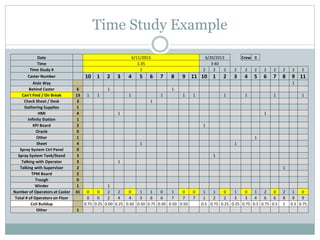

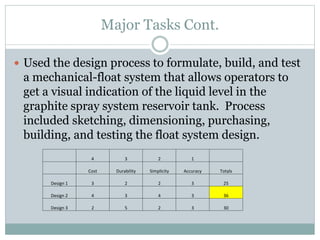

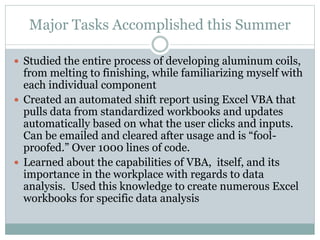

The document summarizes Trevor Huggins' internship at JW Aluminum over the summer. Some of the major tasks he accomplished included creating an automated shift report using VBA, conducting time studies of the 11 casters, and designing a mechanical float system to indicate liquid levels. He also entered data, assisted with audits, and performed various other jobs. Trevor learned about consistency in production, data analysis, and the business aspects of engineering. He believes his work added value through increased efficiency and convenience. Some areas for improvement include focusing more on smaller tasks and departments. Overall, it was a valuable learning experience.

![Automated Shift Report Picture

Casting Analysis based on: Instructions: 1. Click the 'Create Report' button to request data

Day,Shift, and Crew 2. Select the date, shift, and crew from the user-boxes

3. Click the 'Email Report' button if you wish to email the data

Date 4. Click 'Clear Report' after you are finished analyzing the data!!!

Shift

Week Num Coil Type Caster Operator Scrap Weight Reason

Crew

Week Num Type Caster Holder Start Time (00:00) Finish Time (00:00) Minutes Reason

Caster # Planned Actual Caster # Planned Actual

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

10 10

11 11

Total Total

Short Coil, Drainout, Scrap Coil Analysis

Notes

Production Yield [lbs]

Daily Goal: Shift Goal:

Cleaning and Equipment Information

Shift Log

Notes

Create Report Clear Report Email Report](https://image.slidesharecdn.com/7274a2cb-ccab-4633-af9b-3ca777005540-160516145657/85/Summer-2013-Internship-Reflection-4-320.jpg)