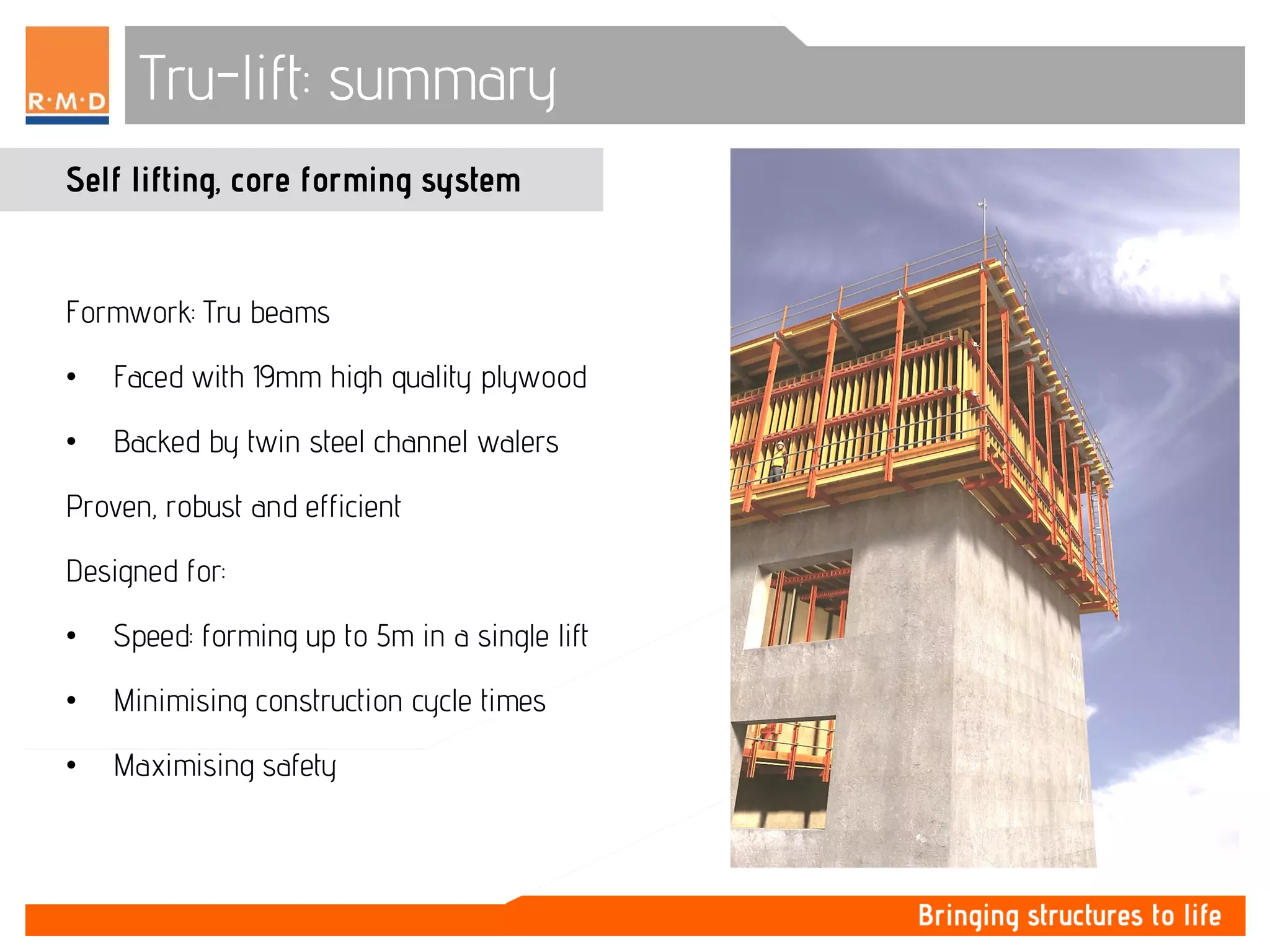

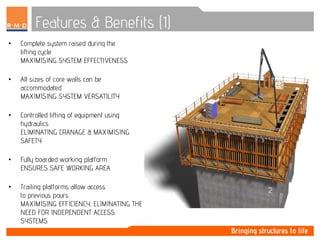

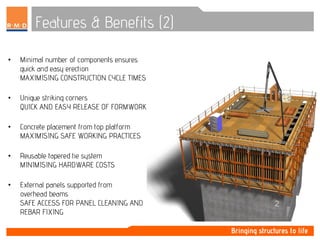

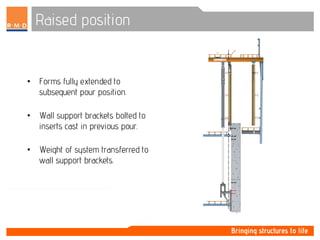

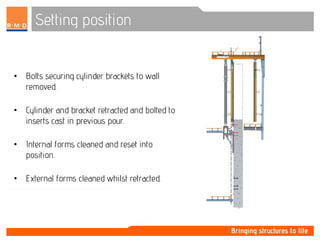

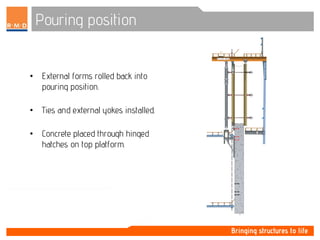

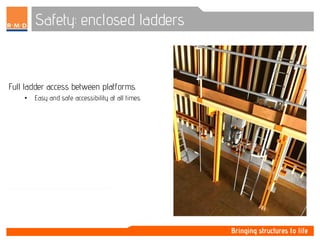

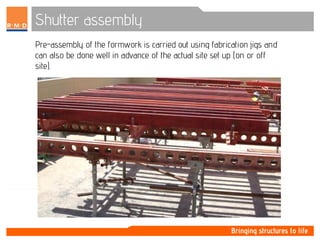

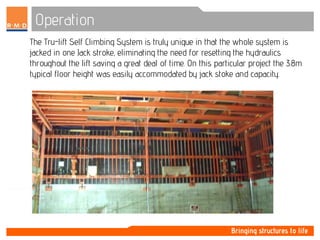

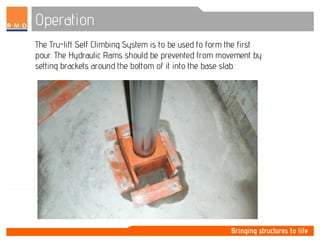

The Tru-lift system is a self lifting, core forming system using Tru beams and faced plywood formwork. It is designed for speed, minimizing construction cycle times, and maximizing safety. The system lifts the entire formwork in a single stroke, eliminating the need for resetting hydraulics. It allows for controlled lifting of equipment and access platforms using hydraulics. The system provides a safe, enclosed working environment during construction.