Human Failings

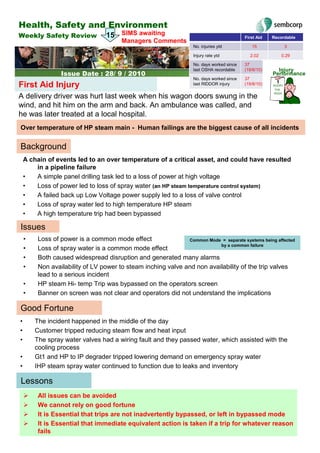

- 1. Health, Safety and Environment Weekly Safety Review 15 SIMS awaiting First Aid Recordable Managers Comments No. injuries ytd 15 3 Injury rate ytd 2.02 0.29 No. days worked since 37 last OSHA recordable (19/8/10)10) Injury Issue Date : 28/ 9 / 2010 Performance No. days worked since 37 1 First Aid Injury last RIDDOR injury (19/8/10)10 INJURY THS WEEK A delivery driver was hurt last week when his wagon doors swung in the wind, and hit him on the arm and back. An ambulance was called, and he was later treated at a local hospital. Over temperature of HP steam main - Human failings are the biggest cause of all incidents Background A chain of events led to an over temperature of a critical asset, and could have resulted in a pipeline failure • A simple panel drilling task led to a loss of power at high voltage • Loss of power led to loss of spray water (an HP steam temperature control system) • A failed back up Low Voltage power supply led to a loss of valve control • Loss of spray water led to high temperature HP steam • A high temperature trip had been bypassed Issues • Loss of power is a common mode effect Common Mode = separate systems being affected by a common failure • Loss of spray water is a common mode effect • Both caused widespread disruption and generated many alarms • Non availability of LV power to steam inching valve and non availability of the trip valves lead to a serious incident • HP steam Hi- temp Trip was bypassed on the operators screen • Banner on screen was not clear and operators did not understand the implications Good Fortune • The incident happened in the middle of the day • Customer tripped reducing steam flow and heat input • The spray water valves had a wiring fault and they passed water, which assisted with the cooling process • Gt1 and HP to IP degrader tripped lowering demand on emergency spray water • IHP steam spray water continued to function due to leaks and inventory Lessons All issues can be avoided We cannot rely on good fortune It is Essential that trips are not inadvertently bypassed, or left in bypassed mode It is Essential that immediate equivalent action is taken if a trip for whatever reason fails