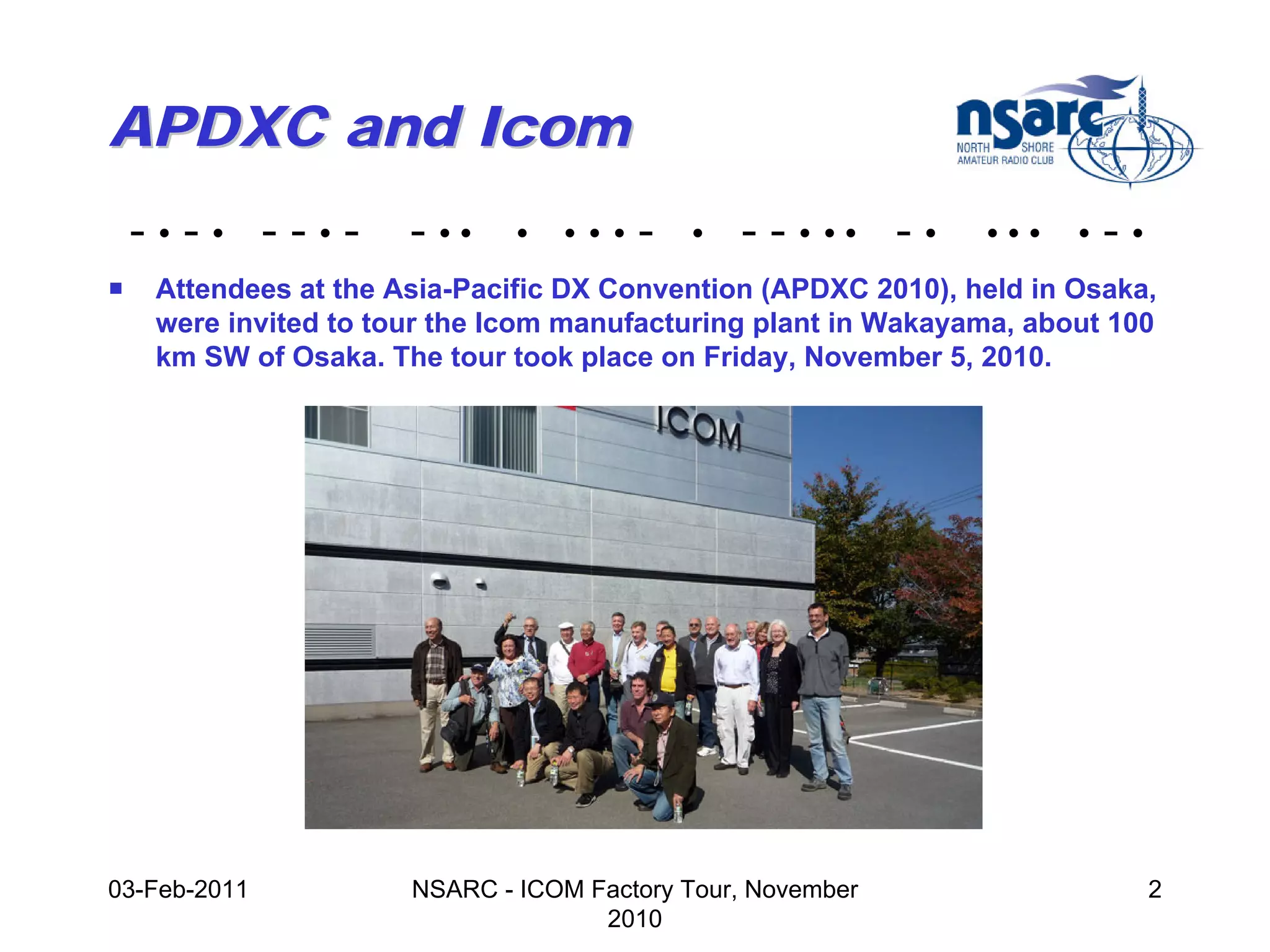

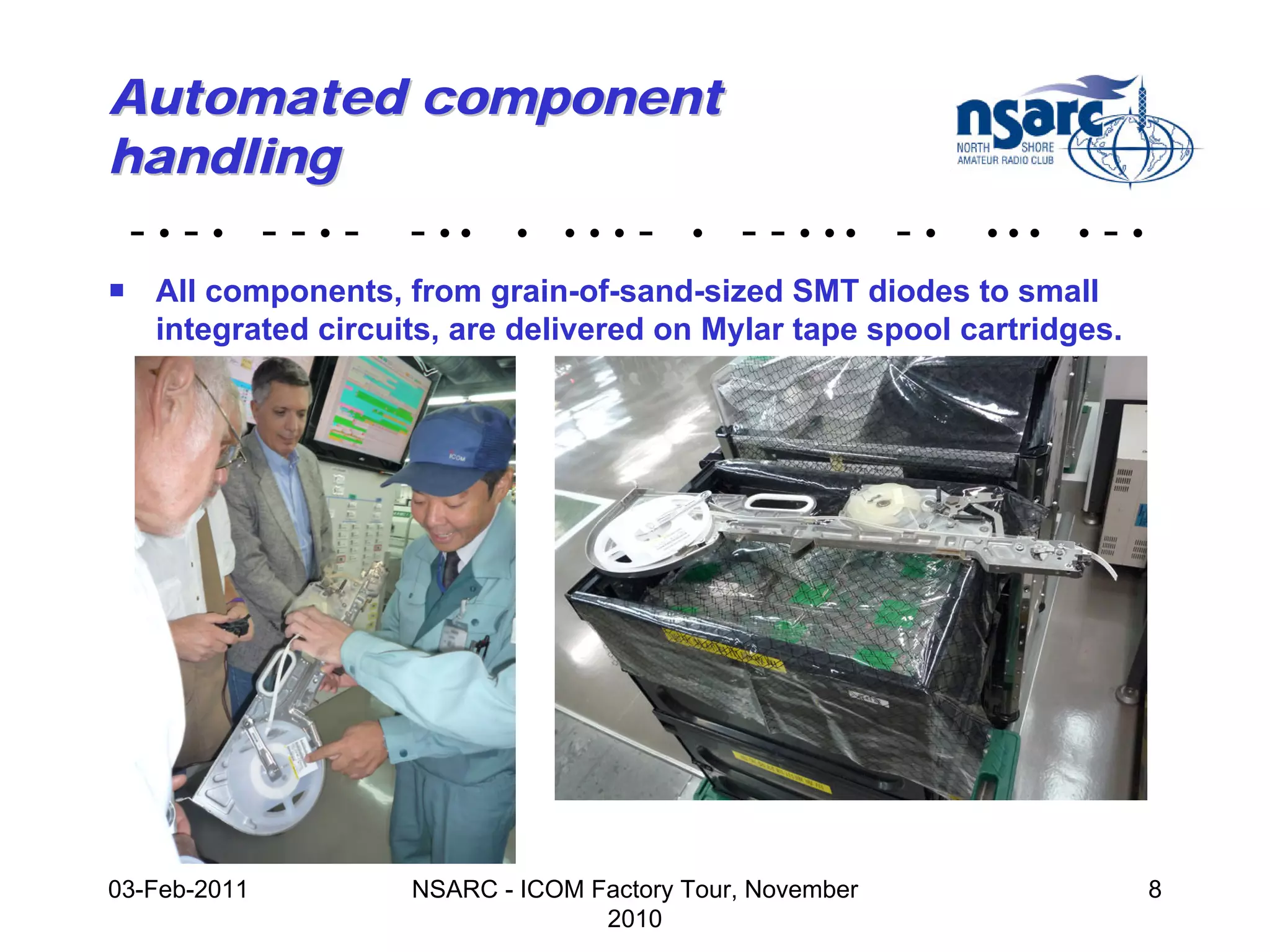

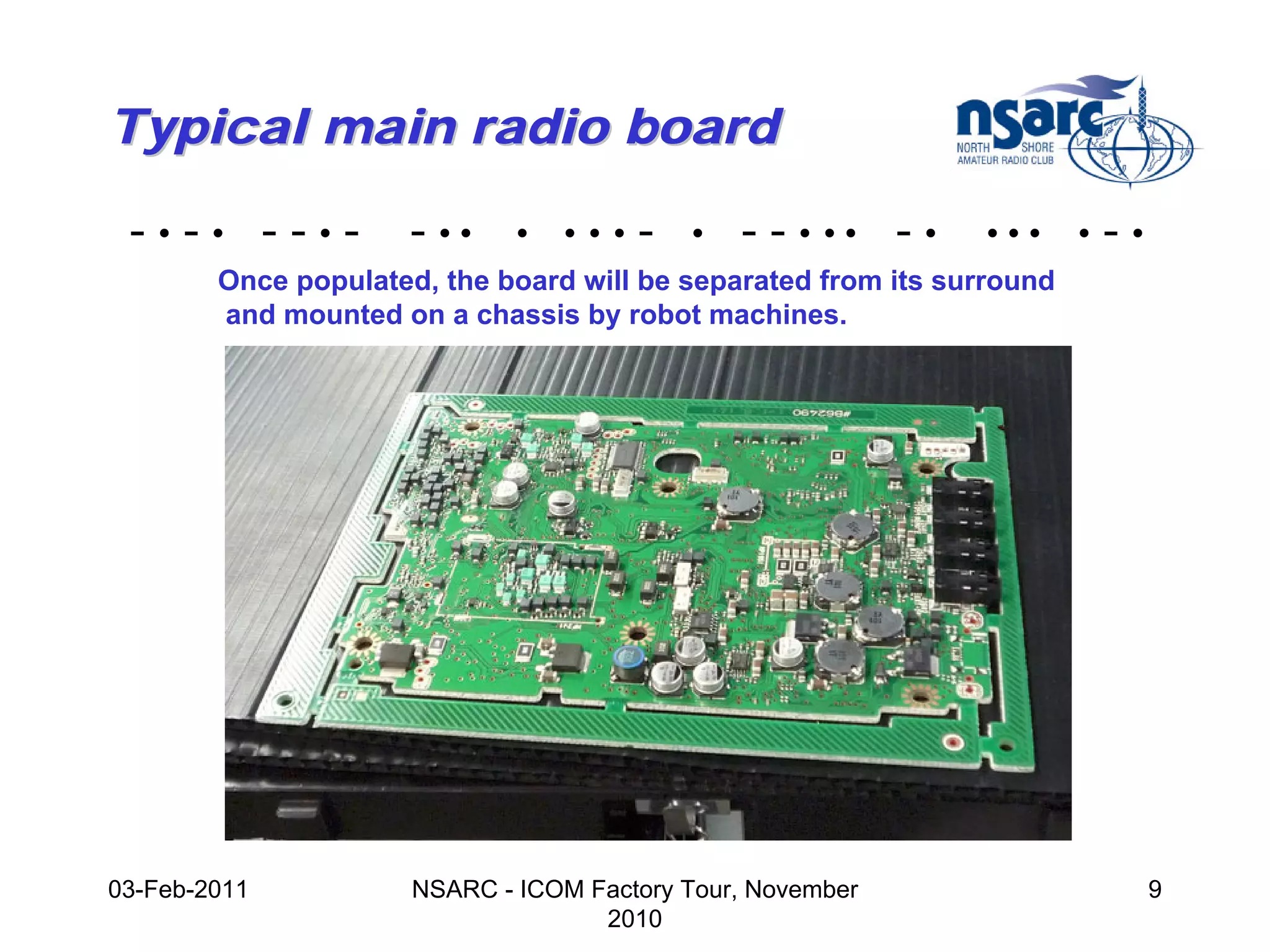

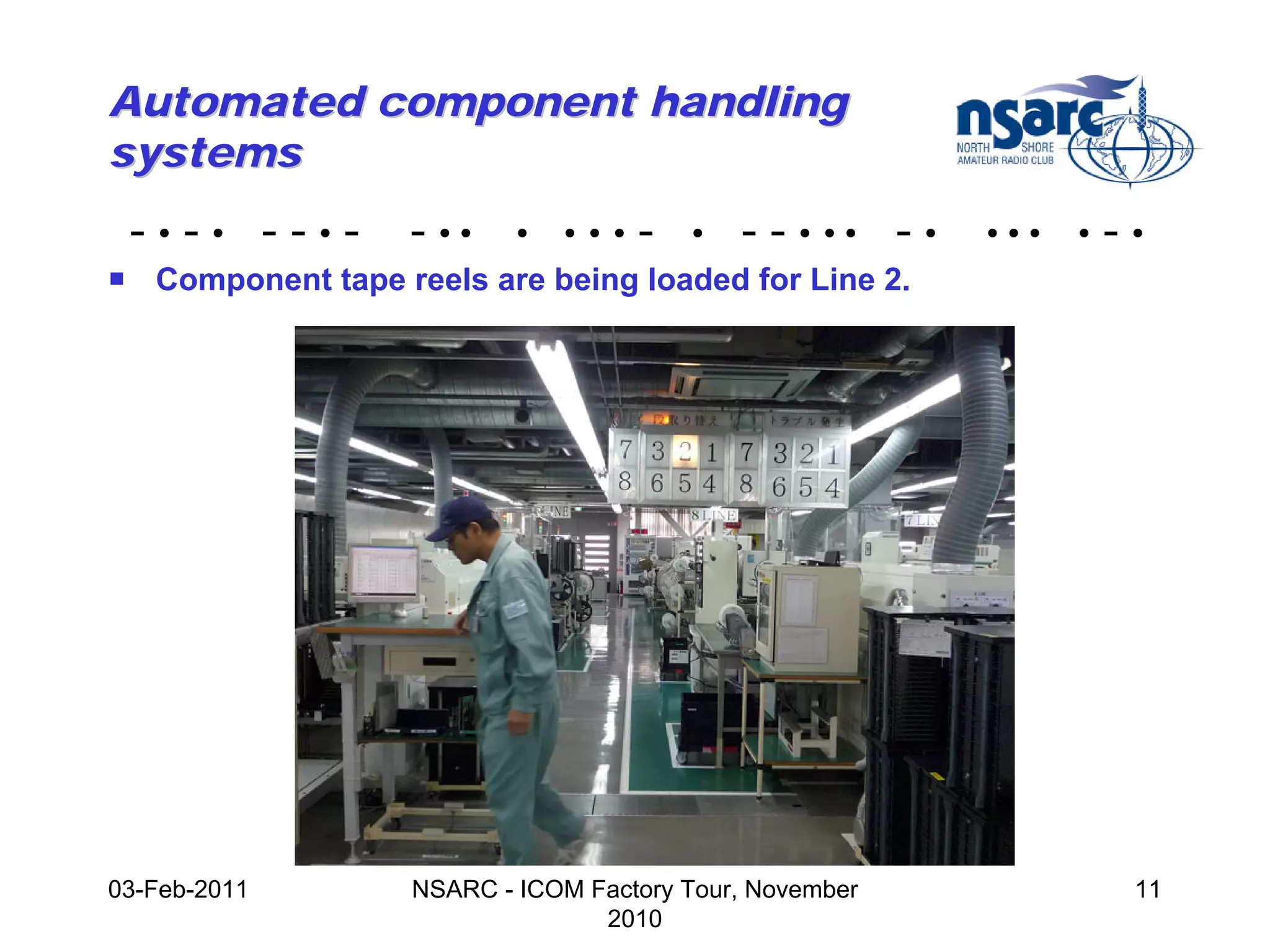

