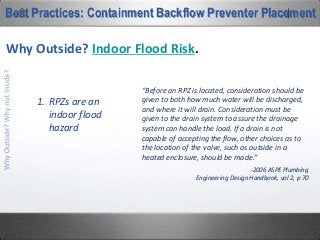

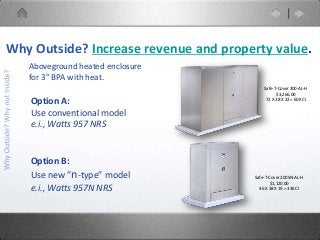

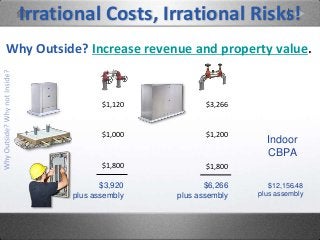

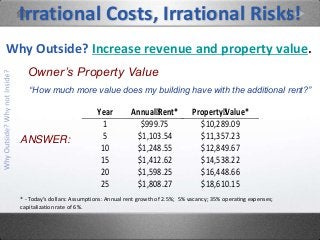

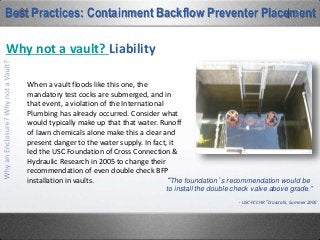

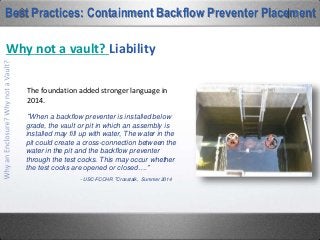

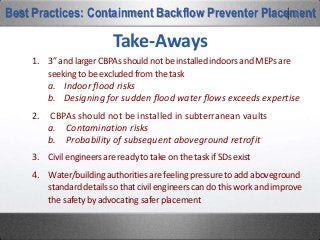

On January 12, 2017 consultant for Safe-T-Cover Randy Holland presented this to the San Antonio branch of the American Backflow Prevention Association at the TCEQ headquarters. Now you can learn all about the new professional liability concerns and solutions they covered as well. Now that industry thought leaders have started making recommendations on RPZ backflow preventer installation, it has caught the legal industry's attention.