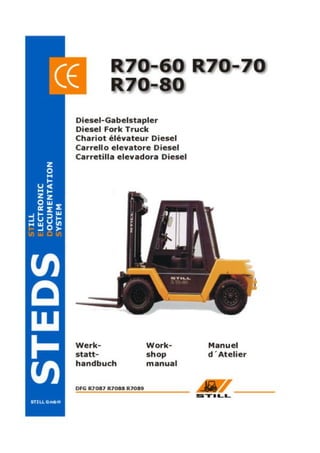

Still r70 70 diesel fork truck service repair manual

- 2. 01 Workshop manual 7087- 89 1 Table of contents Page Chassis and counterweight 1 Jacking up the vehicle 2

- 3. 4 6 2 5 7 1 3 01 Workshop manual 7087- 89 Chassis and counterweight 3 The chassis is a welded construction. The chassis and counterweight are bolted together with 8 hexagon bolts (1) M24x180. Bolt tightening torque(1) : 660 Nm Weight of counterweights: 7087 - 4392kg 7088 / 7089 - 5418 kg 1 - SKS (8x) M24 x 180 8.8 660 Nm 2 - SKS (2x) M24 x 65 8.8 660 Nm 3 - SKS (12x) M24 x 50 10.9 939 Nm 4 - SKS (10x) M24 x 85 8.8 660 Nm 5 - SKS (2x) M27 x 170 10.9 940 Nm 6 - SKS (6x) M24 x 70 8.8 660 Nm 7 - SKS (4x) M24 x 50 10.9 930 Nm

- 4. Attention! Before jacking up the vehicle, apply the parking brake! The fork truck must be jacked up for various maintenance work. When jacking up the fork truck, suitable measures must be taken to prevent the truck slipping or tilting, e.g. wooden blocks. Only jacks with sufficient bearing capacity must be used and the fork truck must be jacked up only on a level surface and secured to prevent it rolling. Only jack up the fork truck at the points shown in the diagrams, i.e. on the left or right of the mast and at the counterweight. When jacking up the fork truck at the mast, the safety regulations for working on masts must be observed. 01 Workshop manual 7087- 89 Jacking up the vehicle 4

- 5. 1 02 Workshop manual 7087- 89 Table of contents Page Technical service data Steering axle design 3 Removing the steering axle 3 Fitting the steering axle 3 Removing the wheel hub 4 Fitting the wheel hub 4 Adjusting the steering angle 5 Checking the steering angle 5 Removing the stub axle 6 Fitting the stub axle 7 Greasing the running axle 7 Removing the tie rods 8 Fitting the tie rods 8 Removing the steering cylinder 9 Fitting the steering cylinder 9 Steering axle

- 6. 2 02 Workshop manual 7087- 89 Steering axle Technical service data h W e l x a g n i r e e t S e l g n a g n i r e e t S ° 2 8 - 0 8 n i - e o T m m 1 ± 0 r e b m a c l e e h W ° 0 r e t s a C ° 0 e u q r o t g n i n e t h g i T b u h l e e h W MA m N 5 4 1 = t u n l e e h W MA m N 5 4 1 = g n i r a e b e l x A MA m N 5 4 1 = g n i x i f r e d n i l y c g n i r e e t S MA m N 5 4 1 = n i p g n i k t a M K S MA m N 5 4 1 = t n a c i r b u L g n i r a e b b u h l e e h W , 0 2 - K 2 P K - 5 2 8 1 5 N I D o t g n i d r o c c a F e s a e r G d e i f i n o p a s m u i h t i l , 0 3 - K 2 P K - 5 2 8 1 5 N I D o t g n i d r o c c a F e s a e r G d e i f i n o p a s m u i h t i l g n i r a e b e l x a b u t S , 0 2 - N 2 F P K - 5 2 8 1 5 N I D o t g n i d r o c c a L F e s a e r G d e i f i n o p a s m u i h t i l 9 5 6 8 4 1 . o N . t n e d I L L I T S

