Still wagner efv 200 forklift service repair manual

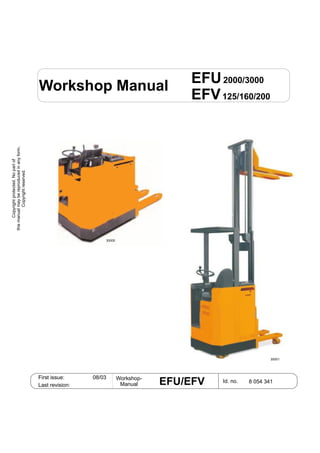

- 1. 07/01 01 Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. First issue: 08/03 Workshop- ManualLast revision: EFU/EFV Id. no. Workshop Manual EFU2000/3000 EFV125/160/200 30000 30001 8 054 341

- 2. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. First issue: 08/03 Workshop- ManualLast revision: EFU/EFV Id. no. Workshop Manual EFU2000/3000 EFV125/160/200 8 054 341 This Workshop Manual can be used for the truck types EFU2000: 2t Nominal Load Capacity 24V Battery Voltage EFU3000: 3t Nominal Load Capacity 48V Battery Voltage EFV125/160/200: 1,25/1,6/2,0t Nominal Load Capacity 24V Battery Voltage

- 3. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 1 Foreword Foreword This workshop manual provides specifications and describes functional characteristics of the standard truck. This provides you with a comprehensive documentation to ensure better understanding of the vehicle technology and so permit correct maintenance and repair work to be carried out. The workshop manual is always updated by supplementary sheets. Updating of workshop manuals The industrial truck range is subject to continuous further development. This means that certain components or assemblies are exchanged or modified. To ensure that the holder of this manual always has the most up to date version of the documentation, it is important to abide by the following updating system. 00255 50002 50003 50004

- 4. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 Updating workshop manuals Exchanging faulty sheets If a particular page contains mistakes, for example due to altered setting values, the respective sheet must be exchanged. A newly inserted sheet can be recognized by the altered left-hand baseline (1). Here, the date of compilation is updated in the line entitled Issue (2). In the line Replaces issue (3) is the compilation date of the sheet to be replaced. The sheet no. remains the same (4). With every revision the first sheet will be re- placed. In (9) you see the first issue and the date of the last revision. This tells you the revision state of the whole book. Insertion of supplementary sheets If new, modified or additional components are included in the series truck, it may be necessary to add one or more supplementary sheets. The additional sheet is recognized by the left- hand and right-hand page baseline (5+6). In the Issue line on the left-hand side is the compilation date (7). On the right, the supplementary sheet is marked by the sheet no. with continuous index (8). In addition, the table of contents of the respective assembly must also be exchan- ged. Newly compiled sheets, whether replacements or supplementary sheets, and the new tables of contents are sent by post to all known holders of workshop manuals. Issue: 5/03 Replaces issue: Workshop Manual sheet.no. 4-01 Issue: 11/03 Replaces issue: 5/03 Workshop Manual sheet-no.4-01 Page baseline of the existing sheet Page baseline of the corrected sheet 1 4 2 3 Issue: 5/03 Replaces issue: Workshop Manual sheet-no.4-01 Issue: 11/03 Replaces issue: Workshop Manual sheet-no.4-01 Page baseline of the existing sheet Page baseline of the supplementary sheet 65 7 8 First issue: 5/03 Last revision: 11/03 Workshop Manual N° id. ------- Page baseline of the first sheet 9 Foreword

- 5. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. Vorwort 3 Remarks, imprint No guarantee claims arise as a result of working in accordance with the instructions contained in this manual. This does not affect the guarantee stipulations. We are continuously involved in the further development of our industrial trucks. Please appreciate that this documentation is subject to alteration and error, and that no claims may be derived from information, illustrations and descriptions contained in the workshop manual. STILL WAGNER GMBH & CO KG Trainingszentrum Ernst-Wagner-Weg 1-5 72766 Reutlingen-Mittelstadt Foreword

