This document is an overhaul manual for Thermo King TK482 and TK486 diesel engines. It provides specifications, torque values, and step-by-step instructions for disassembling, inspecting, reconditioning, and reassembling the engines. The manual covers both Tier 1 and earlier engine models as well as Tier 2 models, detailing any differences between them. It aims to inform users and should not be considered a complete guide covering all scenarios, as further consultation with Thermo King may be required.

![TK482 & TK486 Diesel Engine Specifications

12

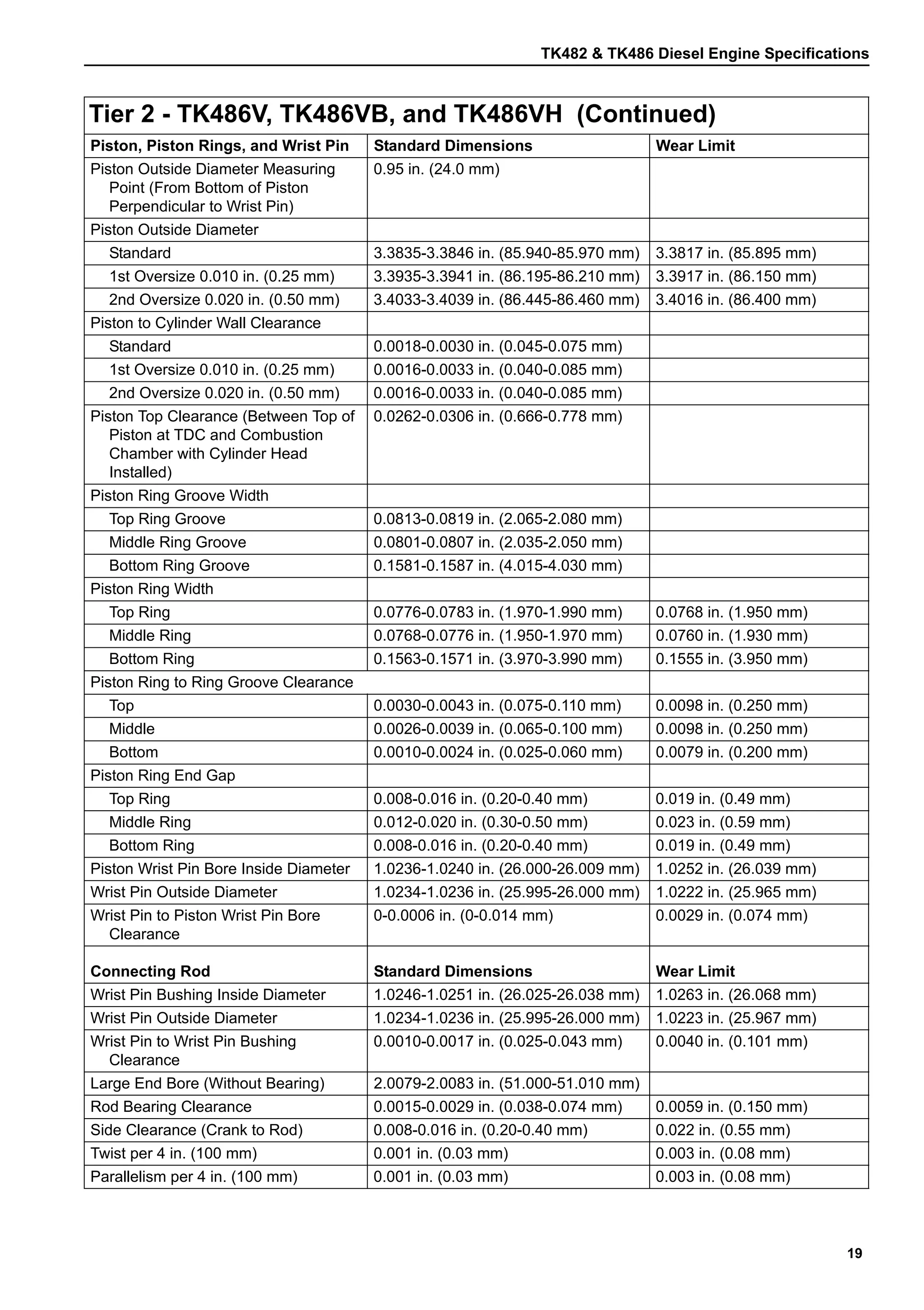

General (Continued)

