2001 dodge neon service repair manual

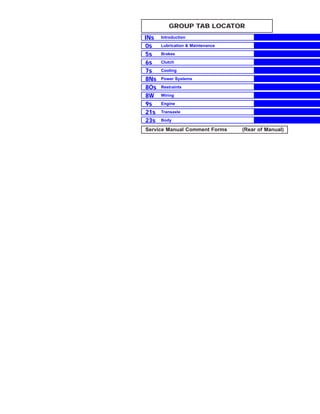

- 1. GROUP TAB LOCATOR INs Introduction 0s Lubrication & Maintenance 5s Brakes 6s Clutch 7s Cooling 8Ns Power Systems 8Os Restraints 8W Wiring 9s Engine 21s Transaxle 23s Body Service Manual Comment Forms (Rear of Manual)

- 2. INTRODUCTION TABLE OF CONTENTS page page E-MARK LABEL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 VEHICLE IDENTIFICATION NUMBER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 TORQUE REFERENCES DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 E-MARK LABEL DESCRIPTION - E-MARK LABEL An E-mark Label (Fig. 1) is located on the rear shut face of the driver’s door. The label contains the following information: • Date of Manufacture • Month-Day-Hour (MDH) • Vehicle Identification Number (VIN) • Country Codes • Regulation Number • Regulation Amendment Number • Approval Number VEHICLE IDENTIFICATION NUMBER DESCRIPTION The Vehicle Identification Number (VIN) can be viewed through the windshield at the upper left cor- ner of the instrument panel next to the left A-pillar on left-hand-drive and right-hand-drive vehicles (Fig. 2) (Fig. 3). The VIN consists of 17 characters in a combination of letters and numbers that provide spe- cific information about the vehicle. Refer to the VIN Decoding Information Table to interpret VIN code. Fig. 1 E-Mark Label 1 - Country Code 2 - Regulation Number 3 - Approval Number 4 - Amendment Number Fig. 2 VIN Plate Location – R.H.D. PL INTRODUCTION 1s 2001 NEON

- 3. VIN CHECK DIGIT To protect the consumer from theft and possible fraud the manufacturer is required to include a check digit at the ninth position of the VIN. The check digit is used by the manufacturer and government agen- cies to verify the authenticity of the vehicle and offi- cial documentation. The formula to use the check digit is not released to the general public. VIN DECODING INFORMATION POSITION INTERPRETATION CODE = DESCRIPTION 1 Country of origin 1 = Built in the U.S. by DaimlserChrysler Corporation 2 Make C = Chrysler 3 Vehicle Type 3 = Passenger Car 4 Passenger Safety E = Active Restraints, Driver and Passenger Airbags 5 Car Line S = Neon BUX L.H.D. V = Neon BUX R.H.D. 6 Series M = DD5 5-Speed Manual Transmission A = 3-Speed Automatic Transmission 7 Body Style 7 = 4 Door Pillared Hardtop 8 Engine C = 2.0L 4 Cyl. 16V SOHC A = 1.8L 4 Cyl. 16V SOHC D = 1.9L 4 Cyl. Turbo Diesel 9 Check Digit See explanation in this section. 10 Model Year 1 = 2001 11 Assembly Plant D = Belvedere Assembly 12 Thru 17 Build Sequence 6 Digit number assigned by assembly plant Fig. 3 V.I.N. Plate Location – L.H.D. 2s INTRODUCTION PL VEHICLE IDENTIFICATION NUMBER (Continued) 2001 NEON

- 4. TORQUE REFERENCES DESCRIPTION Individual Torque Charts appear within many or the Groups. Refer to the Standard Torque Specifica- tions Chart for torque references not listed in the individual torque charts. TORQUE SPECIFICATIONS PL INTRODUCTION 3s 2001 NEON

