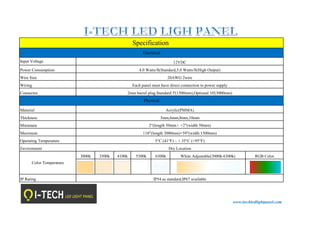

This document provides specifications and information about I-Tech LED light panels. Key details include:

- The panels are made of acrylic and come in various thicknesses, sizes, and color temperatures ranging from 3000K to 6300K.

- They have an IP54 or IP67 rating and operate between 5-35 degrees Celsius.

- Installation, handling, cleaning, and operation instructions are provided to ensure proper use and avoid damage.