Storage Solutions Publ 2128 En

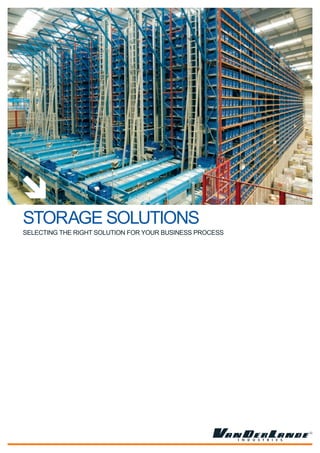

- 1. STORAGE SOLUTIONS SELECTING THE RIGHT SOLUTION FOR YOUR BUSINESS PROCESS

- 2. STORAGE SOLUTIONS SELECTING THE RIGHT STORAGE SOLUTION FOR YOUR BUSINESS PROCESS Distribution centre operations today are increasingly under pressure from labour scarcity, increasingly expensive floorspace and higher customer demands regarding response times and accuracy of deliveries. At Vanderlande Industries, we recognise the important role storage solutions can play in meeting the tough demands placed on your logistics operation. That is why we offer storage solutions, which enable you to maximise efficiency and productivity in your distribution centre and which make optimal use of available floorspace. We can provide a complete range of miniload and conveyor systems, Warehouse Management and Control Systems and services to implement a storage solution that is seamlessly integrated into your logistics operation. With our experience in logistics and material handling, we can assist you in selecting the right storage solution for your specific business process. Our storage solutions have been implemented in a wide range of industries such as parts & components, automotive, retail, food and care. Companies which have implemented our storage solutions include Thermote & Vanhalst (TVH), Arrow Electronics, Herma, Audi, Smart, Entertainment UK, Game Stores, Micarna and Bourjois.

- 4. STORAGE IN THE DISTRIBUTION CENTRE WORKFLOW Goods Put receiving away = main application areas Storage of storage technology in a distribution centre Picking Consolidation Shipping

- 5. Our storage solutions can be used in different phases of the distribution centre workflow: • Bulk storage: The need to minimise handling and make better use of available floor space in the distribution centre is leading to a rise in the use of miniload systems for bulk storage. We recognise this trend and we have developed a range of miniload systems especially for this purpose. This application is especially suitable for retailers. • Order picking: Our storage systems can be seamlessly integrated into our goods-to-man order picking solutions. Essential part of these solutions is the new PICK@EASETM workstation family, which enables a sustainable high operator performance - up to 900 picks per operator per hour - thanks to ergonomic design principles which were applied right from the start. These solutions are ideal for medium and slow-moving products in retail and wholesale distribution centres. They are also beneficial for distribution centres handling parts & components and automotive products, which face a large product range and very high service-level requirements. • Consolidation: Optimising the number of shipments, improving accuracy and store-friendly delivery, and reducing manual handling are important reasons to automate your consolidation and packing operation. Our storage solutions can play an important role in consolidation, packing and delivery unit filling processes. Material flows from different (picking) areas come together in a miniload system. Within a short time period, flows are sorted and grouped per order, delivery unit or shipment, and then dispatched in the exact sequence you require.

- 6. OUR QUICKSTORE MINILOAD SYSTEMS TM The core component of our storage solutions is our range of QUICKSTORETM miniload systems. Selecting the right one for your application depends on the storage capacity and throughput you require. HDS Miniload quad-belt shuttle single deep Miniload twin telescopic shuttle double deep Moving beam twin-belt Miniload Miniload shuttle twin-belt shuttle single telescopic shuttle single deep double deep 0 10,000 20,000 Locations per aisle

- 7. Our portfolio With our broad portfolio of QUICKSTORETM miniloads you can optimise throughput and improve the accuracy of your deliveries, enabling you to deliver a consistently high service level to your customers. Our miniloads are suitable for a wide range of storage applications. Depending on your specific situation, throughput can be increased substantially by applying multiple lifts or shuttles. With our QUICKSTORETM HDS up to 1,000 tote movements per hour can be achieved. Storage capacity can be increased significantly by applying double deep storage. Our miniloads can store and retrieve totes, trays and cartons, depending on the type of load handling device applied.