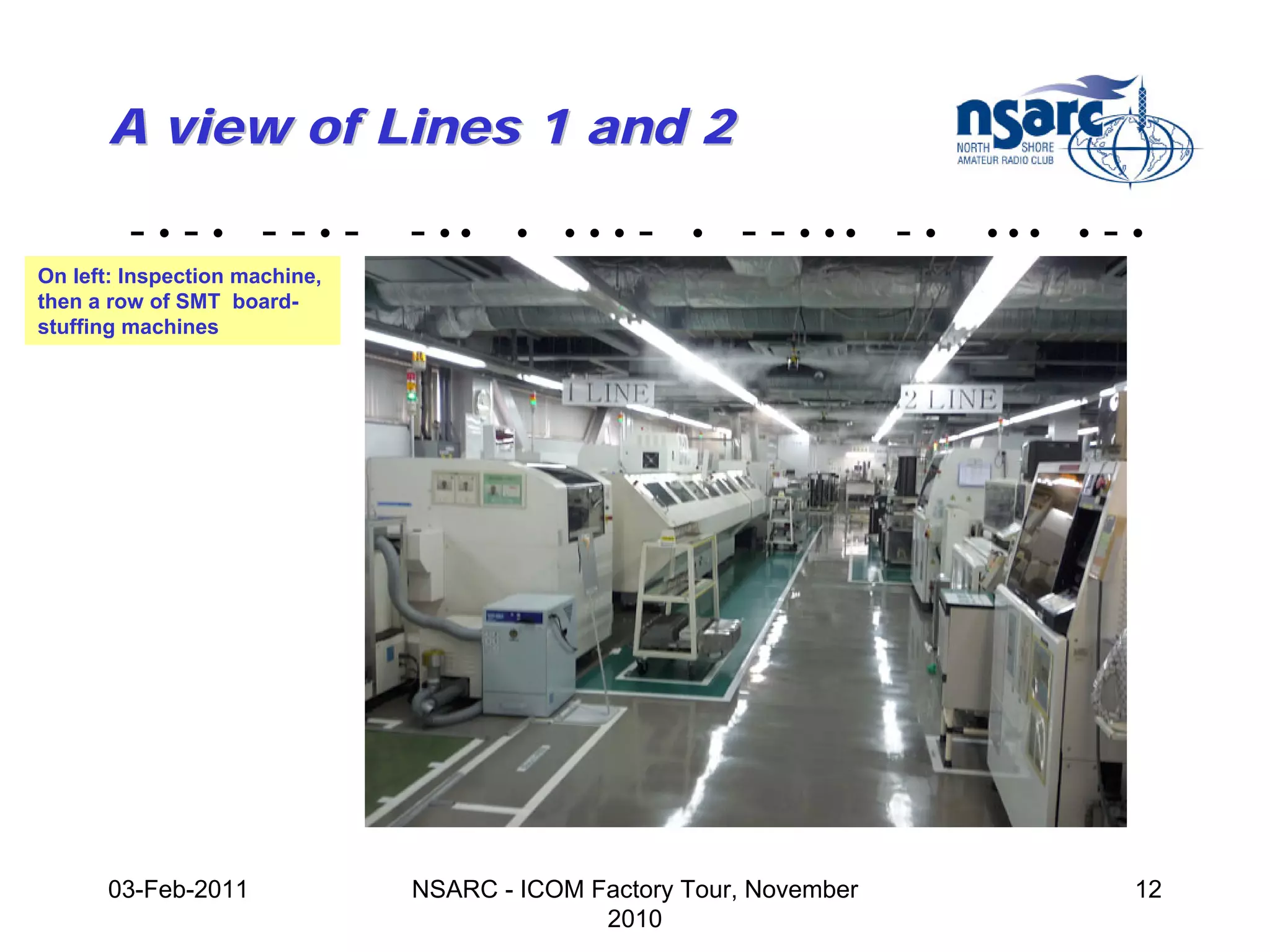

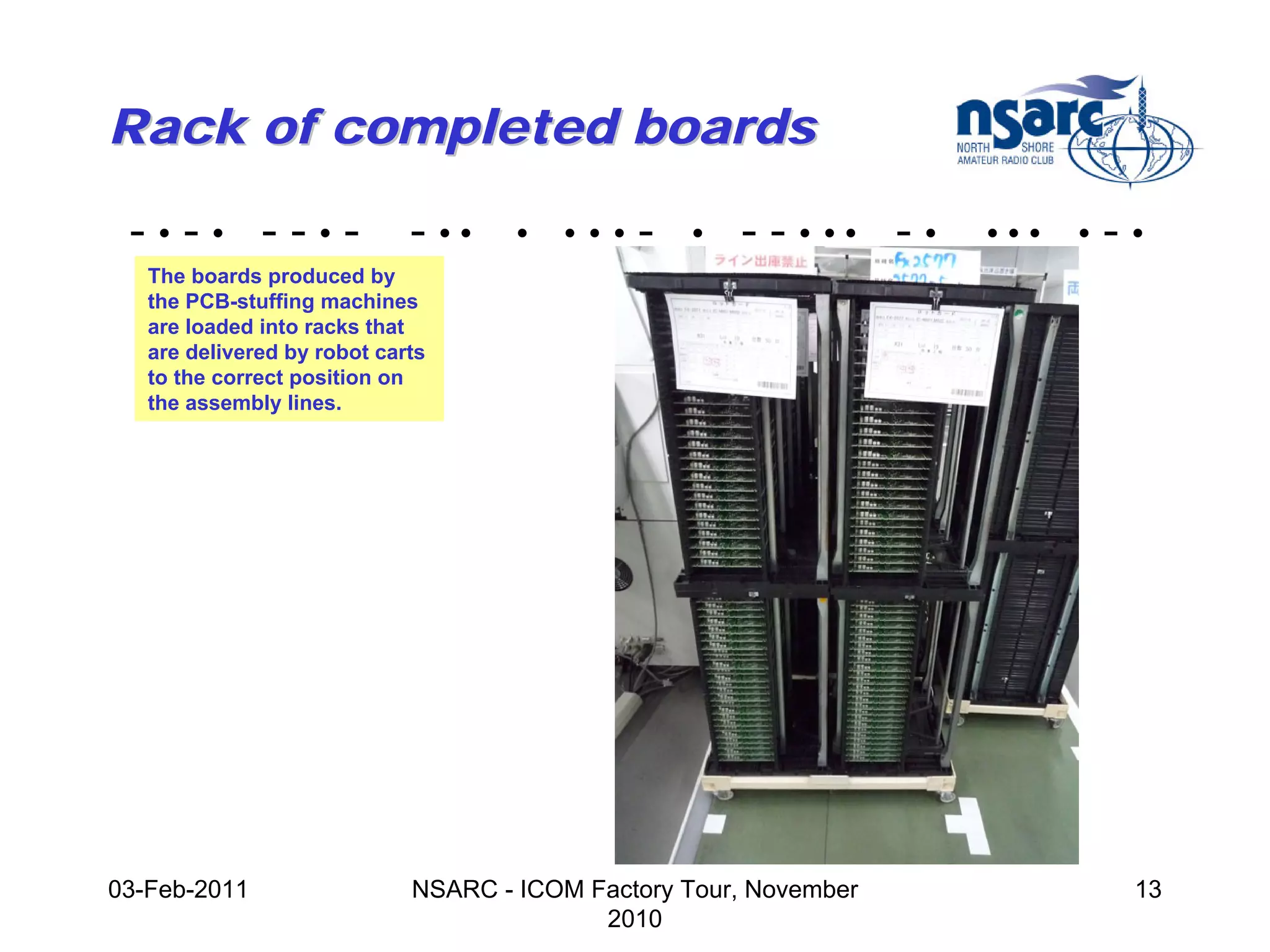

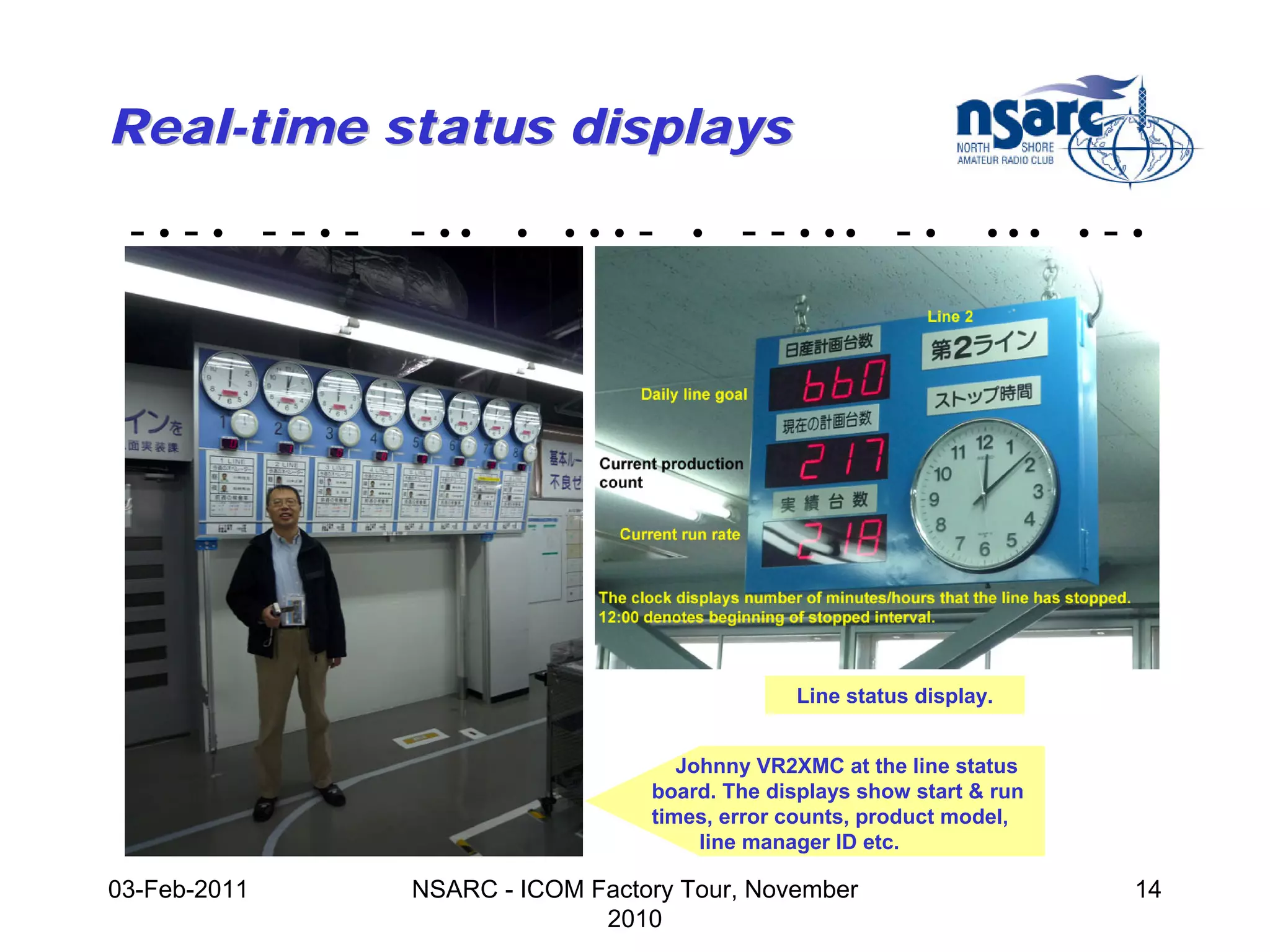

