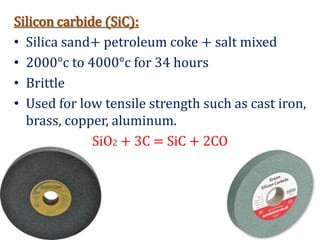

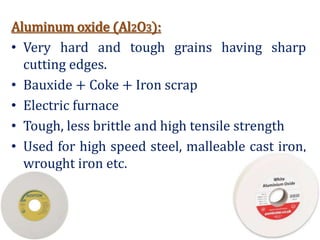

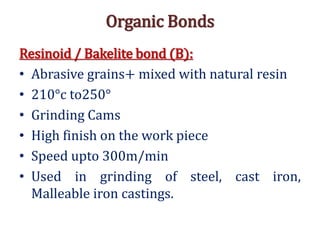

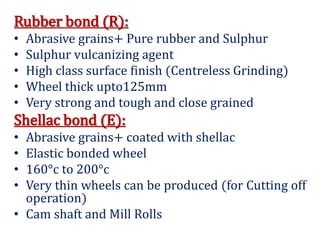

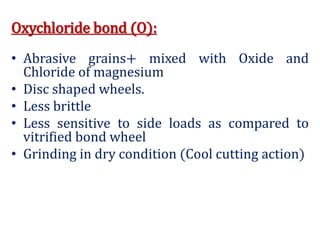

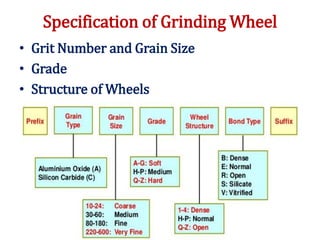

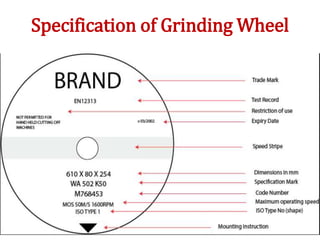

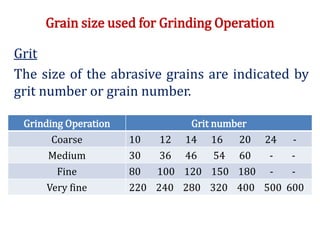

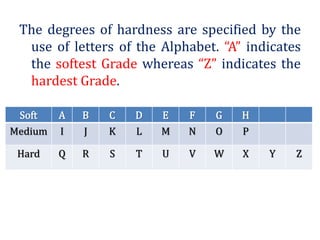

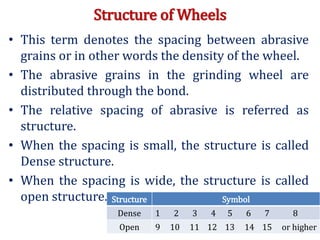

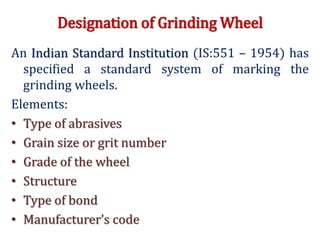

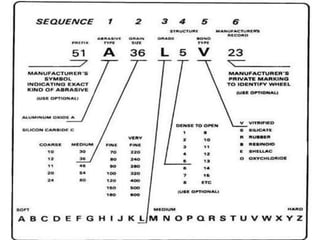

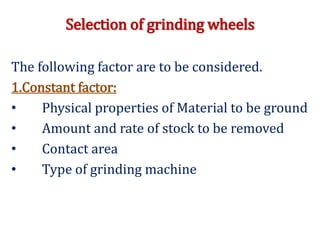

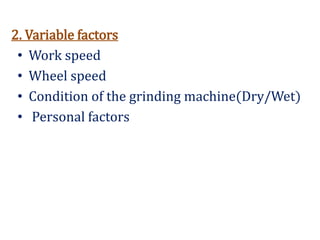

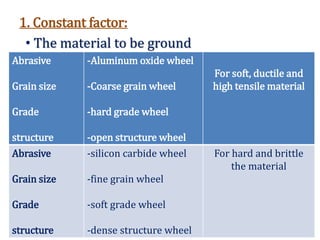

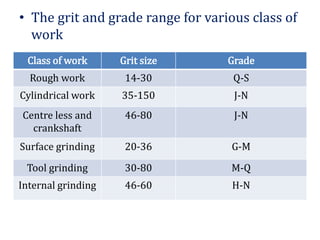

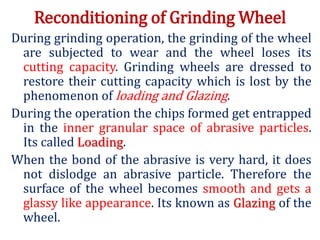

