Still Wagner EK10 Forklift Service Repair Manual.pdf

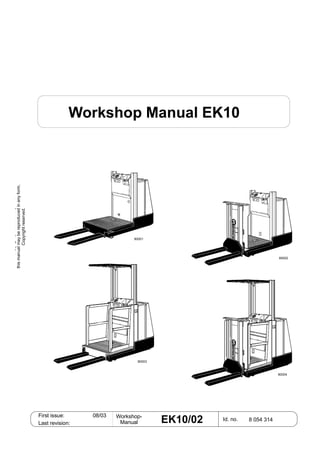

- 1. 07/01 01 First issue: 08/03 Workshop- Manual Last revision: EK10/02 Id. no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. 8 054 314 80001 80004 80003 80002 Workshop Manual EK10

- 2. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. 4 1 Vehicle data 2 Travel motor 3 Drive wheel 4 Gear 5 Brake 6 Idling wheels 7 Hydraulic 8 Cylinder 9 Line break protection 10 Hydraulic pump 11 Aisle recognition 12 Steering 13 Vehicle control system (FZS) 14 Operating panel 15 End-of-aisle safety system (EASS) 16 Speed sensor 17 Braking monitor (ABÜ) 18 Travel control 19 Travel switch 20 BDI/HM 21 Travel control software 22 Steering software 23 Hand-held programming unit 99 Maintenance Sections

- 3. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. 5 Section Contents Sheet Foreword ......................................................................................2 Updating of workshop manuals............................................2 Exchanging faulty sheets .....................................................3 Insertion of supplementary sheets .......................................3 Remarks, imprint ..........................................................................4 Sections........................................................................................5 1 Vehicle data Definition of vehicle model names...........................................1-01 Signs on the vehicle ................................................................1-02 Travel speed ...........................................................................1-03 Outside the aisle .............................................................1-03 Inside the aisle................................................................1-03 2 Travel motor General....................................................................................2-01 Temperature monitor ...............................................................2-01 Technical data .........................................................................2-02 Terminals.................................................................................2-02 Removing the travel motor ......................................................2-03 Installation ...............................................................................2-04 Maintenance............................................................................2-05 General ...........................................................................2-05 Cleaning..........................................................................2-05 Visual inspection, replacing damaged parts ...................2-06 Checking the brush mechanism......................................2-08 Commutator ....................................................................2-09 Bearings..........................................................................2-09 3 Drive wheel General....................................................................................3-01 Removing the drive wheel.......................................................3-01 Installing the drive wheel.........................................................3-01 4 Gear Remove ...................................................................................4-01 Installing the gear....................................................................4-02 Changing oil ............................................................................4-03 Oil change method ..................................................................4-04 Checking the oil level ..............................................................4-05 Lubricating the bogie bearing..................................................4-05 Table of Contents

- 4. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. 6 Table of Contents Section Contents Sheet 5 Brake Electromagnetic spring brake ..................................................5-01 General ...........................................................................5-01 Function ..........................................................................5-02 Removal..........................................................................5-03 Checking the rotor...........................................................5-03 Adjusting the brake clearance.........................................5-04 General...................................................................5-04 Adjustment process................................................5-04 Adjusting the braking force..............................................5-05 Maintenance....................................................................5-06 Measuring the brake deceleration ...........................................5-07 General ...........................................................................5-07 Preparations for measurement........................................5-07 Evaluating the measurement ..........................................5-08 6 Idling wheels General....................................................................................6-01 Removal ..................................................................................6-01 7 Hydraulic Montagevorschrift ....................................................................7-01 Hydraulic circuit plan ...............................................................7-01 Block diagram for NO/HO........................................................7-02 Block diagram for NM/HM .......................................................7-03 Pump unit ................................................................................7-04 General ...........................................................................7-04 Components:...................................................................7-04 Electrically releasable non-return valve ..........................7-05 Replacing the carbon brushes (NO, NM)........................7-06 Replacing the carbon brushes (HO, HM)........................7-07 Removal..........................................................................7-08 Removing the pump motor (NO, NM) .............................7-09 Removing the pump motor (HO, HM) .............................7-10 Adjustment Pressure release valve.................................7-11 Changing the hydraulic oil...............................................7-12 Bleeding the lift cylinders and the hydraulic system................7-13 Procedure........................................................................7-13 Distributor block.......................................................................7-14 Bubble reservoir ......................................................................7-15 Hydraulic hoses .......................................................................7-16

