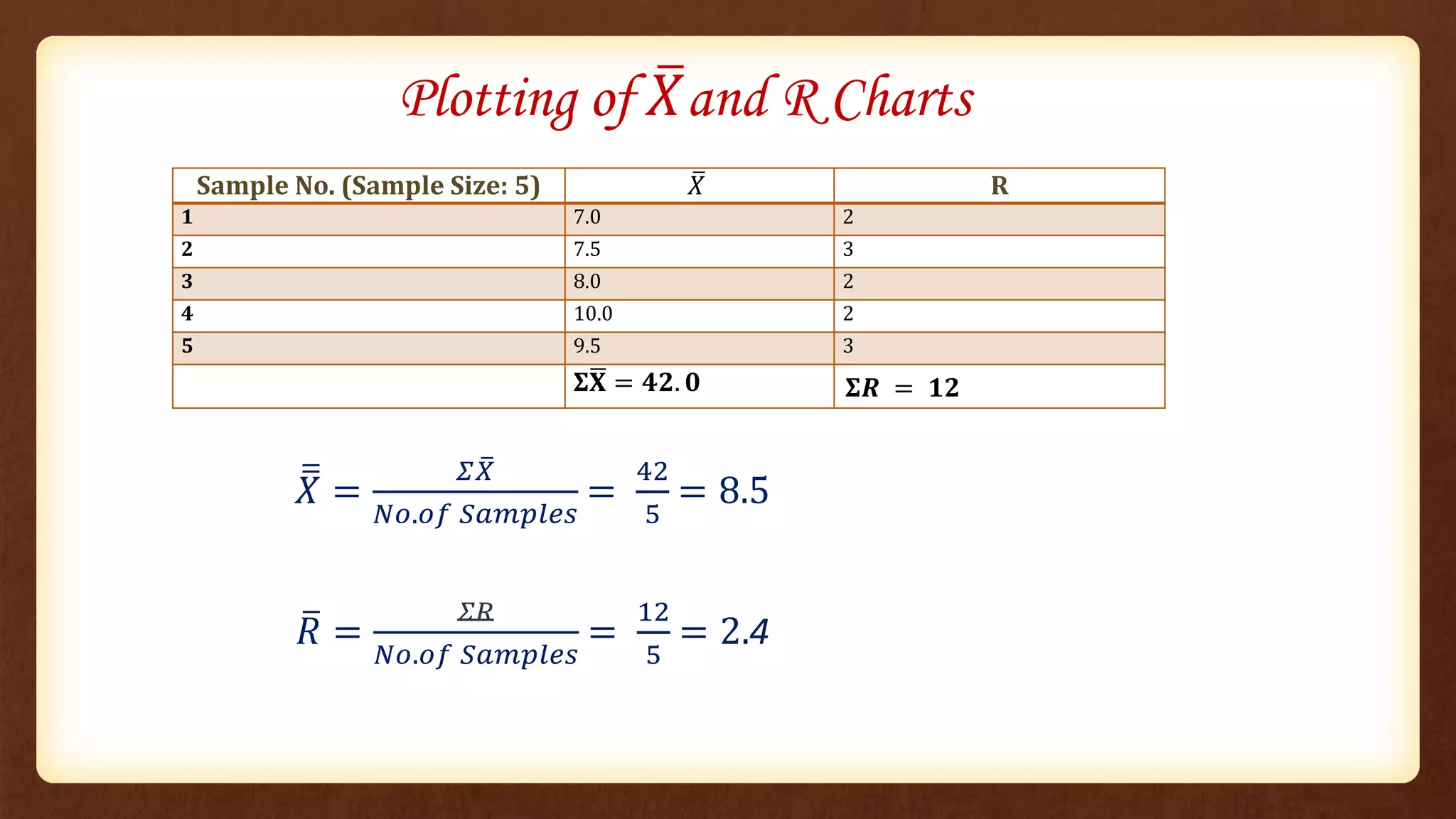

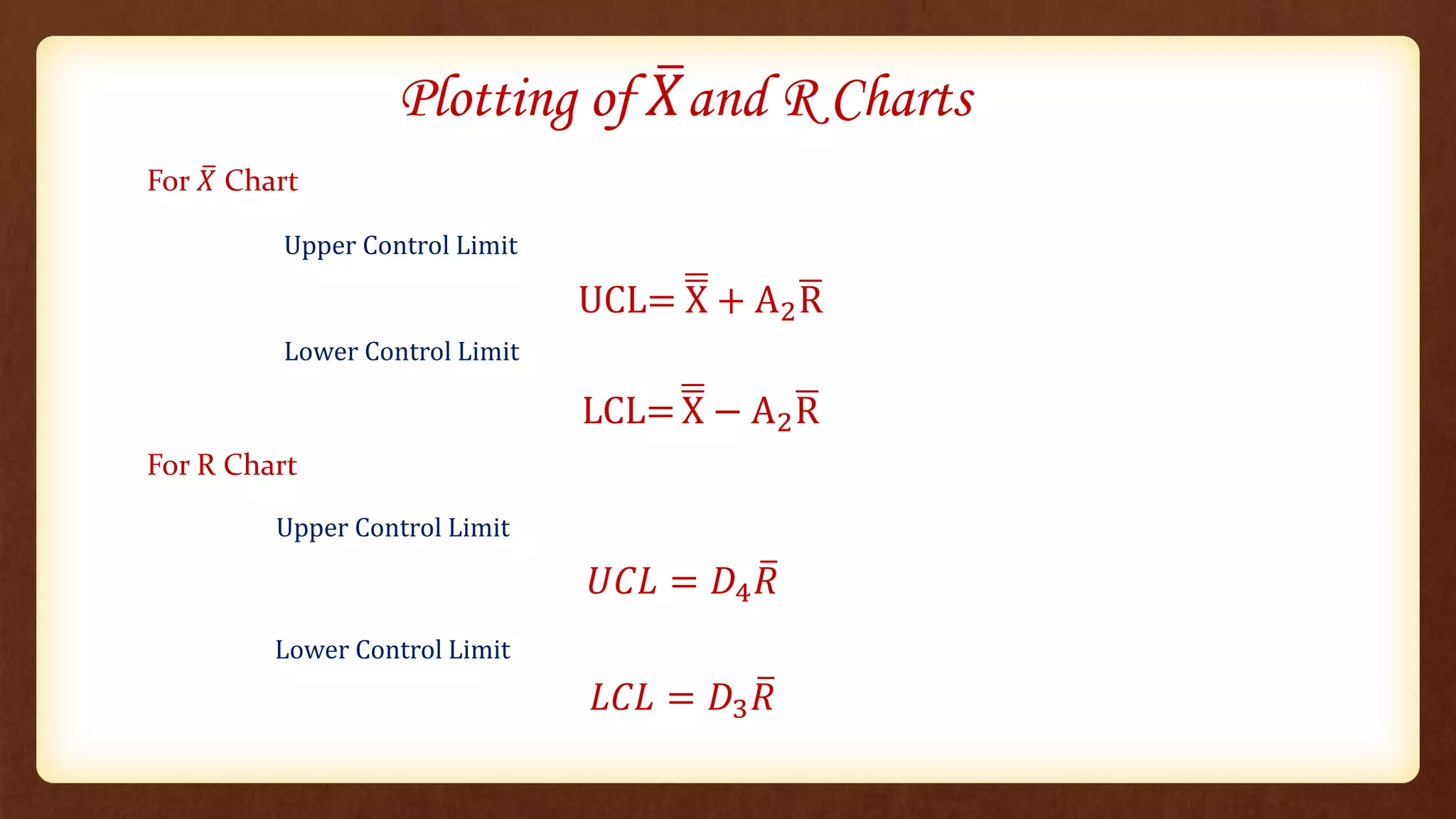

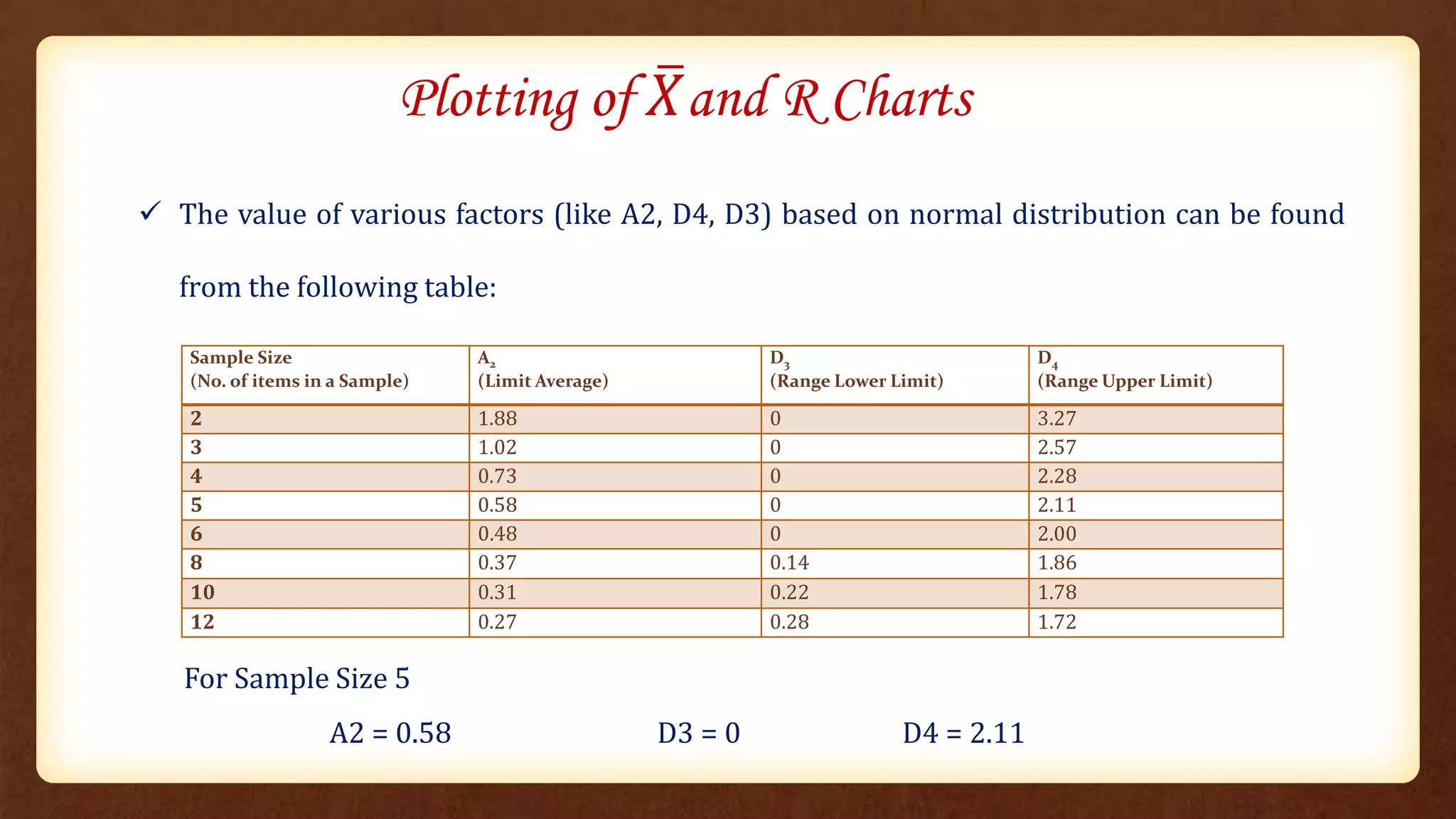

