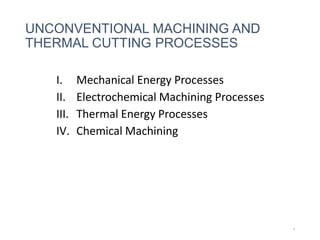

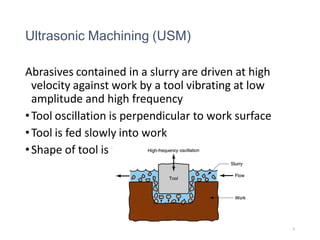

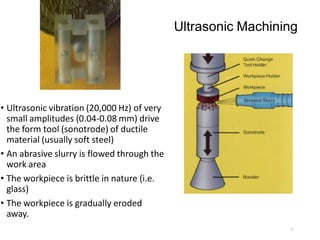

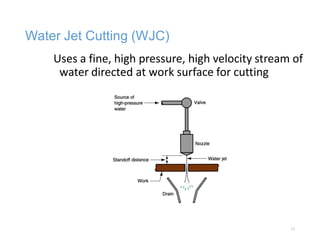

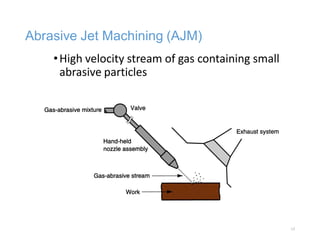

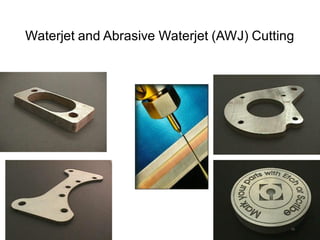

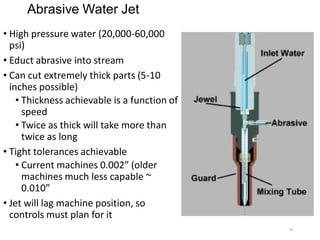

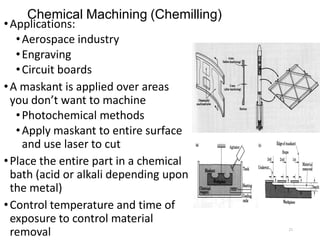

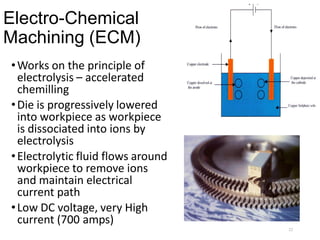

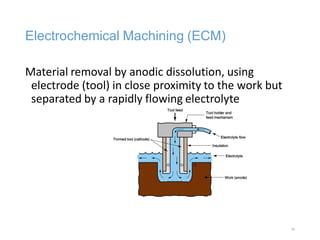

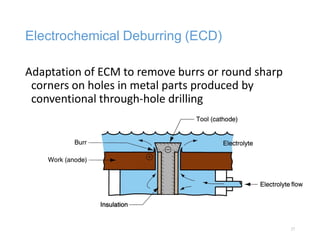

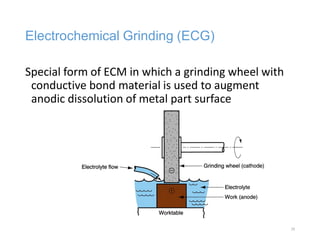

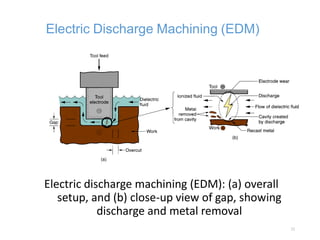

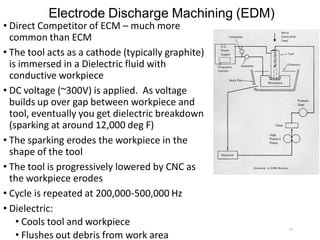

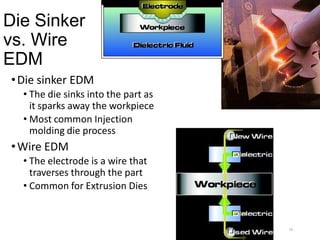

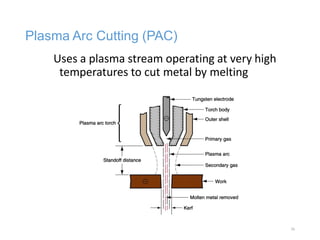

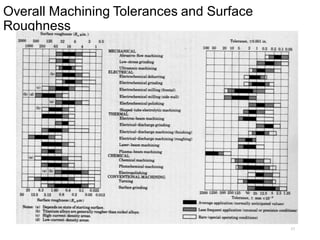

This document provides information on various unconventional machining processes. It begins by classifying these processes into categories based on the type of energy used, including mechanical, electrical, thermal, and chemical. Specific processes discussed include ultrasonic machining, water jet cutting, abrasive jet machining, electrochemical machining, electric discharge machining, and chemical machining. Key aspects like principles of operation, equipment, process variables, applications, and limitations are summarized for each process.