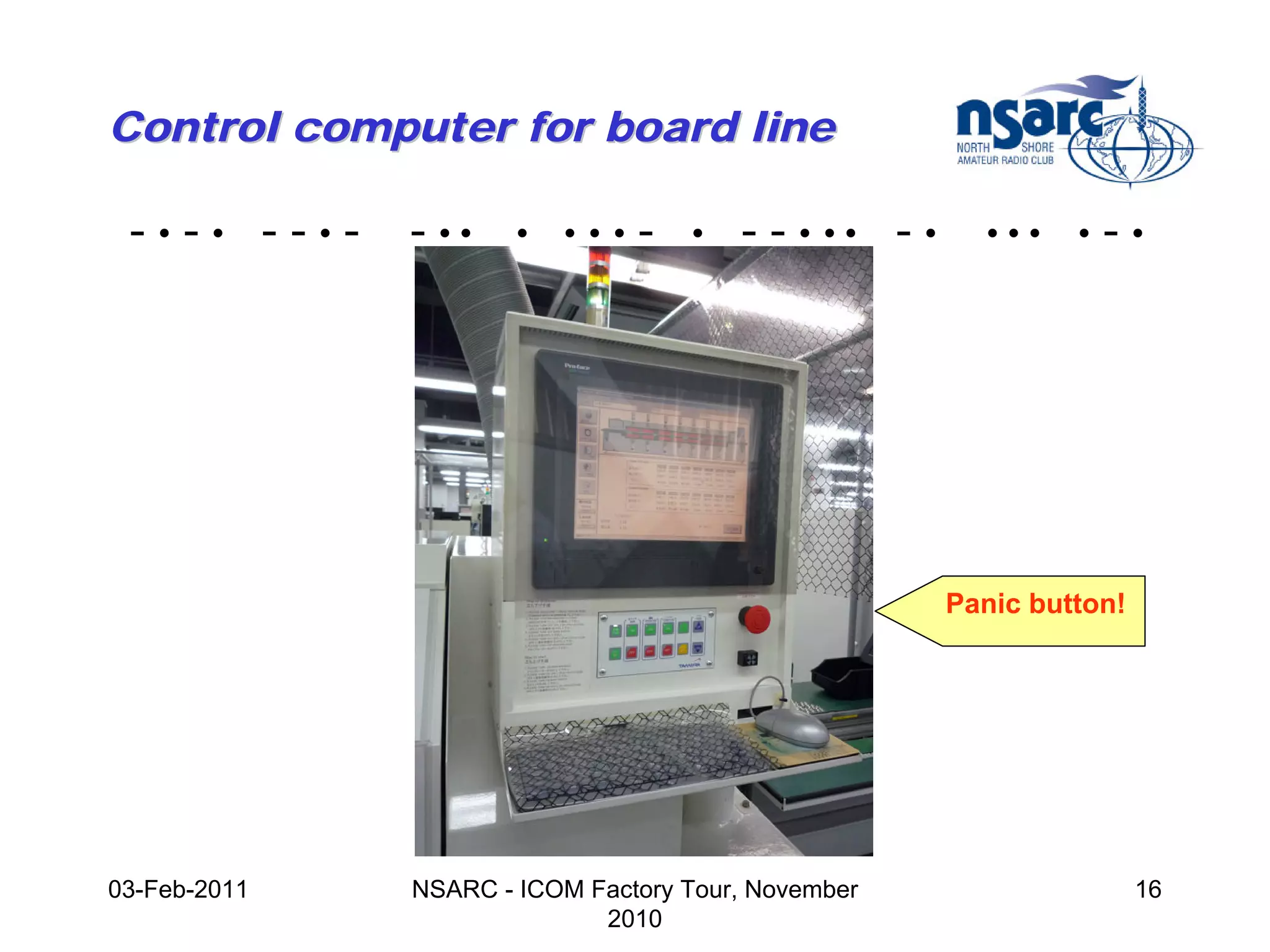

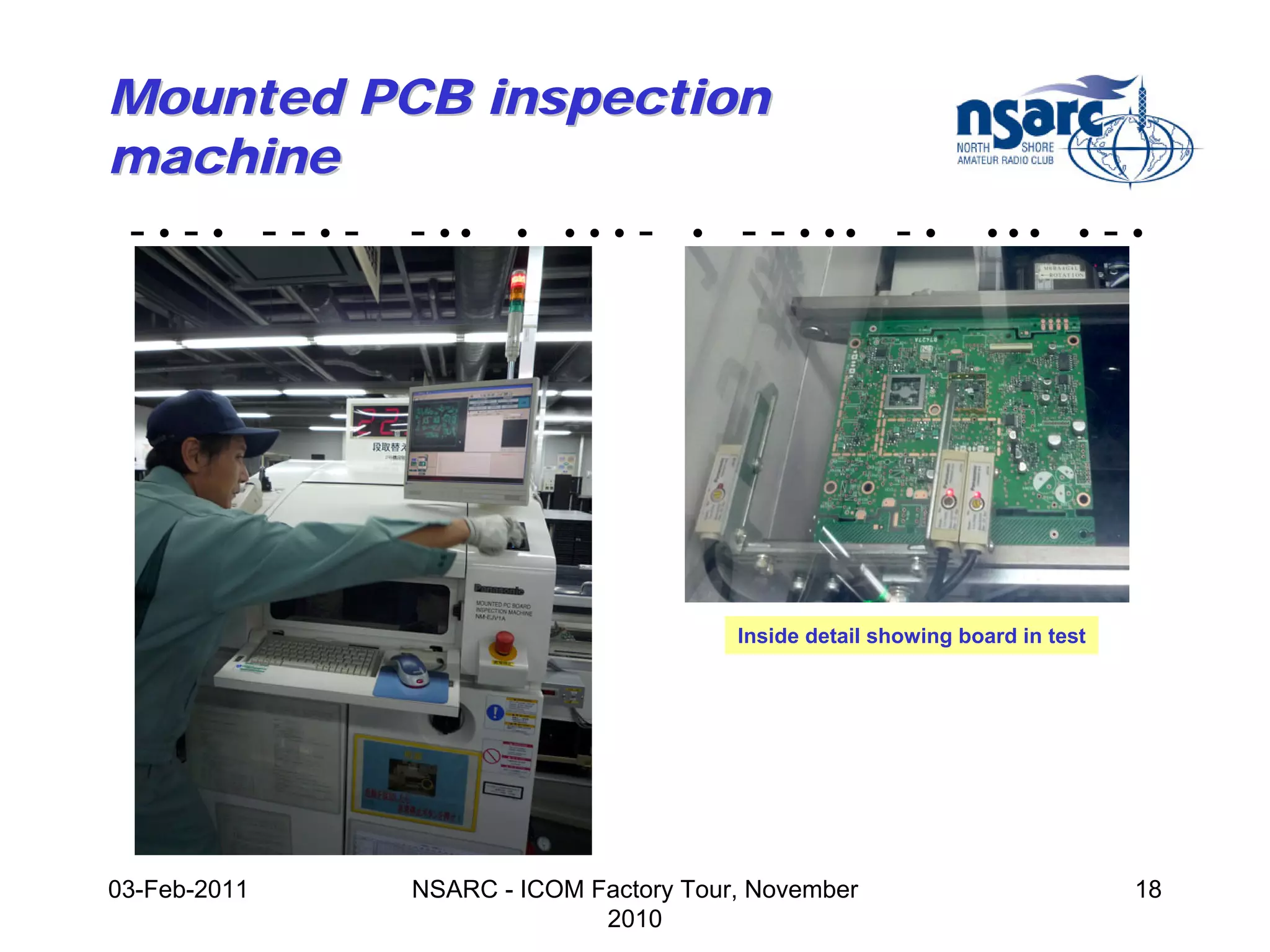

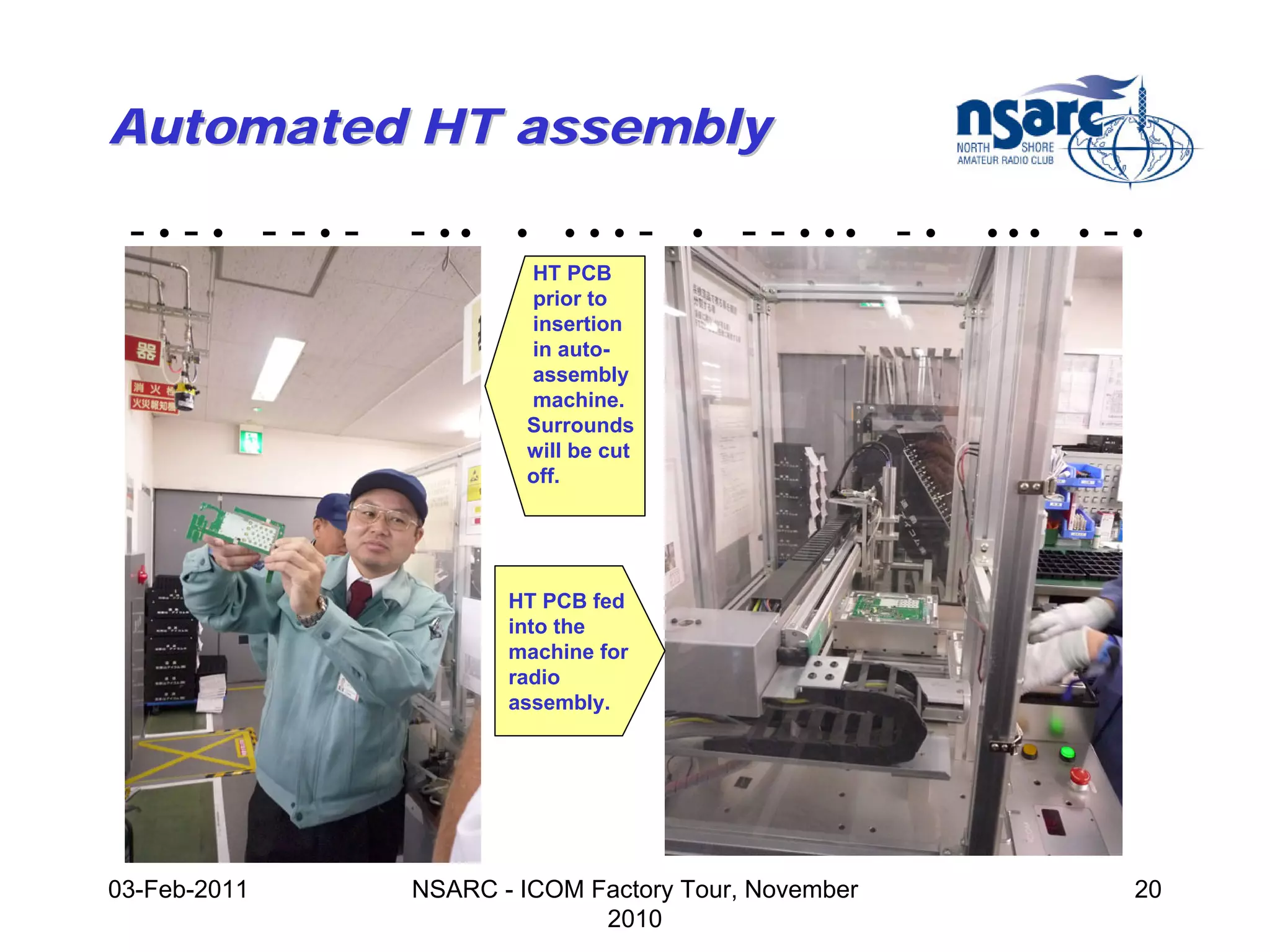

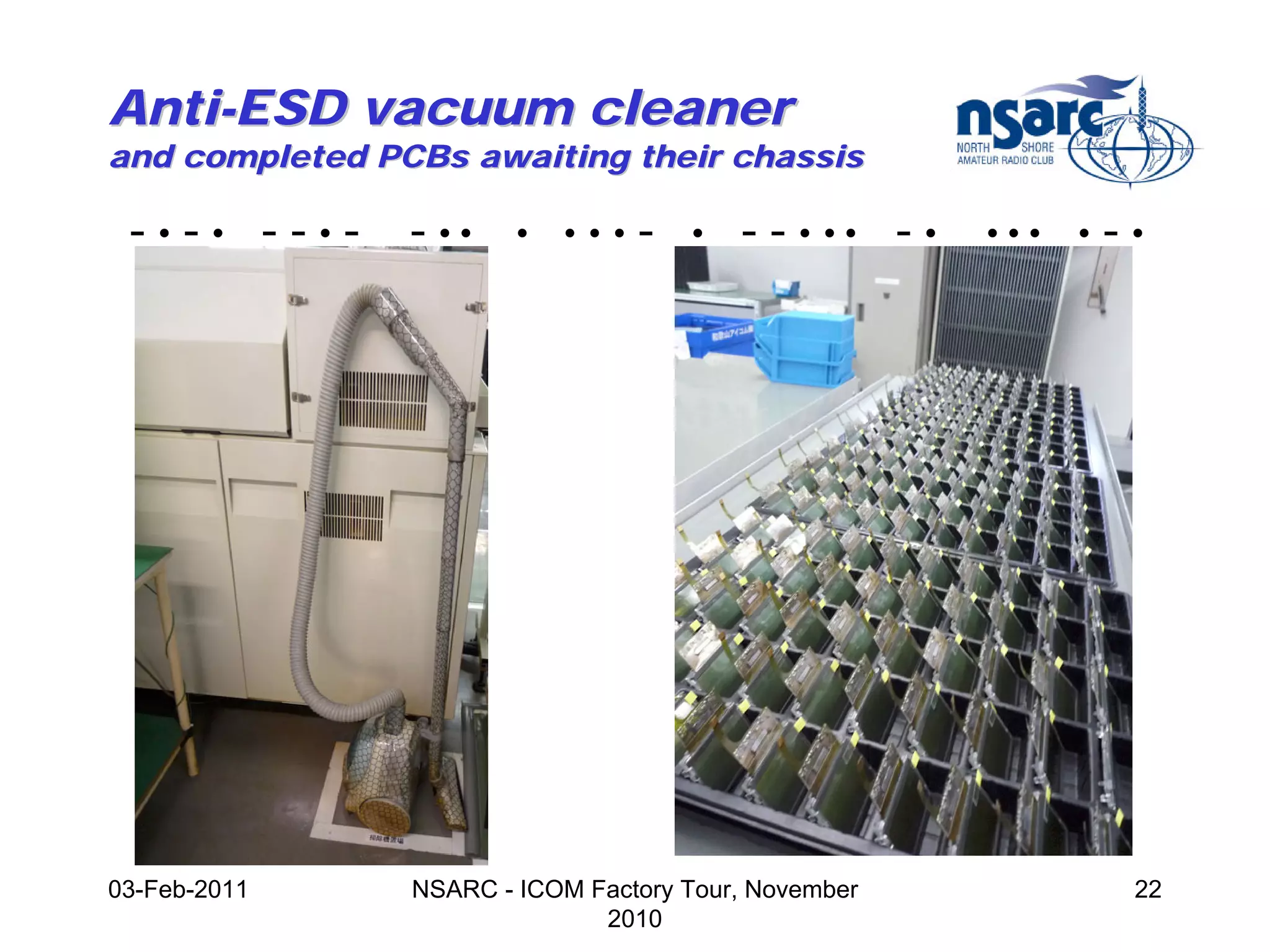

