2010 Nissan Rogue Service Repair Manual.pdf

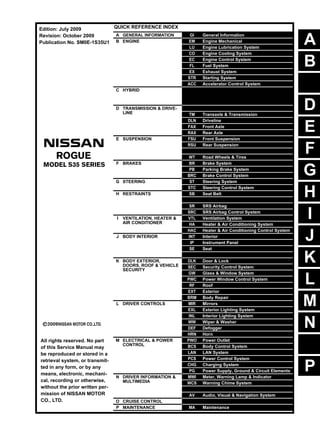

- 1. A B D E F G H I J K L M N P O C QUICK REFERENCE INDEX A GENERAL INFORMATION GI General Information B ENGINE EM Engine Mechanical LU Engine Lubrication System CO Engine Cooling System EC Engine Control System FL Fuel System EX Exhaust System STR Starting System ACC Accelerator Control System C HYBRID HBC Hybrid Control System HBB Hybrid Battery System HBR Hybrid Brake System D TRANSMISSION & DRIVE- LINE CL Clutch TM Transaxle & Transmission DLN Driveline FAX Front Axle RAX Rear Axle E SUSPENSION FSU Front Suspension RSU Rear Suspension SCS Suspension Control System WT Road Wheels & Tires F BRAKES BR Brake System PB Parking Brake System BRC Brake Control System G STEERING ST Steering System STC Steering Control System H RESTRAINTS SB Seat Belt SBC Seat Belt Control System SR SRS Airbag SRC SRS Airbag Control System I VENTILATION, HEATER & AIR CONDITIONER VTL Ventilation System HA Heater & Air Conditioning System HAC Heater & Air Conditioning Control System J BODY INTERIOR INT Interior IP Instrument Panel SE Seat ADP Automatic Drive Positioner K BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY DLK Door & Lock SEC Security Control System GW Glass & Window System PWC Power Window Control System RF Roof EXT Exterior BRM Body Repair L DRIVER CONTROLS MIR Mirrors EXL Exterior Lighting System INL Interior Lighting System WW Wiper & Washer DEF Defogger HRN Horn M ELECTRICAL & POWER CONTROL PWO Power Outlet BCS Body Control System LAN LAN System PCS Power Control System CHG Charging System PG Power Supply, Ground & Circuit Elements N DRIVER INFORMATION & MULTIMEDIA MWI Meter, Warning Lamp & Indicator WCS Warning Chime System SN Sonar System AV Audio, Visual & Navigation System O CRUISE CONTROL CCS Cruise Control System P MAINTENANCE MA Maintenance All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmit- ted in any form, or by any means, electronic, mechani- cal, recording or otherwise, without the prior written per- mission of NISSAN MOTOR CO., LTD. Edition: July 2009 Revision: October 2009 Publication No. SM0E-1S35U1

- 2. FOREWORD This manual contains maintenance and repair procedure for the 2010 NISSAN ROGUE. In order to assure your safety and the efficient functioning of the vehicle, this manual should be read thoroughly. It is especially important that the PRECAUTIONS in the GI section be completely understood before starting any repair task. All information in this manual is based on the latest product information at the time of publication. The right is reserved to make changes in specifi- cations and methods at any time without notice. IMPORTANT SAFETY NOTICE The proper performance of service is essential for both the safety of the technician and the efficient functioning of the vehicle. The service methods in this Service Manual are described in such a manner that the service may be performed safely and accurately. Service varies with the procedures used, the skills of the technician and the tools and parts available. Accordingly, anyone using service procedures, tools or parts which are not specifically recommended by NISSAN must first be completely satisfied that neither personal safety nor the vehicle’s safety will be jeopardized by the service method selected.

