Service Manual Guide for GDP/GLP80-120DB and GDP/GLP130-160EB Lift Trucks

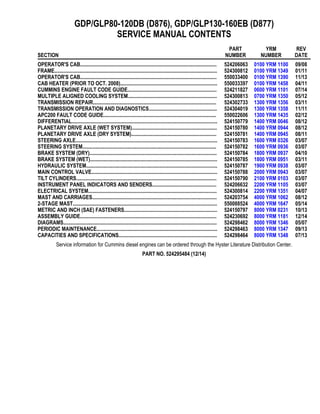

- 1. GDP/GLP80-120DB (D876), GDP/GLP130-160EB (D877) SERVICE MANUAL CONTENTS SECTION PART NUMBER YRM NUMBER REV DATE OPERATOR'S CAB........................................................................................................ 524206063 0100 YRM 1100 09/08 FRAME............................................................................................................................ 524300812 0100 YRM 1349 01/11 OPERATOR'S CAB........................................................................................................ 550033400 0100 YRM 1390 11/13 CAB HEATER (PRIOR TO OCT. 2008).......................................................................... 550033397 0100 YRM 1458 04/11 CUMMINS ENGINE FAULT CODE GUIDE.................................................................... 524211827 0600 YRM 1101 07/14 MULTIPLE ALIGNED COOLING SYSTEM.................................................................... 524300813 0700 YRM 1350 05/12 TRANSMISSION REPAIR.............................................................................................. 524302733 1300 YRM 1356 03/11 TRANSMISSION OPERATION AND DIAGNOSTICS.................................................... 524304019 1300 YRM 1358 11/11 APC200 FAULT CODE GUIDE...................................................................................... 550022606 1300 YRM 1435 02/12 DIFFERENTIAL............................................................................................................... 524150779 1400 YRM 0046 08/12 PLANETARY DRIVE AXLE (WET SYSTEM)................................................................. 524150780 1400 YRM 0944 08/12 PLANETARY DRIVE AXLE (DRY SYSTEM)................................................................. 524150781 1400 YRM 0945 08/11 STEERING AXLE............................................................................................................ 524150783 1600 YRM 0326 03/07 STEERING SYSTEM...................................................................................................... 524150782 1600 YRM 0936 03/07 BRAKE SYSTEM (DRY)................................................................................................. 524150784 1800 YRM 0937 04/10 BRAKE SYSTEM (WET)................................................................................................. 524150785 1800 YRM 0951 03/11 HYDRAULIC SYSTEM.................................................................................................... 524150787 1900 YRM 0938 03/07 MAIN CONTROL VALVE................................................................................................ 524150788 2000 YRM 0943 03/07 TILT CYLINDERS........................................................................................................... 524150790 2100 YRM 0103 03/07 INSTRUMENT PANEL INDICATORS AND SENDERS................................................. 524206632 2200 YRM 1105 03/07 ELECTRICAL SYSTEM.................................................................................................. 524300814 2200 YRM 1351 04/07 MAST AND CARRIAGES............................................................................................... 524203754 4000 YRM 1062 08/12 2-STAGE MAST.............................................................................................................. 550088524 4000 YRM 1647 05/14 METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13 ASSEMBLY GUIDE........................................................................................................ 524230692 8000 YRM 1181 12/14 DIAGRAMS..................................................................................................................... 524298462 8000 YRM 1346 05/07 PERIODIC MAINTENANCE............................................................................................ 524298463 8000 YRM 1347 09/13 CAPACITIES AND SPECIFICATIONS........................................................................... 524298464 8000 YRM 1348 07/13 Service information for Cummins diesel engines can be ordered through the Hyster Literature Distribution Center. PART NO. 524295484 (12/14)