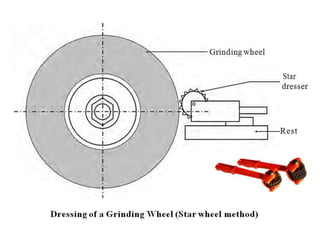

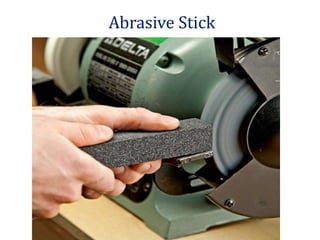

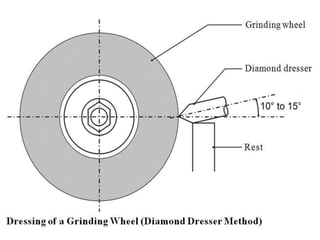

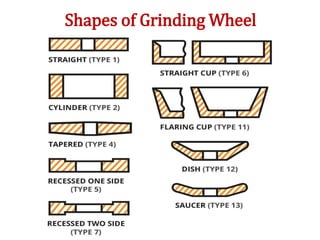

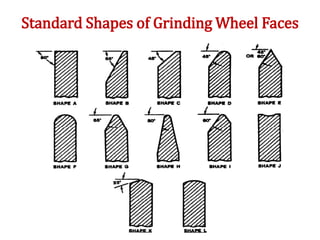

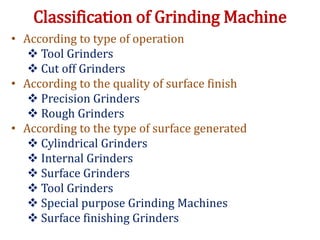

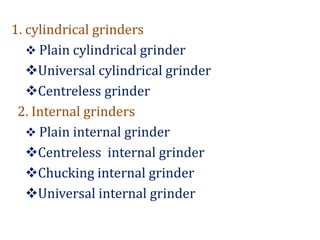

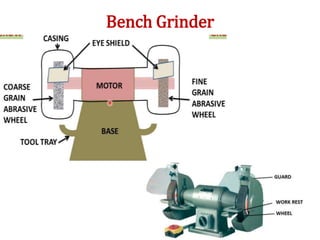

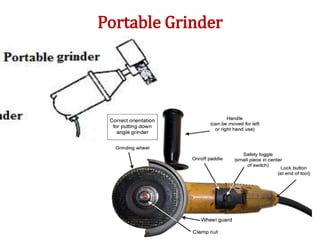

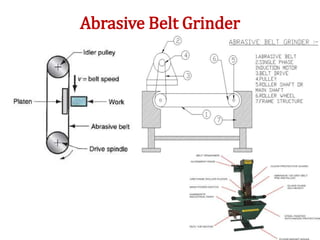

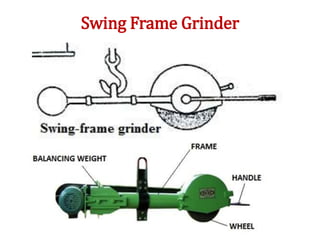

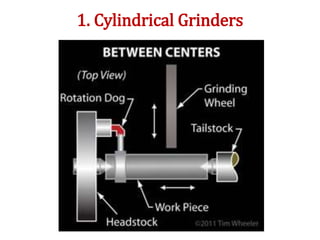

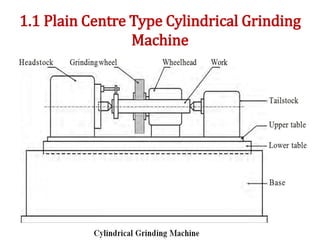

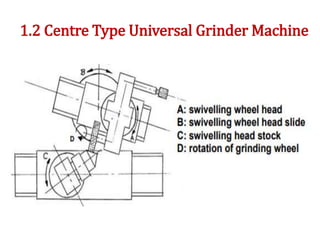

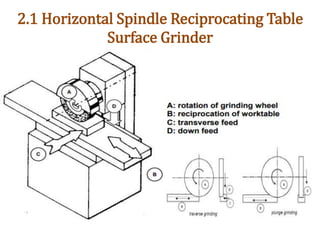

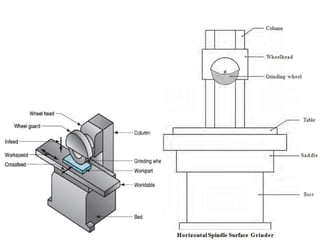

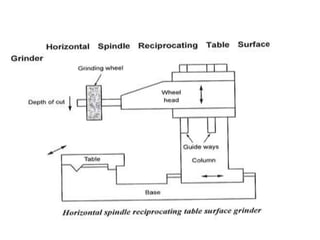