Oil Pressure 18.5 psi (127 kPa) Minimum @ 230 F (110 C) & 1600 rpm

45-57 psi (310-390 kPa) @ 230 F (110 C) & 2200 rpm

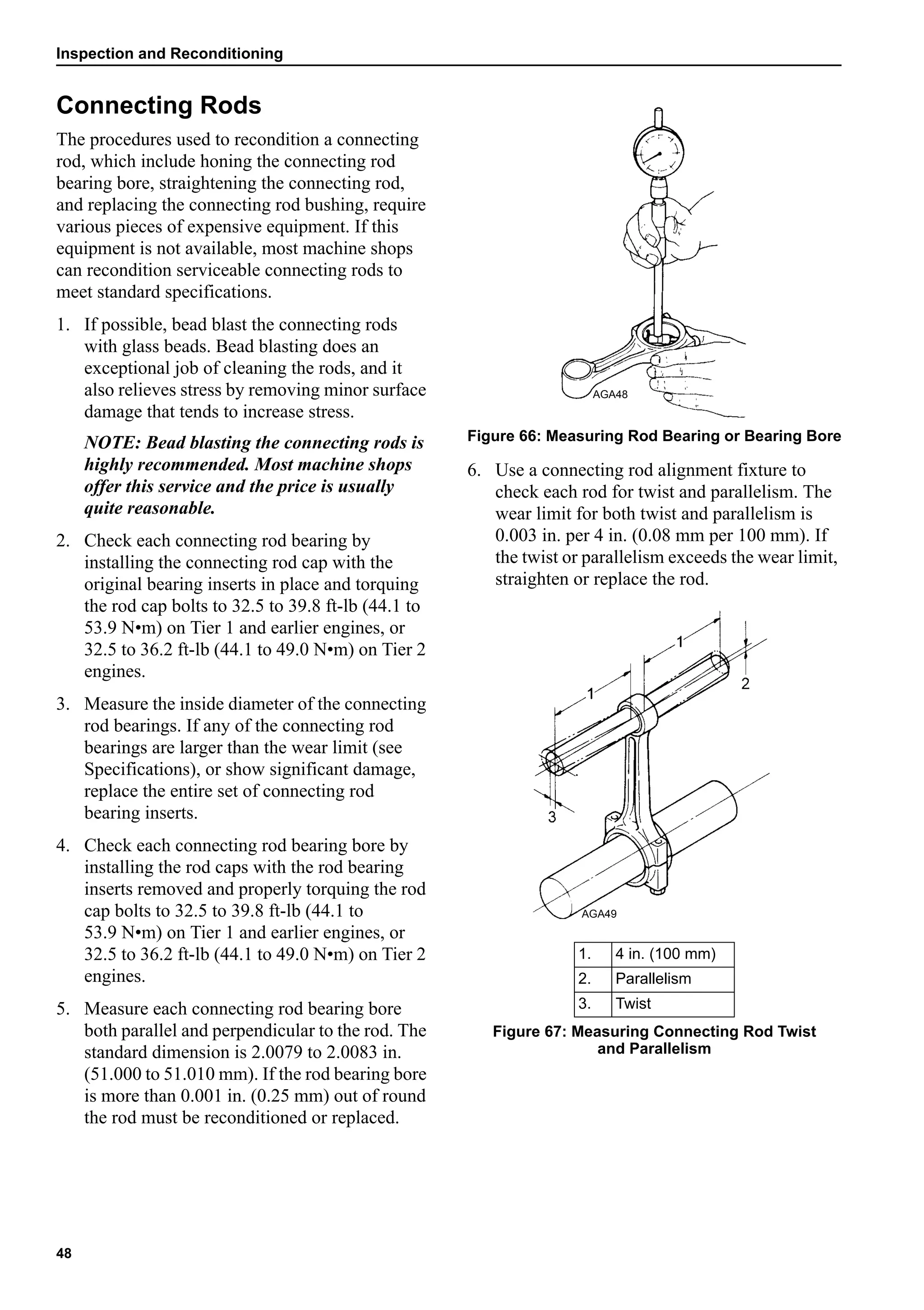

Engine Coolant Thermostat 180 F (82 C)

Valve Clearance (Static @ 70 F [21 C])

Intake 0.006-0.010 in. (0.15-0.25 mm)

Exhaust 0.006-0.010 in. (0.15-0.25 mm)

Valve Train Standard Dimensions Wear Limit

Valve Spring

Free Length 1.75 in. (44.5 mm) 1.67 in. (42.5 mm)

Inclination (Top to Bottom from

Vertical)

0-0.04 in. (0-1.1 mm) 0.04 in. (1.1 mm)

Valve Guide Inside Diameter

Intake 0.3154-0.3159 in. (8.010-8.025 mm) 0.3189 in. (8.100 mm)

Exhaust 0.3156-0.3161 in. (8.015-8.030 mm) 0.3189 in. (8.100 mm)

Valve Stem Outside Diameter

Intake 0.3132-0.3140 in. (7.955-7.975 mm) 0.3110 in. (7.900 mm)

Exhaust 0.3132-0.3138 in. (7.955-7.970 mm) 0.3110 in. (7.900 mm)

Valve Stem to Valve Guide Clearance

Intake 0.0014-0.0028 in. (0.035-0.070 mm) 0.0079 in. (0.200 mm)

Exhaust 0.0018-0.0030 in. (0.045-0.075 mm) 0.0079 in. (0.200 mm)

Valve Margin

Intake 0.0490-0.0569 in. (1.244-1.444 mm) 0.020 in. (0.50 mm)

Exhaust 0.0531-0.0610 in. (1.350-1.550 mm) 0.020 in. (0.50 mm)

Valve Depth (Cylinder Head Deck to

Valve)

Intake 0.0120-0.0199 in. (0.306-0.506 mm) 0.039 in. (1.00 mm)

Exhaust 0.0118-0.0197 in. (0.300-0.500 mm) 0.039 in. (1.00 mm)

Valve Guide Projection (Above Valve

Spring Seat in Cylinder Head)

Intake 0.591 in. (15.00 mm)

Exhaust 0.591 in. (15.00 mm)

Valve Angle

Intake 30 Degrees

Exhaust 45 Degrees

Valve Seat Angle

Intake 30 Degrees

Exhaust 45 Degrees

Valve Seat Width

Intake 0.042-0.049 in. (1.07-1.24 mm) 0.069 in. (1.74 mm)

