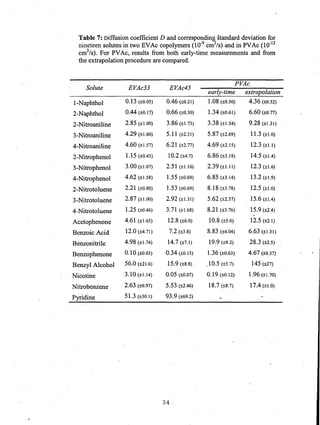

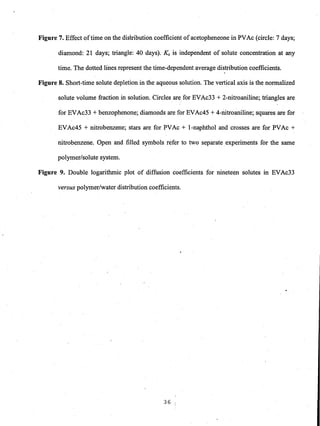

This document reports on an experimental study that measured distribution coefficients and diffusivities for 19 non-volatile solutes in 3 polymers. The study found that:

- Distribution coefficients ranged from near unity to several hundred and increased with vinyl acetate content in the polymers.

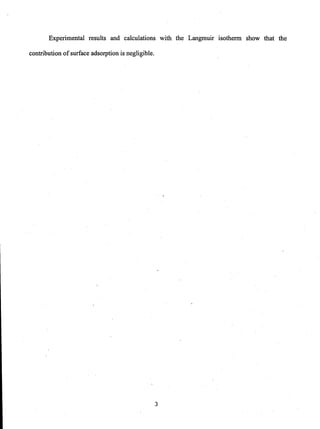

- Diffusion coefficients in EVAc copolymers ranged from 10-10 to 10-8 cm2/sec, much faster than 10-12 cm2/sec in PVAc.

- A long time (over 4-5 weeks) was required to reach equilibrium for solutes in PVAc, so diffusion models were used to calculate equilibrium values.

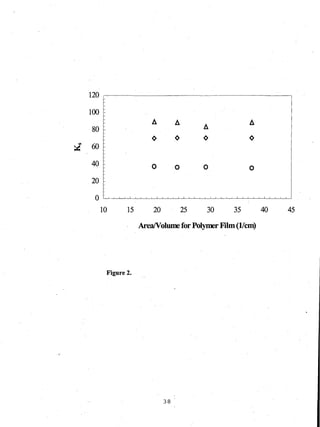

- Surface adsorption effects were found to be negligible.

![LBNL-48573

Preprint

ERNEST ORLANDO LAWRENCE

BERKELEY NATIONAL LABORATORY

Distribution Coefficients

and Diffusivities in Three

Polymers for Nineteen

Aqueous Nonvolatile Solutes

F. Fornasiero, M.M. Olaya, B. Esprester,

V. Nguyen, and ].M. Prausnitz

Chemical Sciences Division

June 2001

Submitted.,to'_.__._....;.-.:.................. ..... "

Journal"oJApplied .'--.

Polymer Science' .](https://image.slidesharecdn.com/e2e033e8-066f-40ba-8a5b-de592948667f-151003214116-lva1-app6892/75/UC-Berkeley-Research-1-2048.jpg)