- 6. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 4 1 Vehicle data 2 Travel motor 3 Drive wheel 4 Gear 5 Brake 6 Steering 7 BDI/HM 8 Circuit board 9 Travel control 10 Accelerator pedal 11 Hydraulic EFU 12 Hydraulic EFV 13 Lifting device 14 Mast EFV 99 Maintenance Sections

- 7. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 5 Section Contents Sheet Foreword........................................................................................1 Updating of workshop manuals.............................................1 Exchanging faulty sheets ......................................................2 Insertion of supplementary sheets ........................................2 Remarks, imprint............................................................................3 Sections .........................................................................................4 Contents.........................................................................................5 1 Vehicle data Identification..............................................................................1-01 Signs on the vehicle..................................................................1-02 2 Travel motor General.....................................................................................2-01 Technical Data ..........................................................................2-02 Terminals ..................................................................................2-02 Removing the drive motor.........................................................2-03 Replacing the carbon brushes..................................................2-04 Maintenance .............................................................................2-05 General ............................................................................2-05 Cleaning...........................................................................2-05 Visual inspection, replacing damaged parts.....................2-06 Checking the brush unit, replacing the carbon brushes...........................................2-07 Commutator .....................................................................2-08 Bearings...........................................................................2-08 3 Drive wheel Replacing..................................................................................3-01 Removal....................................................................................3-01 4 Gear Removing..................................................................................4-01 Lubricating the bogie bearing ...................................................4-02 Changing the gear oil................................................................4-02 Oil change.................................................................................4-03 Oil change procedure.......................................................4-03 Table of Contents

- 8. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 6 Table of Contents Section Contents Sheet 5 Brake Function....................................................................................5-01 Service brake (brake pedal)......................................................5-01 Parking brake (handbrake) .......................................................5-01 Guide to components................................................................5-02 Installing/removing the drive motor brake.................................5-03 Removal...........................................................................5-03 Installation........................................................................5-03 Adjusting the brake clearance ..................................................5-04 Checking the brake lining thickness.................................5-04 Adjusting the brakes.........................................................5-04 Adjusting the handbrake...........................................................5-05 Checking the setting.........................................................5-05 Adjusting the brake pedal .........................................................5-06 Measuring the brake deceleration ............................................5-07 General ............................................................................5-07 Preparations for measurement.........................................5-07 Measuring the brake deceleration ............................................5-08 Evaluating the measurement ...........................................5-08 Main brake cylinder...................................................................5-09 Bleeding / filling the brake system ............................................5-10 Filling the brake system ...................................................5-10 Bleeding the brake system...............................................5-10 6 Steering General.....................................................................................6-01 Structure of the steering system...............................................6-02 Steering sensor.........................................................................6-03 General ............................................................................6-03 Slipring system.................................................................6-04 Adjusting the steering sensor ...................................................6-05 General ............................................................................6-05 Adjustment when installed ...............................................6-05 Adjustment when not installed .........................................6-07 Servo unit..................................................................................6-08 General ............................................................................6-08 Terminal markings on terminal board...............................6-08 Exchanging the carbon brushes.......................................6-09 Specifications...................................................................6-09 Steering controler .....................................................................6-10 General ............................................................................6-10 Function ...........................................................................6-10 Safety monitoring .............................................................6-11 Adjusting the current limitation.........................................6-12

- 9. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. Table of Contents 7 Section Contents Sheet 7 BDI/HM Curtis Combi-Controller 803 .....................................................7-01 General ............................................................................7-01 Pin assignment.................................................................7-02 Setting the final discharge voltage ...................................7-03 Technical data ..................................................................7-04 Accumeter EL-AC5 (up to 6/93)...............................................7-05 Battery discharge indicator...............................................7-05 Hour meter .......................................................................7-06 Accumeter EL-AC5 (from 7/93) ................................................7-07 General ............................................................................7-07 Installation........................................................................7-07 Electrical connection ........................................................7-08 Specifications...................................................................7-09 Adjusting accumeter EL-AC......................................................7-10 8 Circuit board Circuit board A1with adapter card A8 .......................................8-01 Components.....................................................................8-01 Fuses........................................................................................8-02 Testing the fuses ..............................................................8-03 Components .............................................................................8-04 Rating plate......................................................................8-04 Contactor clearance.........................................................8-04 Contact pressure..............................................................8-04 9 Travel control General.....................................................................................9-01 Functional characteristics.................................................9-01 Cycle ratio and current profile ..........................................9-01 Setpoint value current, frequency characteristic.......................9-02 Primary current circuit...............................................................9-03 Ignition process................................................................9-03 Thyristors..................................................................................9-04 Function ...........................................................................9-04 Thyristors..................................................................................9-05 Installation........................................................................9-05 Installation instructions.....................................................9-05 Thyristor power block................................................................9-06 General ............................................................................9-06 Diodes.......................................................................................9-07 Functional characteristics.................................................9-07 Layout, installation ...........................................................9-07