- 5. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. 7 Table of Contents Section Contents Sheet 8 Cylinders Cylinder support ......................................................................8-01 Main lift cylinder on NO/NM.....................................................8-02 Removal .........................................................................8-02 Dismantling ....................................................................8-03 Main lift cylinder on HO/HM.....................................................8-04 Removal .........................................................................8-04 Dismantling ....................................................................8-05 Additional lift cylinder on NM/HM.............................................8-06 Removal .........................................................................8-06 Dismantling ....................................................................8-07 9 Line break protection General....................................................................................9-01 10 Hydraulic pump General..................................................................................10-01 Removing ..............................................................................10-02 Dismantling............................................................................10-03 11 Aisle recognition General ..................................................................................11-01 12 Steering Block diagram of the steering system....................................12-01 Pin assignment......................................................................12-02 Setpoint potentiometer, steering wheel .................................12-04 Replacing ......................................................................12-04 Setpoint potentiometer, steering knob...................................12-05 Replacing ......................................................................12-05 Actual value potentiometer....................................................12-06 Replacing ......................................................................12-06 Quick start .............................................................................12-07 Travel on curves function.......................................................12-08 Steering lock..........................................................................12-09 13 Vehicle control system (FZS) General..................................................................................13-01 Location.................................................................................13-01 Identification ..........................................................................13-01 Technical data........................................................................13-01 Guide to versions...................................................................13-02 Pin assignment......................................................................13-03 Input/output assignment ........................................................13-06

- 6. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Table of Contents Section Contents Sheet 13 Vehicle control system Error diagnosis........................................................................13-07 Flashing code, FZS2......................................................13-07 Table of functions, FZS2.........................................................13-08 Application......................................................................13-08 Pedestrian operating mode ...........................................13-09 Switch-over, 2nd operating console ...............................13-10 Power outputs ................................................................13-11 Travel enable..................................................................13-12 14 Operating console Position of the operating elements .........................................14-01 Removal..................................................................................14-01 Installing..................................................................................14-01 Wheel position display............................................................14-02 Adjustment .....................................................................14-02 Teaching in the FZS2 .....................................................14-02 2nd operating console ............................................................14-03 Pedestrian operating mode.....................................................14-04 15 End-of-aisle safety system (EASS) End-of-aisle safety system (EASS).........................................15-01 General ..........................................................................15-01 EASS Universal ......................................................................15-02 Error codes.....................................................................15-03 EASS Inductive.......................................................................15-04 Function .........................................................................15-04 Guide to the system .......................................................15-06 Monitoring .....................................................................15-07 Mounting the proximity switches ....................................15-08 Testing the proximity switches........................................15-08 Displays and pin assignment ........................................15-09 EASS Magnetic (bistable).......................................................15-10 Function .........................................................................15-10 Guide to the system .......................................................15-12 Monitoring ......................................................................15-13 Magnetic switch..............................................................15-14 Description.............................................................15-14 Bistable action .......................................................15-14 Switching magnet...........................................................15-15 Description.............................................................15-15 Handling instructions .............................................15-15 Displays and pin assignment .......................................15-16 8

- 7. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Table of Contents 9 Section Contents Sheet 16 Speed sensor General..................................................................................16-01 Terminals block connector X2 .......................................16-01 Signal sequence............................................................16-01 Testing the speed sensor.......................................................16-02 17 ABÜ - Braking monitor Block diagram........................................................................17-01 Pin assignment......................................................................17-02 General..................................................................................17-04 Functions...............................................................................17-05 Travel on curves............................................................17-05 Signal adaptation..................................................17-05 Flashing error codes..............................................................17-06 18 Travel control Block diagram for "Travel" .....................................................18-01 General..................................................................................18-02 Main current section - terminals ............................................18-03 Pin assignment......................................................................18-04 Description of functions .........................................................18-07 Braking modes ..............................................................18-07 Table of operating modes..............................................18-07 Hour meter ....................................................................18-08 Service hour meter........................................................18-08 Battery discharge indicator............................................18-08 Monitoring function........................................................18-09 Error display ..........................................................................18-10 Test procedure.......................................................................18-10 19 Direction sender General..................................................................................19-01 Replacing...............................................................................19-01 20 BDI/HM General..................................................................................20-01 Pin assignment......................................................................20-02 Function.................................................................................20-03 Error display ..........................................................................20-03 Battery discharge indicator....................................................20-03 Hour meter.............................................................................20-04

