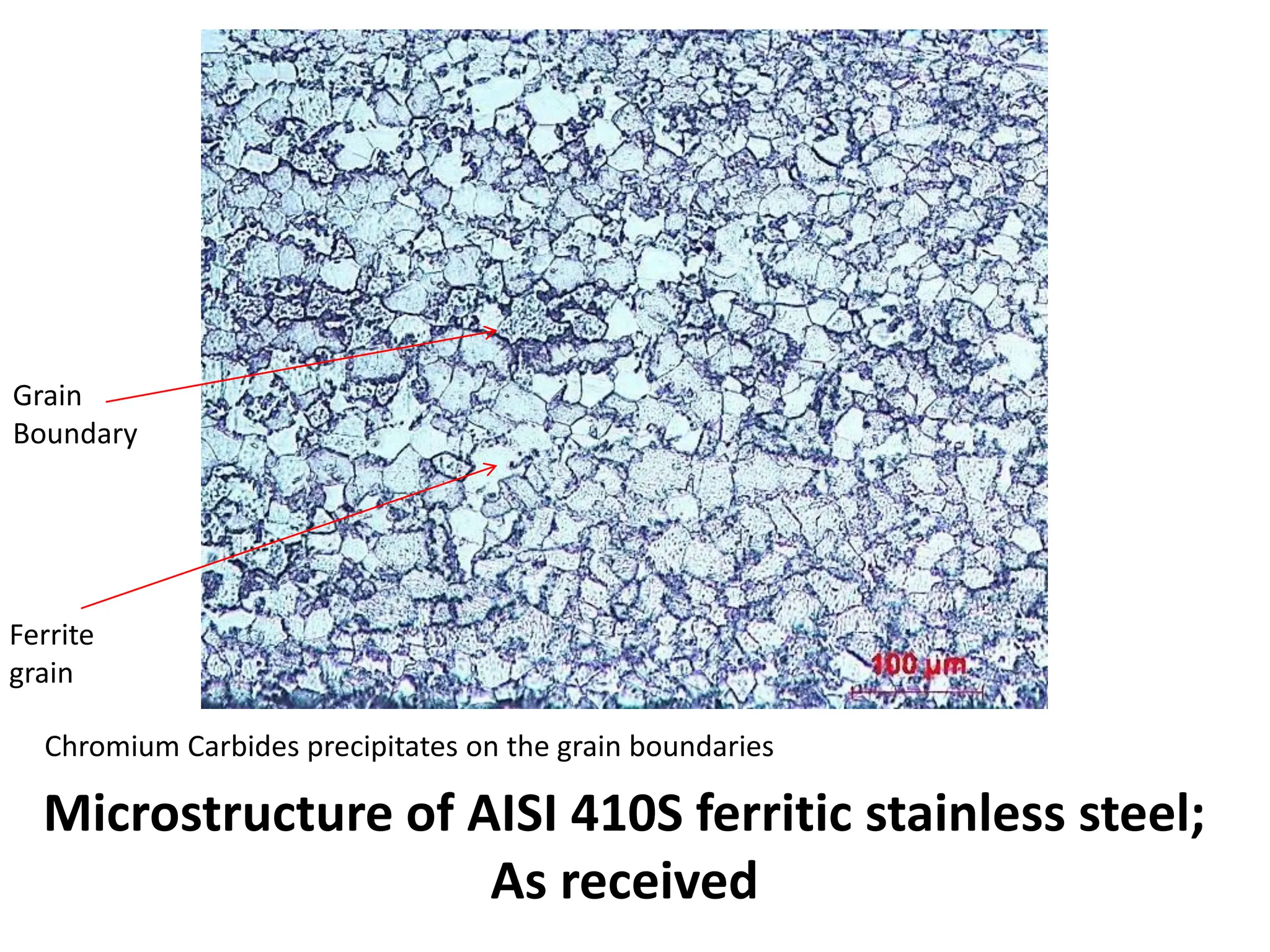

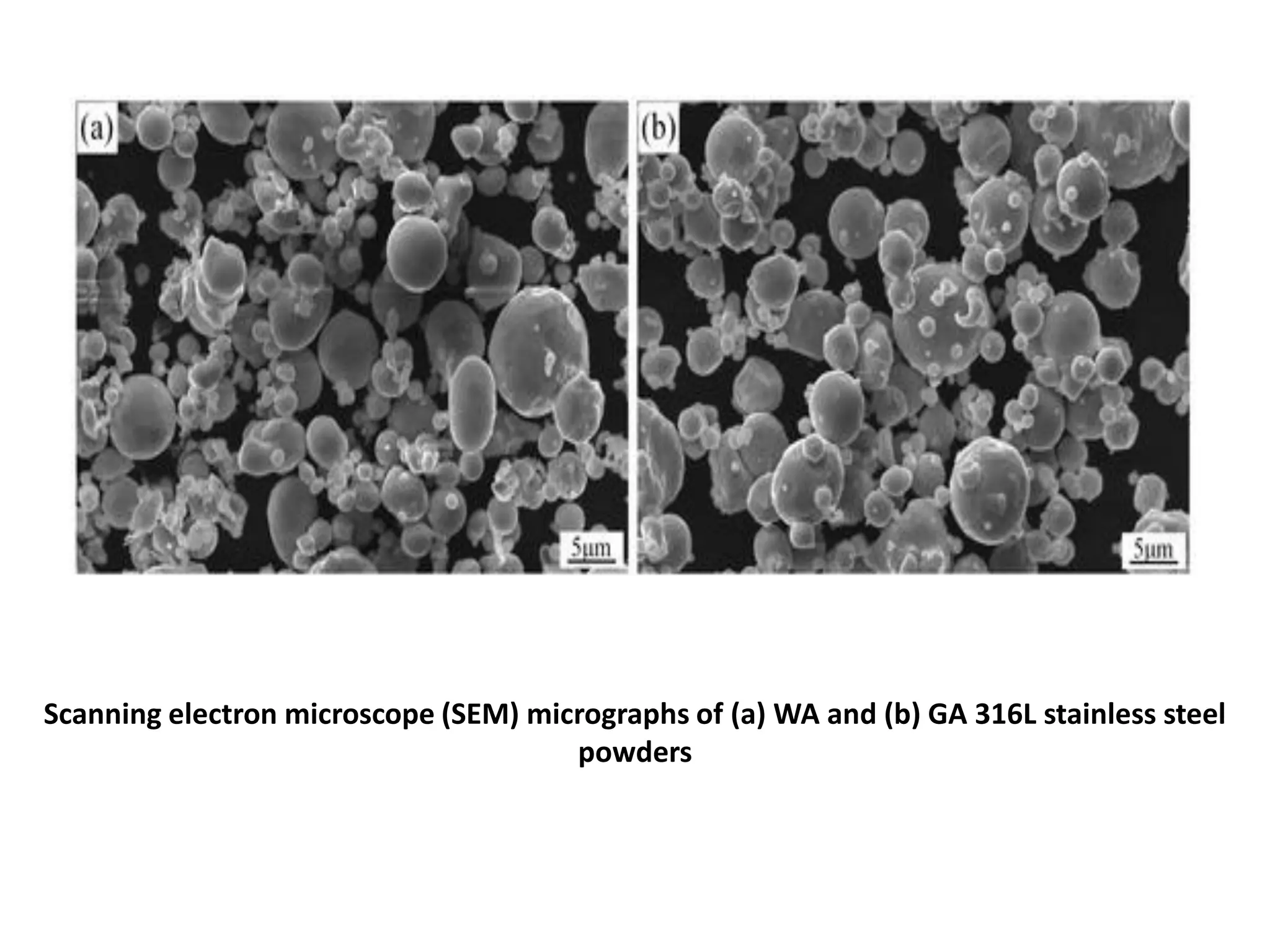

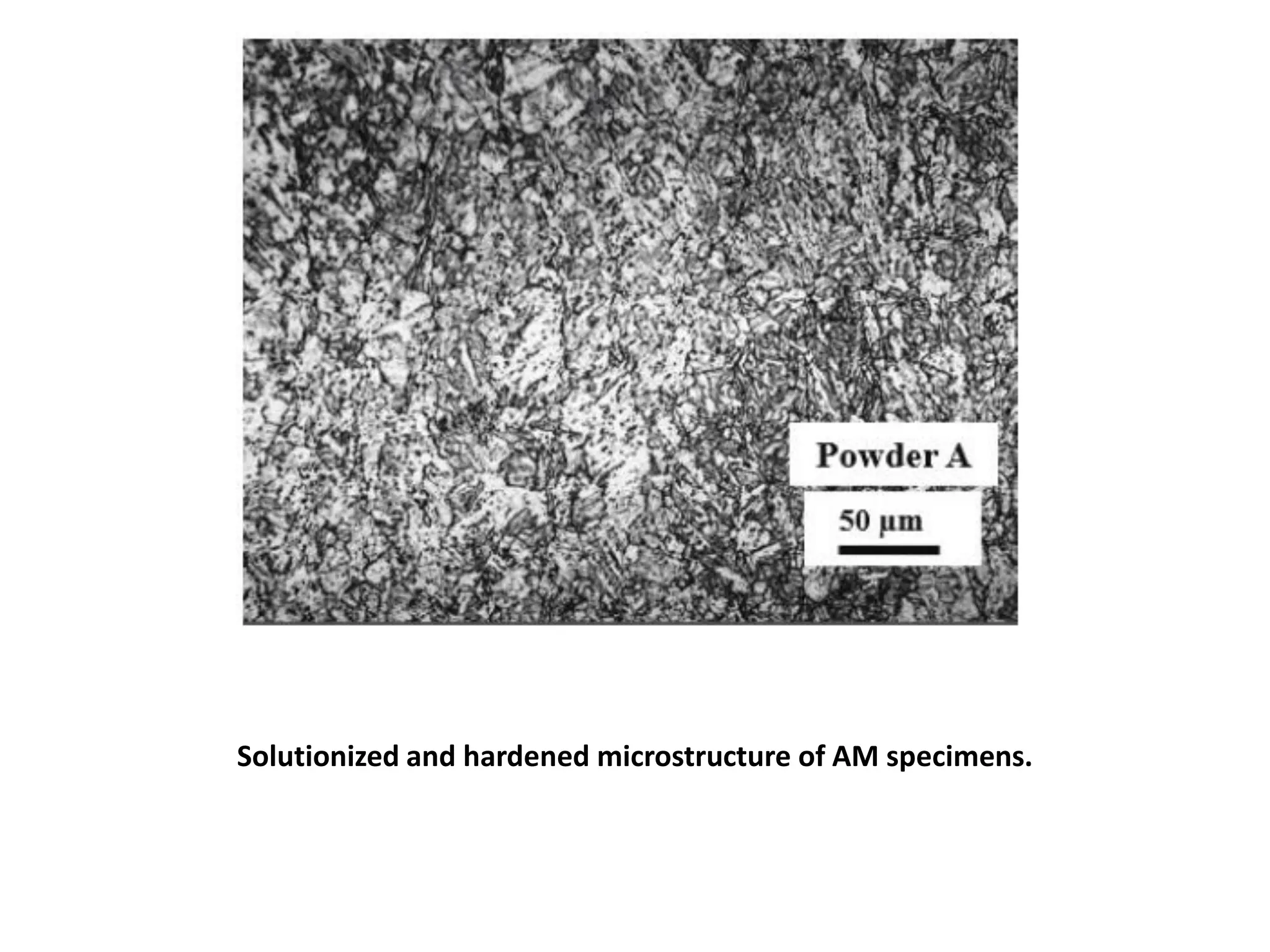

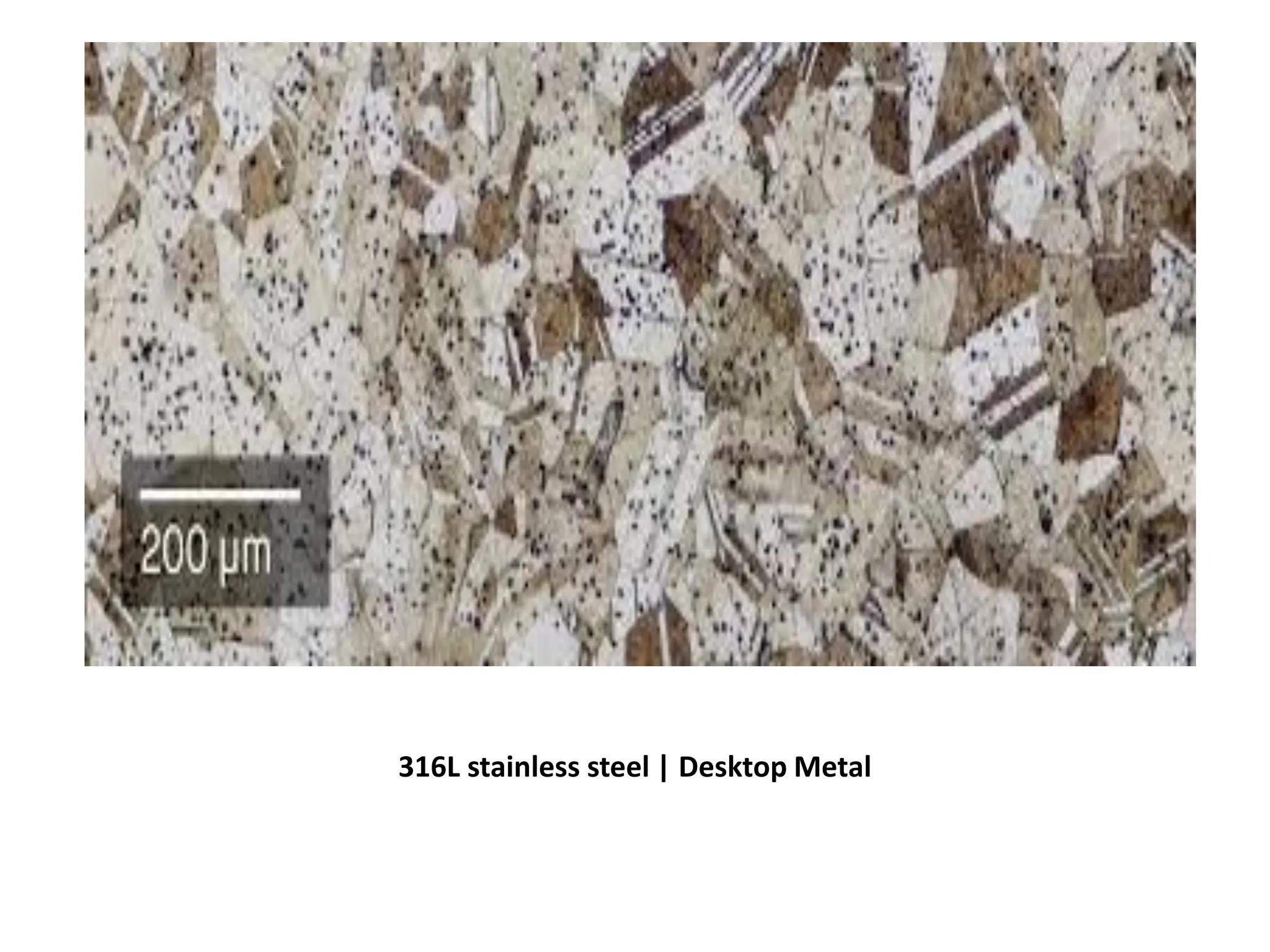

This document discusses the microstructure of various powder metallurgy stainless steels. It shows optical microscope images of the microstructure of austenitic 316L stainless steel, ferritic 410S stainless steel, and duplex and ferritic stainless steels sintered at different temperatures. The microstructures show features like austenite grains, ferrite grains, porosity, twin bands, and chromium carbide precipitates. As sintering temperature increases, the porosity size decreases. The document also discusses sintered stainless steel components and scanning electron microscope images of 316L stainless steel powders.