- 5. LUBRICATION & MAINTENANCE TABLE OF CONTENTS page page LUBRICATION & MAINTENANCE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 FLUID TYPES DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 FLUID CAPACITIES SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 4 MAINTENANCE SCHEDULES DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 LUBRICATION & MAINTENANCE DESCRIPTION This Service Manual Supplement includes ONLY the information that is new or updated for 2001 Model Year. All other Service Manual information is in the 2000 Model Year Service Manual. When you are using this information you may be referred to another section of the Service Manual. The “Refer to” is written differently than in prior years. FLUID TYPES DESCRIPTION - ENGINE COOLANT WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL BASE COOLANT AND IS HARMFUL IF SWAL- LOWED OR INHALED. IF SWALLOWED, DRINK TWO GLASSES OF WATER AND INDUCE VOMIT- ING. IF INHALED, MOVE TO FRESH AIR AREA. SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT STORE IN OPEN OR UNMARKED CONTAINERS. WASH SKIN AND CLOTHING THOROUGHLY AFTER COMING IN CONTACT WITH ETHYLENE GLYCOL. KEEP OUT OF REACH OF CHILDREN. DISPOSE OF GLYCOL BASE COOLANT PROPERLY, CONTACT YOUR DEALER OR GOVERNMENT AGENCY FOR LOCATION OF COLLECTION CENTER IN YOUR AREA. DO NOT OPEN A COOLING SYSTEM WHEN THE ENGINE IS AT OPERATING TEMPERATURE OR HOT UNDER PRESSURE, PERSONAL INJURY CAN RESULT. AVOID RADIATOR COOLING FAN WHEN ENGINE COMPARTMENT RELATED SERVICE IS PERFORMED, PERSONAL INJURY CAN RESULT. CAUTION: Use of Propylene Glycol based coolants is not recommended, as they provide less freeze protection and less corrosion protection. The cooling system is designed around the coolant. The coolant must accept heat from engine metal, in the cylinder head area near the exhaust valves and engine block. Then coolant carries the heat to the radiator where the tube/fin radiator can transfer the heat to the air. The use of aluminum cylinder blocks, cylinder heads, and water pumps requires special corrosion protection. Mopart Antifreeze/Coolant, 5 Year/100,000 Mile Formula (MS-9769), or the equiva- lent ethylene glycol base coolant with organic corro- sion inhibitors (called HOAT, for Hybrid Organic Additive Technology) is recommended. This coolant offers the best engine cooling without corrosion when mixed with 50% Ethylene Glycol and 50% distilled water to obtain a freeze point of -37°C (-35°F). If it loses color or becomes contaminated, drain, flush, and replace with fresh properly mixed coolant solu- tion. CAUTION: MoparT Antifreeze/Coolant, 5 Year/100,000 Mile Formula (MS-9769) may not be mixed with any other type of antifreeze. Doing so will reduce the corrosion protection and may result in premature water pump seal failure. If non-HOAT coolant is introduced into the cooling system in an emergency, it should be replaced with the specified coolant as soon as possible. DESCRIPTION - AUTOMATIC TRANSMISSION FLUID NOTE: Refer to the maintenance schedules for the recommended maintenance (fluid/filter change) intervals for this transaxle. PL LUBRICATION & MAINTENANCE 0s - 1 2001 NEON

- 6. NOTE: For fluid level checking procedures, (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 31TH/FLUID - STANDARD PROCEDURE). NOTE: The 31TH transaxle has a common transmis- sion and differential sump. Filling the transaxle accommodates the differential as well. TRANSMISSION FLUID Mopart ATF+4 (Automatic Transmission Fluid- Type 9602) is required in this transaxle. Substitute fluids can induce torque converter clutch shudder. Mopart ATF+4 (Automatic Transmission Fluid- Type 9602) when new is red in color. The ATF is dyed red so it can be identified from other fluids used in the vehicle such as engine oil or antifreeze. The red color is not permanent and is not an indicator of fluid condition. As the vehicle is driven, the ATF will begin to look darker in color and may eventually become brown. This is normal. A dark brown/black fluid accompanied with a burnt odor and/or deterioration in shift quality may indicate fluid deterioration or transmission component failure. FLUID ADDITIVES DaimlerChrysler strongly recommends against the addition of any fluids to the transmission, other than those automatic transmission fluids listed above. Exceptions to this policy are the use of special dyes to aid in detecting fluid leaks. Various “special” additives and supplements exist that claim to improve shift feel and/or quality. These additives and others also claim to improve converter clutch operation and inhibit overheating, oxidation, varnish, and sludge. These claims have not been sup- ported to the satisfaction of DaimlerChrysler and these additives must not be used. The use of trans- mission “sealers” should also be avoided, since they may adversely affect the integrity of transmission seals. DESCRIPTION - GEAR LUBRICATION RATINGS SAE ratings also apply to multiple grade gear lubricants. In addition, API classification defines the lubricants usage. DESCRIPTION - FUEL REQUIREMENTS Your engine is designed to meet all emissions reg- ulations and provide excellent fuel economy and per- formance when using high quality unleaded gasoline having an octane rating of 87. The use of premium gasoline is not recommended. The use of premium gasoline will provide no benefit over high quality reg- ular gasoline, and in some circumstances may result in poorer performance. Light spark knock at low engine speeds is not harmful to your engine. However, continued heavy spark knock at high speeds can cause damage and immediate service is required. Engine damage result- ing from operation with a heavy spark knock may not be covered by the new vehicle warranty. Poor quality gasoline can cause problems such as hard starting, stalling and hesitations. If you experi- ence these symptoms, try another brand of gasoline before considering service for the vehicle. Over 40 auto manufacturers world-wide have issued and endorsed consistent gasoline specifications (the Worldwide Fuel Charter, WWFC) to define fuel properties necessary to deliver enhanced emissions, performance and durability for your vehicle. We rec- ommend the use of gasolines that meet the WWFC specifications if they are available. REFORMULATED GASOLINE Many areas of the country require the use of cleaner burning gasoline referred to as “reformulat- ed” gasoline. Reformulated gasoline contain oxygen- ates, and are specifically blended to reduce vehicle emissions and improve air quality. We strongly support the use of reformulated gaso- line. Properly blended reformulated gasoline will pro- vide excellent performance and durability for the engine and fuel system components. GASOLINE/OXYGENATE BLENDS Some fuel suppliers blend unleaded gasoline with oxygenates such as 10% ethanol, MTBE, and ETBE. Oxygenates are required in some areas of the country during the winter months to reduce carbon monoxide emissions. Fuels blended with these oxygenates may be used in your vehicle. CAUTION: DO NOT use gasoline containing METH- ANOL. Gasoline containing methanol may damage critical fuel system components. MMT IN GASOLINE MMT is a manganese-containing metallic additive that is blended into some gasoline to increase octane. Gasoline blended with MMT provide no performance advantage beyond gasoline of the same octane num- ber without MMT. Gasoline blended with MMT reduce spark plug life and reduce emission system performance in some vehicles. We recommend that gasolines free of MMT be used in your vehicle. The MMT content of gasoline may not be indicated on the gasoline pump; therefore, you should ask your gaso- line retailer whether or not his/her gasoline contains MMT. It is even more important to look for gasoline with- out MMT in Canada because MMT can be used at 0s - 2 LUBRICATION & MAINTENANCE PL FLUID TYPES (Continued) 2001 NEON