- 8. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Section Contents Sheet 21 Travel control software General..................................................................................21-01 Making a connection..............................................................21-01 Setting parameters ................................................................21-02 Test........................................................................................21-03 Diagnosis...............................................................................21-03 "File" menu ............................................................................21-03 Summary of the most important parameters .........................21-05 Battery discharge curves.......................................................21-06 List of parameters..................................................................21-07 Description of parameters .....................................................21-12 Errors displayed with flashing code.......................................21-17 List of error codes..................................................................21-18 Tester Table ...........................................................................21-19 22 Steering software General..................................................................................22-01 Making a connection..............................................................22-02 Errors.....................................................................................22-03 Current errors................................................................22-03 Stored errors .................................................................22-03 Teaching in ............................................................................22-04 General .........................................................................22-04 Procedure......................................................................22-04 Setpoint potentiometer..................................................22-05 Actual value potentiometer............................................22-06 Tester.....................................................................................22-09 Speed measurement.....................................................22-09 Amplifier data ................................................................22-10 Digital inputs and outputs..............................................22-11 Travel on curves active .........................................22-11 Deadman ..............................................................22-11 Steering wheel/ -knob ...........................................22-11 Steering OK ..........................................................22-11 Steering motor contactor ......................................22-12 Safety relay...........................................................22-12 Potentiometer voltages .................................................22-13 Supply voltage of actual and setpoint values .......22-13 Setpoint voltage at the steering wheel..................22-13 Actual value voltages at the drive wheel ..............22-13 Table of errors........................................................................22-14 10 Table of Contents

- 9. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Section Contents Sheet 23 Hand-held programming unit General..................................................................................23-01 Operating elements...............................................................23-01 Switching on ..........................................................................23-02 Switching off ..........................................................................23-02 Language selection ...............................................................23-03 Setting parameters ................................................................23-04 PROGRAM menu .........................................................23-04 Function ........................................................................23-05 Special program menu ..........................................................23-06 Resetting to initial settings ............................................23-07 Loading settings from the control system into the programming unit .............................................23-08 Loading settings from the programming unit into the control system..................................................23-09 Deleting the diagnosis data...........................................23-10 Adjusting the display contrast .......................................23-11 Language selection.......................................................23-12 Displaying information about the programming unit......23-12 Displaying information about the control.......................23-12 Test menu..............................................................................23-13 Displaying current errors .......................................................23-14 Error history...........................................................................23-14 11 Table of Contents

- 10. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Section Contents Sheet 99 Maintenance General...................................................................................99-01 Safety instructions ..................................................................99-02 Handling fuels and lubricants.........................................99-02 Brake ......................................................................................99-03 Functional check of the deadman brake ........................99-03 Functional check of the neutral brake ............................99-03 Functional check of the reversing brake ........................99-03 Maximum wear on the brake lining ................................99-03 Brake clearance .............................................................99-03 Battery ....................................................................................99-04 Checking the electrolyte level ........................................99-04 Checking the electrolyte density ....................................99-04 Cleaning the battery.......................................................99-04 Battery lock ....................................................................99-05 Battery charger...............................................................99-05 Operating elements ................................................................99-06 Ease of movement .........................................................99-06 Function test...................................................................99-06 Steering ..................................................................................99-07 Ease of movement .........................................................99-07 Reversed steering..........................................................99-07 Steering angle................................................................99-07 Switching-off in the event of error ..................................99-07 Toothed gear ring ...........................................................99-07 Lifting chains...........................................................................99-08 General ..........................................................................99-08 Checking the lifting chains for damage ..........................99-09 Checking the chain elongation.......................................99-13 Main lift ..................................................................99-13 Checking the chain elongation.......................................99-14 Additional lift ..........................................................99-14 Replacing the lifting chains ............................................99-15 Repairing the lifting chains.............................................99-15 Lubricating the lifting chains...........................................99-16 Cleaning the chains........................................................99-17 Hydraulic tank.........................................................................99-18 Volume ...........................................................................99-18 Seals ..............................................................................99-18 12 Table of Contents

- 11. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Section Contents Sheet 99 Maintenance Wheels....................................................................................99-19 Wear...............................................................................99-19 Wheel bearings ..............................................................99-19 Castor wheels ................................................................99-19 Motor.......................................................................................99-20 Carbon brushes..............................................................99-20 Checking the brush springs............................................99-20 Other maintenance work................................................99-20 Gear........................................................................................99-21 Changing the gear oil.....................................................99-21 Noises ............................................................................99-21 Leaks..............................................................................99-21 Mast........................................................................................99-22 Mast rollers.....................................................................99-22 Guide rollers...................................................................99-22 Windscreen ....................................................................99-22 Lifting cylinder ................................................................99-22 Guides, surfaces ............................................................99-22 Forks ..............................................................................99-22 Chain adjustment ...........................................................99-22 Pump assembly ......................................................................99-23 Carbon brushes..............................................................99-23 Oil level ..........................................................................99-23 Noises ............................................................................99-23 Soiling ............................................................................99-23 Lubrication ..............................................................................99-24 Lubricants.......................................................................99-24 Disposal .........................................................................99-24 Lubrication plan..............................................................99-25 13 Table of Contents