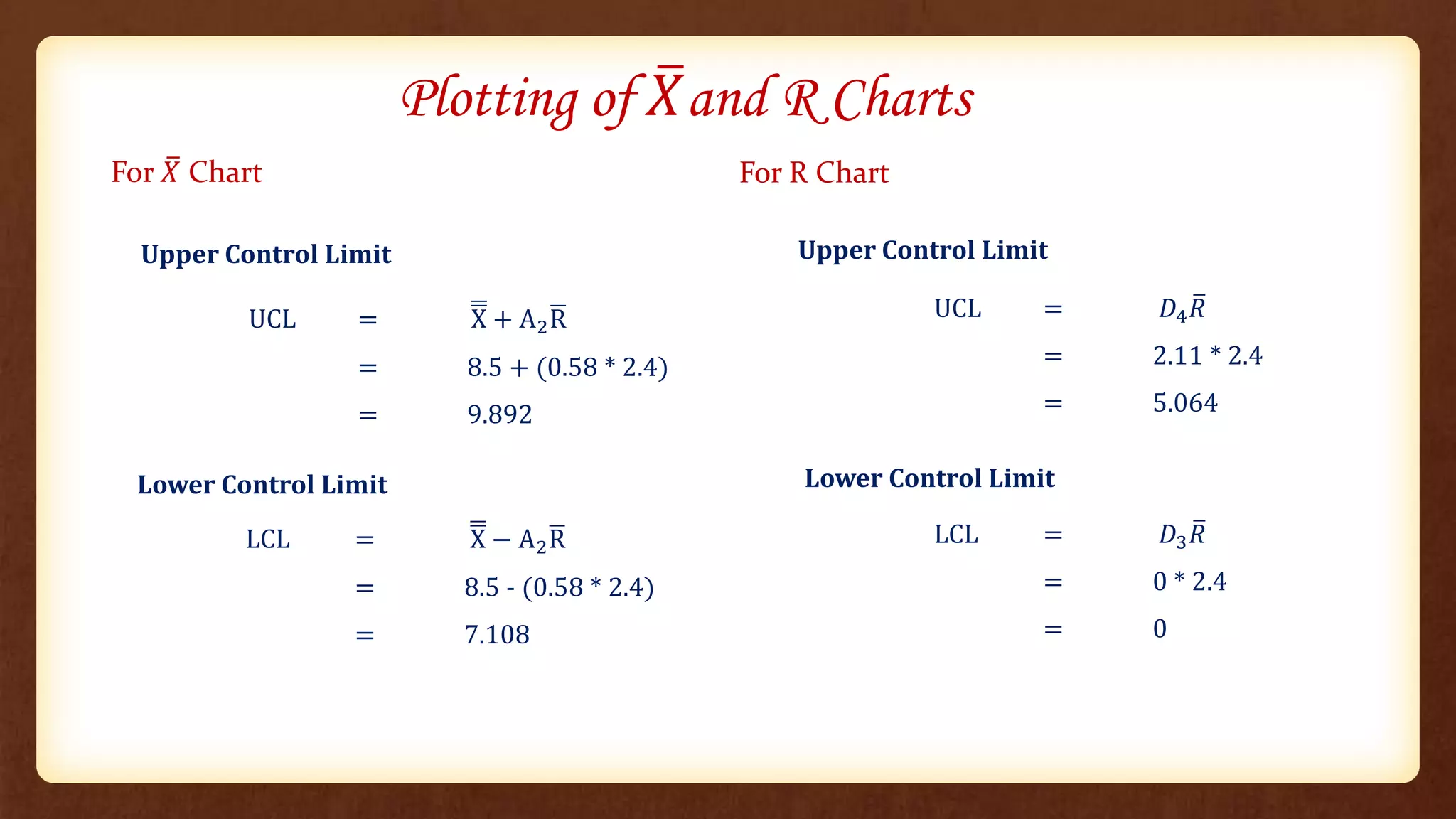

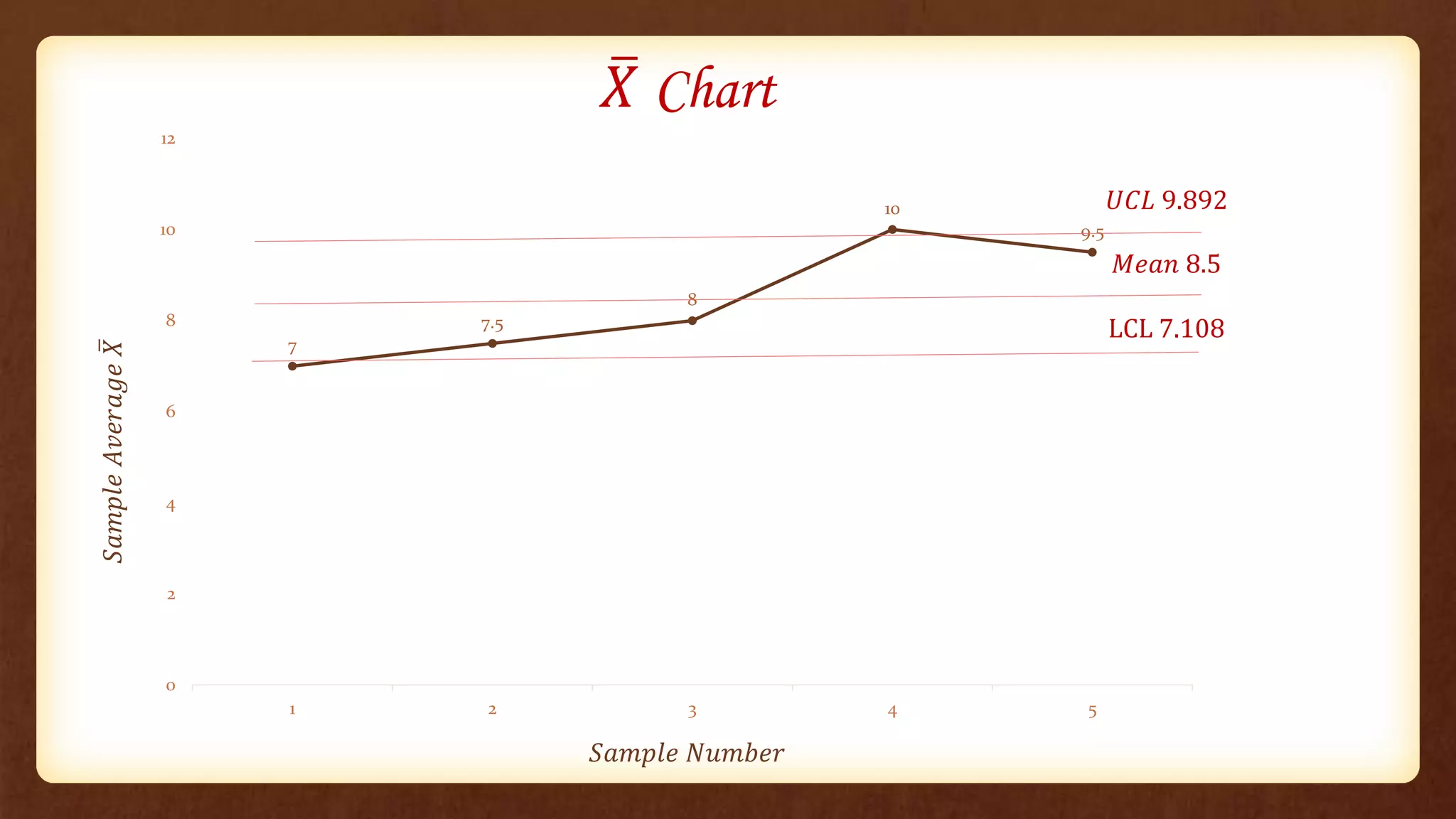

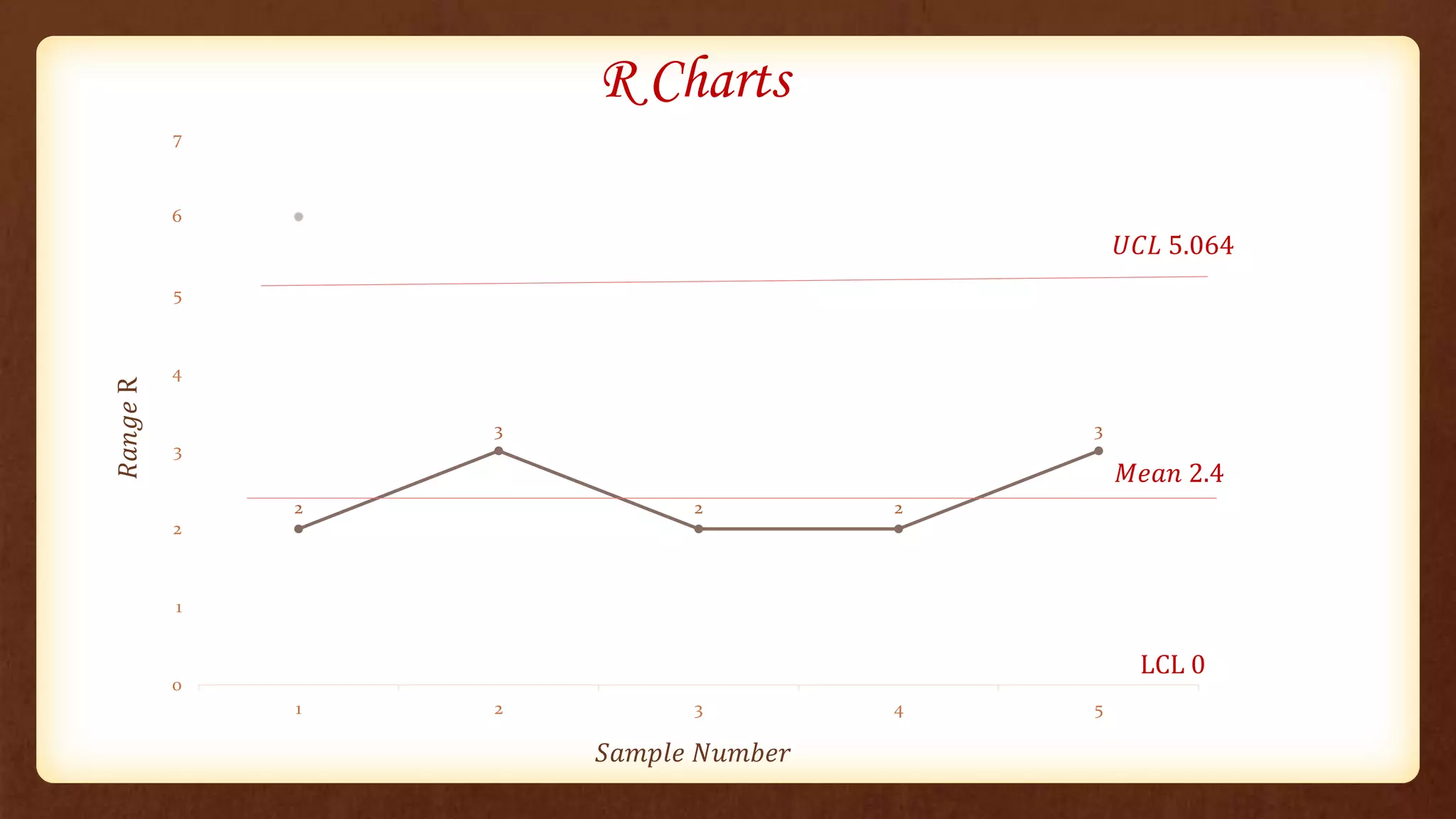

This document discusses X and R control charts, which are statistical process control tools. The X chart shows changes in the process average and is affected by changes in process variability. It detects shifts in the process center. The R chart controls general variability of the process and is affected by changes in process variability. It monitors the spread of data around the average. Together, the X and R charts form a powerful method for diagnosing quality problems by monitoring both the central tendency and variability in a process over time.