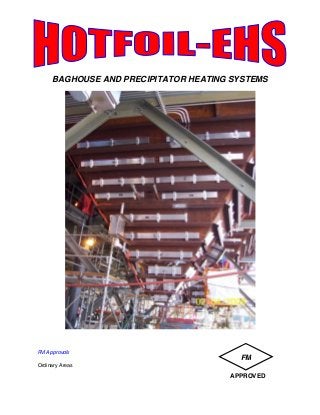

Pluggage of flyash collection hoppers due to flue condensation is an expensive and unnecessary problem. Type HB Heating Module systems are specifically designed to eliminate the maintenance nightmare of hopper pluggage.

The HB Heating Module system is designed to provide low watt density heat spread over the maximum surface area available for heating. Uniform heating is essential to avoid cold spots, especially near the hopper throat where fly ash pluggage is most prevalent and problematic. To obtain maximum heater coverage, both rectangular and trapezoidal heaters are available to provide the most effective and efficient application of heat.