- 2. 100 YRM 1100 General General A fully-enclosed operators cab is positioned on four large rubber anti-vibration mounts to isolate operator from shock, noise, and vibration. See Figure 1. Op- erator’s compartment includes electronic controls for hydraulic systems, steering wheel, instrument panel, transmission, brake system controls, and operators seat. An overhead guard forms an integral part of the operators cab. The cab is installed on a platform above main frame members. Step plates on both sides of lift truck give access to cab. The operators cab can be tilted, providing access to major components. For major repairs to cab, cab can be completely removed from frame of lift truck. 1. INCHING, BRAKE, AND THROTTLE PEDALS 2. SEAT 3. STEERING COLUMN 4. FRONT, REAR, AND TOP WIPER ASSEMBLIES 5. FRONT, REAR, AND TOP WINDOWS 6. OPERATOR’S CONSOLE, CONTROLS, AND ARMREST 7. HEATER SECTION Figure 1. Operators Cab 1

- 3. Cab Repair 100 YRM 1100 Cab Repair REAR CAB ASSEMBLY See Figure 2 for rear cab assembly. NOTE: Interior covers are affixed with self-tapping screws. 1. COVER PLATE 2. FUSE SECTION 3. RELAY SECTION 4. HYDRAULIC VALVE CONTROLLER 5. FOAM COVER 6. HEADLINER 7. REAR DUCT ASSEMBLY 8. CONSOLE COVER 9. CONSOLE TOP 10. INSTRUMENT PANEL Figure 2. Rear Cab Assembly 2

- 4. 100 YRM 1100 Cab Repair BOTTOM CAB ASSEMBLY See Figure 3 for bottom cab assembly. 1. WIPER MOTOR ASSEMBLY 2. WIPER COUPLING 3. AIR FILTER 4. COVER PLATE 5. STEERING PUMP 6. HORN Figure 3. Bottom Cab Assembly RAISING AND LOWERING CAB Raise Cab WARNING Make sure no one is under cab when raising or low- ering cab. WARNING Before you place any part of your body under cab, always make sure that cab is fully tilted, or when partially open, is locked by tilt latch. CAUTION Cab damage may occur if mast is not completely tilted forward. 1. Tilt mast fully forward. 2. Remove all unsecured items from cab. 3. Close and securely latch both cab doors. 4. Clear all obstacles from right-hand side (as seen from driver’s position) of truck. Provide minimum of 2 m (7 ft) of clearance space. 5. Use pump lever to turn direction valve clockwise to "Raise" position. See Figure 4. 1. PUMP LEVER CONNECTION 2. DIRECTION VALVE SELECTION: CLOCKWISE - RAISE, COUNTERCLOCKWISE - LOWER Figure 4. Pump and Direction Valve 6. Operate pump with pump lever until cab locks in partially open position. NOTE: Just before fully open position is reached, move- ment may be gravity controlled. 7. Pull tilt latch release and continue to raise cab to fully open position. See Figure 5. NOTE: If cab will not fully raise, lower cab until cab locks in partially open position, and fill tilt system with oil. See Oil Filling for Tilt System. NOTE: Raising cab gives access to components such as engine, transmission/hydraulic compartment, throt- tle/brake and steering control, heater, air conditioner, and electrical connectors. 3

- 5. Cab Repair 100 YRM 1100 1. CAB 2. FRAME 3. TILT LATCH RELEASE 4. PUMP LEVER Figure 5. Pump Lever and Tilt Latch Release Knob Lower Cab WARNING Make sure no one is under cab when raising or low- ering cab. WARNING Before you place any part of your body under cab, always make sure that cab is fully tilted, or when partially open, is locked by tilt latch. CAUTION Cab damage may occur if mast is not completely tilted forward. 1. Use pump lever to turn direction valve counterclock- wise to "Lower" position. See Figure 4. 2. Check that all foreign items/tools are cleared away. 3. Operate pump with pump lever until cab locks in partially open position. 4. Pull tilt latch release and continue to lower cab until it is in fully lowered position and latched. See Fig- ure 5. NOTE: An electric-powered cab tilt system is available to replace standard manual tilt system. The electric tilt system contains a push button located on left side of pump direction control. Procedure to raise or lower is the same. CAB REPAIR Remove WARNING Before removing heater hoses, allow time for heater hoses to cool down. Hot water may cause severe burns. WARNING Make sure the lifting device has a minimum capac- ity to lift 1000 kg (2205 lb). A lifting device that does not have the minimum capacity can break causing the cab to drop and may result in serious personal injury. CAUTION Lift the operator’s cab carefully. Make sure all wires and attachments are disconnected and loose com- ponents are not obstructing the movement. 1. Switch off engine. 2. Disconnect battery ground lead. 3. Raise operator’s cab. See Raise Cab. 4. Remove four hex bolts holding steering pump. See Figure 6. 5. Remove two bolts holding brake valve. 6. Disconnect electrical cable to throttle pedal sensor. See Figure 11. 7. Disconnect electrical cable. 8. Disconnect electrical plugs that are located to right of heater unit. 9. Disconnect window washer hoses and mark their positions. 10. Remove three bolts and swing heater unit down. 11. Disconnect electrical connections, control cables, and air duct from heater unit. 12. Disconnect ground lead. 4