Exhaust 0.049-0.057 in. (1.24-1.45 mm) 0.076 in. (1.94 mm)

Rocker Arm Bushing Inside Diameter 0.6299-0.6307 in. (16.000-16.020 mm) 0.6335 in. (16.090 mm)

Rocker Arm Shaft Outside Diameter 0.6286-0.6293 in. (15.966-15.984 mm) 0.6280 in. (15.950 mm)

Tier 1 and Earlier -

TK482, TK482E, TK486, TK486E, and TK486EH (Continued)](https://image.slidesharecdn.com/yammarmanualtk486vtk486e1-201015200004/75/Yammar-manual-tk486_v-_tk486e-1-12-2048.jpg)

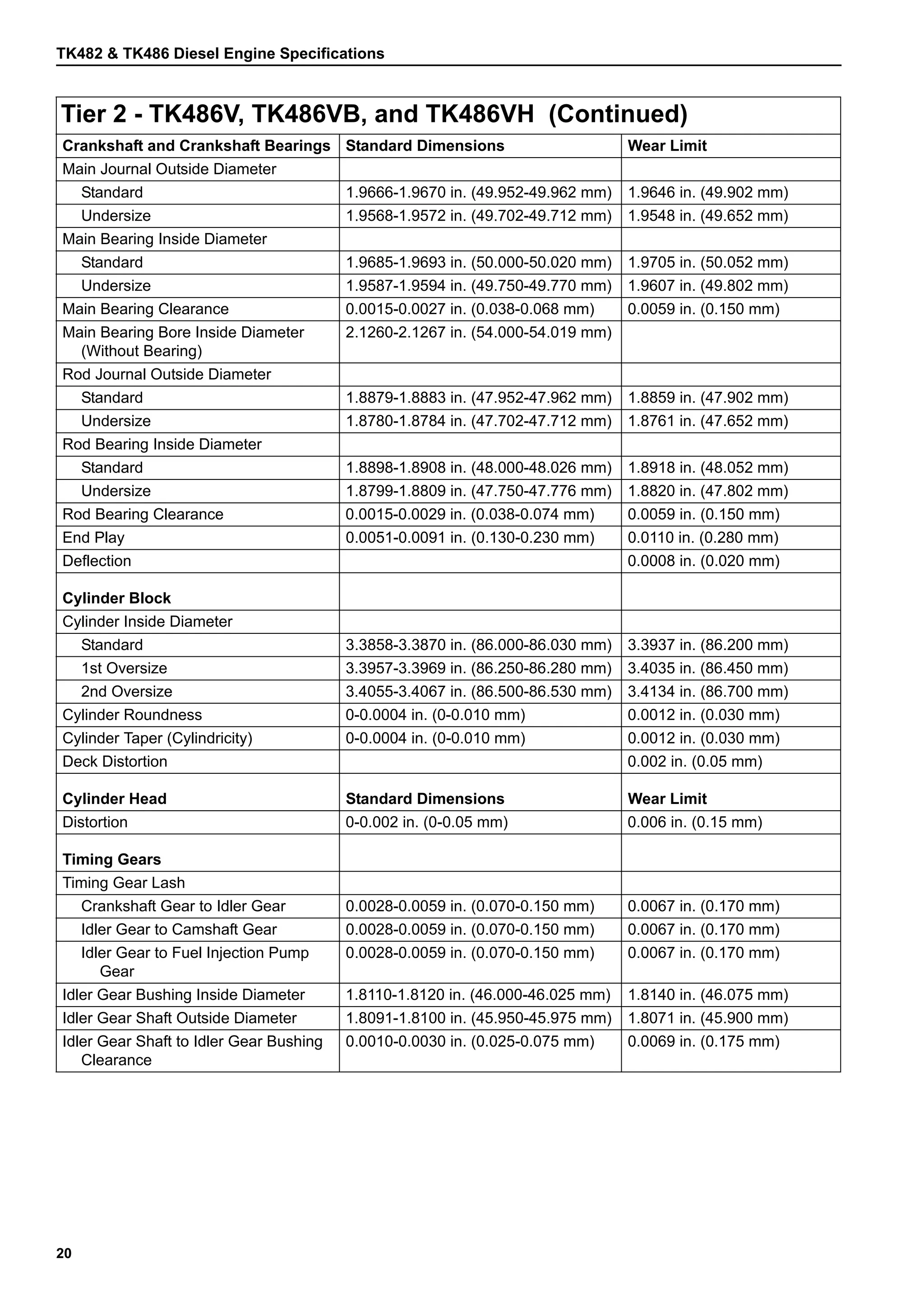

![17

Tier 2 - TK486V, TK486VB, and TK486VH

Except where noted, the specifications for these engines are the same.

General

Type Four Stroke Cycle Water Cooled

Number of Cylinders 4

Cylinder Arrangement In-line Vertical, Number 1 on Flywheel End

Bore 3.39 in. (86.0 mm)

Stroke 3.54 in. (90.0 mm)

Displacement 128 cu. in. (2.09 liters)

Power Rating

TK486V and TK486VB 33.9 hp (25.3 kW) @ 2200 rpm

TK486VH 35.0 hp (26.1 kW) @ 2600 rpm

Compression Ratio 19.1 to 1

Direction of Rotation Counterclockwise (Viewed from Flywheel)

Firing Order 1-3-4-2 (Number 1 on Flywheel End)

Fuel Injection Timing See “Injection Pump Timing Tier 2 Engines” on page 102.

