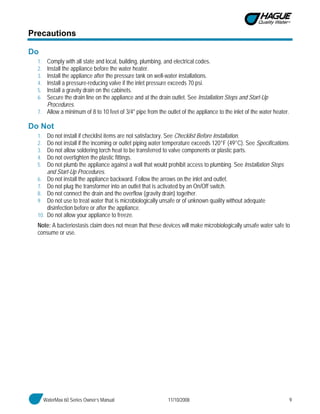

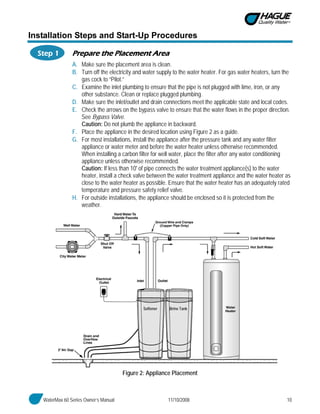

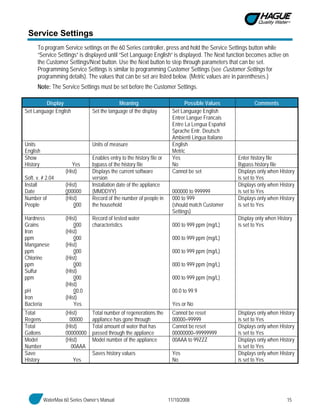

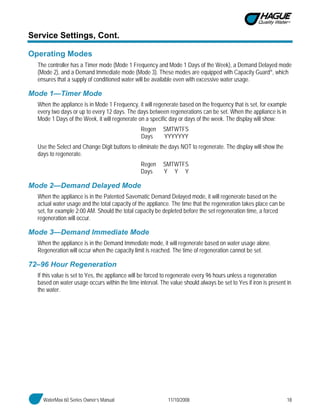

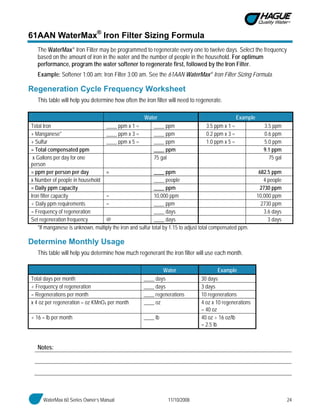

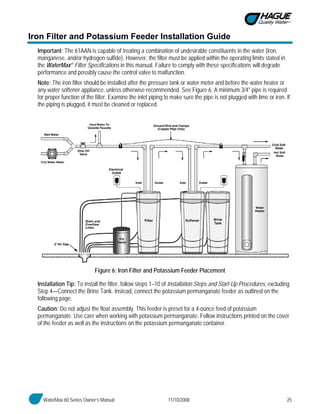

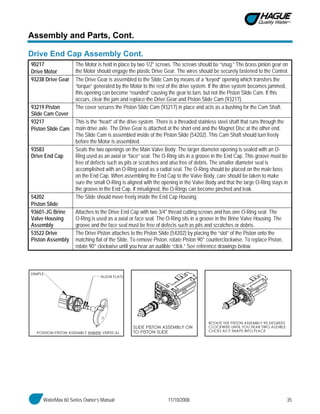

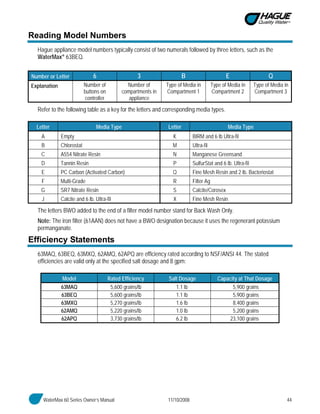

The document details the owner’s manual and installation guide for the Hague WaterMax 60 series water conditioning appliance, including a 25-year limited warranty covering defects in workmanship and materials. It outlines warranty registration requirements, exclusions, conditions for valid claims, and procedures for reporting defects. Additionally, the manual provides operational guidelines, installation precautions, and maintenance tips to ensure optimal performance of the appliance.