- 10. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. Table of Contents 8 Section Contents Sheet 9 Travel control Diodes.......................................................................................9-08 Testing the diodes ............................................................9-08 Diode power block ....................................................................9-09 General ............................................................................9-09 Testing..............................................................................9-09 Terminal............................................................................9-09 Functional Characteristics................................................9-10 Testing the primary current ......................................................9-11 Test procedure .................................................................9-12 Current actual value sensor n35...............................................9-13 Functional characteristics.................................................9-13 Control circuit board u200.........................................................9-14 Functional characteristics.................................................9-14 Checking the safety circuit ...............................................9-14 Removing.........................................................................9-15 Settings ............................................................................9-15 Speed restriction GB (from 12/90)...........................9-15 Ramp-up time HZ ....................................................9-15 Reversing current RS ..............................................9-16 Drive current FS.......................................................9-16 Drive reduction 2,5kph .....................................................9-17 Adjustment of drive current ..............................................9-18 Current setting .........................................................9-18 Adapter card A8........................................................................9-20 General ............................................................................9-20 Settings ............................................................................9-21 Default factory settings.....................................................9-21 LED display......................................................................9-22 Measured signals.............................................................9-23 Block circuit diagram........................................................9-24 Wiring diagram .........................................................................9-25 Circuit board A1 with adapter card A8..............................9-25 10 Accelerator pedal General...................................................................................10-01 Functional characteristics of the magnetoresistor..........10-01

- 11. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. Table of Contents 9 Section Contents Sheet 11 Hydraulics Block diagram .........................................................................11-01 Hydraulic circuit diagram.........................................................11-01 Pump assembly ......................................................................11-02 General...........................................................................11-02 Function LIFTING...........................................................11-03 Function LOWERING .....................................................11-04 Electrically pilot controlled non-return valve ...................11-05 Replacing the carbon brushes........................................11-06 Removal / Installation .....................................................11-06 Removal .........................................................................11-07 Installation ......................................................................11-07 Removing the pump motor .............................................11-08 Hydraulic pump ..............................................................11-09 General ..................................................................11-09 Removing the hydraulic pump........................................11-10 Setting the maximum pressure.......................................11-12 Recommended values for pressure adjustment: ...11-12 Hydraulic oil change .......................................................11-13 Bleeding the lifting cylinder and hydraulic system of air .........11-14 Procedure.......................................................................11-14 12 Hydraulic system Diagram of the hydraulic system ............................................12-01 Pump unit................................................................................12-02 Removal.........................................................................12-02 Carbon brushes..............................................................12-02 Directional slide valve block....................................................12-02 Adjusting the maximum pressure valve .........................12-03 13 Lifting device Function of the angled lever ...................................................13-01 Adjustment..............................................................................13-01 Drawbar adjuster............................................................13-01 End stops at bottom .......................................................13-01 End stops at top .............................................................13-02 Lift stop...........................................................................13-02 Angled lever - pressure rods..........................................13-03 Lifting cylinder, low lift.............................................................13-04 Guide to parts.................................................................13-04 Adjusting the tension springs .........................................13-04