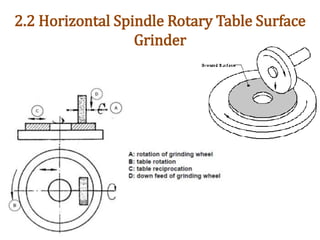

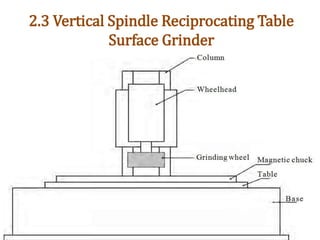

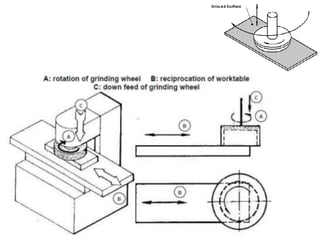

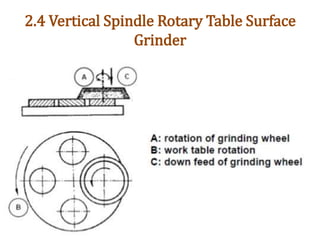

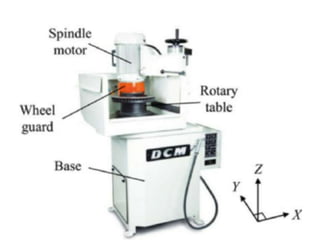

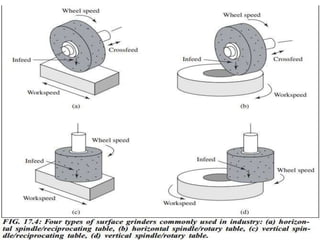

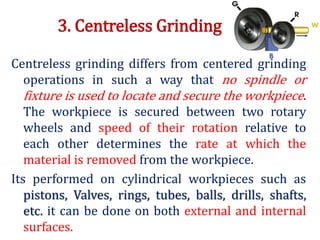

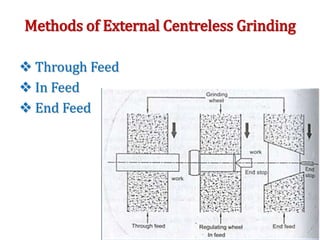

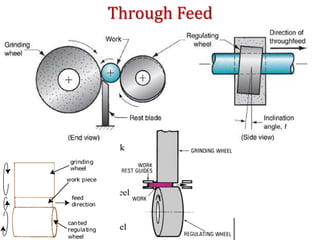

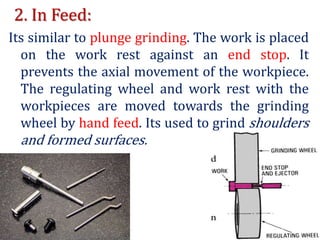

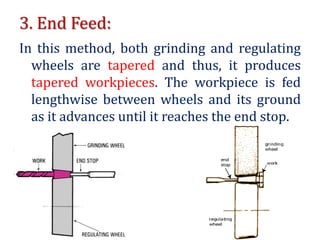

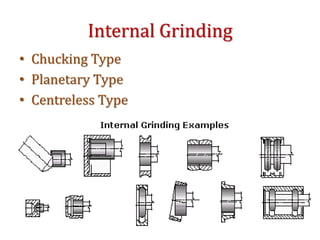

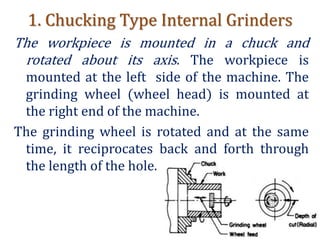

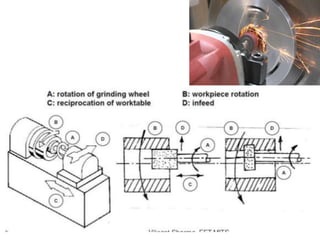

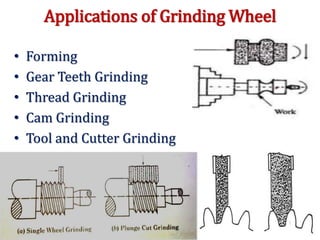

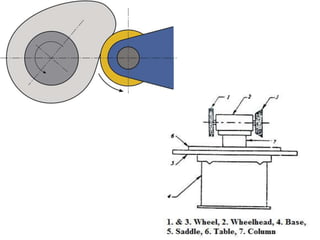

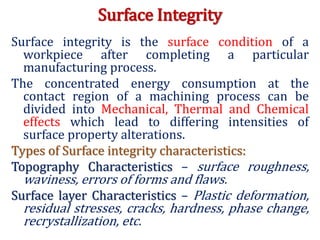