- 8. WHY VANDERLANDE INDUSTRIES? The value of experience We have broad experience in storage solutions and related services, enabling fast implementation with minimum risk. This gives you the assurance that your system will be operational on time and that it will deliver the specified productivity right from the start and throughout the system’s life cycle. As a material handling systems developer and manufacturer, service requirements are an integral part of our system design process, ensuring minimal service efforts and costs. In addition, our ‘lean engineering’ concept ensures excellent reliability and serviceability, keeping life cycle costs down. Storage that meets your needs We offer a broad range of storage solutions and load handling devices, enabling us to optimise the solution to your specific needs. Our high-speed QUICKSTORETM HDS system for example achieves up to 1,000 tote movements per hour. Complete warehousing and distribution solutions We can provide you with a complete warehousing and distribution solution, all from a single source. Our automated storage, picking and consolidation concepts have been implemented many times, ensuring that your system is operational on-time, and that it will deliver the specified productivity right from the start, reducing risk. Our concepts have been applied in segments as diverse as parts & components, automotive, care, food, fashion, retail and business-to-consumer. By delivering the right level of automation with the flexibility for future changes, we enable you to provide consistently high service levels to your customers.

- 10. THE VALUE OF EXPERIENCE TVH Forklift Parts TVH is Europe’s largest independent distributor of fork lift trucks and components. We were asked to supply the complete material handling system for their distribution centre in Belgium. In the facility TVH stocks 450,000 SKUs from which it meets an average of 4,000 orders and 13,000 order lines per day. The system contains six miniloads with 52,000 storage locations. For picking, totes are conveyed to workstations. On one side of the aisle the crane replenishes flow racks with faster moving products. Eight miniloads are used as a consolidation buffer. Totes are sorted to orders in flow racks. There are 1,100 positions for orders in progress. When an order is complete, the packer at the end of the flow racks takes the totes and packs the order. Thanks to the high level of automation in order processing, order lead times have been shortened significantly and orders can now be based on actual customer demand. Orders received before 17:00 hours are shipped the same day. Entertainment UK Entertainment UK is the UK’s leading wholesale distributor of home entertainment products supplying many well-known stores and e-tailers. We were asked to deliver a highly automated order fulfillment system. The system is based on a batch picking concept. Eight miniload systems are used as storage for medium movers and to store and retrieve medium movers to ‘goods-to-man’ workstations. The miniload systems are also used to consolidate manually picked slow movers for dispatch in a 2-hour wave. The new distribution centre is proving remarkably accurate and provides Entertainment UK with the efficiency and flexibility essential to the company’s business success.

- 11. Arrow Electronics Arrow Electronics is a major global provider of products, services, and solutions to the electronic component and computer product industries. The company asked us to build its European distribution centre in The Netherlands. It supplies up to 10,000 shipments per day. It is equipped with the latest technology, including semi-automatic picking systems, conveyor belts, high-bay pallet storage and three miniloads. Two miniloads are used for consolidation of totes coming from the shelving area. When an order is complete, the totes are sent to a predefined packing station. One miniload is used for consolidation of weekly orders to reduce transport costs. The new distribution centre has allowed Arrow to streamline loading, order picking and shipping, improving responsiveness and customer service. Delivery reliability now exceeds 99.5% and 95% of shipments are delivered the next day.

- 12. STORAGE SOLUTIONS FACTS & FIGURES QUICKSTORE Product Range TM System: Storage: Load type: Max. Number of load load: handling devices: QUICKSTORETM 2.1 Single deep Totes 50 kg 1 QUICKSTORETM 2.2 Single deep Totes 100 kg 2 QUICKSTORETM 3.1 Double deep Totes, cartons, trays 100 kg 1 QUICKSTORETM 3.2 Double deep Totes, cartons, trays 200 kg 2 QUICKSTORETM 4.2 Single deep Totes, cartons, trays 100 kg 2 QUICKSTORETM 4.4 Single deep Totes, cartons, trays 200 kg 4 QUICKSTORETM 7 Single deep Totes 50 kg 1 QUICKSTORETM HDS Single deep Totes 35 kg Multiple shuttles Load Handling Devices Telescopic shuttle • Used for double deep tote storage • Standard combination with twin-belt on shuttle for fast transfer at pick-up and delivery station Belt shuttle • Used for single deep storage of totes and cartons Telescopic shuttle • Very short shuttle cycle times to achieve the highest system throughput Vacuum telescopic shuttle • ‘Single-load’ type used for single deep storage of cartons and totes • ‘Multiple-load’ type can handle four loads for double deep storage of cartons and totes. Two-belt shuttle This information is subject to change without notice and should not be construed as a commitment on the part of Vanderlande Industries. Four-belt shuttle Vacuum telescopic shuttle PUBL 2128 EN/08-07