Nozzle Injection Pressure 3,100-3,300 psi (21,600-22,600 kPa)

Oil Pressure 18.5 psi (127 kPa) Minimum @ 230 F (110 C) & 1600 rpm

45-57 psi (310-390 kPa) @ 230 F (110 C) & 2200 rpm

Engine Coolant Thermostat 160 F (71 C)

Valve Clearance (Static @ 70 F [21 C])

Intake 0.006-0.010 in. (0.15-0.25 mm)

Exhaust 0.006-0.010 in. (0.15-0.25 mm)

Valve Train Standard Dimensions Wear Limit

Valve Spring

Free Length 1.65 in. (42.0 mm) 1.63 in. (41.5 mm)

Inclination (Top to Bottom from

Vertical)

0-0.04 in. (0-1.4 mm) 0.06 in. (1.4 mm)

Valve Guide Inside Diameter

Intake 0.3154-0.3159 in. (8.010-8.025 mm) 0.3189 in. (8.100 mm)

Exhaust 0.3156-0.3161 in. (8.015-8.030 mm) 0.3189 in. (8.100 mm)

Valve Stem Outside Diameter

Intake 0.3132-0.3140 in. (7.955-7.975 mm) 0.3110 in. (7.900 mm)

Exhaust 0.3132-0.3138 in. (7.955-7.970 mm) 0.3110 in. (7.900 mm)

Valve Stem to Valve Guide Clearance

Intake 0.0014-0.0028 in. (0.035-0.070 mm) 0.0071 in. (0.180 mm)

Exhaust 0.0018-0.0030 in. (0.045-0.075 mm) 0.0071 in. (0.180 mm)

Valve Margin

Intake 0.053 in. (1.34 mm) 0.020 in. (0.50 mm)

Exhaust 0.057 in. (1.45 mm) 0.020 in. (0.50 mm)](https://image.slidesharecdn.com/yammarmanualtk486vtk486e1-201015200004/75/Yammar-manual-tk486_v-_tk486e-1-17-2048.jpg)

