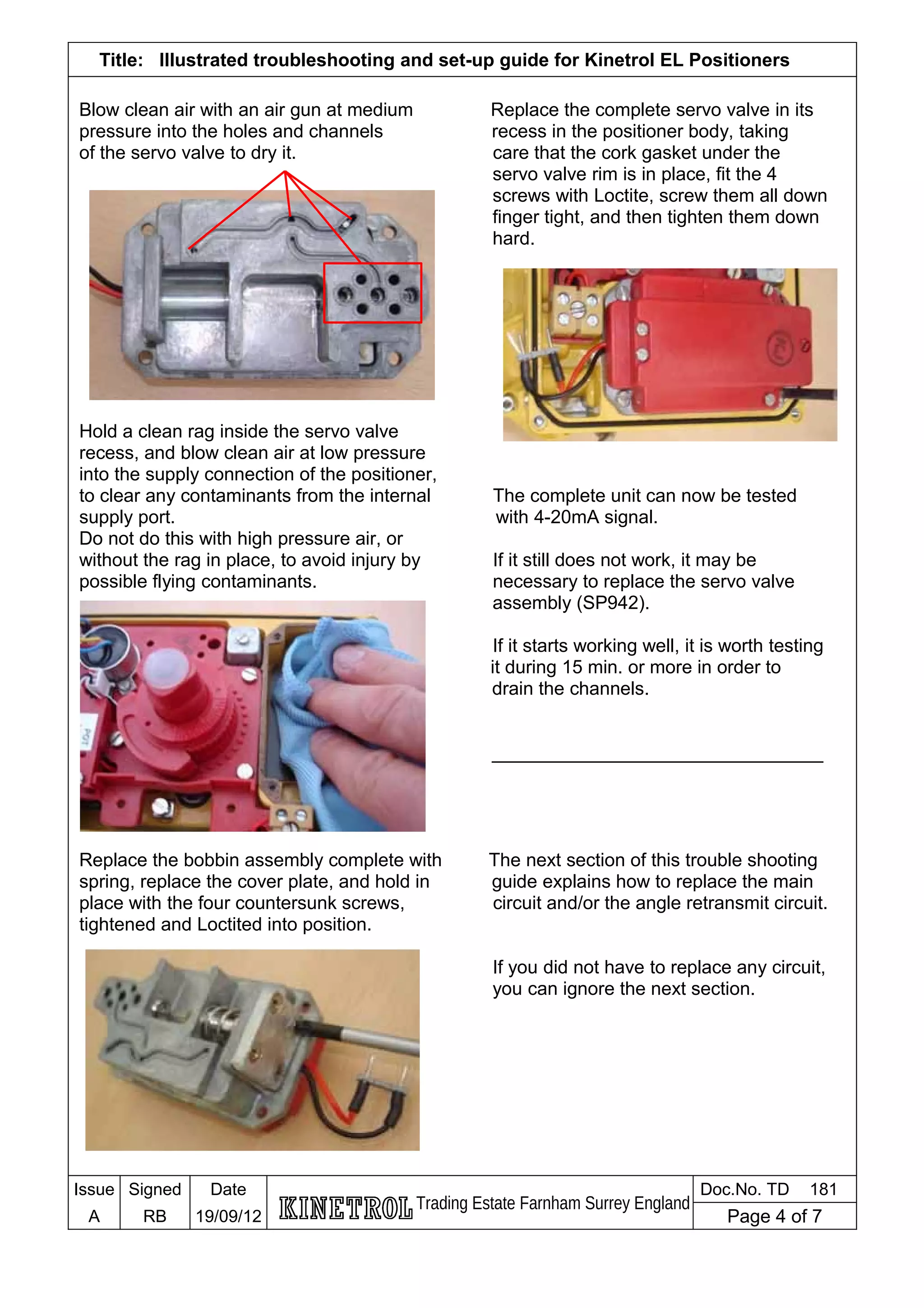

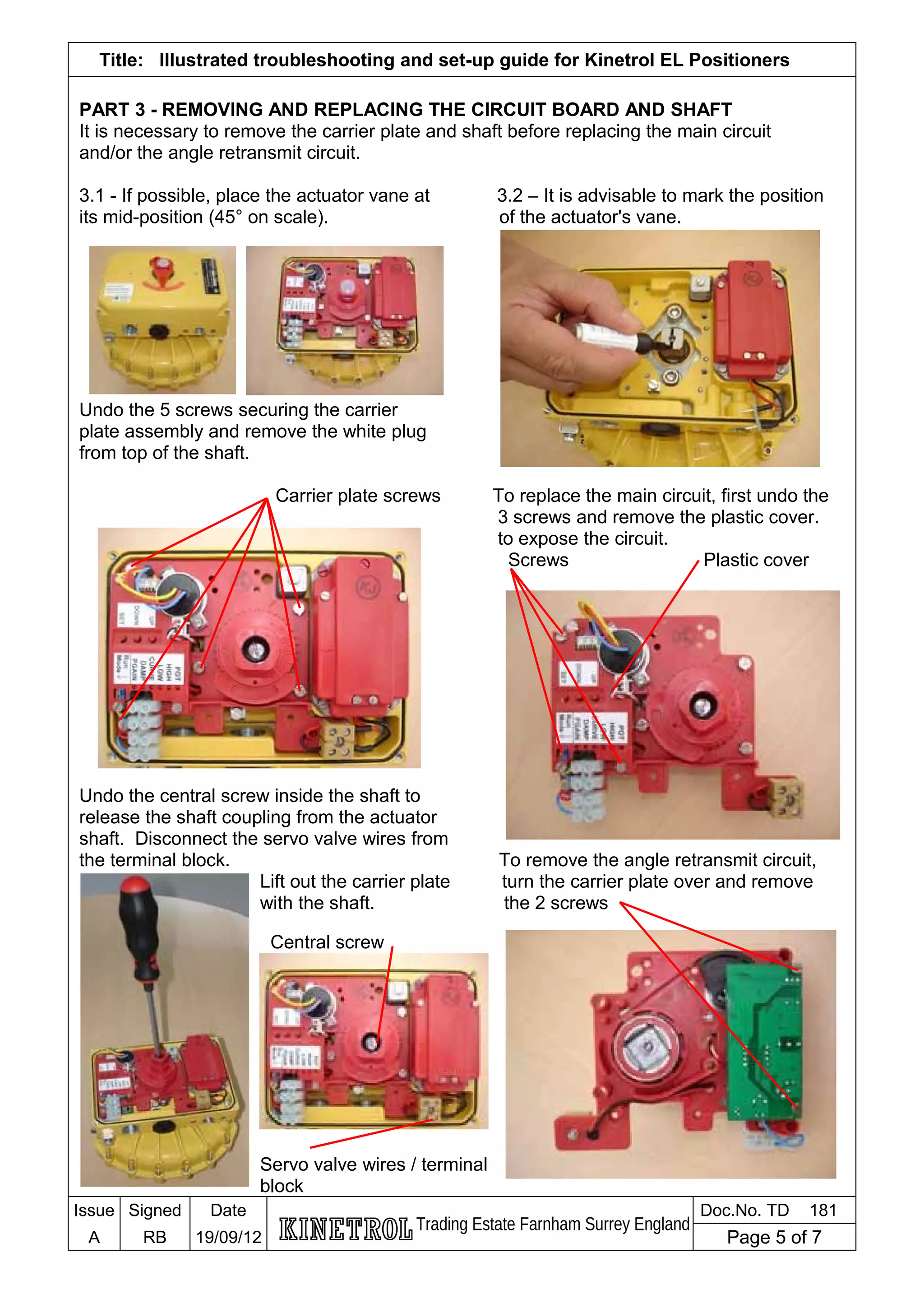

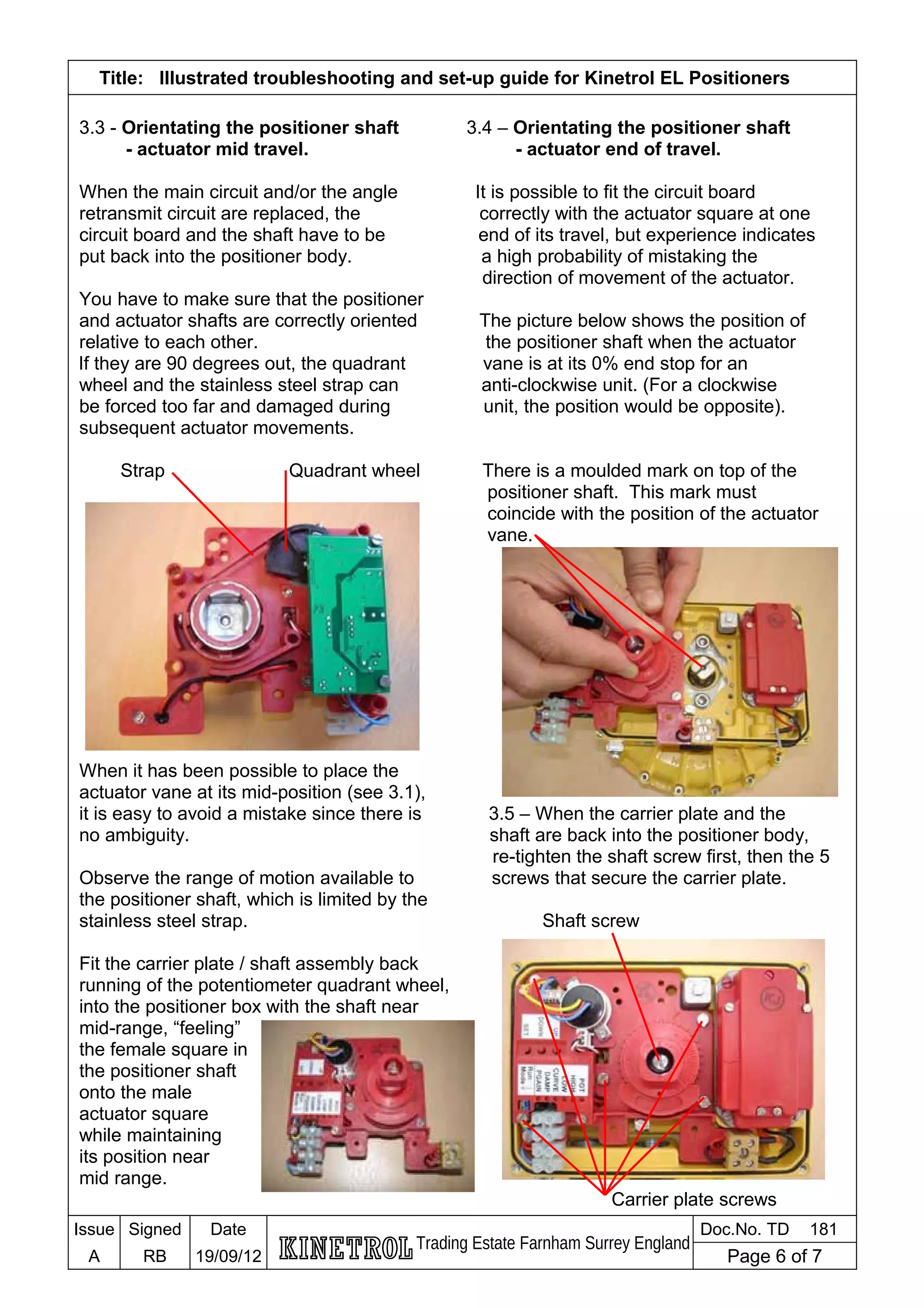

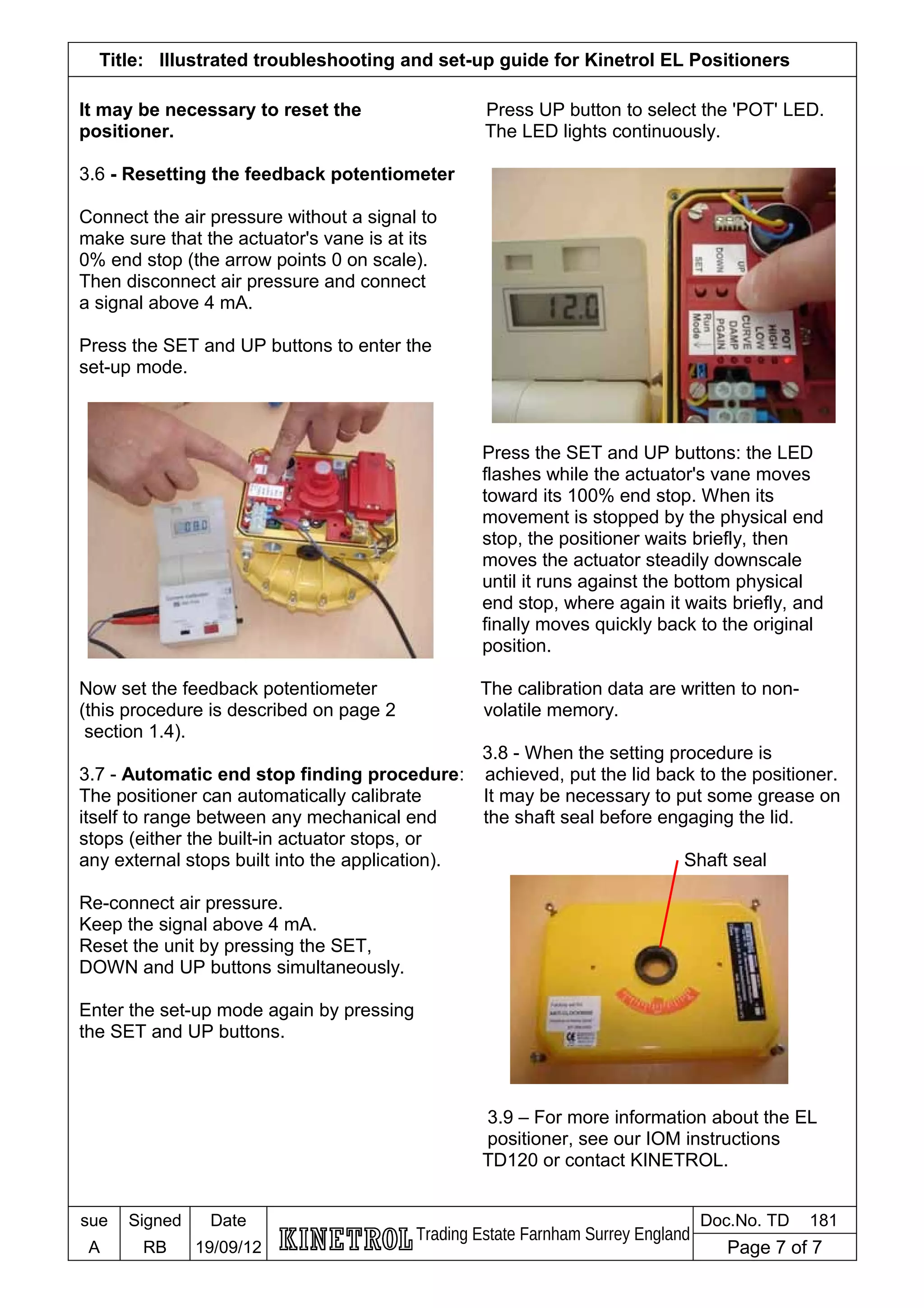

The document is an illustrated troubleshooting and set-up guide for Kinetrol EL positioners, detailing procedures for checking electrical and pneumatic components, as well as instructions for removing and replacing circuit boards. It emphasizes the importance of ensuring proper signal polarity and air supply, detailed step-by-step checks, and resets for various components. The guide also provides safety warnings and maintenance tips for effective operation of the positioners.