- 7. levels higher than allowed in the United States. MMT is prohibited in Federal and California refor- mulated gasoline. SULFUR IN GASOLINE If you live in the northeast United States, your vehicle may have been designed to meet California low emission standards with Cleaner-Burning Cali- fornia reformulated gasoline with low sulfur. If such fuels are not available in states adopting California emission standards, your vehicles will operate satis- factorily on fuels meeting federal specifications, but emission control system performance may be adversely affected. Gasoline sold outside of California is permitted to have higher sulfur levels which may affect the performance of the vehicle’s catalytic con- verter. This may cause the Malfunction Indicator Lamp (MIL), Check Engine or Service Engine Soon light to illuminate. We recommend that you try a dif- ferent brand of unleaded gasoline having lower sulfur to determine if the problem is fuel related prior to returning your vehicle to an authorized dealer for service. CAUTION: If the Malfunction Indicator Lamp (MIL), Check Engine or Service Engine Soon light is flash- ing, immediate service is required; see on-board diagnostics system section. MATERIALS ADDED TO FUEL All gasoline sold in the United States and Canada are required to contain effective detergent additives. Use of additional detergents or other additives is not needed under normal conditions. FUEL SYSTEM CAUTIONS CAUTION: Follow these guidelines to maintain your vehicle’s performance: • The use of leaded gas is prohibited by Federal law. Using leaded gasoline can impair engine perfor- mance, damage the emission control system, and could result in loss of warranty coverage. • An out-of-tune engine, or certain fuel or ignition malfunctions, can cause the catalytic converter to overheat. If you notice a pungent burning odor or some light smoke, your engine may be out of tune or malfunctioning and may require immediate service. Contact your dealer for service assistance. • When pulling a heavy load or driving a fully loaded vehicle when the humidity is low and the tem- perature is high, use a premium unleaded fuel to help prevent spark knock. If spark knock persists, lighten the load, or engine piston damage may result. • The use of fuel additives which are now being sold as octane enhancers is not recommended. Most of these products contain high concentrations of methanol. Fuel system damage or vehicle perfor- mance problems resulting from the use of such fuels or additives is not the responsibility of DaimlerChrysler Corporation and may not be covered under the new vehicle warranty. NOTE: Intentional tampering with emissions control systems can result in civil penalties being assessed against you. DESCRIPTION - ENGINE OIL WARNING: NEW OR USED ENGINE OIL CAN BE IRRITATING TO THE SKIN. AVOID PROLONGED OR REPEATED SKIN CONTACT WITH ENGINE OIL. CONTAMINANTS IN USED ENGINE OIL, CAUSED BY INTERNAL COMBUSTION, CAN BE HAZARDOUS TO YOUR HEALTH. THOROUGHLY WASH EXPOSED SKIN WITH SOAP AND WATER. DO NOT WASH SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO NOT POLLUTE, DISPOSE OF USED ENGINE OIL PROPERLY. CONTACT YOUR DEALER OR GOVERN- MENT AGENCY FOR LOCATION OF COLLECTION CENTER IN YOUR AREA. API SERVICE GRADE CERTIFIED Use an engine oil that is API Service Grade Certi- fied. MOPARt provides engine oils, meeting Material Standard MS-6395, that conform to this service grade. PL LUBRICATION & MAINTENANCE 0s - 3 FLUID TYPES (Continued) 2001 NEON

