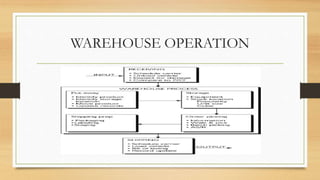

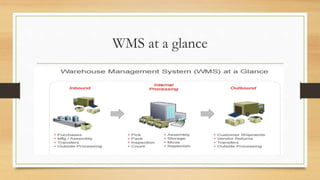

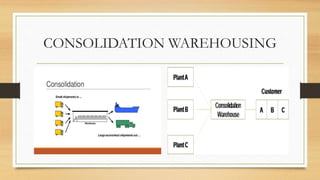

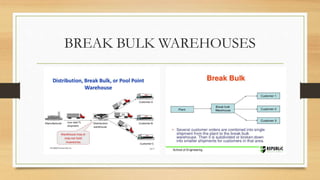

The document discusses the history, functions, and types of warehousing, highlighting its evolution from ancient granaries to modern large-scale storage facilities. It details various types of warehouses, their operational functions, and the strategic role they play in logistics, such as inventory management and cost reduction. Additionally, it covers warehouse management systems, the benefits of cloud-based solutions, and challenges faced in warehousing, along with solutions and characteristics of ideal warehouses.