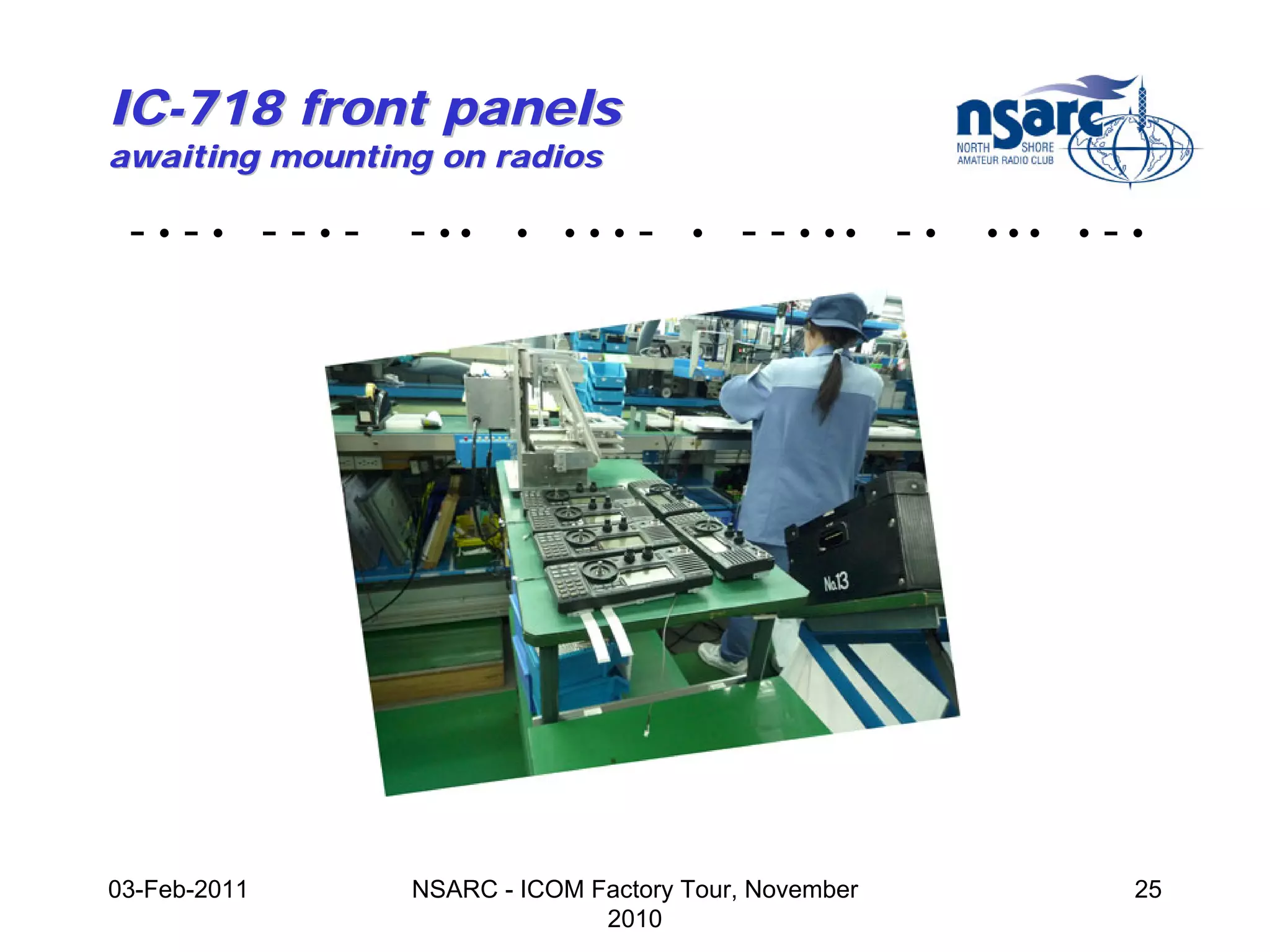

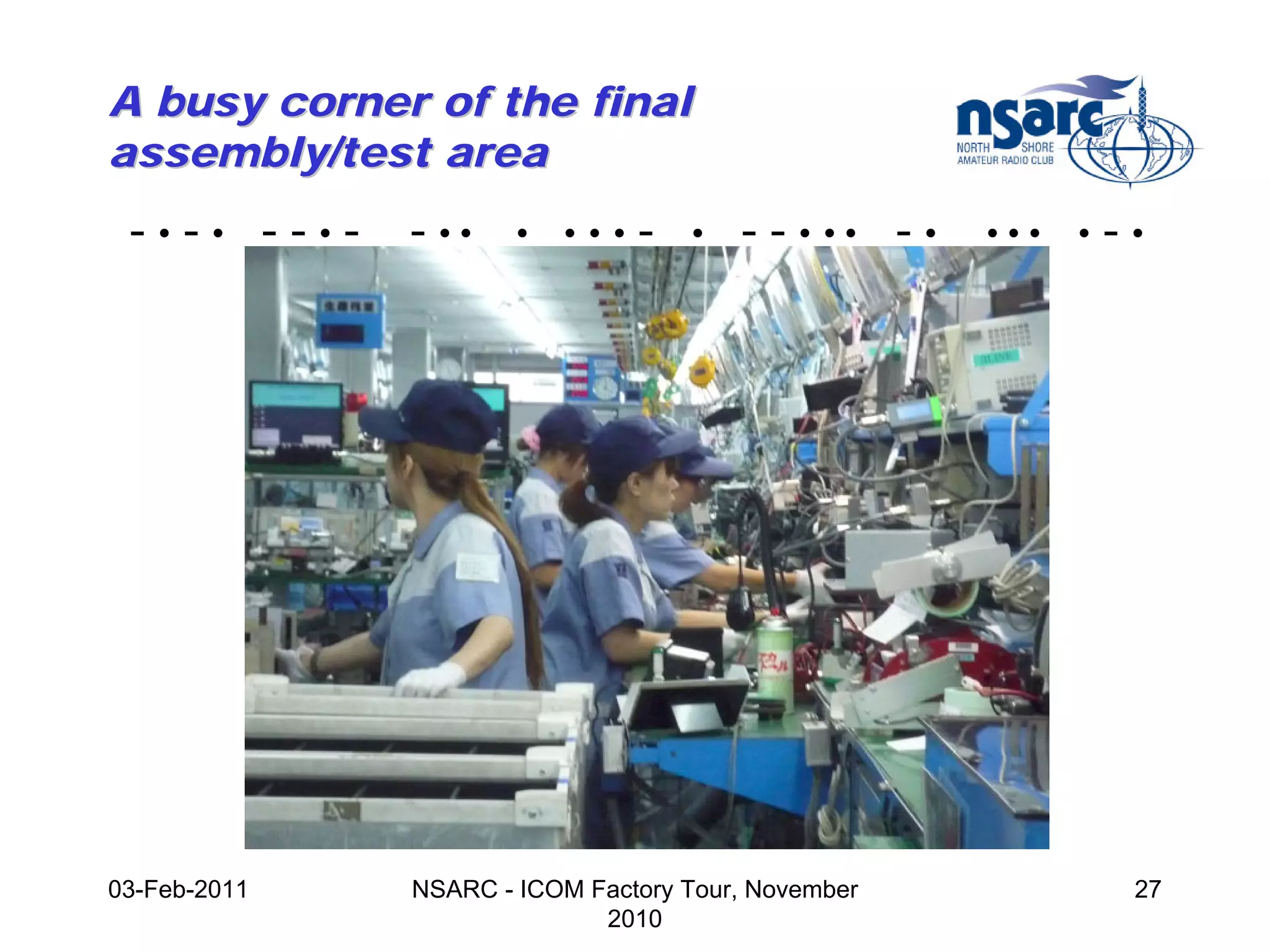

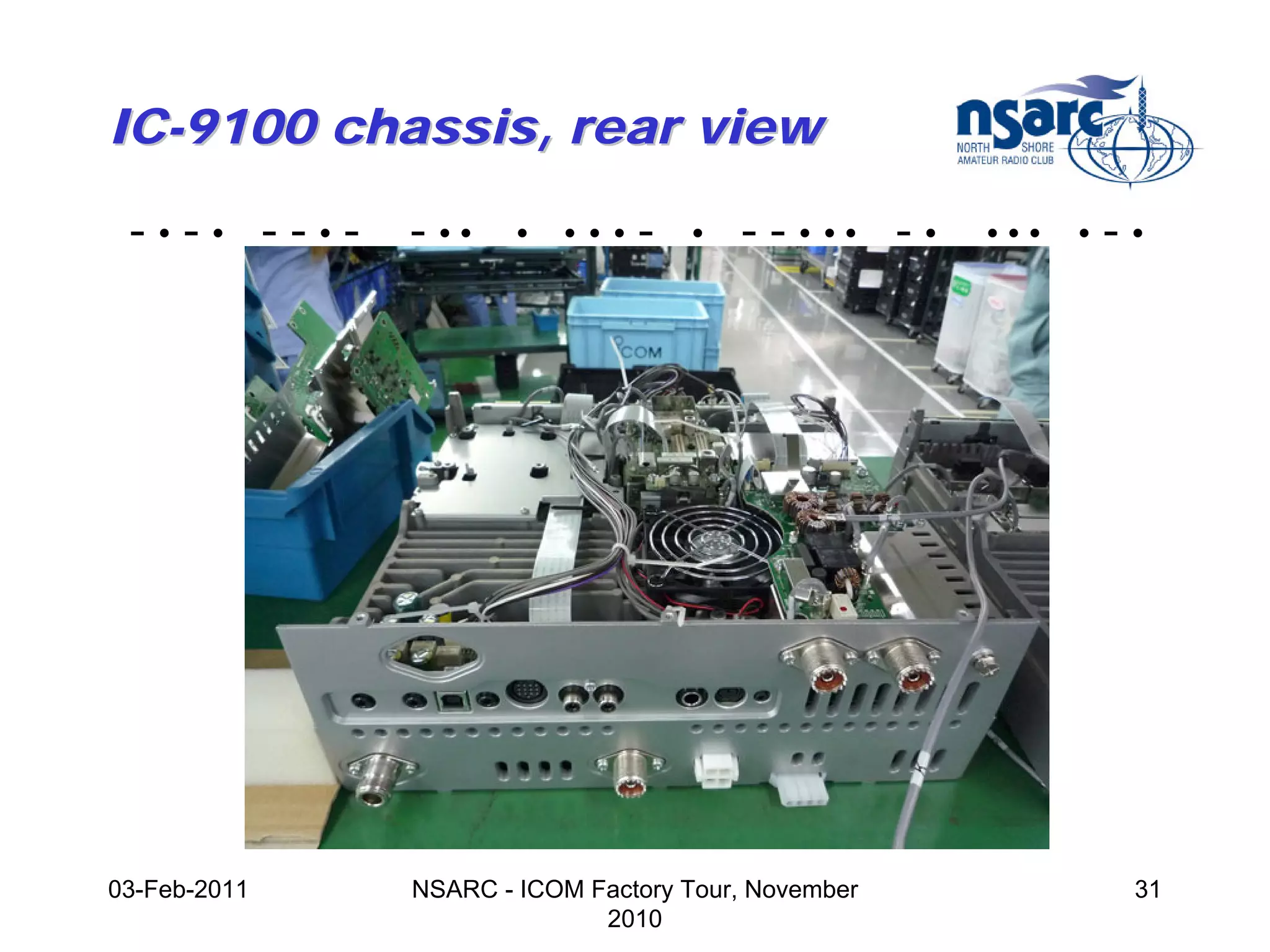

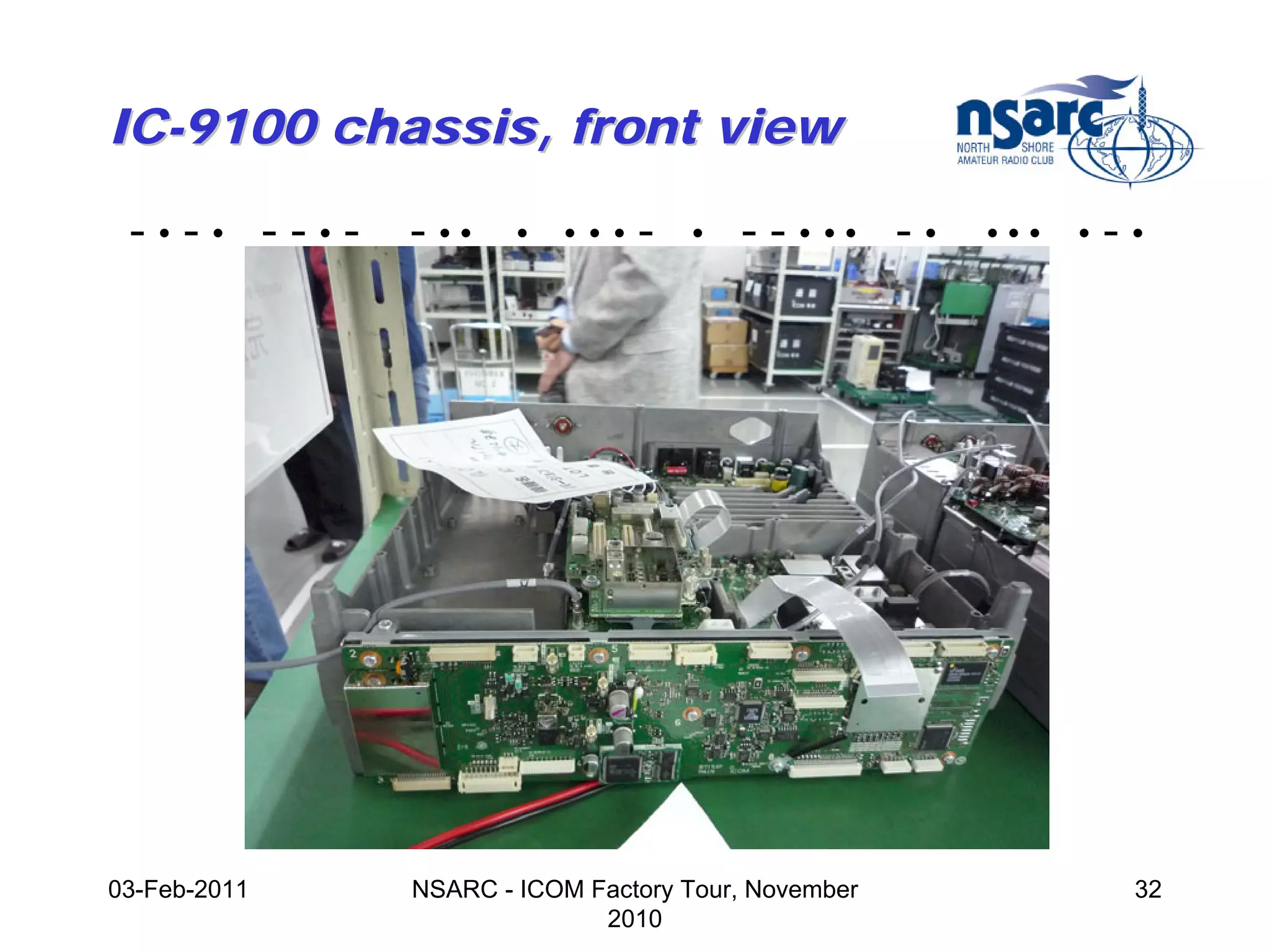