- 8. SAE VISCOSITY An SAE viscosity grade is used to specify the vis- cosity of engine oil. Use only engine oils with multi- ple viscosities such as 5W-30 or 10W-30. These are specified with a dual SAE viscosity grade which indi- cates the cold-to-hot temperature viscosity range. Select an engine oil that is best suited to your par- ticular temperature range and variation (Fig. 1). ENERGY CONSERVING OIL An Energy Conserving type oil is recommended for gasoline engines. The designation of ENERGY CON- SERVING is located on the label of an engine oil con- tainer. CONTAINER IDENTIFICATION Standard engine oil identification notations have been adopted to aid in the proper selection of engine oil. The identifying notations are located on the label of engine oil plastic bottles and the top of engine oil cans (Fig. 2). This symbol on the front of an oil container means that the oil has been certified by the American Petro- leum Institute (API) to meet all the lubrication requirements specified by DaimlerChrysler. OPERATION - ENGINE COOLANT The cooling system is designed around the coolant. The coolant must accept heat from engine metal, in the cylinder head area near the exhaust valves and engine block. Then coolant carries the heat to the radiator where the tube/fin radiator can transfer the heat to the air. WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL BASE COOLANT AND IS HARMFUL IF SWAL- LOWED OR INHALED. IF SWALLOWED, DRINK TWO GLASSES OF WATER AND INDUCE VOMIT- ING. IF INHALED, MOVE TO FRESH AIR AREA. SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT STORE IN OPEN OR UNMARKED CONTAINERS. WASH SKIN AND CLOTHING THOROUGHLY AFTER COMING IN CONTACT WITH ETHYLENE GLYCOL. KEEP OUT OF REACH OF CHILDREN. DISPOSE OF GLYCOL BASE COOLANT PROPERLY, CONTACT YOUR DEALER OR GOVERNMENT AGENCY FOR LOCATION OF COLLECTION CENTER IN YOUR AREA. DO NOT OPEN A COOLING SYSTEM WHEN THE ENGINE IS AT OPERATING TEMPERATURE OR HOT UNDER PRESSURE, PERSONAL INJURY CAN RESULT. AVOID RADIATOR COOLING FAN WHEN ENGINE COMPARTMENT RELATED SERVICE IS PERFORMED, PERSONAL INJURY CAN RESULT. FLUID CAPACITIES SPECIFICATIONS SPECIFICATIONS - FLUID CAPACITIES DESCRIPTION SPECIFICATION Fuel Tank 47.5 L (12.5 gal.) Engine Oil* 4.3 L (4.5 qts.) Cooling System** 6.2 L (6.5 qts.) Automatic Transaxle - Estimated Service Fill 3.8 L (4.0 qts.) Automatic Transaxle - Overhaul Fill Capacity with Torque Converter Empty 8.1 L (8.6 qts.) Manual Transaxle - NV T350 2.4–2.7 L (2.5-2.8 qts.) *(includes filter) **(includes heater and recovery/reserve bottle) Fig. 1 TEMPERATURE/ENGINE OIL VISCOSITY Fig. 2 Engine Oil Container Standard Notations 0s - 4 LUBRICATION & MAINTENANCE PL FLUID TYPES (Continued) 2001 NEON

- 9. MAINTENANCE SCHEDULES DESCRIPTION There are two maintenance schedules that show proper service for your vehicle. First is Schedule – A. It lists all the scheduled maintenance to be performed under “normal” operat- ing conditions. Second is Schedule – B. It is a schedule for vehi- cles that are operated under the following conditions: • Frequent short trip driving less than 5 miles (8 km) • Frequent driving in dusty conditions • Extensive idling • More than 50% of the driving is at sustained high speeds during hot weather, above 90° F (32° C) UNSCHEDULED INSPECTION At Each Stop For Fuel • Check engine oil level and add as required. • Check windshield washer solvent and add as required. Once A Month • Check tire pressure and look for unusual wear or damage. • Inspect the battery and clean and tighten termi- nals as required. • Check fluid levels of coolant reservoir, brake master cylinder, power steering and transmission. Add fluid as required. • Check all lights and all other electrical items for correct operation. At Each Oil Change • Inspect the exhaust system. • Inspect brake hoses. • Inspect the CV joints and front suspension com- ponent boots and seals. • Rotate the tires at each oil change interval shown on Schedule – A (7,500 miles - 12 000 km) or every other interval on Schedule – B (6,000 miles - 10 000 km). • Check the engine coolant level, hoses, and clamps. If mileage is less than 7,500 miles (12 000 km) yearly, replace the engine oil filter at each oil change. EMISSION CONTROL SYSTEM MAINTENANCE The scheduled emission maintenance listed in bold type on the Maintenance Schedules, must be done at the mileage specified to assure the continued proper functioning of the emission control system. These, and all other maintenance services included in this manual, should be done to provide the best vehicle performance and reliability. More frequent mainte- nance may be needed for vehicles in severe operating conditions such as dusty areas and very short trip driving. FLUID FILL POINTS AND LUBRICATION LOCATIONS The fluid fill/check locations and lubrication loca- tions are located in each applicable group. SCHEDULE – A 7,500 Miles (12 000 km) or at 6 months • Change the engine oil. • Replace the engine oil filter. 15,000 Miles (24 000 km) or at 12 months • Change the engine oil. • Replace the engine oil filter. 22,500 Miles (36 000 km) or at 18 months • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 30,000 Miles (48 000 km) or at 24 months • Change the engine oil. • Replace the engine oil filter. • Inspect the tie rod ends and boot seals. • Adjust the generator belt tension. • Replace the engine air cleaner element (fil- ter). • Replace the engine spark plugs 37,500 Miles (60 000 km) or at 30 months • Change the engine oil. • Replace the engine oil filter. 45,000 Miles (72 000 km) or at 36 months • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 52,500 Miles (84 000 km) or at 42 months • Change the engine oil. • Replace the engine oil filter. 60,000 Miles (96 000 km) or at 48 months • Change the engine oil. • Replace the engine oil filter. • Inspect the tie rod ends and boots seals. • Check the PCV valve and replace, if neces- sary. Not required if previously changed.* • Replace the drive belts. PL LUBRICATION & MAINTENANCE 0s - 5 2001 NEON

