Embed presentation

Download to read offline

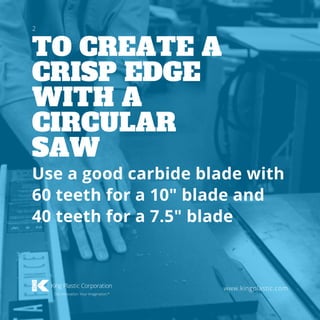

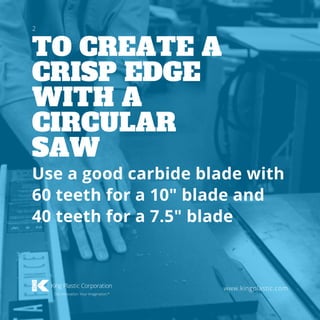

The document provides 8 tips for using handheld cutting tools effectively on King Starboard®. Key recommendations include wearing appropriate safety gear, using specific blades for circular saws, and employing clamps and router bits for clean cuts. It also advises against sanding the surface to maintain its matte finish.