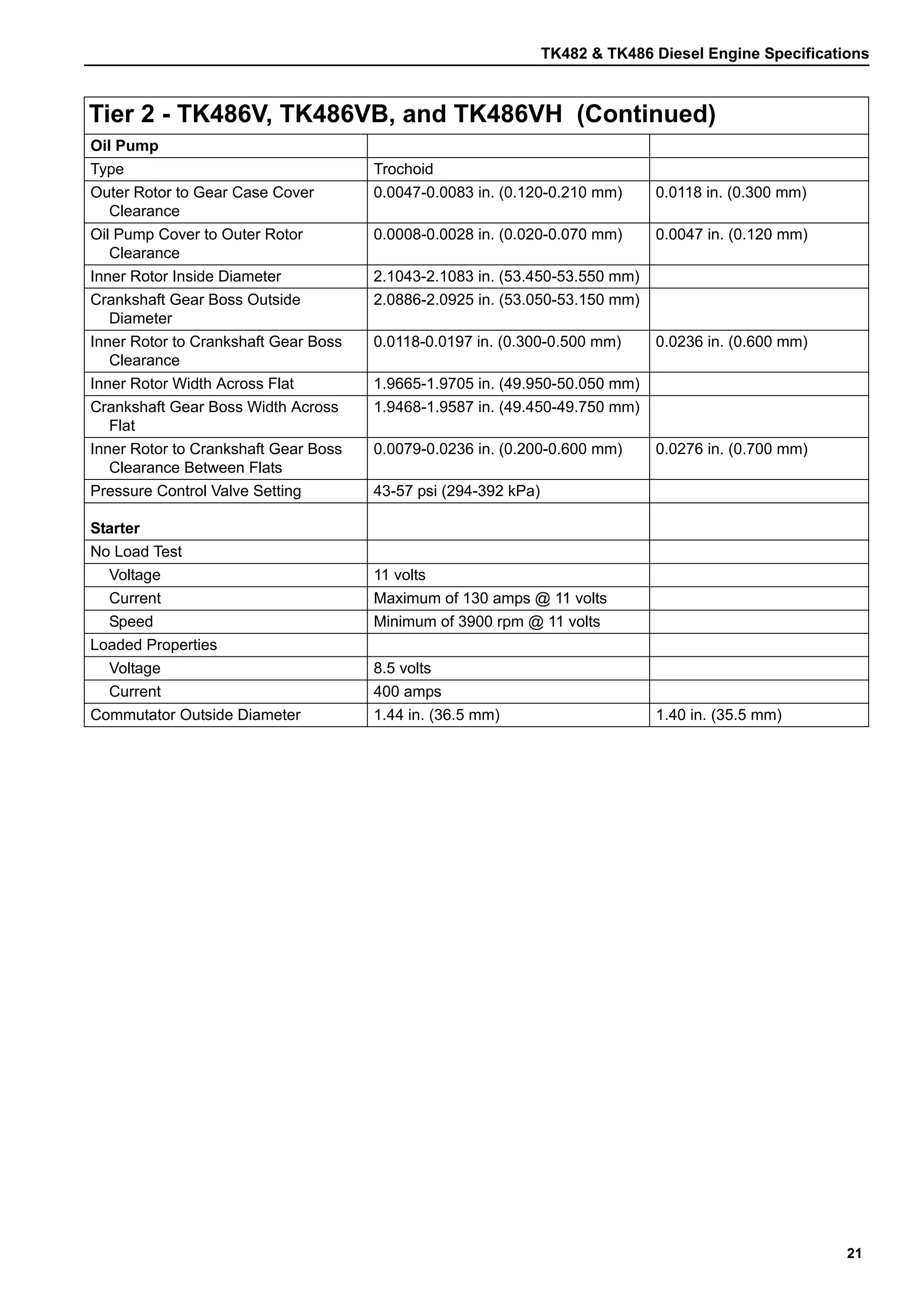

![Inspection and Reconditioning

67

Checking Crankcase Pressure

1. An adapter to check crankcase pressure can be

made from a TK482/486 dipstick (P/N

11-8667) and a fitting (P/N 55-2857).

2. Cut the dipstick off of the cap and cut a

section out of the tab on top of the cap. Make

the section cut out of the tab wide enough to

install the fitting (P/N 55-2857).

3. Drill a 11/32 in. (8.7 mm) hole in the cap. Tap

the hole with an 1/8 in. NPT tap and install the

fitting.

4. This adapter provides a convenient hook-up

for the Magnehelic gauge to monitor

crankcase pressure.

5. To use the adapter, remove the oil dipstick and

replace it with the adapter. Connect the low

pressure side of the Magnehelic gauge (10 in.

[254 mm] minimum) to the adapter and

observe the readings on high and low speed.

1. Fitting

2. Cut Section Out of Tab

3. Dipstick Cap

4. Cut Dipstick Off

Figure 113: Magnehelic Gauge Adapter

1 2 3 4

1. Adapter

2. Magnehelic Gauge

Figure 114: Measuring Crankcase Pressure

1

2](https://image.slidesharecdn.com/yammarmanualtk486vtk486e1-201015200004/75/Yammar-manual-tk486_v-_tk486e-1-67-2048.jpg)

