Virtual Asset Simulation Technology: Accelerating Innovation through Intelligent Digital Replication

In the rapidly evolving digital era, organizations are under constant pressure to innovate, optimize, and deliver faster than ever before. Traditional development and testing methods often fall short in addressing the complexity of modern products, systems, and infrastructure. Virtual Asset Simulation Technology (VAST) has emerged as a game-changing approach, enabling businesses to create intelligent, data-driven virtual replicas of physical assets, systems, and environments to simulate real-world performance with high accuracy.

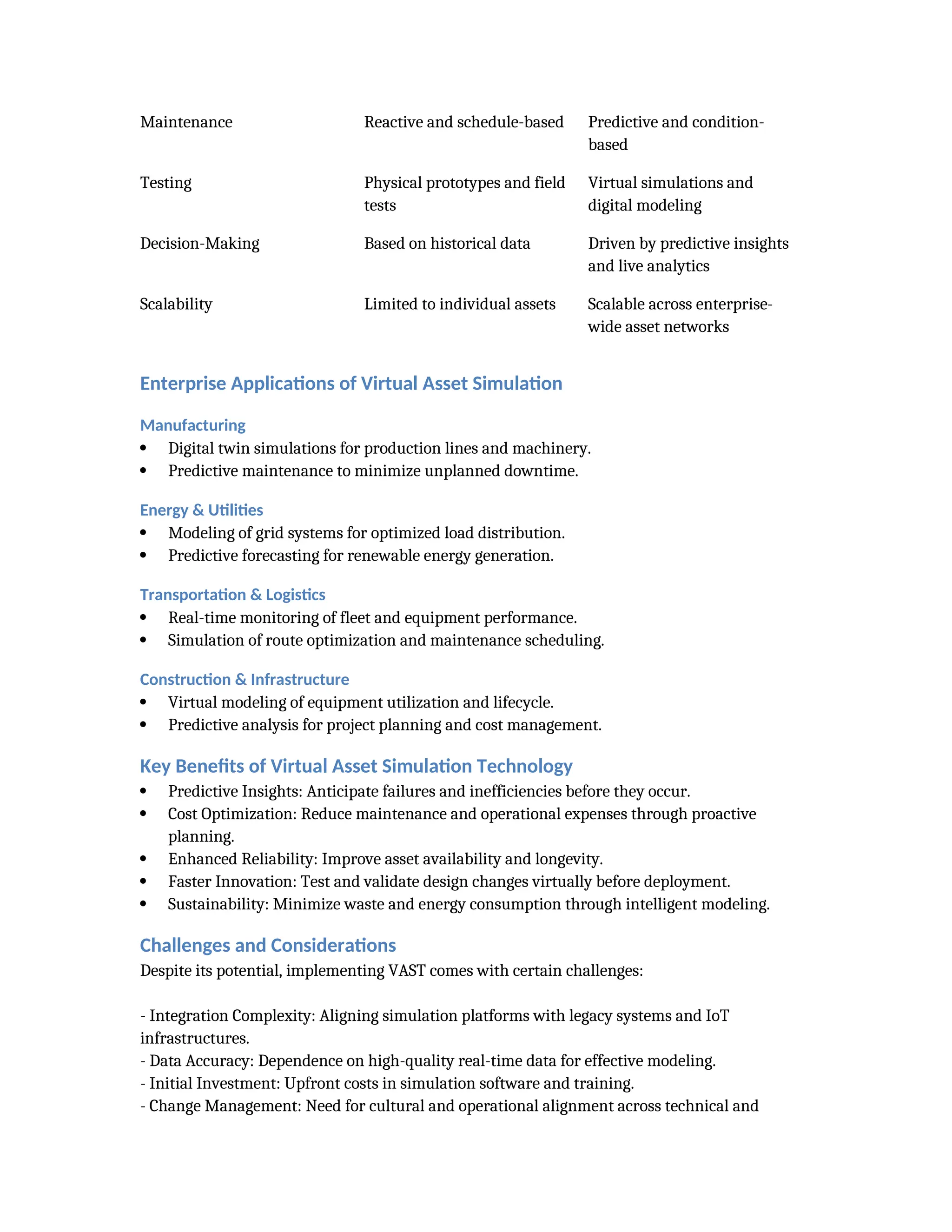

At its core, Virtual Asset Simulation Technology integrates digital twins, advanced modeling, AI-driven analytics, and real-time data visualization to provide a dynamic representation of an asset’s lifecycle—from design and prototyping to deployment and maintenance. By mirroring physical behaviors in a virtual environment, engineers and decision-makers can test various scenarios, predict outcomes, and optimize performance without incurring the cost or risk of real-world experimentation.

This technology bridges the gap between the physical and digital worlds, leveraging data from IoT sensors, cloud platforms, and machine learning models to continuously enhance accuracy and adaptability. Whether it’s an aircraft engine, an industrial plant, a smart vehicle, or an energy grid, Virtual Asset Simulation enables seamless experimentation and innovation through predictive insights and intelligent automation.

Key Capabilities and Advantages:

Real-Time Performance Modeling:

VAST allows simulation of asset behavior under diverse operating conditions, enabling proactive identification of design flaws, inefficiencies, or potential failures before deployment.

Predictive Maintenance and Reliability:

By combining AI algorithms with sensor data, the technology forecasts maintenance needs, preventing costly downtime and extending asset lifespan.

Accelerated Product Development:

Engineers can test multiple design configurations virtually, shortening development cycles, reducing physical prototypes, and cutting overall R&D costs.

Operational Optimization:

Virtual simulations help identify process bottlenecks, energy inefficiencies, and performance deviations, supporting continuous operational improvements.

Sustainability Enablement:

Through virtual testing, organizations can minimize waste, reduce energy consumption, and design more sustainable systems before physical implementation.

Collaborative Innovation:

VAST promotes cross-functional collaboration by offering a shared, interactive digital environment where engineers, designers, and stakeholders can visualize, modify, and validate models in real time.

Applications Across Industries:

Manufacturing: Digital twins of machinery optimize production lines, monitor equipment health, and improve output quality.

Aerospace and Automotive: Virtual testing of engines and vehicles ensure