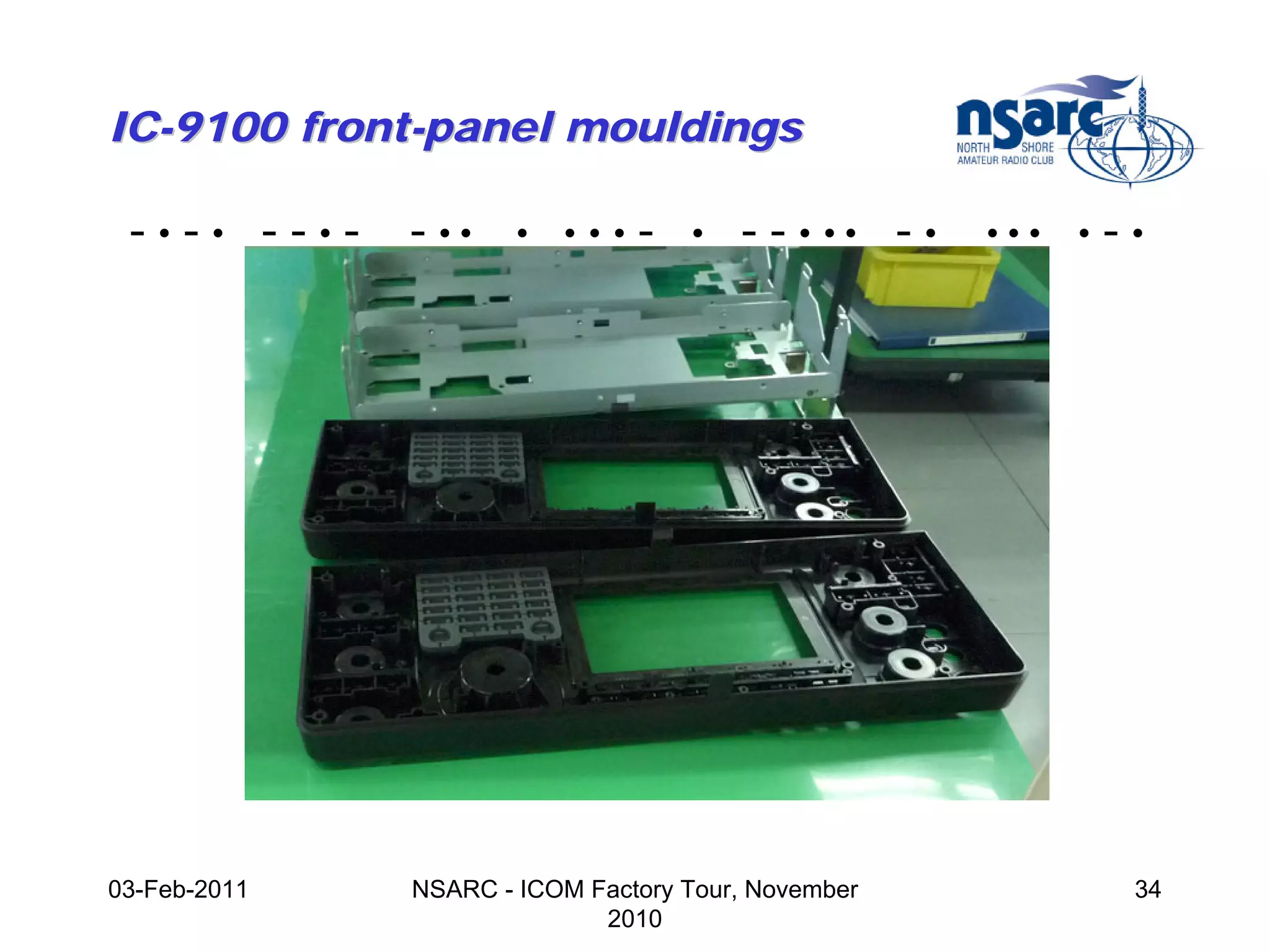

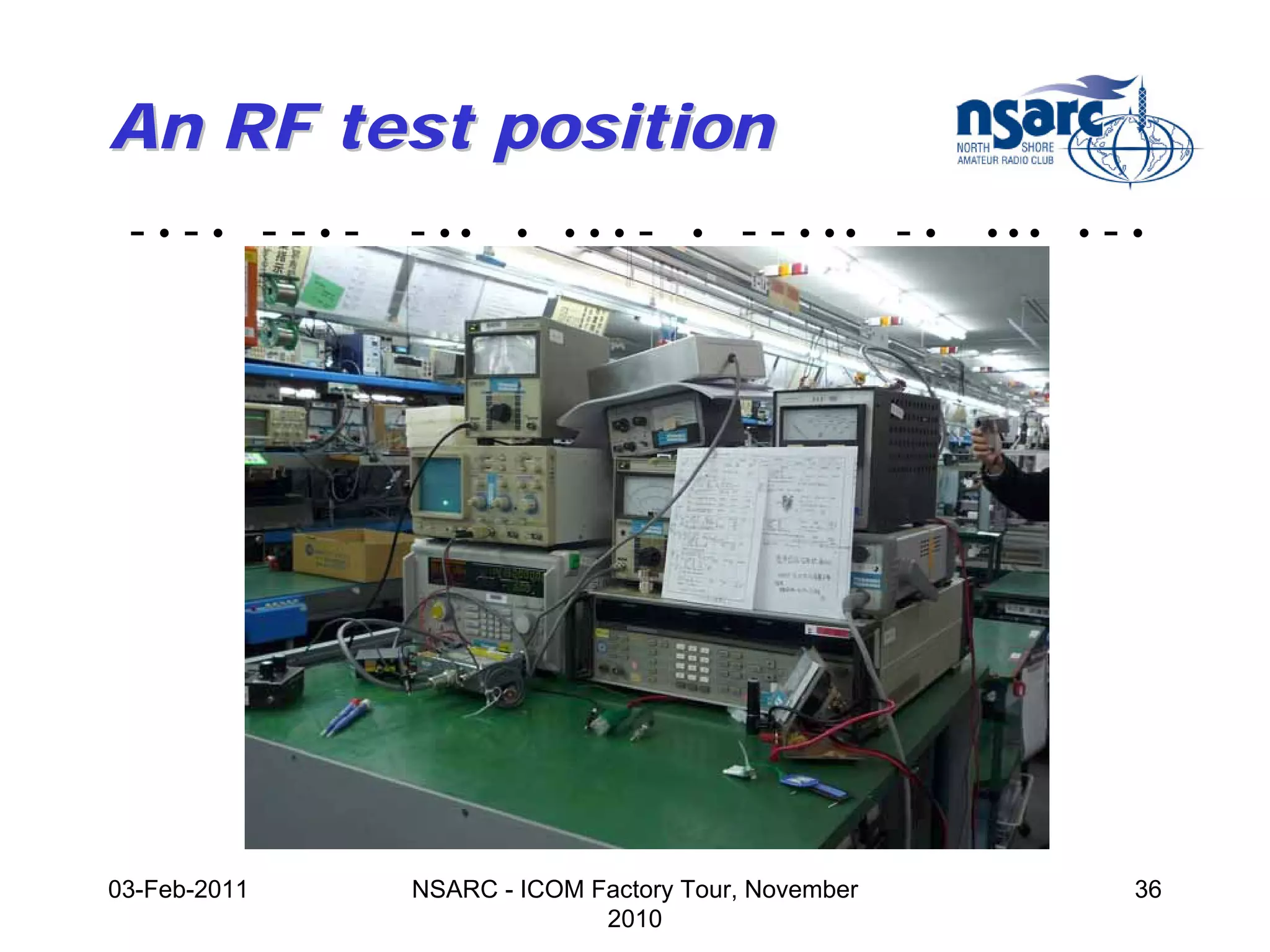

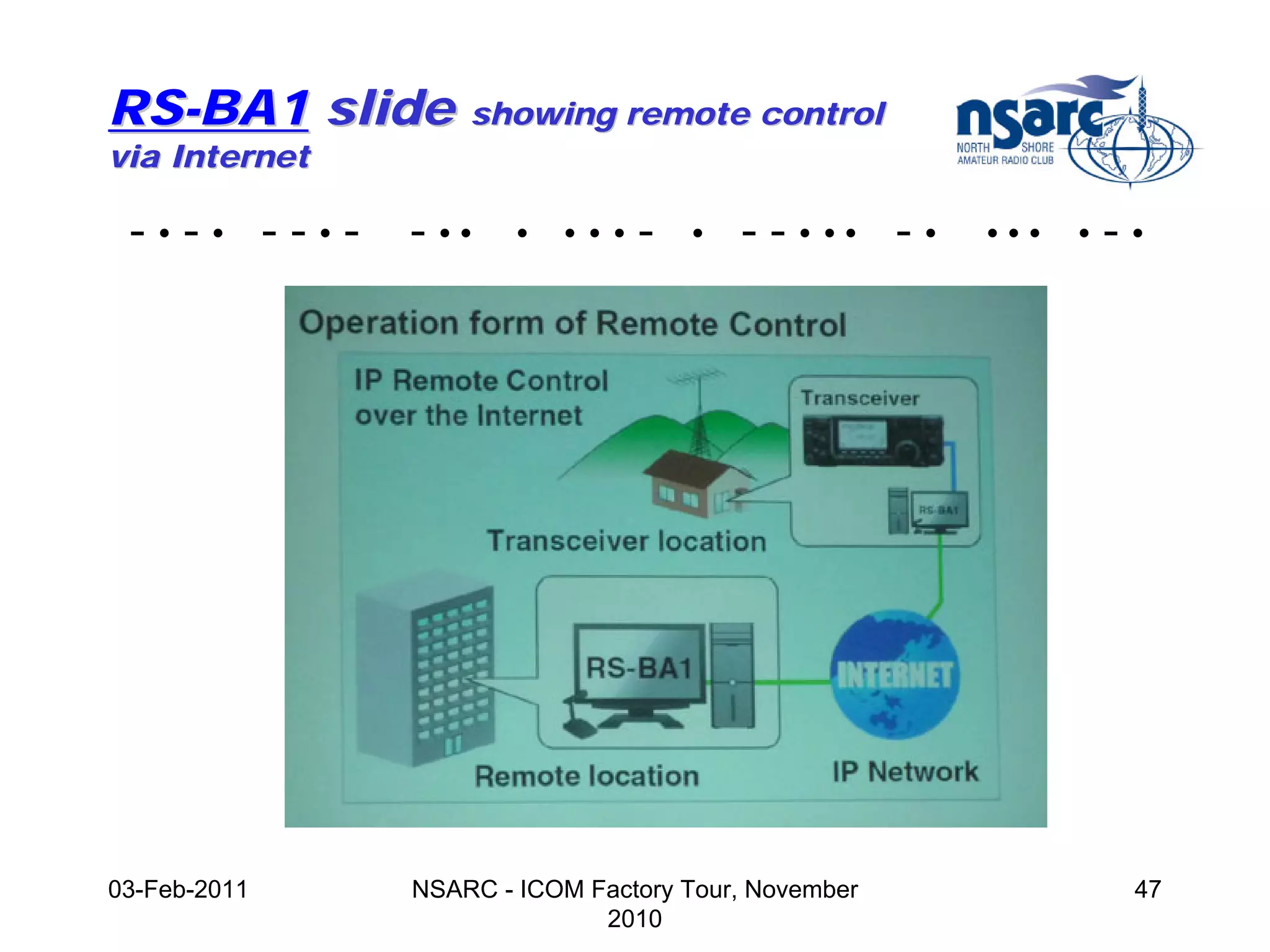

The document summarizes a tour of Icom's manufacturing plant in Wakayama, Japan. Attendees of the Asia-Pacific DX Convention were invited to tour the factory. The factory uses advanced automated systems to produce 130,000 radio units per month across eight production lines. The tour showed various stages of the production process from component handling to board assembly, testing, chassis assembly, packaging, and storage. Icom aims to produce high-quality radios entirely within Japan.