- 7. 3 02 Workshop manual 7087- 89 Steering axle Steering axle design The steering axle is mounted with 2 buffer elements on the counterweight. The stub axles are supported in taper roller bearings in the axle body. Steering limitation takes place via stop bolts in the stub axle. 1 Axle body 2 Fixing plates 3 Hexagon bolt 4 Lock washer 5 Buffer elements Removing the steering axle CAUTION: Only remove steering axle with the mast mounted! Risk of tilting! - Apply the hand brake. - Place wooden wedges under the front wheels to prevent the vehicle from rolling. - Loosen the wheel nuts on the steering axle wheels. - Jack up the vehicle as directed (see Group 01). - Remove the wheels. - Unscrew the hydraulic connections of the steering cylinder. CAUTION: When unscrewing the hydraulic connections, hydraulic oil will discharge. Collect the hydraulic oil and dispose of it in a proper manner. - Place a hand pallet truck or similar with timbers under the steering axle. - Unscrew the four cheese-head screws for fixing the steering axle. Fitting the steering axle - Fitting takes place in reverse order to removal - Tightenting torque of the 4 cheese head screws: 385 Nm CAUTION: Take care not to confuse the left and right hydraulic connections!

- 8. 4 1 2 3 4 6 5 9 10 7 8 11 12 02 Removing the wheel hub 1 Axle body 2 Stub axle 3 Radial seal 4 Taper roller bearing 5 Wheel hub 6 Pin 7 Wheel cap 8 Hexagon nut 9 Washer 10 Taper roller bearing 11 Wheel bolt 12 Nut - Loosen the nuts (12) and remove the wheel. - Remove the dust cap (7). - Loosen the hexagon nut (8). - Remove the washer (9) with the pin (6). - Remove the wheel hub. - Remove the taper roller bearings (4) and (10) from the wheel hub; the seal (3) must be removed for this purpose. - If necessary, remove the outer rings of the taper roller bearings (4) and (10). Fitting the wheel hub - Thoroughly grease the sealing lips of the radial seal. - Fill the taper roller bearings with grease F between the inner ring and cage. - Fill the bearing spaces with grease F at the marked points (x). - Fitting takes place in reverse order to removal. - Tighten the hexagon nut (8) while continuously turning the wheel hub. Tightening torque: MA = 150 Nm Workshop manual 7087- 89 Steering axle

- 9. 5 Linkskurve = 82° +0/-2 Lenkeinschlag Rechtskurve 1 02 Workshop manual 7087- 89 Steering axle Checking the steering angle The steering angle “a“ must be 80° - 82°. To facilitate measurement, the supplementary angle “b“ can be used. It must be 98° - 100°. ATTENTION: It must be ensured that the steering angle is clearly limited by the stop bolts (1). Steering lock must not take place in the steering cylinder. Adjusting the steering angle The steering angle is limited on each side by one stop bolt (1) respectively. - Adjust the left and right steering angle with the stop bolts (1) to 80° - 82°. - Check the opposite angle. - Check for clearance with steering wheel at full lock. - Check that steering lock does not take place in the steering cylinder. steering angles turn right turn left

- 10. 6 4 5 6 7 8 9 11 10 12 1 2 3 13 14 15 16 02 Removing the stub axle 1 Hexagon bolt 2 Washer 3 King pin 4 Plug 5 Stub axle 6 Hexagon bolt 7 Hexagon nut 8 Spacer 9 Wiper 10 Taper roller bearing 11 Spacer 12 Nipple 13 Taper roller bearing 14 Scraper ring 15 O-ring 16 Spacer - Remove the wheel. - Press out the pin between the tie rod and the stub axle. - Loosen the hexagon nut (1). - Remove the washer (2). - Press out the king pin (3) downwards. - Remove the stub axle from the axle. - Remove the spacers, O-ring, scraper rings, taper roller bearings and spacers (8 - 16) from the stub axle. Workshop manual 7087- 89 Steering axle