- 12. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. Section Contents Sheet 14 Mast Basic lift ..................................................................................14-01 General ..........................................................................14-01 Setting the height when lowered....................................14-01 General...................................................................................14-02 Load carriage, concealed cylinder version.....................14-02 Load carriage, exposed cylinder version........................14-02 Function..................................................................................14-03 Removing the telscopic load carriage.....................................14-04 Mounting ........................................................................14-04 Removing the lift cylinder .......................................................14-05 Support rollers - outer mast ....................................................14-06 Lift bracket ..............................................................................14-07 General ..........................................................................14-07 Removing ......................................................................14-07 Lift bracket ..............................................................................14-08 Setting the adjusting screws .........................................14-08 Chains.....................................................................................14-09 General ..........................................................................14-09 Setting the control chains .......................................................14-10 Setting the clearance lift chain................................................14-11 Chain setting at the triplex load carriage ................................14-12 Testing with/without rated load.......................................14-12 99 Maintenance General...................................................................................99-01 Safety instructions ..................................................................99-02 Handling fuels and lubricants.........................................99-02 Brake ......................................................................................99-03 Testing the function of the service brake........................99-03 Testing the function of the parking brake .......................99-03 Testing the function of the reversing brake ....................99-03 Wear limit for the brake lining.........................................99-03 Battery ....................................................................................99-04 Checking the electrolyte level ........................................99-04 Checking the electrolyte density ....................................99-04 Cleaning the battery.......................................................99-04 Battery lock ....................................................................99-05 Battery charger...............................................................99-05 Operating elements ................................................................99-06 Ease of movement .........................................................99-06 Steering ..................................................................................99-07 Ease of movement .........................................................99-07 Cut-out in the event of error ...........................................99-07 Steering chain ................................................................99-07 Reverse steering............................................................99-07 Table of Contents 10

- 13. Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. Section Contents Sheet 99 Maintenance Lifting chains...........................................................................99-08 General ..........................................................................99-08 Checking the lifting chains for damage ..........................99-09 Checking the lifting chains for damage ..........................99-12 Checking the chain elongation.......................................99-13 Replacing the lifting chains ............................................99-14 Lubricating the lifting chains ...................................................99-15 Cleaning the chains ................................................................99-16 Hydraulic tank.........................................................................99-17 Volume ...........................................................................99-17 Seals ..............................................................................99-17 Soiled oil.........................................................................99-17 Wheels....................................................................................99-18 Wear...............................................................................99-18 Wheel bearings ..............................................................99-18 Load wheels...................................................................99-18 Motor.......................................................................................99-19 Carbon brushes..............................................................99-19 Checking the brush springs............................................99-19 Other maintenance work................................................99-19 Gear........................................................................................99-20 Changing the gear oil.....................................................99-20 Noises ............................................................................99-20 Leaks..............................................................................99-20 Mast........................................................................................99-21 Mast rollers.....................................................................99-21 Guide rollers of the fork holder.......................................99-21 Windscreen ....................................................................99-21 Lifting cylinder ................................................................99-21 Guides, surfaces ............................................................99-21 Forks ..............................................................................99-21 Chain adjustment ...........................................................99-21 Pump assembly ......................................................................99-22 Carbon brushes..............................................................99-22 Oil level ..........................................................................99-22 Noises ............................................................................99-22 Soiling ............................................................................99-22 Lubrication plan ......................................................................99-23 Lubricants.......................................................................99-23 Disposal .........................................................................99-23 Lubrication plan..............................................................99-24 Table of Contents 11

- 14. 07/01 01 Chapter 1 Vehicle data Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 1 – Identification 01 EFU 2000/ 3000 EFV 125/ 160/ 200 • Load bearing capacity 2000/ 3000kg 1250/ 1600/ 2000kg • Tavel motor 2,8/ 4,2kW 2,8kW • Maximum speed 12km/h 8km/h • Dimensions L/W/H ca. 2330-4700/ 980/ 1550mm 2230/ 980/ 2350mm • Weight with battery 1450-2100kg 1700-2200kg • Battery voltage 24/ 48V 24V 30000 30001

- 15. Chapter 1 Vehicle data Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 1 – Signs on the vehicle 1 Nameplate (beside driver seat) 2 UVV check 3 Maximum pressure hydraulic 4 Towing points 5 Vehicle no. on chassis 6 Carrying load diagram 10309 1 23 4 02 30000 6 30002 5