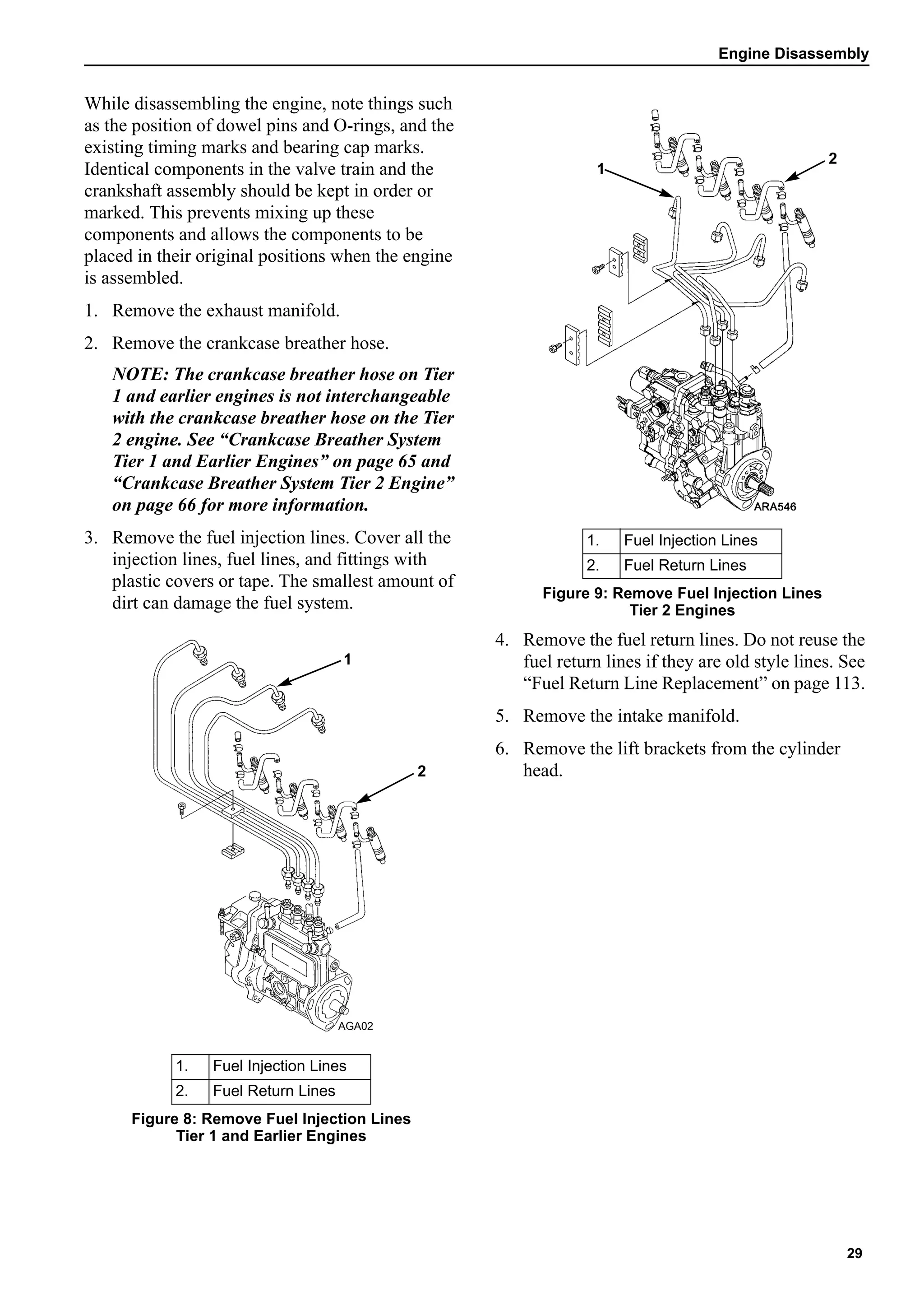

![Fuel System

99

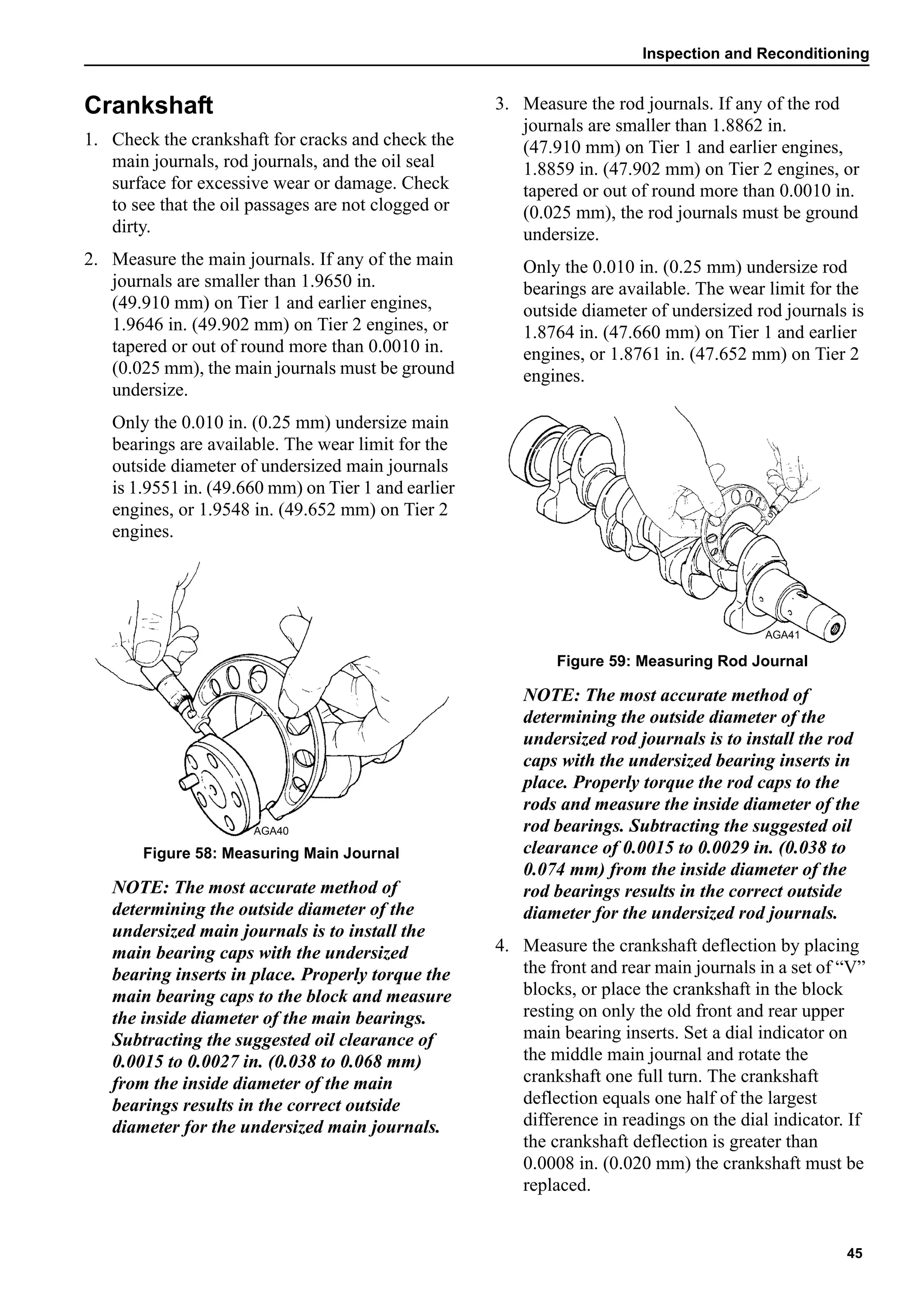

11. Slowly turn the engine in the normal direction

of rotation until you see the fuel rise in the end

of the delivery valve holder. Stop as soon as

you see the fuel rise slowly.

12. Check position of the timing marks.

a. On TK482 and TK486 engines the

injection timing mark on the flywheel

should be aligned with the index mark on

the side of the timing mark access hole.

b. On TK482E and TK468E engines the 10

degree BTDC timing mark on the flywheel

should be aligned with the index mark on

the side of the timing mark access hole.

c. On TK486EH engines the index mark

should align with the midpoint between

the two timing marks on the flywheel.

13. Repeat steps 8 through 12 to recheck the

timing.

