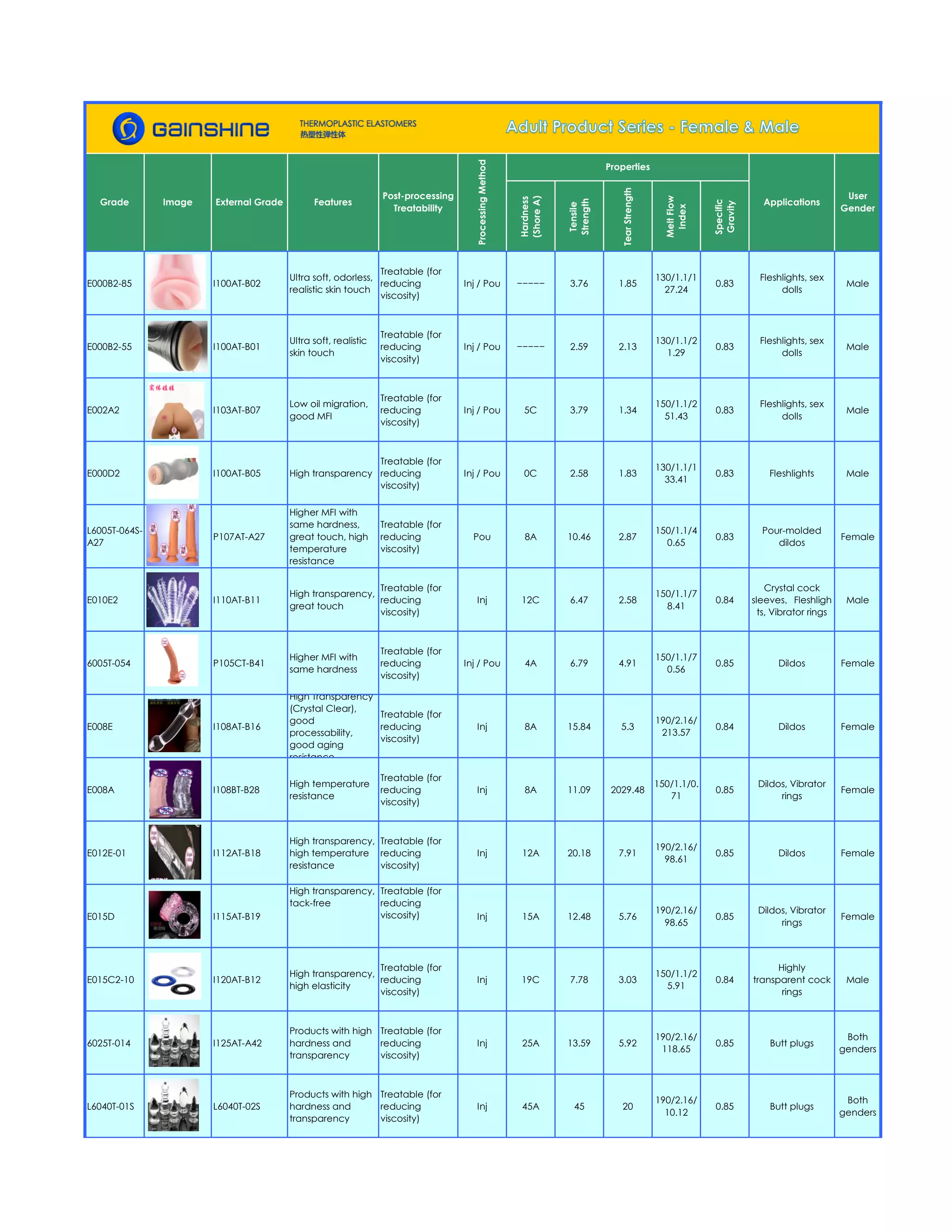

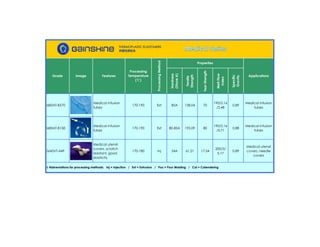

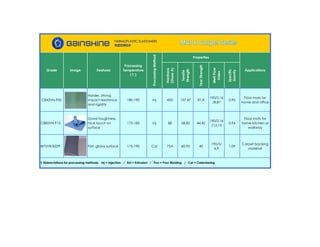

The document provides information on various silicone and thermoplastic elastomer grades for use in sex toys and medical devices. It includes data on properties like hardness, tensile strength, melt flow index and specific gravity. The grades listed can be processed via injection, pouring or extrusion molding and are treated to reduce viscosity. They have applications for items like fleshlights, dildos, butt plugs, cock rings and sleeves for males and females.