- 16. 07/01 01 Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – General Series-wound motors are used in the travel drive unit. The armature and field winding are connected in se- ries, so ensuring greater torque particularly in the lo- wer speed ranges. Remark: Series-wound motors must never be operated for long periods without load, i.e. without being in gear. Otherwise, they automatically increase their speed to the point of self-destruction . The motor speed is controlled by the stroke ratio of the main thyristor, which is timed by the control circuit board of the pulse control system. The sense of rotation of the motor is controlled by the flow direction of the current through the field winding. The direction of flow is determined by the travel direction contactors. In 24V appliances, the motor is self-ventilating. Ventilation is effected by a fan impeller wheel mounted on the armature shaft. 48 V motors are additionally separately ventilated by an external radial fan in the area of the commutator. 01 30003

- 17. Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – 02 Technical Data Manufacturer JULI JULI Model GF 116-14/1.9/2.8 Motor version Series-wound Voltage (V) 24 48 Current (A) 145 108 Output (kW) 2,8 4,2 Speed (min -1 ) 1700 2000 Protection class IP 21 IP21 Insulation class B B/F Terminals Designation new old Armature coil A1/A2 A/B Field coil D1/D2 E/F The rotary direction of the motor (1) depends on the direction in which the current (2) flows through the field coil. The current direction is determined by the travel direction contactors. 1 2 A2 • • • • • • • • A1 D2 D1 A2 A1 D2 D1 1 2 10279

- 18. Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – 03 Removing the drive motor Note: Because the brake (1) is flange- mounted on the drive motor, the vehicle is no longer braked once the motor has been removed. The vehicle must be secured before work commences, to prevent it rolling away. Removal • Pull out the battery plug. • Jack up the vehicle and secure it to prevent it from roling away. • Mark the motor connecting cable and disconnect it. • Release the 4 hexagon socket screws M8x30 (4) and remove them completely. • Lift the drum brake up and out and set it down to one side. • Remove the 6 hexagon socket screws M8x30 (5). • Lift and remove the motor (2) together with the flange (6). • The pinion stays on the shaft end of the motor. • Cover the gear opening to protect the inside from dirt. Remark: When you install the motor again, you must ensure that the bearing bridge is in the correct position when the wheel is in the straight-on position. When it is in the right position, an optimal cooling effect is achieved. 6 4 2 5 Bearing bridge End shield Ventilation shafts Wheel in straight-on position 10280 10281 30003 1 2

- 19. Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – 04 Replacing the carbon brushes The carbon brushes must be replaced when they re- ach a residual length of 16mm resp. 20mm. At this length, they are worn down by 50 %. Length of a new carbon brush: 32mm (24V) 40mm (48V) The entire set of brushes must always be replaced (4 brushes). Removal: • Pull out the battery plug. • Remove the tensioning belt of the drive motor. • Raise the brush spring (1). • Pull out the carbon at the connecting cable (2). • Disconnect the connecting cable. • Clean out the commutator compartment (blow it out). Caution: Never inhale carbon dust! • Mount the new carbon brushes. Remark: After replacing the carbon brushes, do not run the motor straight away at full power. The carbon brushes run in relatively quickly under low loads (see drive motor maintenance). Checking the brush springs Brush springs with insufficient pre-tension cause the commutator to burn. Ensure that the carbon brushes move easily in the shaft. 60163 10282 1 2

- 20. Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – 05 Maintenance General Maintenance work between major overhauls should consist of the following: • Cleaning • General visual inspection • Replacing damaged parts • Checking the brush unit and commutator • Replacing the carbon brushes (if necessary) This work should be carried out at least every 500 operating hours or once a quarter. We recommend having major motor overhauls carried out by a specially equipped workshop, as special tools and specialist knowledge are required. Note: Before carrying out any work on the mo- tor, always first pull out the battery plug to avoid short circuits or injury. Cleaning • Remove the sealing tape and take out the brushes. • Clean the motor thoroughly using compressed air, taking care not to breathe in any dust (wear a pro- tective mask). • Clean soiled commutators and brush unit using a clean cloth (not cleaning wool) moistened with benzine and dry well. Remark: Do not lift the brush springs more than is necessary and do not bend them to the side. 10288

