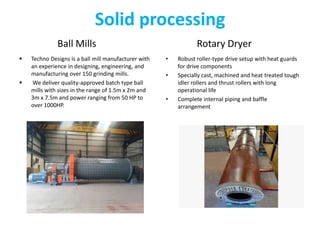

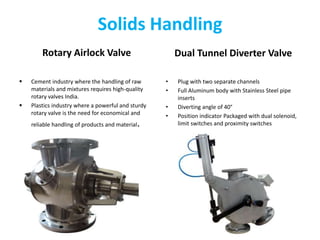

Techno Designs manufactures plants and equipment for the mineral, paint, resin, chemical, and pharmaceutical industries, operating from two facilities in Anand, Gujarat since 1993. The company has expanded its offerings to include solids handling products and specialized processing equipment, demonstrating a commitment to quality and customer satisfaction. Their product range includes grinding mills, rotary dryers, air classifiers, rotary valves, and storage silo systems, emphasizing innovative solutions that meet global standards.