- 10. • Replace the engine air cleaner element (fil- ter). • Replace the ignition cables. • Replace the spark plugs. 67,500 Miles (108 000 km) or at 54 months • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 75,000 Miles (120 000 km) or at 60 months • Change the engine oil. • Replace the engine oil filter. • Flush and replace engine coolant if 60 months have been reashed before 100,000 miles (160 000 km). 82,500 Miles (132 000 km) or at 66 months • Change the engine oil. • Replace the engine oil filter. 90,000 Miles (144 000 km) or at 72 months • Change the engine oil. • Replace the engine oil filter. • Inspect the tie rod ends and boots seals. • Check the PCV valve and replace, if neces- sary. Not required if previously changed.* • Inspect the front brake pads and rear brake lin- ings. • Adjust the generator belt tension. • Replace the engine air cleaner element (fil- ter). • Replace the spark plugs. 97,500 Miles (156 000 km) or at 78 months • Change the engine oil. • Replace the engine oil filter. 100,000 Miles (160 000 km) • Flush and replace the engine coolant if it was not done at 60 months. 105,000 Miles (168 000 km) or at 84 months • Change the engine oil. • Replace the engine oil filter. • Replace the engine timing belt. *This maintenance is recommended by DaimlerChrysler Corporation to the owner but is not required to maintain the emissions warranty. NOTE: Inspection and service should also be per- formed anytime a malfunction is observed or sus- pected. Retain all receipts. SCHEDULE – B 3,000 Miles (5 000 km) • Change the engine oil. • Replace the engine oil filter. 6,000 Miles (10 000 km) • Change the engine oil. • Replace the engine oil filter. 9,000 Miles (14 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 12,000 Miles (19 000 km) • Change the engine oil. • Replace the engine oil filter. 15,000 Miles (24 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the engine air cleaner element (fil- ter). Replace as necessary.* 18,000 Miles (29 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 21,000 Miles (34 000 km) • Change the engine oil. • Replace the engine oil filter. 24,000 Miles (38 000 km) • Change the engine oil. • Replace the engine oil filter. 27,000 Miles (43 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 30,000 Miles (48 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the tie rod ends and boots seals. • Inspect the PCV valveand replace as neces- sary.* • Adjust the generator belt tension. • Replace the engine air cleaner element (fil- ter). • Replace the spark plugs 0s - 6 LUBRICATION & MAINTENANCE PL MAINTENANCE SCHEDULES (Continued) 2001 NEON

- 11. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 12. 33,000 Miles (53 000 km) • Change the engine oil. • Replace the engine oil filter. 36,000 Miles (58 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 39,000 Miles (62 000 km) • Change the engine oil. • Replace the engine oil filter. 42,000 Miles (67 000 km) • Change the engine oil. • Replace the engine oil filter. 45,000 Miles (72 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. • Inspect the engine air cleaner element (fil- ter). Replace as necessary.* 48,000 Miles (77 000 km) • Change the engine oil. • Replace the engine oil filter. • Change the automatic transaxle fluid and filter and adjust the bands. 51,000 Miles (82 000 km) • Change the engine oil. • Replace the engine oil filter. 54,000 Miles (86 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 57,000 Miles (91 000 km) • Change the engine oil. • Replace the engine oil filter. 60,000 Miles (96 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the tie rod ends and boot seals. • Inspect the PCV valveand replace if necessary.* • Replace the drive belts. • Replace the engine air cleaner element (fil- ter). • Replace the ignition cables • Replace the spark plugs • Change the automatic transaxle fluid/filter and adjust bands. 63,000 Miles (101 000 km) • Change the engine oil. • Replace the engine oil filter. 66,000 Miles (106 000 km) • Change the engine oil. • Replace the engine oil filter. 69,000 Miles (110 000 km) • Change the engine oil. • Replace the engine oil filter. 72,000 Miles (115 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 75,000 Miles (120 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the engine air cleaner element (fil- ter) and replace as necessary.* 78,000 Miles (125 000 km) • Change the engine oil. • Replace the engine oil filter. 81,000 Miles (130 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 84,000 Miles (134 000 km) • Change the engine oil. • Replace the engine oil filter. 87,000 Miles (139 000 km) • Change the engine oil. • Replace the engine oil filter. 90,000 Miles (144 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect front brake pads and rear brake linings • Inspect the tie rod ends and boots seals. • Check the PCV valve and replace if necessary. Not required if previously changed.* • Adjust the generator belt tension. • Replace the engine air cleaner element (fil- ter). • Replace the spark plugs PL LUBRICATION & MAINTENANCE 0s - 7 MAINTENANCE SCHEDULES (Continued) 2001 NEON

