Embed presentation

Downloaded 58 times

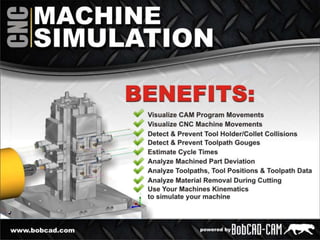

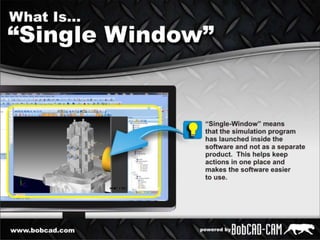

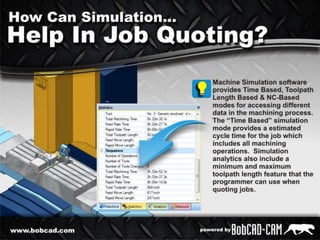

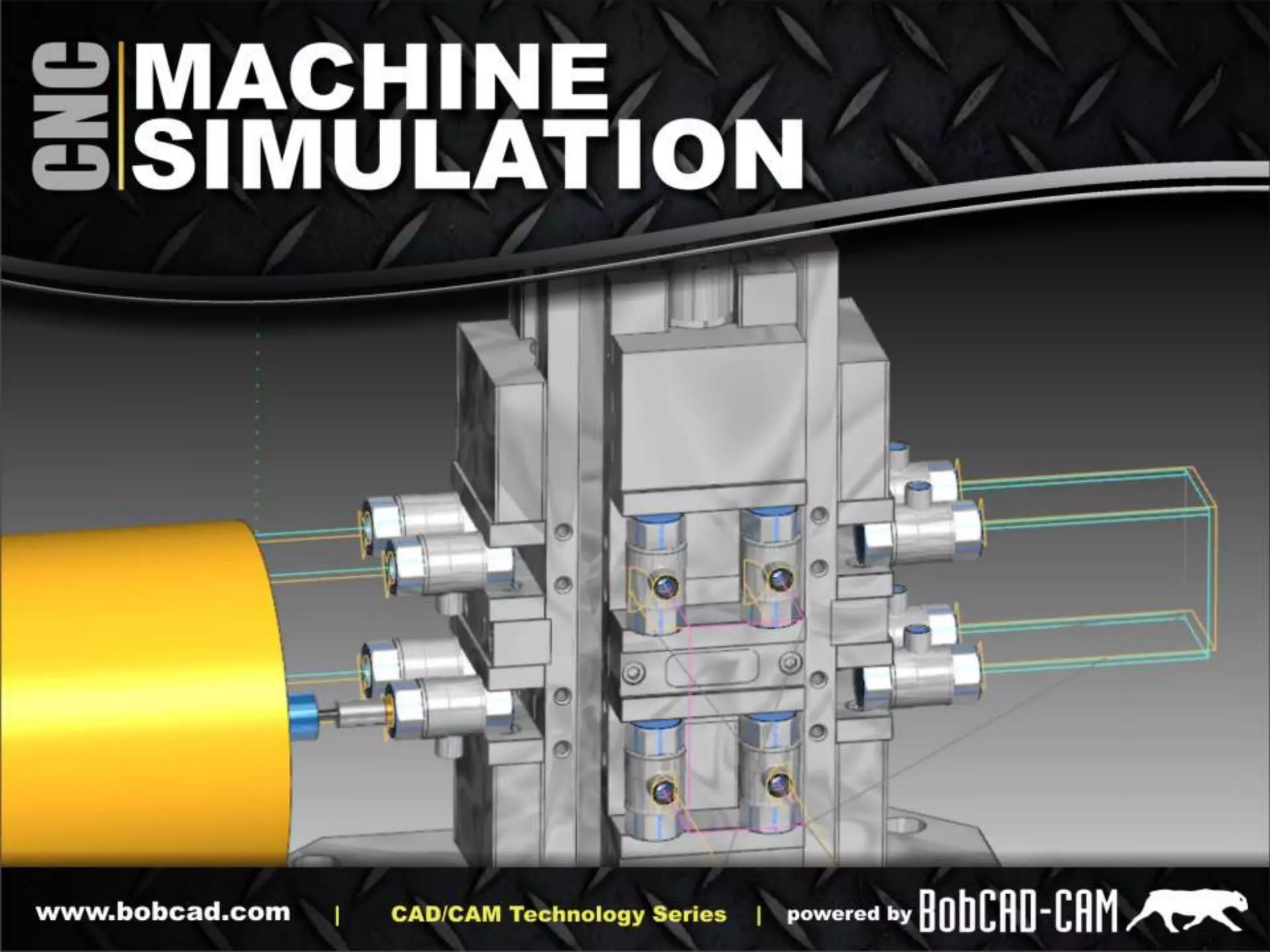

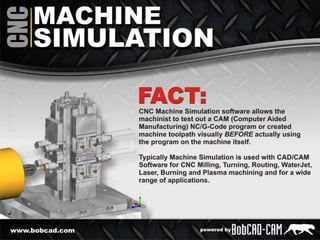

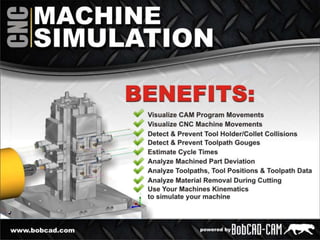

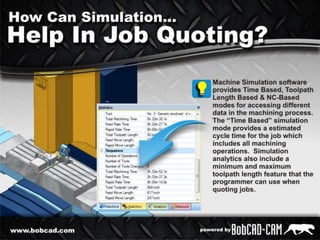

BobCAD-CAM Machine Simulation PRO software is a powerful Add-On product to any of the CAD/CAM systems that we offer. The Machine Simulation PRO offers a wide variety of simulation features including the ability to use your machines kinematics for simulation. What are the benefits of Simulation? How will it help your shop save time and become more profitable? Find out here!