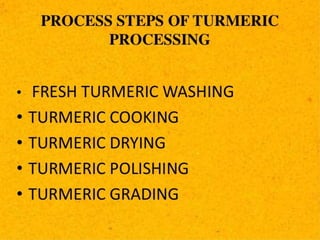

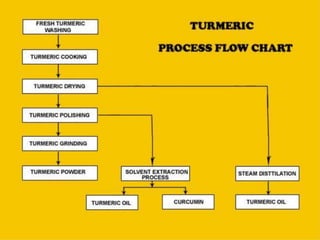

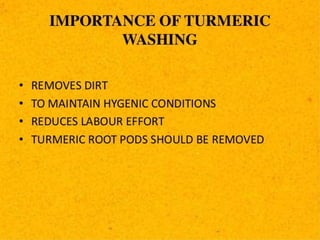

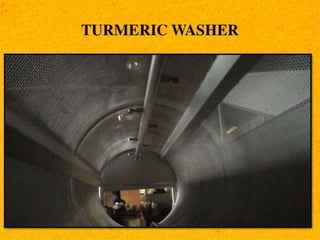

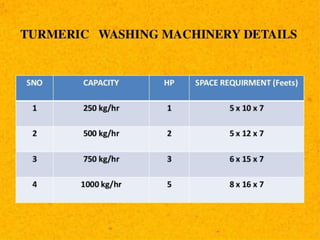

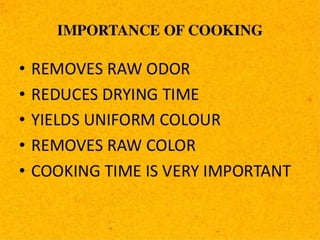

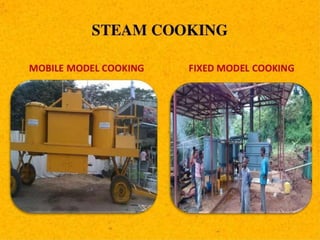

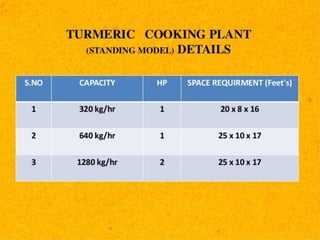

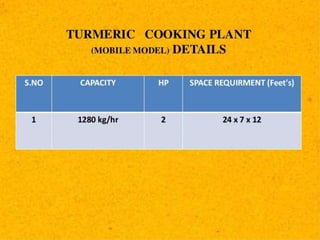

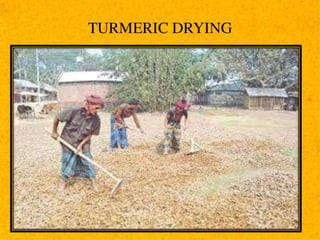

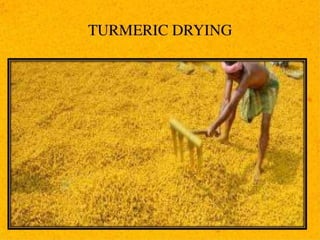

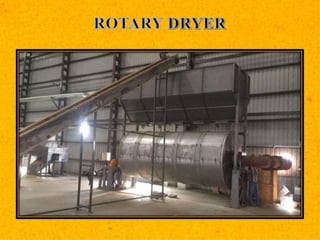

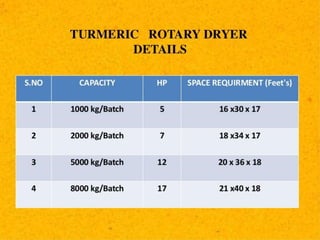

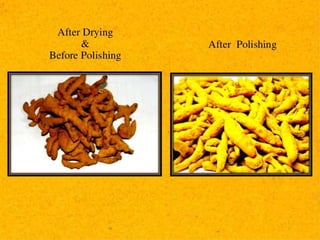

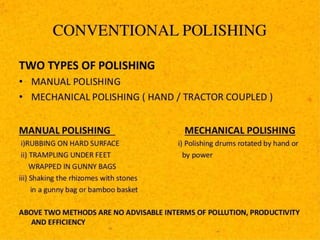

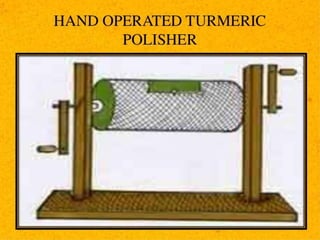

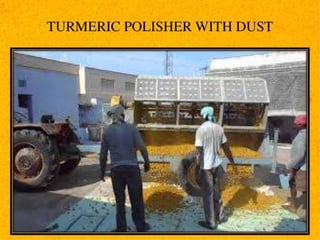

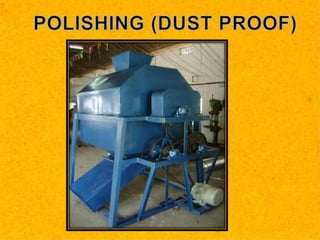

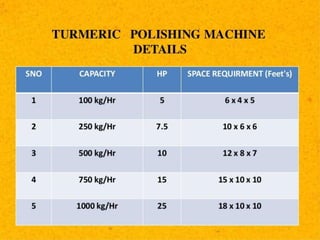