- 3. QUICK REFERENCE CHART S35 QUICK REFERENCE CHART S35 PFP:00000 ENGINE TUNE-UP DATA (QR25DE) ELS0003W FRONT WHEEL ALIGNMENT Engine model QR25DE Firing order 1 - 3 - 4 - 2 Idle speed CVT (In “P” or “N” position) rpm 700 ± 50 Ignition timing (BTDC at idle speed) 10° ± 5° CO% at idle 0.7 - 9.9 % and engine runs smoothly Tensions of drive belts Auto adjustment by auto tensioner Radiator cap relief pressure kPa (kg/cm2 , psi) Standard 78.4 - 98.0 (0.8 - 1.0, 11 - 14) Limit 59 (0.6, 9) Cooling system leakage testing pressure kPa (kg/cm2 , psi) 157 (1.60, 22.8) Compression pressure kPa (kg/cm2 , psi)/rpm Standard 1,412 (14.4, 204.7)/250 Minimum 1,216 (12.4, 176.3)/250 Differential limit between cylinders 100 (1.0, 14.5)/250 Spark plug (Iridium-tipped type) Make NGK Standard type DILKAR6A-11 Gap (Nominal) mm (in) 1.1 (0.043) Axle type 2WD 4WD Tire size 215/70R16 225/60R17 215/70R16 225/60R17 Camber Degree minute (Decimal degree) Minimum Left side –1° 00′ (–1.00°) Right side –1° 15′ (–1.25°) Nominal Left side –0° 15′ (–0.25°) Right side –0° 30′ (–0.50°) Maximum Left side 0° 30′ (0.50°) Right side 0° 15′ (0.25°) Left and right difference 0° 33′ (0.55°) or less Caster Degree minute (Decimal degree) Minimum 3° 55′ (3.92°) 4° 00′ (4.00°) Nominal 4° 40′ (4.67°) 4° 45′ (4.75°) Maximum 5° 25′ (5.41°) 5° 30′ (5.50°) Left and right difference 0° 36′ (0.60°) or less Kingpin inclination Degree minute (Decimal degree) Minimum 9° 45′ (9.75°) Nominal 10° 30′ (10.50°) Maximum 11° 15′ (11.25°) 2010

- 4. QUICK REFERENCE CHART S35 Measure value under unladen* conditions. *: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions. REAR WHEEL ALIGNMENT ELS0003Y Measure value under unladen* conditions. *: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions. BRAKE PEDAL Unit: mm (in) FRONT DISK BRAKE Unit: mm (in) REAR DISK BRAKE Unit: mm (in) Toe-in Total toe-in Distance Minimum In 1 mm (0.04 in) Nominal In 2 mm (0.08 in) Maximum In 3 mm (0.12 in) Toe angle (left wheel or right wheel) Degree minute (Decimal de- gree) Minimum In 0° 02′ 30″ (0.05°) Nominal In 0° 05′ (0.08°) Maximum In 0° 07′ 30″ (0.12°) Axle type 2WD 4WD Tire size 215/70R16 225/60R17 215/70R16 225/60R17 Camber Degree minute (Decimal degree) Minimum –1° 25′ (–1.42°) Nominal –0° 55′ (–0.92°) Maximum –0° 25′ (–0.42°) Toe-in Total toe-in Distance Minimum 0 mm (0 in) Nominal In 2 mm (0.08 in) Maximum In 4 mm (0.16 in) Toe angle (Left wheel or right wheel) Degree minute (Decimal degree) Minimum 0° 00′ (0.00°) Nominal In 0° 05′ (0.08°) Maximum In 0° 10′ (0.16°) Depressed brake pedal height (H1) 183.7 - 193.7 (7.23 - 7.63) Brake pedal reserve height (H2) [Depressing 490 N (50 kg, 110 lb) while turning the engine ON] 65 (2.56) or more Brake pad Wear limit thickness 2.0 (0.079) Disc rotor Wear limit thickness 24.0 (0.945) Brake pad Wear limit thickness 1.5 (0.059) Disc rotor Wear limit thickness 14.0 (0.551) 2010