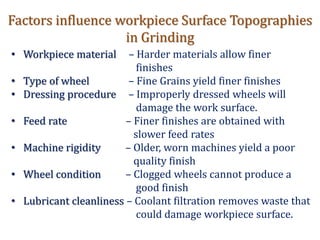

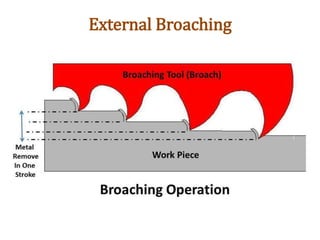

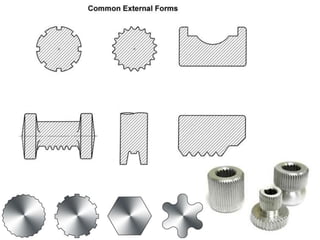

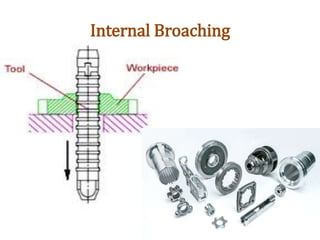

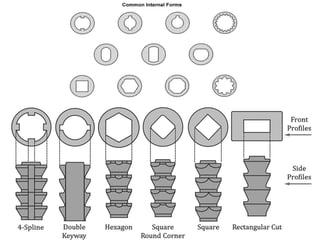

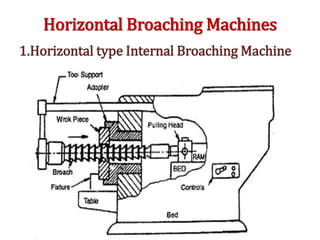

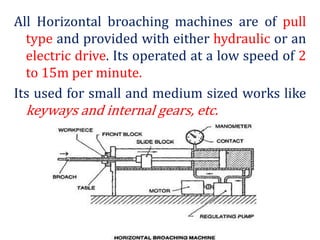

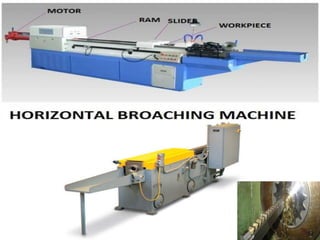

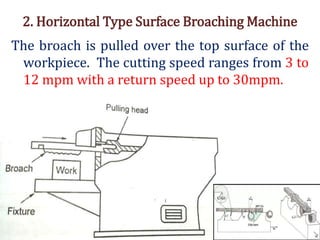

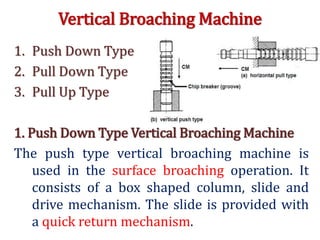

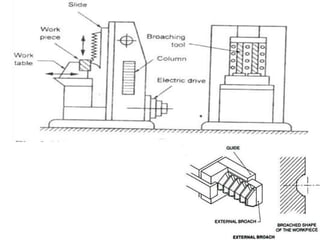

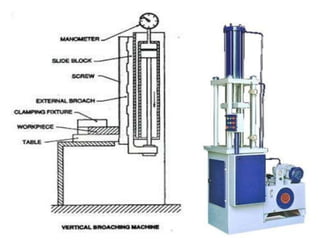

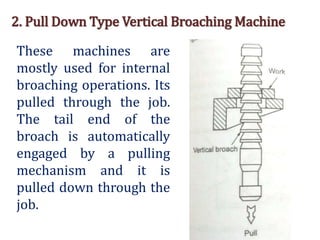

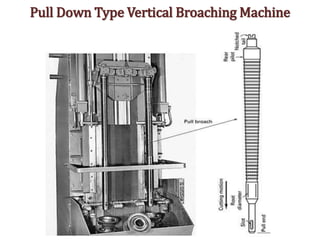

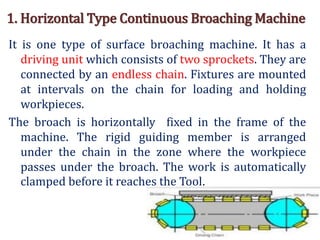

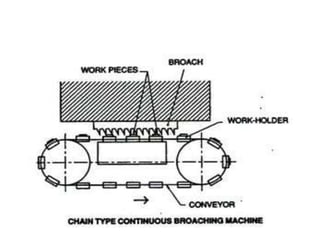

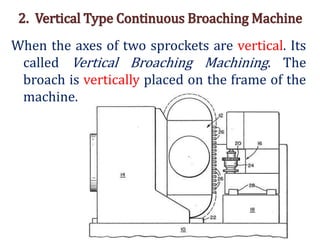

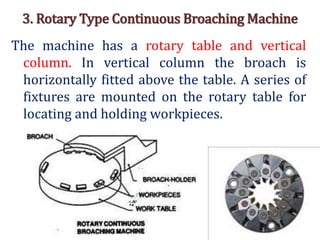