- 13. 93,000 Miles (149 000 km) • Change the engine oil. • Replace the engine oil filter. 96,000 Miles (154 000 km) • Change the engine oil. • Replace the engine oil filter. • Change the automatic transaxle fluid and filter and adjust the bands. 99,000 Miles (158 000 km) • Change the engine oil. • Replace the engine oil filter. • Inspect the front brake pads and rear brake lin- ings. 102,000 Miles (163 000 km) • Change the engine oil. • Replace the engine oil filter. 105,000 Miles (168 000 km) • Replace the engine timing belt. • Change the engine oil. • Replace the engine oil filter. • Inspect the engine air cleaner element (fil- ter) and replace as necessary.* * This maintenance is recommended by DaimlerChrysler Corporation to the owner but is not required to maintain the emissions warranty. NOTE: Operating the vehicle more than 50% in heavy traffic during hot weather, above 90° F (32° C), using vehicle for police, taxi, limousine type operation or trailer towing require the more fre- quent transaxle service noted in Schedule – B. Per- form these services if vehicle usually operate under these conditions. NOTE: Inspection and service should also be per- formed anytime a malfunction is observed or sus- pected. Retain all receipts. 0s - 8 LUBRICATION & MAINTENANCE PL MAINTENANCE SCHEDULES (Continued) 2001 NEON

- 14. BRAKES TABLE OF CONTENTS page page BRAKES-BASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 BRAKES-ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 BRAKES-BASE TABLE OF CONTENTS page page BRAKES-BASE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . . . 2 BASE BRAKE SYSTEM DIAGNOSIS CHARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 STANDARD PROCEDURE . . . . . . . . . . . . . . . . . . . 5 BASE BRAKE BLEEDING. . . . . . . . . . . . . . . . . . 5 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 6 BRAKE FLUID LEVEL SWITCH DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 HYDRAULIC/MECHANICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 BRAKE PADS/SHOES-FRONT CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 BRAKE PADS/SHOES-REAR DISC CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 DISC BRAKE CALIPERS-FRONT CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 DISC BRAKE CALIPERS-REAR CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 FLUID RESERVOIR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 10 MASTER CYLINDER-LHD REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 11 MASTER CYLINDER-RHD REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 12 PEDAL REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 14 POWER BRAKE BOOSTER-RHD REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 16 PROPORTIONING VALVE DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . . 16 PROPORTIONING VALVE. . . . . . . . . . . . . . . . . 16 REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 18 SHOES-PARKING BRAKE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 20 CABLES-PARKING BRAKE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 24 LEVER-PARKING BRAKE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 26 BRAKES-BASE DESCRIPTION This Service Manual Supplement includes ONLY the information that is new or updated for 2001 Model Year. All other Service Manual information is in the 2000 Model Year Service Manual. When you are using this information you may be referred to another section of the Service Manual. The refer to is written differently than in prior years. PL BRAKES 5s - 1 2001 NEON