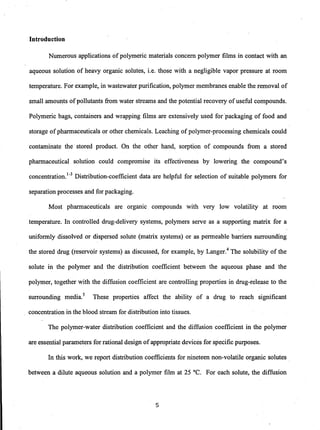

![101

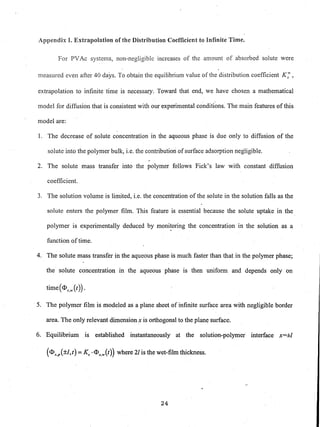

~

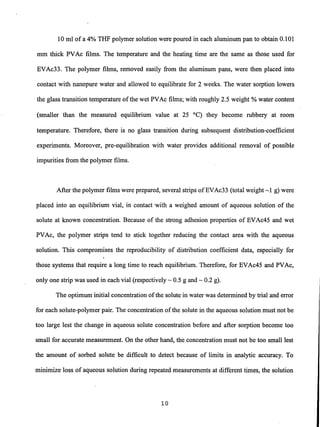

- - - - - - - - - -,- - - - - - - - - - -,- - EVAc33

, ,

, ,

~ 1 AI ........... , ~ >':+:.v ;.....'

, ,

o'('r..,;·"",,~.,.~.... ~.,,._ ">""w'-'.'y.~'" I

,

----------~----------~

, ,

99 - - - - - - - - - - - - - - - - - - - _1- __________ 1___________I __________ _

. 'EVAc45'

97 - - - - - - - - 1- - - - - - - - - - -1- - - - - - - - - - -1- - - - - - --:- - - - -I - - - - - - - - - - ..,

-~

95 , "

--------------------------------------~----------~

................

= PVAc.....

93 -------~----------~

91

25 75 125 175 225 275

Temperature [ C ]

Figure 1.

37](https://image.slidesharecdn.com/e2e033e8-066f-40ba-8a5b-de592948667f-151003214116-lva1-app6892/85/UC-Berkeley-Research-40-320.jpg)

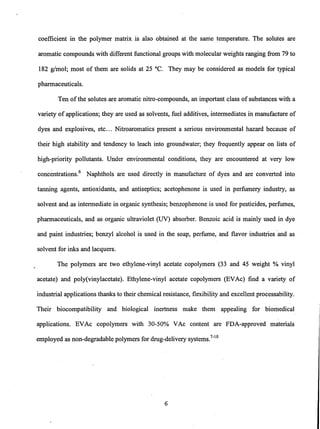

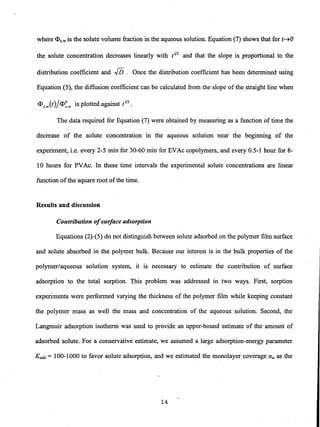

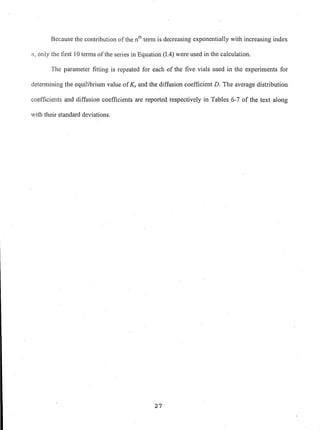

![1.0

~

- ~~A

- ~ ~~ Ai'

0.9

.~'~A :I:

.. ~ ., A t

~ i-

A ±rii

~ *'

..0

A ·t

a' of,

~

0.8 - !!!I

.. +~ .. :I:'rii

cP·a %

c

0.7 - o~ ~

ec ~

- 01;1 :K

o ' . . ~.

0.6 • . . .

0 5 10 15 20 25

t1!2 [min1!2]

Figure 8.

44](https://image.slidesharecdn.com/e2e033e8-066f-40ba-8a5b-de592948667f-151003214116-lva1-app6892/85/UC-Berkeley-Research-47-320.jpg)