- 5. QUICK REFERENCE CHART S35 REFILL CAPACITIES ELS00040 UNIT Liter US measure Fuel tank TYPE1 60 15-7/8 gal TYPE2 65 17-1/8 gal Engine Coolant ( With reservoir tank ) at MAX level 7.3 7-3/4 qt Engine oil Drain and refill With oil filter change 4.6 4-7/8 qt Without oil filter change 4.3 4-1/2 qt Dry engine (Overhaul) 5.4 5-3/4 qt Transaxle CVT 2WD Without fluid cooler 7.3 7-3/4 qt With fluid cooler 7.5 7-7/8 qt AWD Without fluid cooler 8.4 8-7/8 qt With fluid cooler 8.6 9-1/8 qt Transfer 0.36 3/4 pt Final drive 0.55 1-1/8 pt Air conditioning system Compressor oil 0.15 5.03 fl oz Refrigerant 0.50 kg 1.11 lb 2010

- 6. GI-1 GENERAL INFORMATION C D E F G H I J K L M B GI SECTION GI N O P CONTENTS GENERAL INFORMATION REGULAR GRADE HOW TO USE THIS MANUAL .................. .... 3 HOW TO USE THIS MANUAL ....................... ..... 3 Description .......................................................... ......3 Terms .................................................................. ......3 Units .................................................................... ......3 Contents .............................................................. ......3 Relation between Illustrations and Descriptions . ......4 Components ........................................................ ......4 HOW TO FOLLOW TROUBLE DIAGNOSES..... 6 Description .......................................................... ......6 How to Follow Test Groups in Trouble Diagnosis......6 Key to Symbols Signifying Measurements or Pro- cedures ............................................................... ......7 HOW TO READ WIRING DIAGRAMS ........... ..... 9 Connector Symbols ............................................. ......9 Sample/Wiring Diagram -Example- ..................... ....10 Connector Information ......................................... ....12 ABBREVIATIONS .......................................... ....14 Abbreviation List .................................................. ....14 TIGHTENING TORQUE OF STANDARD BOLTS ............................................................ ....15 Description .......................................................... ....15 Tightening Torque Table (New Standard Includ- ed) ....................................................................... ....15 RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS ............................................ ....18 Recommended Chemical Products and Sealants ....18 VEHICLE INFORMATION ......................... ...19 IDENTIFICATION INFORMATION ................. ....19 Model Variation ................................................... ....19 Information About Identification or Model Code .. ....20 Dimensions except for Mexico ............................ ....22 Dimensions for Mexico ........................................ ....22 Wheels & Tires .................................................... ....22 PRECAUTION ........................................... ...23 PRECAUTIONS .................................................23 Description ........................................................... ....23 FOR USA AND CANADA ...................................... ....23 FOR USA AND CANADA : Precaution for Supple- mental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER" ........................ ....23 FOR USA AND CANADA : Precautions For Xenon Headlamp Service ............................................... ....23 FOR USA AND CANADA : Precaution Necessary for Steering Wheel Rotation After Battery Discon- nect ...................................................................... ....24 FOR USA AND CANADA : Precaution for Proce- dure without Cowl Top Cover .............................. ....24 FOR MEXICO ......................................................... ....24 FOR MEXICO : Precaution for Supplemental Re- straint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER" .............................................. ....24 FOR MEXICO : Precautions For Xenon Headlamp Service ................................................................. ....25 FOR MEXICO : Precaution Necessary for Steer- ing Wheel Rotation After Battery Disconnect ...... ....25 FOR MEXICO : Precaution for Procedure without Cowl Top Cover ................................................... ....26 General Precautions ............................................ ....26 Three Way Catalyst ............................................. ....27 Multiport Fuel Injection System or Engine Control System ................................................................. ....28 Hoses .................................................................. ....28 Engine Oils .......................................................... ....29 Air Conditioning ................................................... ....29 FUEL ...................................................................... ....29 FUEL : Fuel ......................................................... ....29 LIFTING POINT .................................................31 Revision: 2009 October 2010 Rogue