14. If the timing is off by more than 1 degree (0.1

in. [2.5 mm]), loosen the mounting nuts on the

studs that fasten the injection pump to the

engine and rotate the injection pump to change

the timing.

a. Pull the top of the injection pump away

from the engine to advance the timing.

b. Push the top of the injection pump toward

the engine to retard the timing.

15. Tighten the injection pump mounting nuts and

recheck the timing. Repeat steps 8 through 15

until the timing is correct.

16. Install the cover in the timing mark access

hole, install the injection line for the number

one cylinder, tighten the other injection lines,

and reconnect the 8S wire to the starter

solenoid when finished with the procedure.

1. Index Mark

2. Injection Mark

Figure 188: Correct Timing Mark Alignment

for TK482 and TK486

1. Index Mark

2. 12 Degree BTDC Timing Mark

3. 10 Degree BTDC Timing Mark

Figure 189: Correct Timing Mark Alignment

for TK482E and TK468E

AEA703

1 2

1 2

3

1. Index Mark

2. 12 Degree BTDC Timing Mark

3. 10 Degree BTDC Timing Mark

Figure 190: Correct Timing Mark Alignment

for TK486EH

1

2

3](https://image.slidesharecdn.com/yammarmanualtk486vtk486e1-201015200004/75/Yammar-manual-tk486_v-_tk486e-1-99-2048.jpg)

![Fuel System

121

Static Air Leaks Tier 1 and Earlier

Engines

There are two places where air can leak into the

static fuel system:

• One is the through the plungers in the

injection pump. It leaks from the pump

camshaft and lifter area around the plungers

and into the fuel galley in the pump. Over the

years the plunger clearances have been

reduced to try to prevent air leaks.

• The other is anywhere else.

If air is leaking through the plungers the engine

will not start, not even try to fire because the air is

in the injection pump.

If the air is getting in anywhere else, it will end up

in the fuel filter and the engine will start, run for a

few seconds, and then die. In this case you may

see an Alarm Code 63 on a unit with a

microprocessor.

Solution for Static Air Leaks

Understanding the problem helped find a solution.

The vacuum cannot be stopped from forming in

return line. The air leakage at the injection pump

plungers can be minimized, but not stopped. The

solution was to stop the vacuum from forming in

the whole system by moving the 5-psi (34-kPa)

relief valve from the outlet of the injection pump

to the return fuel outlet in the fuel filter head.

NOTE: Even though it is often called a check

valve, it functions as a relief valve, not a check

valve. A check valve would close when return

fuel tried to go to the tank. This functions a 5-psi

(34-kPa) relief valve. When the return fuel

pressure reaches 3 to 5 psi (21 to 34 kPa), the

spring in the relief valve allows the piston to

retract, which allows the return fuel to flow back

to the fuel tank. When the engine stops, the

spring pushes the piston closed and traps a

positive pressure in the fuel system. The relief

valve is not always a perfect seal, but as the

pressure side drops from leakage, the spring

pushes the piston closed tighter. By the time the

pressure reaches zero, the piston is usually

completely sealed.

This relief valve has been installed on production

units since 1999 and many units have been

retrofitted with kit P/N 10-342.

This solution provides a positive way to keep

5 psi (34 kPa) in the injection pump when the

engine is running to answer Yanmar's

requirement, and prevents a vacuum from forming

in the fuel system when the engine is off.

NOTE: You must remove the original Yanmar

relief valve from the injection pump when

installing kit P/N 10-342. If not, it will take a

pressure of at least 10 psi (69 kPa) to overcome

the relief valves. This will make it much harder

to prime the system with the hand pump.

FAQ (Frequently Asked Questions)

If the unit is leaking air when it’s off, why

doesn't it leak fuel when it runs?

It is probably a matter of time and size. Most of

the hard starting problems caused by air take a

long engine off period, usually days or weeks,

indicating they are extremely small. It could be

that the fuel boils off a warm engine before it is

even seen.

Why can't I find the leaks when I pressurize

the fuel system?

Again, it is time and size. If you pressurize the

fuel tank, do not go over 5 to 10 psi (34 to 69

kPa). Never pressurize a fuel system without a

relief valve in the supply regulator set at 10 psi

[69 kPa] maximum. A leak that pulls in 50 cc of

air in a week (enough to affect starting) is going to

take hours or days to show under pressure.

How can I check the fuel return relief valve?

Probably the quickest way is to replace it. If that

fixes it, then that was the problem. If not, it means

it is something else, or you have another faulty

relief valve.

The only sure way of checking a relief valve is to

take a clear hose at least 8 ft (2.4 m) long and

immerse it in water or fuel. Make sure the hose

fills completely with liquid. Keep the hose

immersed and insert the outlet end of the valve

into the hose. Slowly raise the valve out of the

liquid with the hose following it. The liquid

should not drop out of the hose. Raise the valve

8 ft (2.4 m) in the air and keep the other end of the](https://image.slidesharecdn.com/yammarmanualtk486vtk486e1-201015200004/75/Yammar-manual-tk486_v-_tk486e-1-121-2048.jpg)

![Electrical

134

During the time the fuel solenoid relay is

momentarily energized, the fuel solenoid pull-in

coil is energized by the 2A circuit through the

normally open contacts of the fuel solenoid relay

and the 8DP circuit.

When power is removed from the 8D circuit the

fuel solenoid hold-in coil is de-energized, and the

fuel solenoid resets.

