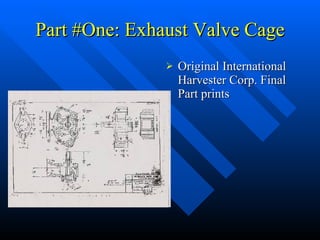

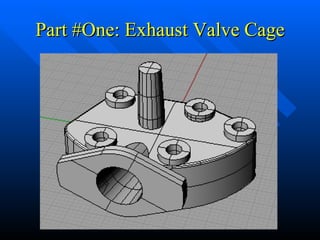

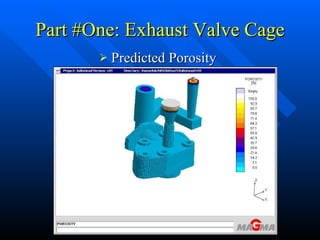

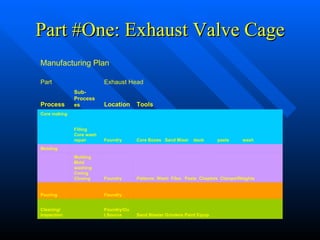

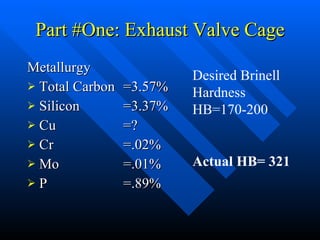

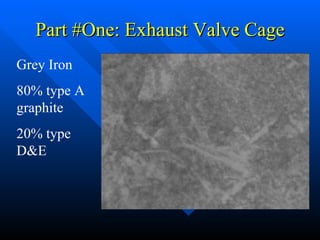

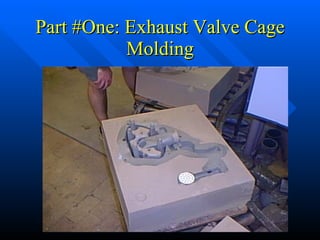

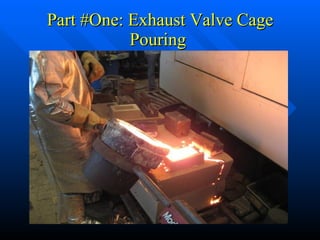

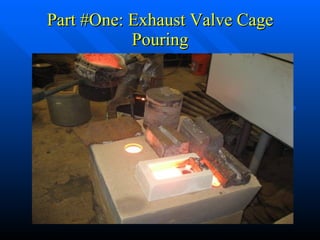

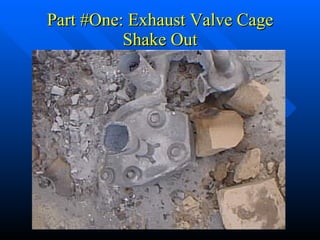

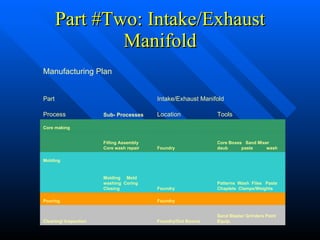

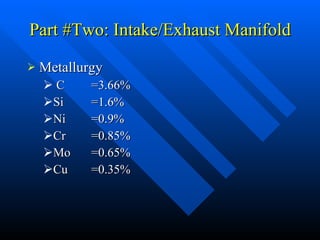

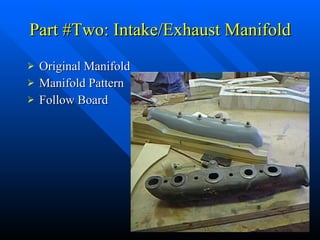

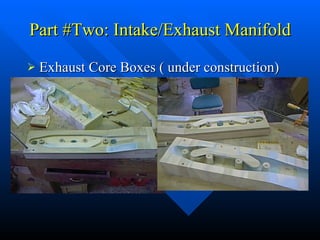

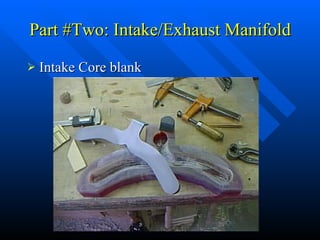

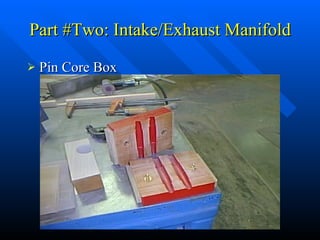

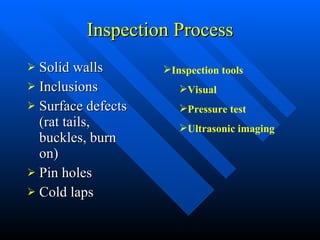

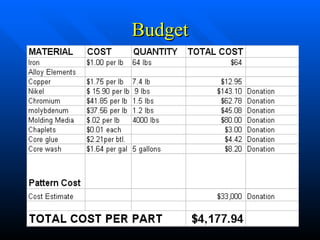

This document discusses two senior design projects for tractor components: an exhaust valve cage and an intake/exhaust manifold. It provides details on the manufacturing plans, processes, locations, tools, and metallurgical specifications for producing the parts. It also mentions predicted defects for the exhaust valve cage and inspection processes and tools for the intake/exhaust manifold. Budget and schedule information is briefly referenced at the end.