- 7. GI-2 Commercial Service Tools ................................... ... 31 Garage Jack and Safety Stand and 2-Pole Lift ... ... 31 Board-On Lift ....................................................... ... 32 TOW TRUCK TOWING ................................... ... 33 Tow Truck Towing ............................................... ... 33 Vehicle Recovery (Freeing a Stuck Vehicle) ....... ... 34 BASIC INSPECTION ................................ ... 36 SERVICE INFORMATION FOR ELECTRICAL INCIDENT ....................................................... ... 36 Work Flow ............................................................ ... 36 Control Units and Electrical Parts ........................ ... 36 How to Check Terminal ....................................... ... 37 Intermittent Incident ............................................. ... 40 Circuit Inspection ................................................. ... 43 CONSULT-III/GST CHECKING SYSTEM ...... ... 48 Description ........................................................... ... 48 CONSULT-III Function and System Application*1... 48 CONSULT-III/GST Data Link Connector (DLC) Circuit .................................................................. ... 49 Wiring Diagram - CONSULT-III/GST CHECKING SYSTEM - ............................................................ ... 50 INSPECTION AND ADJUSTMENT ................ ... 53 ADDITIONAL SERVICE WHEN REMOVING BAT- TERY NEGATIVE TERMINAL ............................... ... 53 ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Required Procedure After Battery Disconnection ................ ... 53 Krom VEHICLE INFORMATION .......................... 54 IDENTIFICATION INFORMATION ................. ... 54 Model Variation .................................................... ... 54 DIMENSIONS AND WEIGHTS ....................... ... 55 Dimensions and Weights ..................................... ... 55 PRECAUTION ............................................ 56 TOW TRUCK TOWING .................................. ... 56 Tow Truck Towing ................................................ ... 56 Vehicle Recovery (Freeing a Stuck Vehicle) ........ ... 56 Revision: 2009 October 2010 Rogue

- 8. HOW TO USE THIS MANUAL GI-3 < HOW TO USE THIS MANUAL > [REGULAR GRADE] C D E F G H I J K L M B GI N O P HOW TO USE THIS MANUAL HOW TO USE THIS MANUAL Description INFOID:0000000005254783 This volume explains “Removal, Disassembly, Installation, Inspection and Adjustment” and “Trouble Diag- noses”. Terms INFOID:0000000005254784 • The captions WARNING and CAUTION warn you of steps that must be followed to prevent personal injury and/or damage to some part of the vehicle. WARNING indicates the possibility of personal injury if instructions are not followed. CAUTION indicates the possibility of component damage if instructions are not followed. BOLD TYPED STATEMENTS except WARNING and CAUTION give you helpful information. Standard value: Tolerance at inspection and adjustment. Limit value: The maximum or minimum limit value that should not be exceeded at inspection and adjust- ment. Units INFOID:0000000005254785 • The UNITS given in this manual are primarily expressed as the SI UNIT (International System of Unit), and alternatively expressed in the metric system and in the yard/pound system. Also with regard to tightening torque of bolts and nuts, there are descriptions both about range and about the standard tightening torque. “Example” Range Standard Contents INFOID:0000000005254786 • A QUICK REFERENCE INDEX, a black tab (e.g. ) is provided on the first page. You can quickly find the first page of each section by matching it to the section's black tab. • THE CONTENTS are listed on the first page of each section. • THE TITLE is indicated on the upper portion of each page and shows the part or system. • THE PAGE NUMBER of each section consists of two or three letters which designate the particular section and a number (e.g. “BR-5”). • THE SMALL ILLUSTRATIONS show the important steps such as inspection, use of special tools, knacks of work and hidden or tricky steps which are not shown in the previous large illustrations. Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle or transmission, etc. are presented in a step-by-step format where necessary. Outer Socket Lock Nut : 59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb) Drive Shaft Installation Bolt : 44.3 N·m (4.5 kg-m, 33 ft-lb) Revision: 2009 October 2010 Rogue

- 9. GI-4 < HOW TO USE THIS MANUAL > [REGULAR GRADE] HOW TO USE THIS MANUAL Relation between Illustrations and Descriptions INFOID:0000000005254787 The following sample explains the relationship between the part description in an illustration, the part name in the text and the service procedures. Components INFOID:0000000005254788 • THE LARGE ILLUSTRATIONS are exploded views (see the following) and contain tightening torques, lubri- cation points, section number of the PARTS CATALOG (e.g. SEC. 440) and other information necessary to perform repairs. The illustrations should be used in reference to service matters only. When ordering parts, refer to the appro- priate PARTS CATALOG. Components shown in an illustration may be identified by a circled number. When this style of illustration is used, the text description of the components will follow the illustration. SAIA0519E Revision: 2009 October 2010 Rogue