- 6. 100 YRM 1100 Cab Repair 1. STEERING PUMP HEX BOLTS 2. BRAKE VALVE BOLTS 3. STEERING PUMP 4. BRAKE VALVE 5. ELECTRICAL CONNECTIONS Figure 6. Steering Pump, Throttle and Inching Connections CAUTION When lowering cab, make sure loose components are not obstructing the movement. 13. Lower operator’s cab. See Lower Cab. 14. Remove left and right side panels giving access to cab mounting bolts. 15. Remove four mounting bolts, two on left side and two on right side of truck. 16. Remove cab doors before attaching a lifting device. 17. Connect a lift strap under overhead guard structure. Provide a cushion at top of door area to prevent damage. 18. Carefully lift cab away from lift truck. Set cab as- sembly in a suitable storage area and put blocks under cab to stabilize and prevent damage. 19. Remove four rubber isolation mounts from frame and inspect for damage. Reinstall or replace if nec- essary. Install 1. Connect lift strap under overhead guard structure. Provide cushion at top of door area to prevent dam- age. 2. Make sure that insulators are in place. See Fig- ure 7. 1. TOP PART OF INSULATOR 2. BOTTOM PART OF INSULATOR 3. BOLT 4. WASHER 5. LOCKWASHER Figure 7. Insulators 3. Lift operator’s cab. 4. Carefully lower cab on insulators and make sure that it is properly centered. 5. Mount cab with washers and bolts. 6. Tighten cab mounting bolts to 66 N•m (49 lbf ft). 7. Raise cab. See Raise Cab. 8. Connect electrical cables, ground wire, hoses, steering pump, and brake valve. Make sure that all connections have been restored. 9. Mount heater unit to hinge. Connect control cables and electrical connections. Pivot unit up and install with three bolts. 10. Connect inching and throttle cables. See Inching and Brake Pedals. 5

- 7. Oil Filling for Tilt System 100 YRM 1100 11. Lower cab. See Lower Cab. 12. Install doors. 13. Connect battery ground lead. 14. Install side panels. Oil Filling for Tilt System CAUTION When oil has been added, put oil-absorbing mate- rial around filler plug before lowering cab. Excess oil may bleed out of relief valve, which is fitted in filler plug. NOTE: When cab does not reach the maximum opening the oil level is low. 1. Lower cab until it locks in partially open position. See Lower Cab. 2. Put pump lever connection in fully down position to gain access to the fill cap. See Figure 8. 3. Remove fill cap. See Figure 8. 4. Add hydraulic oil into filler opening until level is within 30 to 35 mm (1.18 to 1.38 in.) of top of reservoir. See Figure 9. 5. Install fill cap. See Figure 8. 6. Raise cab and make sure that maximum tilt can be reached. See Raise Cab. 7. Repeat procedure if necessary. 8. Lower cab until it is in fully lowered position and completely latched. 1. FILL CAP Figure 8. Hand Pump Figure 9. Cab Tilt Label 6