- 21. Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – Maintenance Visual inspection, replacing damaged parts • Straighten or replace dented sealing tapes. • Check fan impellers for damage. Damaged fans (imbalance, reduced output) must be replaced. • Clean the gear ventilation channels (1). To do so, remove the drive motor and clean the channels with a vacuum cleaner (do not blow them out with com- pressed air). Soiling impairs the air circulation, which leads to increased temperatures in the motor and possibly to irreparable damage. • Check field and armature coils for signs of over-loa- ding (overheating): dark coloration, brittle or burned insulation, unsoldered commutators. Motors with this kind of damage must be replaced without delay. • If you discover oil or grease in the motor (usually a paste made up of oil, oil vapour mixed with dust and carbon abrasions), investigate the cause immediately and remedy it. The motor must be cleaned extremely thoroughly. Remark: Rapid carbon brush or commutator wear is generally due to the effect of oil. The oil/grease burns in the brush sparks, leaving behind a sharp-edged oil ash which has an abrasive effect. This can lead to inadmissibly high levels of carbon brush wear before the scheduled maintenance date is reached. 50039 1 06

- 22. Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – Maintenance Checking the brush unit, replacing the carbon brushes After the carbon brush unit has been cleaned, it should be possible to move the carbon brushes easily in their guide. If one or more of the carbon brushes jam, they must not be sanded down with emery paper or any other abrasive. In this case, the entire carbon brush unit must be replaced, as it is possible that the brushes were ther- mally overloaded. It is also important that the carbon brushes are not broken or chipped at the running edges. Remarks: • Always replace the entire brush set, basing your assessment on the shortest brush. • Only use original spare carbon brushes (see spare parts list!) • Do not allow the carbon brush springs to knock against the carbon brushes when you are inserting the brushes. • If the minimum length has not quite been reached, replace the brushes anyway, as the remaining running time may be shorter than the next maintenance interval. • A maximum of 3 carbon brush sets should be replaced in succession before a general overhaul of the motor is carried out (by a specialised works- hop). 07

- 23. Thank you very much for your reading. Please Click Here Then Get More Information. NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 24. Chapter 2 Travel motor Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 2 – Maintenance Commutator The running surface of the commutator should be even and smooth with a grey-black appearance. The commutator must not be worn, scored or out of round. Should one of the above conditions occur, the commutator must be reworked (major overhaul). Never attempt to achieve the neccesary finish using a file, emergy paper or similar. Bearings The ball bearings do not need to be re-lubricated. The volume of grease in the bearings is sufficient for the maintenance period between major overhauls. The bearings must be replaced: • without fail during every major overhaul, • after they have been in use for 2000 operating hours, at the latest • if the vehicle is only used with short operating times, then after 5 years at the latest. Only use the bearings specified in the spare parts list. Note on risk of overloading when batteries are run down: If the speed of the motors drops noticeably, work must be stopped immediately. Check the battery without delay, then recharge it if necessary. Never drive the vehicle if the voltage is too low! 08

- 25. 07/01 01 Chapter 3 Drive wheel Copyrightprotected.Nopartof thismanualmaybereproducedinanyform. Copyrightreserved. Issue: 08/03 Workshop- ManualReplaces issue: EFU/EFV Sheet no. 3 – Replacing Dimensions of new wheel: 300 x 130mm The drive wheel must be replaced when: • The running surface is badly cracked or out of round, or its diameter is very different from that of the other drive wheel. • The tyre diameter has reduced by 10 %, e.g. 300mm - 10 % = 270mm. Removal • Pull out the battery plug. • Apply the handbrake. • Jack up the vehicle securely and secure it to pre- vent it from rolling away. • Turn the drive wheel (1) until the wheel nuts (2) are accessible. • Release the wheel nuts. • Remove the drive wheel. • When mounting the new drive wheel, tighten the wheel nuts diagonally in several passes. Tightening torque: 140Nm. 01 10285 2 1