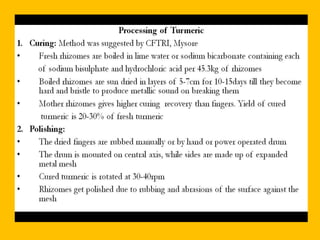

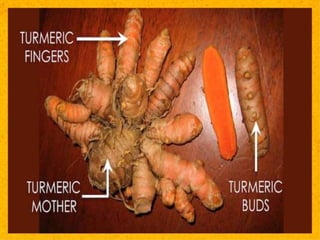

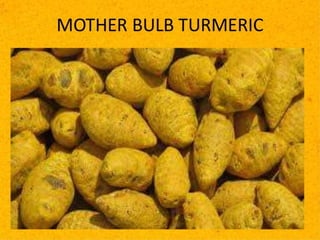

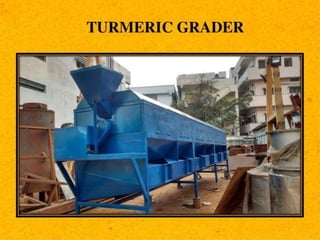

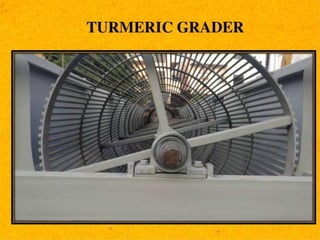

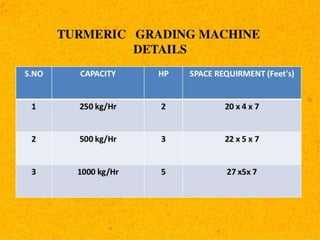

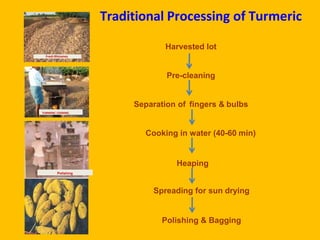

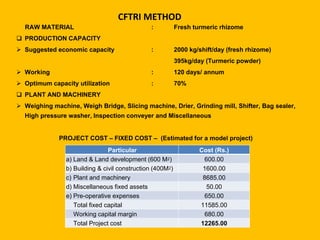

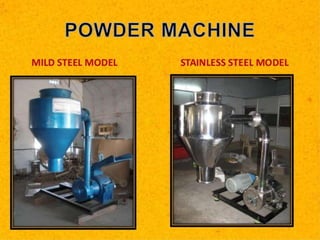

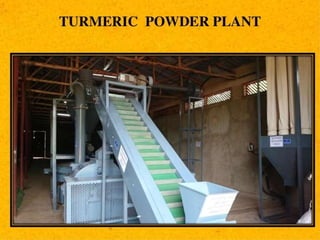

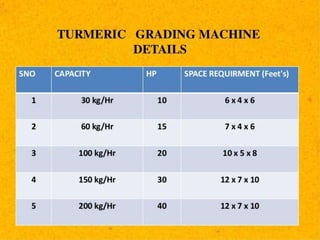

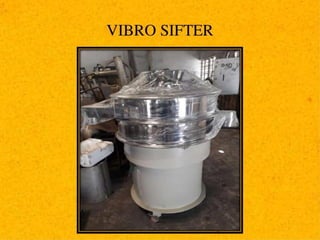

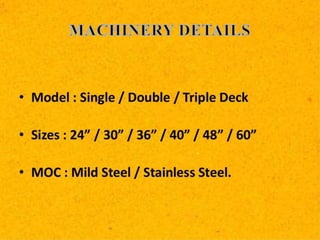

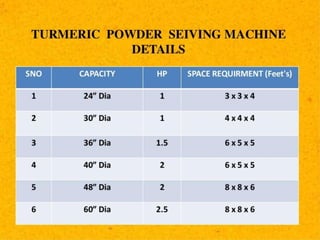

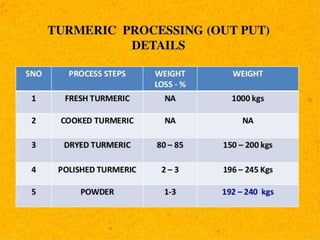

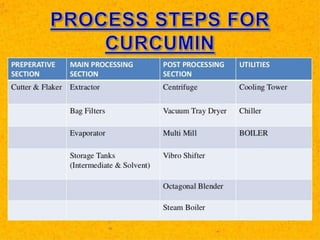

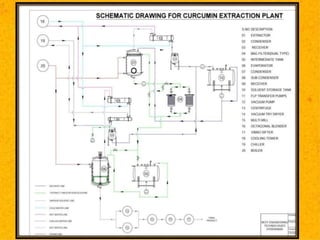

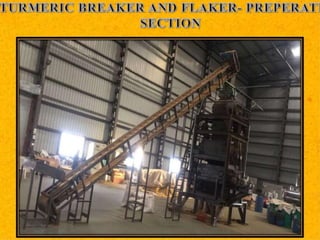

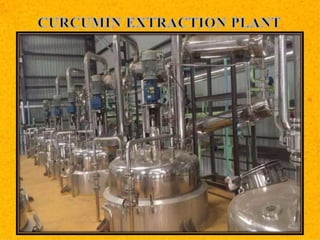