- 8. 100 YRM 1100 Inching and Brake Pedals Inching and Brake Pedals BRAKE PEDAL, ADJUST 1. Adjust bolt (3), behind the brake pedal, on the brake pedal assembly so that the roller has contact with the bolt on the valve until there is no free travel. See Figure 10. 1. BRAKE PEDAL 2. INCHING PEDAL 3. ADJUSTMENT BOLT FOR BRAKE PEDAL 4. ADJUSTMENT BOLT FOR INCHING/BRAKE PEDAL COUPLING 5. ADJUSTMENT BOLT FOR INCHING PEDAL Figure 10. Brake Pedal System 2. Proceed with inching pedal adjustment. INCHING PEDAL, ADJUST NOTE: Adjust the inching pedal so that the brake pedal moves at the same time, which means there is no free play with the brake pedal. NOTE: When brake pedal and inching pedal are in re- leased position their position must be equally high or in line. 1. When activating inching pedal, brake pedal should be activated as soon as top of inching pedal and top of brake pedal are on same plane. Use adjust- ment bolt (4) for inching/brake pedal coupling ad- justment. See Figure 10. 2. Adjust bolt (5) for inching pedal to eliminate free travel of inching pedal before braking action occurs. 3. Proceed with inching pedal sensor adjustment. INCHING PEDAL SENSOR, ADJUST NOTE: When the brake pedals are not activated, the analog output of the inch sensor should be between 600 and 700 mV. This means the sensor is slightly turned as the lowest possible reading is 400 mV. 1. Loosen the two, one shown, sensor mounting bolts. See Figure 11. NOTE: To read the voltage, use the "Inching Pedal Cal- ibration" mode of the Userlink® program as explained in the section Transmission 1300 YRM 1082. 2. Rotate sensor in the slotted holes underneath the inching pedal so that the output voltage of the sen- sor of the released inching pedal is between 600 and 700 mV. 3. Tighten the mounting screws and recheck the volt- age output at the sensor. 4. Calibrate the inching pedal. See the section Trans- mission 1300 YRM 1082. 1. MOUNTING BOLT Figure 11. Sensor Adjustment 7

- 9. Throttle Pedal Sensor 100 YRM 1100 Throttle Pedal Sensor CHECK NOTE: When a new throttle pedal sensor is installed, rotate the throttle pedal sensor counterclockwise, when looking inside the throttle box, until the end of the slotted holes. See Figure 12. 1. Switch engine ON. 2. Operate throttle pedal. See Figure 12. 3. Check position, dimension A, of the throttle pedal at which the engine rpm goes from idle to higher rpm value. 4. If dimension A is not within 6 to 10 mm (0.236 to 0.394 in.), adjust the mechanical position of the electronic throttle potentiometer. See Adjust. ADJUST 1. Raise cab. See Raise Cab. 2. Make sure the throttle pedal stop is adjusted so that it is against the cabin floor plate. 3. Position a 5 mm (0.197 in.) spacer between the throttle pedal and throttle pedal stop. 4. Loosen mounting screws and turn the throttle pedal sensor to position at which engine rpm increases from idle or decreases rpm to idle. 5. Tighten mounting screws. 6. Remove the 5 mm (0.197 in.) spacer between the throttle pedal and throttle pedal stop. 7. Lower cab. See Lower Cab. 1. DIMENSION A 2. THROTTLE PEDAL 3. THROTTLE PEDAL ADJUSTMENT 4. THROTTLE PEDAL SENSOR 5. MOUNTING SCREW 6. COUPLING 7. CABIN FLOOR PLATE 8. THROTTLE PEDAL STOP 9. COUNTERCLOCKWISE 10. SLOTTED HOLE Figure 12. Throttle Arrangement 8

- 10. 100 YRM 1100 Power Assist Armrest Seat Assembly Removal NOTE: Use a lifting device for removal of seat. NOTE: For mechanical seat, there will be one connec- tor. For air suspension seat, there will be two connec- tors. 1. Disconnect battery ground lead. 2. Disconnect connector(s). See Figure 13. 3. Disconnect plug to side console. 4. Loosen four bolts connecting seat to cab. 5. Remove seat. Legend for Figure 13 1. ELECTRICAL CONNECTORS AND PLUG TO SIDE CONSOLE (REAR OF SEAT) 2. BOLTS Figure 13. Operators Seat Power Assist Armrest ADJUST 1. Disconnect cable from lever. See Figure 14. 2. Remove the mounting bolts that hold the gas spring assembly. 3. Loosen nut. 4. Adjust top section, clockwise or counterclockwise, to obtain a free lever movement of 1.5 to 2.0 mm (0.06 to 0.079 in.). NOTE: Apply small bead of non permanent Loctite® to bolt treads. 5. Install gas spring assembly using the two bolts. 6. Install and adjust cable on lever to obtain correct operation. Legend for Figure 14 1. LEVER 2. TOP SECTION 3. NUT 4. BOLT 5. LEVER 6. CABLE Figure 14. Power Assist Armrest 9