- 11. 7 1 2 3 12 14 5 4 8 7 6 10 11 13 9 02 Workshop manual 7087- 89 Steering axle Fitting the stub axle 1 Hexagon nut 2 Washer 3 King pin 4 Plug 5 Stub axle 6 Spacer 7 Scraper ring 8 Taper roller bearing 9 Spacer 10 Taper roller bearing 11 Scraper ring 12 O-ring 13 Spacer 14 Bolt - Fit the spacer (9) in the stub axle. - Fit the two taper roller bearings (8+10). Grease both bearings with grease FL! - Thoroughly grease the sealing lips of the scraper rings (7+11) with grease FL. - Fit the scraper rings (7+11), both spacers (13, 6 ) and the O-ring (12). - Insert the stub axle into the axle. - Insert the king pin (3) from below, lightly oil the pin. - Fit the washer (2). - Fit a new hexagon nut (1) and tighten with a tightening torque of: MA = 600 Nm - Press in the bolt (16) of the tie rod and secure with pins. - Mount the wheel. - Grease the steering axle with grease FL. - The steering must be operated while greasing. - Grease the eight nipples of the steering axle with grease FL, until gresh grease discharges at the bearing points (see diagram on Page 8).

- 12. 8 3 4 4 5 02 Removing the tie rods The steering axle has two tie rods, which are seated between the steering cylinder and the two stub axles. 1 Stub axle 2 Piston rod 3 Seals 4 Pins 5 Bolts 6 Tie rod 7 Ball socket - Remove the pins (4) - Press out the bolts (5) Fitting the tie rods - Fitting takes place in reverse order to removal. Press in force of bolts on cylinder side: max. 21 kN Press in force of bolts on stub axle side: max. 26 kN Steering axle Workshop manual 7087- 89

- 13. 9 2 2 2 2 02 Workshop manual 7087- 89 Steering axle Removing the steering cylinder – Remove the tie rods. – Unscrew the hydraulic connections and mark. ATTENTION: Hydraulic oil discharges – Loosen the four fixing bolts (1). Fitting the steering cylinder – Tighten the fixing bolts (1). Tightening torque: MA = 1050 Nm – Screw on hydraulic connections. ATTENTION: Do not confuse the hydraulic lines. – Fit the tie rods. NOTE: See instructions for removing and fitting the steering cylinder under Group 06. Greasing the steering axle – Relieve the steering axle while greasing and operate the steering. – Grease the eight nipples (2) of the steering axle with grease FL, starting with the top nipple until fresh grease discharges at the bearing points. NOTE: While greasing the upper bearing, grease may not necessarily discharge from the upper seal. It can also discharge downwards.

- 14. 04 Workshop manual 7087- 89 Wheels and tyres 2 s l e e h w d e r y t c i t a m u e n P 5 , 1 x 0 2 M e z i S R P e r y T e r u s s e r p ) r a b ( g n i d a o l e u q r o T t n o r f 5 1 - 0 0 3 2 2 0 1 1 8 T E 5 1 - 0 0 . 8 m N 0 4 6 r a e r 5 1 - 5 2 . 8 8 1 5 . 9 8 3 T E 5 1 - 0 5 . 6 m N 0 4 6 t n o r f 5 1 - 5 6 / 5 5 3 4 2 0 1 1 8 T E 5 1 - 5 7 . 9 m N 0 4 6 r a e r 5 1 - 0 0 3 2 2 0 1 3 6 T E 5 1 - 0 0 . 8 m N 0 4 6 t n o r f 5 1 - 5 2 . 8 8 1 5 . 9 0 4 1 T E 5 1 - 0 5 . 6 m N 0 4 6 r a e r 5 1 - 5 2 . 8 8 1 5 , 9 8 3 T E 5 1 - 0 5 . 6 m N 0 4 6 s l e e h w d e r y t c i t s a l e r e p u S t n o r f 5 1 - 5 6 / 5 5 3 - - 1 8 T E 5 1 - 5 7 . 9 m N 0 4 6 r a e r 5 1 - 0 0 3 - - 3 6 T E 5 1 - 0 0 . 8 m N 0 4 6 t n o r f 5 1 - 5 2 . 8 - - 5 4 1 T E 5 1 - 0 5 . 6 m N 0 4 6 r a e r 5 1 - 5 2 . 8 - - 8 3 T E 5 1 - 0 5 . 6 m N 0 4 6

- 15. 1 06 Workshop manual 7087- 89 Table of contents Page Technical data 2 Mode of operation 3 Functional description 3 Steering column 4 Steering unit 4 Priority valve 6 Steering cylinder 7 Steering