- 15. DIAGNOSIS AND TESTING - BASE BRAKE SYSTEM DIAGNOSIS CHARTS NOTE: There are three diagnosis charts following that cover the RED BRAKE WARNING INDICATOR LAMP, BRAKE NOISE and OTHER BRAKE CONDI- TIONS. RED BRAKE WARNING INDICATOR LAMP CONDITION POSSIBLE CAUSES CORRECTION RED BRAKE WARNING INDICATOR LAMP ON 1. Parking brake lever not fully released. 1. Release parking brake lever. 2. Parking brake warning lamp switch on parking brake lever. 2. Inspect and replace switch as necessary. 3. Brake fluid level low in reservoir. 3. Fill reservoir. Check entire system for leaks. Repair or replace as required. 4. Brake fluid level switch. 4. Disconnect switch wiring connector. If lamp goes out, replace switch. 5. Mechanical instrument cluster (MIC) problem. 5. Refer to Chassis Diagnostic Procedures manual. 6. ABS EBD malfunction. 6. Refer to ABS section and Chassis Diagnostic Procedures manual. BRAKE NOISE CONDITION POSSIBLE CAUSES CORRECTION DISC BRAKE CHIRP 1. Excessive brake rotor runout. 1. Follow brake rotor diagnosis and testing. Correct as necessary. 2. Lack of lubricant on brake caliper slides. 2. Lubricate brake caliper slides. DISC BRAKE RATTLE OR CLUNK 1. Broken or missing anti-rattle spring clips on shoes. 1. Replace brake shoes. 2. Caliper guide pins loose. 2. Tighten guide pins. DISC BRAKE SQUEAK AT LOW SPEED (WHILE APPLYING LIGHT BRAKE PEDAL EFFORT) 1. Brake shoe linings. 1. Replace brake shoes. DRUM BRAKE CHIRP 1. Lack of lubricant on brake shoe support plate where shoes ride. 1. Lubricate shoe contact areas on brake shoe support plates. 2. Wheel cylinder out of alignment. 2. Loosen wheel cylinder mounting bolts, realign wheel cylinder with brake shoes and tighten mounting bolts. DRUM BRAKE CLUNK 1. Drum(s) have threaded machined braking surface. 1. Reface or replace drake drums as necessary. DRUM BRAKE HOWL OR MOAN 1. Lack of lubricant on brake shoe support plate where shoes ride and at the anchor. 1. Lubricate shoe contact areas on brake shoe support plates and at the anchor. 2. Rear brake shoes. 2. Replace rear brake shoes. 5s - 2 BRAKES-BASE PL BRAKES-BASE (Continued) 2001 NEON

- 16. CONDITION POSSIBLE CAUSES CORRECTION DRUM BRAKE SCRAPING OR WHIRRING 1. ABS wheel speed sensor or tone wheel. 1. Inspect, correct or replace faulty component(s). SCRAPING (METAL-TO- METAL). 1. Foreign object interference with brakes. 1. Inspect brakes and remove foreign object. 2. Brake shoes worn out. 2. Replace brake shoes. Inspect rotors and drums. Reface or replace as necessary. OTHER BRAKE CONDITIONS CONDITION POSSIBLE CAUSES CORRECTION BRAKES CHATTER 1. Rear brake drum out of round or disc brake rotor has excessive thickness variation. 1. Isolate condition as rear or front. Reface or replace brake drums or rotors as necessary. BRAKES DRAG (FRONT OR ALL) 1. Contaminated brake fluid. 1. Check for swollen seals. Replace all system components containing rubber. 2. Binding caliper pins or bushings. 2. Replace pins and bushings 3. Binding master cylinder. 3. Replace master cylinder. 4. Binding brake pedal. 4. Replace brake pedal. BRAKES DRAG (REAR ONLY) 1. Parking brake cables binding or froze up. 1. Check cable routing. Replace cables as necessary. 2. Parking brake cable return spring not returning shoes. 2. Replace cables as necessary. 3. Service brakes not adjusted properly (rear drum brakes only). 3. Follow the procedure listed in the adjustment section. 4. Obstruction inside the center console preventing full return of the parking brake cables. 4. Remove console and remove obstruction. BRAKES GRAB 1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes. Repair source of contamination. 2. Improper power brake booster assist. 2. Refer to power brake booster in the diagnosis and testing section. EXCESSIVE PEDAL EFFORT 1. Obstruction of brake pedal. 1. Inspect, remove or move obstruction. 2. Low power brake booster assist. 2. Refer to power brake booster in the diagnosis and testing section. 3. Glazed brake linings. 3. Reface or replace brake rotors as necessary. Replace brake shoes. 4. Brake shoe lining transfer to brake rotor. 4. Reface or replace brake rotors as necessary. Replace brake shoes. EXCESSIVE PEDAL TRAVEL (VEHICLE STOPS OK) 1. Air in brake lines. 1. Bleed brakes. 2. Rear drum brake auto-adjuster malfunctioning. 2. Inspect and replace drum brake components as necessary. Adjust rear brakes. PL BRAKES-BASE 5s - 3 BRAKES-BASE (Continued) 2001 NEON