- 11. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 12. Steering Column Repair 100 YRM 1100 Steering Column Repair REMOVE 1. Raise cab. See Raise Cab. 2. Disconnect battery ground lead. 3. Disconnect steering column connector. See Fig- ure 15 and Figure 16. 4. Remove four hex bolts fastening steering pump to cab and carefully remove steering pump. 5. Remove two cab mounting bolts holding steering column to the floor. 6. Lower cab. See Lower Cab. 7. Remove two hex bolts holding steering column to bracket. 8. Remove steering column. Push grommet out of hole and slide connector through hole. INSTALL 1. Slide connector through hole in floor and push grommet into hole. 2. Connect steering column to bracket with two cab mounting bolts. 3. Raise cab. See Raise Cab. 4. Mount steering column to cab base with two steer- ing column hex bolts. 5. Carefully mount steering pump with four steering pump hex bolts to allow non-forced coupling be- tween steering pump and steering column. 6. Connect electrical connector. 7. Connect battery ground lead. 8. Lower cab. See Lower Cab. 1. STEERING COLUMN TO BRACKET BOLTS 2. STEERING COLUMN TO FLOOR PLATE BOLTS Figure 15. Steering Column 1. STEERING COLUMN CONNECTOR 2. STEERING COLUMN BOLTS 3. STEERING PUMP BOLTS Figure 16. Steering Pump 10

- 13. 100 YRM 1100 Window Wipers Replacement Window Wipers Replacement NOTE: Three window wiper motor assemblies are in- stalled in the cab. The front window has a single-arm, parallelogram-type, wiper motor system to give a large wiped surface area. The wiper motor is mounted under the cab so as not to obstruct visibility. The top window is provided with a wiper motor assembly that has one wiper arm with wiper blade. The rear window is pro- vided with a wiper motor assembly that has one wiper arm with wiper blade. A washer system is connected to all wipers. WINDOW WIPER ASSEMBLY, REPLACE 1. Lift cover. See Figure 17. 2. Loosen and remove nut and washer. 3. Mark position of blade on window. 4. Disconnect wiper. 5. Disconnect washer hose if applicable. 6. Install new wiper assembly. Make sure that wiper assembly is properly positioned to give optimal cov- erage of window. Proceed in reverse order. 1. COVER 2. COVER OPEN 3. NUT WITH WASHER Figure 17. Wiper Assembly FRONT WINDOW WIPER MOTOR ASSEMBLY, REPLACE 1. Disconnect battery ground lead. 2. Disconnect connector. See Figure 18. 3. Remove clamp tightening bolt and arm. 4. Remove three bolts. 5. Remove motor assembly. 6. Install new motor assembly. Proceed in reverse or- der. 1. CLAMP TIGHTENING BOLT AND ARM 2. BOLTS 3. MOTOR ASSEMBLY 4. CONNECTOR Figure 18. Front Window Wiper Motor Assembly 11

- 14. Window Wipers Replacement 100 YRM 1100 REAR WINDOW WIPER MOTOR ASSEMBLY, REPLACE 1. Disconnect battery ground lead. 2. Remove wiper assembly. See Window Wiper As- sembly, Replace. 3. Remove cover of motor assembly unit. 4. Disconnect connector. See Figure 19. 5. Remove nuts and washers. 6. Remove motor assembly. 7. Install new motor assembly. Proceed in reverse or- der. 1. CONNECTOR 2. NUTS AND WASHERS Figure 19. Rear Wiper Motor Assembly TOP WINDOW WIPER MOTOR ASSEMBLY, REPLACE 1. Disconnect battery ground lead. 2. Remove 10 screws fastening headliner to cab. See Figure 20. 3. Remove headliner. 4. Follow procedure as listed under Rear Window Wiper Motor Assembly, Replace. 5. Replace cab headliner. 6. Connect battery ground lead. 1. SCREWS Figure 20. Cab Headliner 12