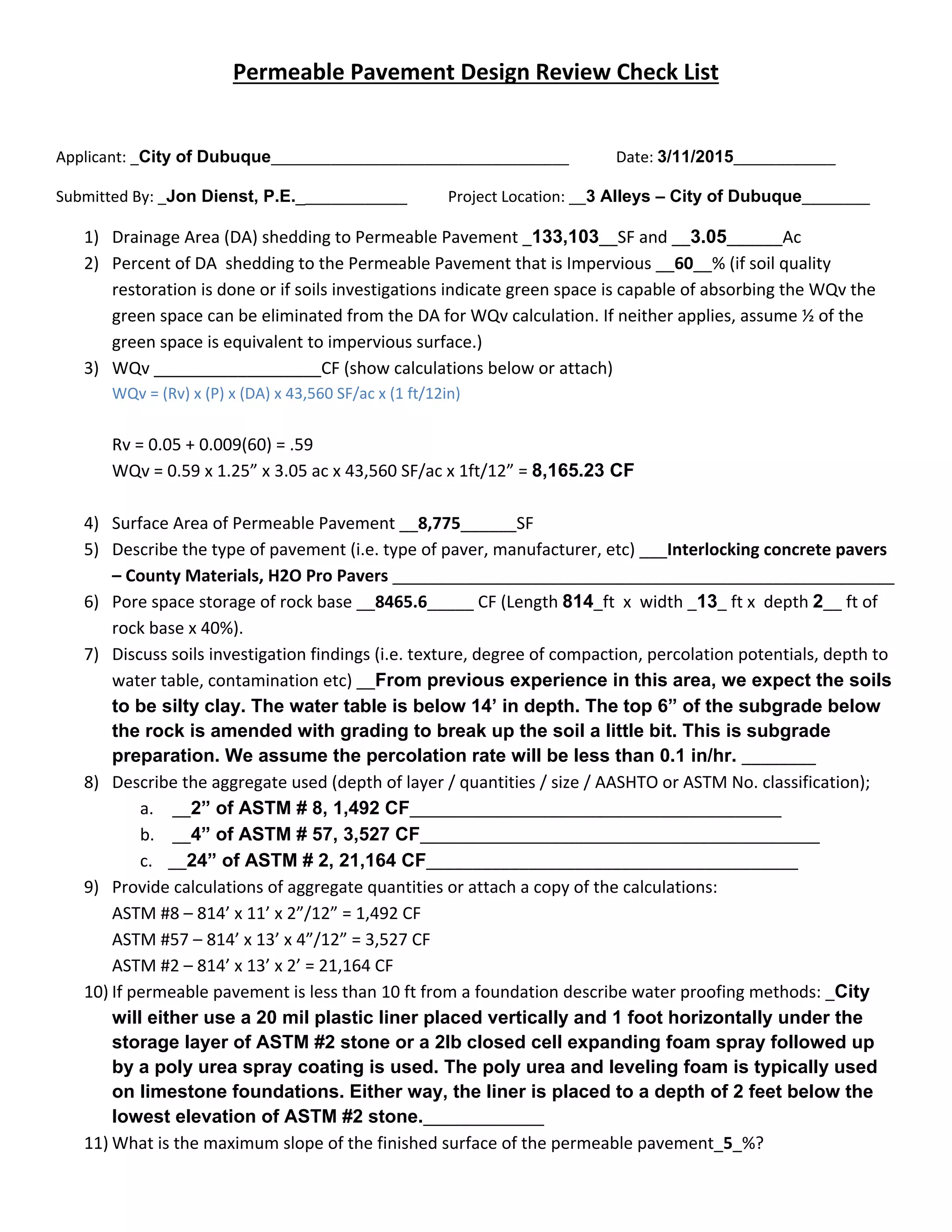

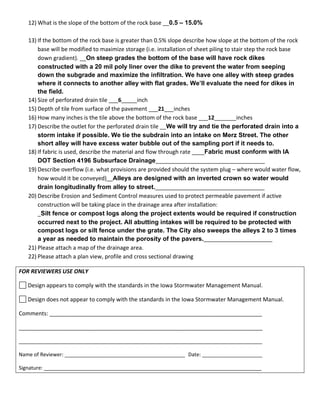

This document is a design review checklist for a permeable pavement project in three alleys in Dubuque, Iowa. It provides details on the project location, drainage area characteristics, stormwater calculations, pavement and base materials, subgrade and foundation protection, construction details, and erosion control measures. Key information includes the project will treat runoff from 3.05 acres of 60% impervious area, include interlocking concrete pavers over gravel bases totaling over 21,000 cubic feet of storage, and tie into existing storm intakes with overflow draining longitudinally down the alleys.