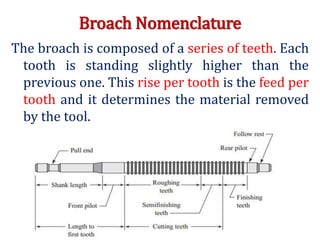

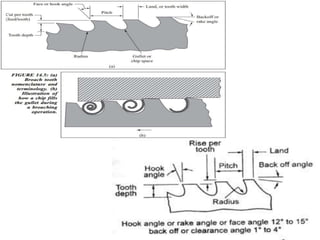

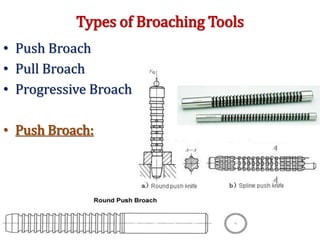

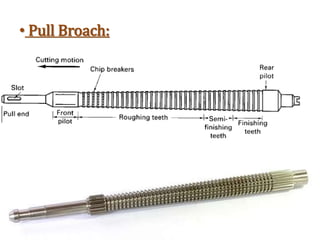

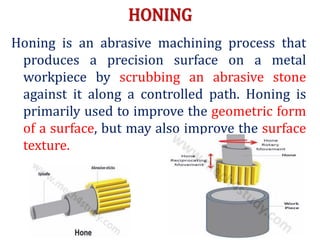

The document provides a comprehensive overview of abrasive processes, particularly focusing on grinding and broaching techniques. It covers the types and specifications of grinding wheels, the properties and classifications of abrasives, and various grinding machine types and operations including cylindrical, internal, and surface grinding. Additionally, it discusses the principles and specifications of broaching machines, outlining different types of broaching methods and their applications.