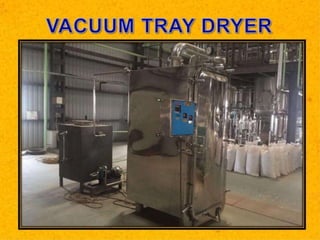

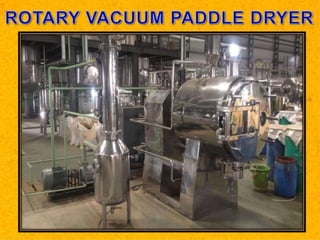

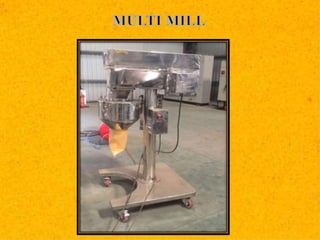

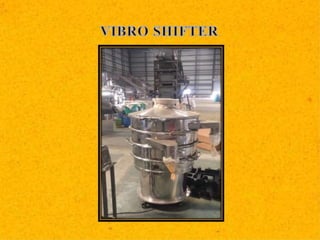

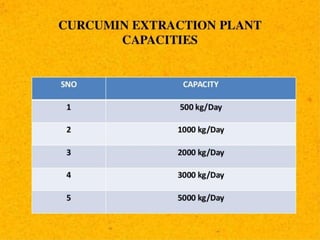

This document summarizes a seminar presentation on traditional and modern processing methods for turmeric. It describes the traditional method of harvesting, cleaning, separating, cooking, drying, and polishing turmeric rhizomes. It then outlines the CFTRI method for more efficient downstream processing of fresh turmeric rhizomes into hygienic turmeric powder within 24 hours, compared to 30 days for traditional methods. Details are provided on production capacity, machinery required, and estimated fixed and total project costs for a model turmeric powder processing plant.