Recommended

Recommended

Advanced Materials International Forum, Bari 18-19 settembre, conferenza internazionale dedicata ai materiali avanzati e alle loro possibili applicazioni nei settori industriali, con un focus particolare sui trasporti (aerospazio, automotive, navale e cantieristico).AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...![AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...ARTI-Apulian Regional Agency for Technology and Innovation

More Related Content

Similar to finalposter

Advanced Materials International Forum, Bari 18-19 settembre, conferenza internazionale dedicata ai materiali avanzati e alle loro possibili applicazioni nei settori industriali, con un focus particolare sui trasporti (aerospazio, automotive, navale e cantieristico).AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...![AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...ARTI-Apulian Regional Agency for Technology and Innovation

Similar to finalposter (20)

A Review: Aeronautical Components and Systems Should have their Weight Reduce...

A Review: Aeronautical Components and Systems Should have their Weight Reduce...

AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...![AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerime...

IRJET- Design and Analysis of Dry Cylinder Liner with FEA

IRJET- Design and Analysis of Dry Cylinder Liner with FEA

IRJET- Design of Integrated Intake Manifold for Formula Race Car

IRJET- Design of Integrated Intake Manifold for Formula Race Car

Leverage Modern Technology to Build Fuel Efficient Aircrafts

Leverage Modern Technology to Build Fuel Efficient Aircrafts

Weight reduction technologies in the automotive industry

Weight reduction technologies in the automotive industry

Technology Innovations for Cost- effective Energy Efficiency Measures

Technology Innovations for Cost- effective Energy Efficiency Measures

Innovation and Sustainability Presentation - October 23 2015

Innovation and Sustainability Presentation - October 23 2015

Mtz 2011-07 the-new_hyundai-kia_1,0_l_three-cylinder_gasoline_engine

Mtz 2011-07 the-new_hyundai-kia_1,0_l_three-cylinder_gasoline_engine

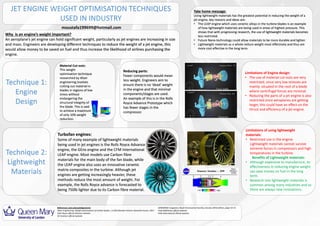

finalposter

- 1. JET ENGINE WEIGHT OPTIMISATION TECHNIQUES USED IN INDUSTRY Take home message: Using lightweight materials has the greatest potential in reducing the weight of a jet engine, key reasons and ideas are: • The LEAP engine which uses ceramic alloys in the turbine blades is an example of how lightweight materials are being used in areas of highest pressure. This shows that with progressing research, the use of lightweight materials becomes less restricted. • Future Nano-technology could allow materials to be more durable and lighter. • Lightweight materials as a whole reduce weight most effectively and thus are more cost effective in the long term. Why is an engine’s weight important? An aeroplane’s jet engine can hold significant weight, particularly as jet engines are increasing in size and mass. Engineers are developing different techniques to reduce the weight of a jet engine, this would allow money to be saved on fuel and thus increase the likelihood of airlines purchasing the engine. Technique 2: Lightweight Materials Technique 1: Engine Design Reducing parts: Fewer components would mean less weight. Engineers aim to ensure there is no ‘dead’ weight in the engine and that minimal components/stages are used. An example of this is in the Rolls Royce Advance Prototype which has fewer stages in the compressor. Limitations of using lightweight materials: • Restricted use in the engine. Lightweight materials cannot survive extreme forces in compressors and high temperatures in the turbine. Benefits of Lightweight materials: • Although expensive to manufacture, its effectiveness in reducing engine weight can save money on fuel in the long term. • Research into lightweight materials is common among many industries and so there are always new innovations. Limitations of Engine design: • The use of material cut-outs are very restricted, since very low stresses are mainly situated in the root of a blade where centrifugal forces are minimal. • Reducing the parts of a jet engine is also restricted since aeroplanes are getting larger, this could have an effect on the thrust and efficiency of a jet engine. Turbofan engines: Some of many example of lightweight materials being used in jet engines is the Rolls Royce Advance engine, the GEnx engine and the CFM International LEAP engine. Most models use Carbon fibre materials for the main body of the fan blade, while the LEAP engine also uses an innovative ceramic matrix composites in the turbine. Although jet engines are getting increasingly heavier, these methods reduce the most amount of weight. For example, the Rolls Royce advance is forecasted to being 750lb lighter due to its Carbon fibre material. Material Cut-outs: This weight optimisation technique researched by Altair engineering involves cutting out material in blades in regions of low stress without endangering the structural integrity of the blade. This is said to achieve a maximum of only 10% weight reduction. References and acknowledgements Altair Engineering, Weight optimization of turbine blades, J.S.RAO Bhaskar Kishore Vasantha Kumar, 2011 Rolls Royce official Advance website GE Aviation official website AEROSPACE magazine, Royal Aeronautical Society, January 2016 edition, page 14-15. Pratt &Whitney official website. CFM international official website moustafa199699@hotmail.com