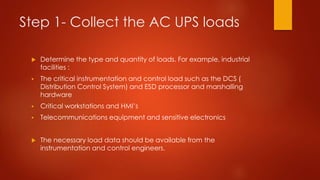

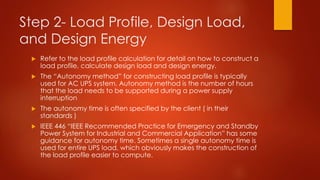

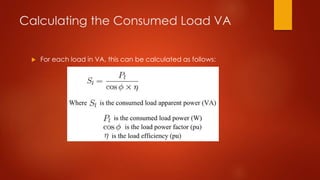

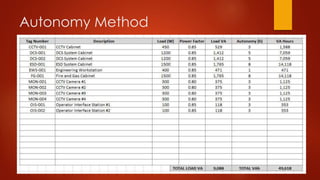

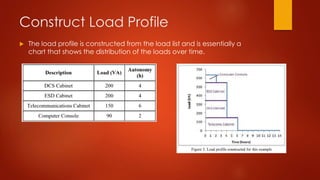

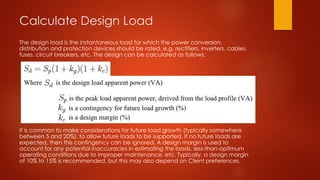

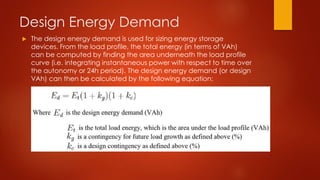

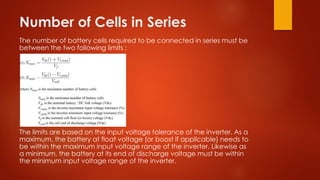

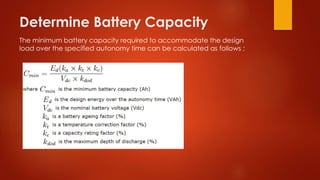

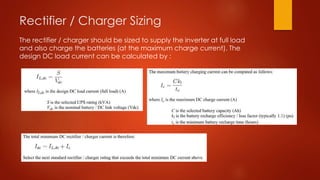

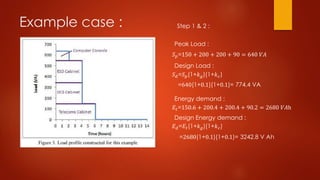

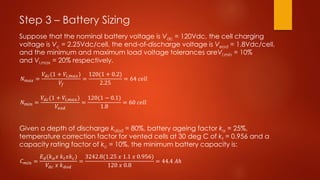

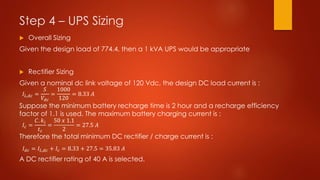

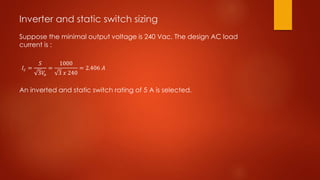

This document provides guidance on sizing uninterruptible power supply (UPS) systems. It discusses UPS components and uses a 4-step methodology to calculate the necessary ratings. Step 1 involves determining the loads to be supported. Step 2 develops a load profile to calculate design load and energy. Step 3 sizes the battery bank based on voltage, capacity, and other factors. Step 4 determines ratings for the rectifier, inverter, and static switch based on the loads and battery sizing. The example provided calculates these values for a sample UPS system.