- 17. CONDITION POSSIBLE CAUSES CORRECTION EXCESSIVE PEDAL TRAVEL (PEDAL GOES TO FLOOR - CAN’T SKID WHEELS) 1. Power brake booster runout (vacuum assist). 1. Check booster vacuum hose and engine tune for adequate vacuum supply. Refer to power brake booster in the diagnosis and testing section. EXCESSIVE PEDAL TRAVEL (ONE FRONT WHEEL LOCKS UP DURING HARD BRAKING) 1. One of the two hydraulic circuits to the front brakes is malfunctioning. 1. Inspect system for leaks. Check master cylinder for internal malfunction. PEDAL PULSATES/ SURGES DURING BRAKING 1. Rear brake drum out of round or disc brake rotor has excessive thickness variation. 1. Isolate condition as rear or front. Reface or replace brake drums or rotors as necessary. PEDAL IS SPONGY 1. Air in brake lines. 1. Bleed brakes. 2. Power brake booster runout (vacuum assist). 2. Check booster vacuum hose and engine tune for adequate vacuum supply. Refer to power brake booster in the diagnosis and testing section. PREMATURE REAR WHEEL LOCKUP 1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes. Repair source of contamination. 2. Inoperative proportioning valve (non-ABS vehicles only). 2. Test proportioning valves folowing procedure listed in diagnosis and testing section. Replace valves as necessary. 3. ABS EBD not functioning. 3. Refer to the ABS section and Chassis Diagnostic Procedures manual. 4. Improper power brake booster assist. 4. Refer to power brake booster in the diagnosis and testing section. STOP LAMPS STAY ON 1. Brake lamp switch out of adjustment. 1. Adjust brake lamp switch. 2. Brake pedal binding. 2. Inspect and replace as necessary. 3. Obstruction in pedal linkage. 3. Remove obstruction. 4. Power Brake Booster not allowing pedal to return completely. 4. Replace power brake booster. VEHICLE PULLS TO RIGHT OR LEFT ON BRAKING 1. Frozen brake caliper piston. 1. Replace frozen piston or caliper. Bleed brakes. 2. Contaminated brake shoe lining. 2. Inspect and clean, or replace shoes. Repair source of contamination. 3. Pinched brake lines. 3. Replace pinched line. 4. Leaking piston seal. 4. Replace piston seal or brake caliper. 5. Suspension problem. 5. Refer to the Suspension group. PARKING BRAKE - EXCESSIVE HANDLE TRAVEL 1. Rear brakes out of adjustment. 1. Adjust rear drum brake shoes, or rear parking brake shoes on vehicles with rear disc brakes. 5s - 4 BRAKES-BASE PL BRAKES-BASE (Continued) 2001 NEON

- 18. STANDARD PROCEDURE - BASE BRAKE BLEEDING NOTE: For bleeding the ABS hydraulic system, refer to Antilock Brake System Bleeding in the Antilock Brake System section. CAUTION: Before removing the master cylinder cap, wipe it clean to prevent dirt and other foreign mat- ter from dropping into the master cylinder reservoir. CAUTION: Use only MoparT brake fluid or an equiv- alent from a fresh, tightly sealed container. Brake fluid must conform to DOT 3 specifications. Do not pump the brake pedal at any time while having a bleeder screw open during the bleeding pro- cess. This will only increase the amount of air in the system and make additional bleeding necessary. Do not allow the master cylinder reservoir to run out of brake fluid while bleeding the system. An empty reservoir will allow additional air into the brake system. Check the fluid level frequently and add fluid as needed. The following wheel circuit sequence for bleeding the brake hydraulic system should be used to ensure adequate removal of all trapped air from the hydrau- lic system. • Left rear wheel • Right front wheel • Right rear wheel • Left front wheel MANUAL BLEEDING NOTE: To bleed the brakes manually, the aid of a helper will be required. (1) Attach a clear plastic hose to the bleeder screw and feed the hose into a clear jar containing enough fresh brake fluid to submerge the end of the hose (Fig. 1). (2) Have a helper pump the brake pedal three or four times and hold it in the down position. (3) With the pedal in the down position, open the bleeder screw at least 1 full turn. (4) Once the brake pedal has dropped, close the bleeder screw. After the bleeder screw is closed, release the brake pedal. (5) Repeat the above steps until all trapped air is removed from that wheel circuit (usually four or five times). (6) Bleed the remaining wheel circuits in the same manner until all air is removed from the brake sys- tem. Monitor the fluid level in the master cylinder reservoir to make sure it does not go dry. (7) Check the brake pedal travel. If pedal travel is excessive or has not been improved, some air may still be trapped in the system. Rebleed the brakes as necessary. (8) Test drive the vehicle to verify the brakes are operating properly and pedal feel is correct. PRESSURE BLEEDING NOTE: Follow pressure bleeder manufacturer’s instructions for use of pressure bleeding equip- ment. Following the same wheel circuit sequence as pre- scribed for manual bleeding. (1) Attach Adapter, Special Tool 6921, to the mas- ter cylinder reservoir (Fig. 2). (2) Attach Bleeder Tank, Special Tool C-3496-B, or an equivalent, to the adapter on the master cylinder. (3) Attach a clear plastic hose to the bleeder screw and feed the hose into a clear jar containing enough fresh brake fluid to submerge the end of the hose (Fig. 1). (4) Open the bleeder screw at least one full turn or more to obtain a steady stream of brake fluid. (5) After approximately 4–8 ounces of fluid have been bled through the brake circuit and an air-free flow is maintained in the clear plastic hose and jar, close the bleeder screw. (6) Repeat this procedure at all the remaining bleeder screws. Fig. 1 Proper Method for Purging Air From Brake System (Typical) 1 - CLEAR HOSE 2 - BRAKE CALIPER 3 - BLEEDER SCREW 4 - CLEAN BRAKE FLUID PL BRAKES-BASE 5s - 5 BRAKES-BASE (Continued) 2001 NEON