Watch 2nd PPT Tutorial on SAP EWM Outbound Process

https://www.usaonlinetrainings.com/sap-s4hana-ewm/

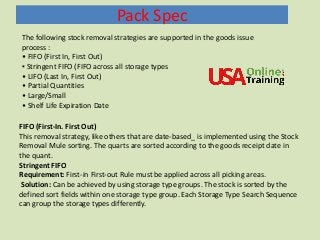

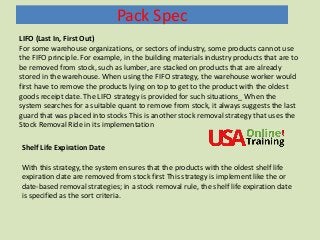

ewm goods issues, ewm storage process step, ewm truck loading, sap ewm, sap ewm handling unit, sap ewm outbound, sap ewm outbound process, sap ewm outbound process flow, sap ewm outbound process flow ppt, sap ewm package sepc, sap ewm pick, sap ewm ppt, sap ewm process, sap ewm process oritented storage, sap ewm transportation unit,fifo,lifo