- 16. 2 06 Workshop manual 7087- 89 Technical service data t i n u g n i r e e t S e k a M s s o f n a D l e d o M 4 4 1 8 – 0 5 1 N Y D S L 0 5 C P S O y t i c a p a c p m u P m c 0 5 3 n o i t a t o r / e v l a v f e i l e R 0 / 5 + 0 0 1 r a b e v l a v g n i n o i h s u c k c o h S r a b 0 / 0 2 + 0 6 1 e v l a v y t i r o i r P e k a M s s o f n a D e p y T 7 1 0 8 B 2 5 1 0 4 S L O e r u s s e r P r a b 4

- 17. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 18. 3 P LS CF EF LS P T P R L R 1 2 3 4 5 6 7 8 Rechts Links Fahrtrichtung <---------- 06 direction right left Mode of operation The vehicle has power assisted steering based on the load sensing (LS) principle and acts on the steering cylinder (7) at the steering axle. A steering unit (3) is flanged to the bottom end of the steering unit (2). It consists of a distributor valve and a measuring pump. When the steering wheel is operated, the measuring pump supplies the steering system with oil, which is directly proportional to rotation of the steering wheel. The distributor valve supplies this oil to the required side of the steering cylinder. In LS systems, the steering and hydraulics are supplied from a common pump unit (1). The distribution of oil between both systems takes place in the priority valve (4). The steering always has priority, i.e. a sufficient quantity of oil is always Workshop manual 7087- 89 Steering supplied to the steering appropriate to the respective steering speed, independent of the load in the steering system and hydraulics. A smaller quantity of oil is required for steering than for specific hydraulic functions. For this reason, the pump unit operates at a slow speed during steering with the hydraulics inactive. In the event of failure of the oil flow, the steering unit functions automatically as a handpump, so that the vehicle can be steered manually (emergency steering). 1 – Pump 5 – Slider bank 2 – Steering column 6 – Hydraulic tank 3 – Steering unit 7 – Steering cylinder 4 – Prority valve 8 – Suction filter

- 19. 4 LS L R T P 2 1 06 Workshop manual 7087- 89 Steering column/Steering unit Steering column adjustment The incliniation of the steering column can be infinitely adjusted within a range of about 10° after loosening the grip screw (2) (turning anticlockwise). After adjusting the steering column to the required position, it must be relocked by tightening the grip screw. Steering unit The steering unit (1) is fixed to the steering column bearing with four cheese-head screws. The following valves are installed in the steering unit, which are set to a fixed value by the manufacturer: Relief valve: 150 bar Shock valve: 220 bar ATTENTION: The valve settings must not be altered. Removing the steering unit – Remove floor plate. – Unscerw left inner covering. – Unscrew rear steering column cover. – Unscrew hydraulic connections T (tank), P (pumps), L (left connection), R (right connection), LS (control connection) and mark. ATTENTION: When unscrewing the hydraulic connections, hydraulic oil will discharge. Collect the hydraulic oil and dispose of in a proper manner. – Loosen the four cheese-head screws and remove handpump downwards. While loosening the screws, the steering wheel with steering column must be tilted forward and back.

- 20. 5 16 13 14 15 17 11 12 12 1 2 3 4 5 4 6 8 7 9 10 9 06 Fitting the steering unit Fitting takes place in reverse order to removal. ATTENTION: It is important that the previously marked hydraulic lines are screwed back into the same position to prevent a risk of accident. Repair of the steering unit – In case of damage, the steering unit must be replaced. – Exception: Oil leakage Available for this repair is a sealing set Ident. No.:144694 consisting of: 1 x Lip seal (14) 1 x Dust seal (15) 7 x Washer (16) 3 x O-ring (17) 1 x Fitting instructions NOTE: For replacement of the lip seal and dust seal, special tools of Messrs Danfoss are required. – To stem union leaks at the steering unit connections, seals are available from STILL Spare Parts Service. However, the connection tightening torques should previously be checked. Workshop manual 7087- 89 Steering unit No. Description Remarks 1 Cheese-head screw MA = 46Nm 2 Washer 7 Steering column Tilt forward and back Remove rear steering column cover. 8 Union MA = 50Nm 9 Reducing union MA = 100 Nm 10 HP hose 11 Relief valve Installed in steering unit. MA = 50 ±1Nm