- 10. Thank you very much for your reading. Please Click Here Then Get More Information. NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 11. HOW TO USE THIS MANUAL GI-5 < HOW TO USE THIS MANUAL > [REGULAR GRADE] C D E F G H I J K L M B GI N O P SYMBOLS 1. Union bolt 2. Copper washer 3. Brake hose 4. Cap 5. Bleed valve 6. Sliding pin bolt 7. Piston seal 8. Piston 9. Piston boot 10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt 13. Washer 14. Sliding pin boot 15. Bushing 16. Torque member 17. Inner shim cover 18. Inner shim 19. Inner pad 20. Pad retainer 21. Pad wear sensor 22. Outer pad 23. Outer shim 24. Outer shim cover 1: PBC (Poly Butyl Cuprysil) grease or silicone-based grease 2: Rubber grease : Brake fluid Refer to GI section for additional symbol definitions. SFIA2959E SAIA0749E Revision: 2009 October 2010 Rogue

- 12. GI-6 < HOW TO USE THIS MANUAL > [REGULAR GRADE] HOW TO FOLLOW TROUBLE DIAGNOSES HOW TO FOLLOW TROUBLE DIAGNOSES Description INFOID:0000000005254789 NOTICE: Trouble diagnoses indicate work procedures required to diagnose problems effectively. Observe the following instructions before diagnosing. • Before performing trouble diagnoses, read the “Work Flow” in each section. • After repairs, re-check that the problem has been completely eliminated. • Refer to Component Parts and Harness Connector Location for the Systems described in each section for identification/location of components and harness connectors. • When checking circuit continuity, ignition switch should be OFF. • Refer to the Circuit Diagram for quick pinpoint check. If you need to check circuit continuity between harness connectors in more detail, such as when a sub-har- ness is used, refer to Wiring Diagram in each individual section and Harness Layout in PG section for identi- fication of harness connectors. • Before checking voltage at connectors, check battery voltage. • After accomplishing the Diagnosis Procedures and Electrical Components Inspection, check that all harness connectors are reconnected as they were. How to Follow Test Groups in Trouble Diagnosis INFOID:0000000005254790 1. Test group number and test group title • Test group number and test group title are shown in the upper portion of each test group. 2. Work and diagnosis procedure • Start to diagnose a problem using procedures indicated in enclosed test groups. 3. Questions and results • Questions and required results are indicated in test group. 4. Action • Next action for each test group is indicated based on result of each question. JPAIA0021GB Revision: 2009 October 2010 Rogue

- 13. HOW TO FOLLOW TROUBLE DIAGNOSES GI-7 < HOW TO USE THIS MANUAL > [REGULAR GRADE] C D E F G H I J K L M B GI N O P Key to Symbols Signifying Measurements or Procedures INFOID:0000000005254791 JPAIA0397GB Revision: 2009 October 2010 Rogue

- 14. GI-8 < HOW TO USE THIS MANUAL > [REGULAR GRADE] HOW TO FOLLOW TROUBLE DIAGNOSES JPAIA0398GB Revision: 2009 October 2010 Rogue

- 15. HOW TO READ WIRING DIAGRAMS GI-9 < HOW TO USE THIS MANUAL > [REGULAR GRADE] C D E F G H I J K L M B GI N O P HOW TO READ WIRING DIAGRAMS Connector Symbols INFOID:0000000005570611 Most of connector symbols in wiring diagrams are shown from the terminal side. • Connector symbols shown from the terminal side are enclosed by a single line and followed by the direction mark. • Connector symbols shown from the harness side are enclosed by a double line and followed by the direction mark. • Certain systems and components, especially those related to OBD, may use a new style slide-locking type harness connector. For description and how to disconnect, refer to PG section, “Description”, “HARNESS CONNECTOR”. • Male and female terminals Connector guides for male terminals are shown in black and female terminals in white in wiring diagrams. SAIA0257E SGI363 Revision: 2009 October 2010 Rogue