- 12. 07/01 01 Chapter 1 Vehicle data Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. 1 – 01 EK10 HM (Hochhub mit Zusatzhub) = high lift with additional lift) EK10 HO (Hochhub ohne Zusatzhub = high lift without additional lift) EK10 NM (Niederhub mit Zusatzhub = low lift with additional lift) EK10 NO (Niederhub ohne Zusatzhub = low lift without additional lift) Definition of vehicle model names 80001 80004 80003 80002

- 13. Chapter 1 Vehicle data Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. 1 – 02 Signs on the vehicle Nameplate UVV check Carrying load diagram Vehicle no. on chassis 30115 30116 30117 30118 30119

- 14. Chapter 1 Vehicle data Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. 1 – 03 Travel speed Outside the aisle • Type NO always vmax = 9.0km/h • Type NM Platform level < 0.5m vmax = 9.0km/h • Type NM Platform level > 0.5m & steering straight-on vmax = 4.0km/h • Type NM Platform level > 0.5m & steering > ±10° vmax = 2.5km/h • Type HO Platform level < 1.2m vmax = 9.0km/h • Type HO Platform level > 1.2m & steering straight-on vmax = 4.0km/h • Type HO Platform level > 1.2m & steering > ±10° vmax = 2.5km/h • Type HM Platform level < 0.5m vmax = 9.0km/h • Type HM Platform level > 0.5m & steering straight-on vmax = 4.0km/h • Type HM Platform level > 0.5m & steering > ±10° vmax = 2.5km/h Inside the aisle Always vmax = 9,0km/h

- 15. Chapter 2 Travel motor Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. 2– General The drive motor used in this vehicle is a 24V shunt motor. The armature and field coils are controlled separately by the travel controller. The travel movement is initiated as follows: voltage is applied to the armature and the field is excited. As soon as the armature voltage is equal to the battery voltage, the field current is reduced in order to achieve an increase in speed. The current speed of the drive motor is determined by a current measurement (measuring shunt) in the travel controller. Temperature monitor The drive motor has a temperature monitor (field coil resistor at normal temperature approx. 1.8 ). If the temperature is >90°C, deceleration is initiated by the MOT WRM parameter. If the temperature rises above 105°C, a traction cut-out is initiated by the Mot Hot parameter (see Software travel controle). 01 30122

- 16. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 17. Chapter 2 Travel motor Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. 2– Technical data Model designation GF 114 - F4 Id. no. W8 408 250 Excitation type shunt wound Voltage 24V Rated output 2000W Rated speed 2700 rpm Direction of rotation right / left Protection / insulation class JP 00 / 20 Field excitation 6V / 9A Armature current 104A On-period S2 = 60min Terminals A 1 Armature winding start A 2 Armature winding end F1 Field winding F2 Field winding 02 Right rot. Left rot. A1 A2 F1 F2 + - - + A1 A2 F1 F2 + - + - M M 30120 2 3 4 1

- 18. Chapter 2 Travel motor Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. 2– 03 Removing the travel motor Because the brake (2) is mounted on the travel motor, the vehicle is no longer braked once the brake and the travel motor have been removed. For this reason, always secure the vehicle to prevent it rolling away! • Pull out the battery plug. • Remove power leads (3. • Unplug speed sensor (9). • Remove electro magnetic break (2) The connection point for the connection cable of the spring brake may be in the cable duct (4)! • Remove the 8 screws (5). • Screw the special eyebolt tool M6 (6), into the armature shaft (min. 20mm). • Pull the rope (7) (special tool: pulley) through the eyebolt (6). Ensure that the rope is pulled through correctly (8). • Set the length (holding it tight with your hand is sufficient). • Lift the travel motor out with a lever rod. Never work without the correct aids. A considerable amount of force is required to release the seal (1) between the travel motor and the gear. • Remove the aids. • Lift the travel motor out by hand. When the travel motor has been removed, the opening left in the gear (2) must be closed off immediately, in order to prevent oil entering the inside of the gear. 2 3 5 3 9 4 60222 7 8 6 62005 62004 00178 48 41.5 min. 20mm M6x60

- 19. Chapter 2 Travel motor Copy g p o e ed o p o this manual may be reproduced in any form. Copyright reserved. Issue: 08/03 Workshop- Manual Replaces issue: EK10/02 Sheet no. 2– 04 Installation To install the travel motor, follow the instructions for removal in reverse order. It can be installed without the use of any special tools. Only use screws of the prescribed length, otherwise the four-point bearing may be damaged! Screw in and tighten the 8 screws (3) diagonally in several passes. 3 MA = 23Nm us Loctite MA = 26Nm MA = 140Nm 1 2 62006