Troubleshooting the Fuel Solenoid Timer

System

NOTE: The fuel solenoid pull-in coil will

require 35 to 45 amps to turn on the fuel. The

unit’s battery must be in good condition. If the

battery has enough power to crank the engine

over, it has enough power to energize the fuel

solenoid pull-in coil.

If you suspect that the engine does not run

because the fuel solenoid is not operating

correctly, use the following procedure:

1. Disconnect the fuel solenoid wire connector

from the main wire harness.

2. Turn the unit on to energize the fuel solenoid

circuits. If the unit has a microprocessor, use

the microprocessor keypad to enter the Relay

Board Test Mode. Energize the fuel solenoid

circuits by energizing the run relay [RUNR]

with the Relay Board Test Mode.

3. Check the voltage on the 8D circuit (pin A) in

the main wire harness connector for the fuel

solenoid. Refer to the following illustrations

to identify the pins in the wire connectors.

a. If battery voltage is not present on the 8D

circuit, check the 8D circuit and the

related circuits and components for a fault.

b. If battery voltage is present on the 8D

circuit, go to step 4.

Figure 263: Main Wire Harness

Connector Pin Identification

4. Check the CH circuit (pin C) in the main wire

harness connector for continuity to a good

chassis ground.

a. If there is no continuity between the CH

circuit and a good chassis ground, check

the CH wire for an open circuit.

b. If there is continuity between the CH

circuit in the main wire harness at the fuel

solenoid wire connector and a good

chassis ground, go to step 5.

1. Fuel Solenoid Relay Contacts

2. Fuel Solenoid Pull-In Coil

3. Fuel Solenoid Hold-In Coil

4. Fuel Solenoid Timer

5. Fuel Solenoid Relay Coil

Figure 262: Simplified Schematic Diagram

of Fuel Solenoid System

1

2

3

45

AGA310

1. Red (8D)

2. White (8DP)

3. Black (CH)

Figure 264: Fuel Solenoid

Connector Pin Identification

AEA704

AEA633](https://image.slidesharecdn.com/yammarmanualtk486vtk486e1-201015200004/75/Yammar-manual-tk486_v-_tk486e-1-134-2048.jpg)

![Electrical

135

5. Place a jumper wire between the black wire

(CH—pin C) in the fuel solenoid connector

and a good chassis ground.

6. Test the pull-in coil by momentarily placing a

jumper between the white wire (8DP—pin B)

in the fuel solenoid connector and the positive

battery terminal. The fuel solenoid should

make a definite click when the pull-in coil is

energized and should click again when the

pull-in coil is de-energized.

NOTE: The pull-in coil will draw 35 to 45

amps so do not leave the jumper connected to

the white wire (8DP—pin B) for more than a

few seconds.

a. If the pull-in coil does not energize, check

the resistance of the pull-in coil by placing

an ohmmeter between the white wire

(8DP—pin B) and the black wire (CH—

pin C) in the fuel solenoid connector. The

resistance of the pull-in coil should be 0.2

to 0.3 ohms. If the resistance of the pull-in

coil is not in this range, replace the fuel

solenoid.

NOTE: If the pull-in coil fails, make sure to

replace the fuel solenoid relay with relay

P/N 41-893. This particular relay is needed

for the high current flow through the hold-in

coil.

b. If the pull-in coil does energize, go to

step 7.

7. Test the hold-in coil.

a. Energize the hold-in coil by placing a

jumper between the red wire (8D—pin A)

in the fuel solenoid connector and the

positive battery terminal.

b. Momentarily energize the pull-in coil by

placing a jumper between the white wire

(8DP—pin B) in the fuel solenoid

connector and the positive battery

terminal. The fuel solenoid should make a

definite click when the pull-in coil is

energized, but should not click when the

pull-in coil is de-energized.

c. De-energize the hold-in coil by removing

the jumper from the red wire (8D—pin A)

and the positive battery terminal. The fuel

solenoid should make a definite click

when the hold-in coil is de-energized.

d. If the hold-in coil does not function

properly, check the resistance of the

hold-in coil by placing an ohmmeter

between the red wire (8D—pin A) and the

black wire (CH—pin C) in the fuel

solenoid connector. The resistance of the

hold-in coil should be 24 to 29 ohms. If

the resistance of the hold-in coil is not in

this range, replace the fuel solenoid.

e. If the hold-in coil does function properly,

go to step 8.

8. Reconnect the fuel solenoid connector and the

main wire harness connector.

9. Remove the fuel solenoid relay from its socket

and make sure the unit is turned on, and is in

the Relay Board Test Mode [RUNR] if it has a

microprocessor.

10. Check the voltage on the 8D circuit at the 86

terminal in the fuel solenoid relay socket.

Refer to the following illustration to identify

the terminals in the relay socket.

a. If battery voltage is not present on the 8D

circuit, check the 8D circuit and the

related circuits and components for a fault

(minimum voltage is 10 volts).

b. If battery voltage is present on the 8D

circuit, go to step 11.

1. 30 Terminal—2A Circuit

2. 86 Terminal—8D Wire

3. 87 Terminal—8DP Wire

4. 85 Terminal to Capacitor and Diode

Figure 265: Relay Socket Terminal Identification

1 2

34](https://image.slidesharecdn.com/yammarmanualtk486vtk486e1-201015200004/75/Yammar-manual-tk486_v-_tk486e-1-135-2048.jpg)