Workshop Manual for STILL R 70 Trucks

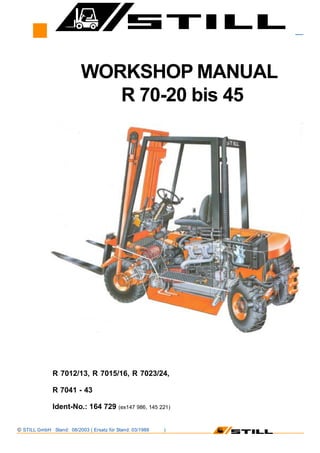

- 1. STILL GmbH Stand: 08/2003 ( Ersatz für Stand: 03/1988 ) WORKSHOP MANUAL R 70-20 bis 45 R 7012/13, R 7015/16, R 7023/24, R 7041 - 43 Ident-No.: 164 729 (ex147 986, 145 221)

- 2. 01 Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Chassis Frame and Counterweight 01 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) 1 2 3 4 1 2 Chassis Frame The chassis frame is constructed of electrically welded steel plate. The fuel tank is positioned within the righthand frame section, whereas the hydraulic tank is housed within the left-hand frame section. Counterweight The removable rear counterweight is secured to the frame weldment by 4 bolts. 1 = hex. hd. bolt M24 x 110, 8.8 DIN 933 Torque loading = 710 Nm 2 = locking ring 3 = spherical washer C25 DIN 6319 4 = ball cup D28 DIN 6319 Weight of the counterweight 7041 = 2200 kgs 7042 = 2570 kgs 7043 = 2910 kgs

- 3. 02 Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Steer Axle 01 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Contents Page Technical Data for Maintenance Service 2 Steer Axle - Construction 3 Steer Axle removal & installation 3 Wheel Hub - Removal & Dismantling 4 Wheel Hub - Reassembling and Installation 4 Checking the steering angles 5 Wheel angle stop adjustment 5 Stub axle removal and installation 6 Track rod and steer cylinder bearing at stub axle 7 Track rod bearing on steering bell crank 7 Steer cylinder mounting at axle beam 8 Bell crank mounting 8

- 4. 02 Technical Data for Maintenance Service 02 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Functional Group 02 Steer axle Wheel lock angle 80-82° Toe-in 01 ± 1 mm Wheel camber 0° Trail 0° Torque loadings for Wheel hub MA = 470 Nm Neoprene blocks MA = 195 Nm Wheel nuts MA = 600 Nm Lubricant Wheel hub bearings lithium soap based grease Stube axle king pin bearings lithium soap based grease Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24)

- 5. 02 Steer axle 03 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Steer axle - Construction The articulating steer axle suspended from the counterweight is mounted in neoprene blocks. The stub axles are supported in the axle beam on roller thrust bearings and bushes. Steering is limited by stop screws on the stubs axles. 1 = axle beam 2 = fixing plates 3 = roll pin 4 = tension washer 5 = hex. hd. screw 6 = neoprene block Steer axle removal Caution: Remove steer axle only wit mast in position on the truck! - Securely chock the front wheels to prevent rolling of the truck - Apply the parking brake - Slacken steer wheel nuts - J ack up rear of the truck at counterweight (x) and place wooden blocks under the counterweight in front of the axle - Remove wheels - Disconnect the hydraulic connections at steer cylinder. Caution: prepare for oil spillage! - Remove the four hex. head screws M16 x 70 which retain the steer axle in place - Slide a hand pallet truck under the steer axle with wooden blocks placed on the fork ends of the hand pallet truck - Using a leverdrive steer axle out of roll pins and lower the axle onto the hand pallet truck Steer axle installation - Reverse the removal procedure - The slots of the roll pins must face the direction of forward travel - Torque socket head screws to: MA 195 Nm - Note: Do not swap hydraulic connections left and right! Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24)

- 6. 02 Steer axle 04 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Wheel Hub - Removal and Dismantling 1 = axle beam 2 = stub axle 3 = radial seal 4 = tapered roller bearing 5 = wheel hub 6 = tapered roller bearing 7 = washer 8 = roll pin 9 = hubcap 10= nut 11 = ball seat nut 12= wheel bolt - Slacken ball seat nuts (11) and remove wheel - Pull hub cap (9) from wheel - Slacken nut (10) - Remove washer (7) together with roll pin (8) - Withdraw the hub - If necessary, drive out of wheel hub outer races of tapered roller bearings (4) and (10) Remove radial seal (3) Wheel hub - Reassembling and Installation - Apply a smear of grease to the sealing lips of the radial seal - Before re-assembling the hub, first fill cavity of taperedrollerbearings andbearingcage withgrease - The corresponding bearing spaces must be repacked with grease at places identified by an X on the drawing - To reassemble the hubs, reverse the procedure - Tighten nut (8) while rotating the wheel hub Torque loading: MA= 470 Nm Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24)

- 7. 02 Steer Axle 05 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Linkskurve = 82° +0/-2 Lenkeinschlag Rechtskurve 1 Checking the steering angles The steering angle ‘a’ must amount to 80° -82°. To facilitate the measurement use the complementary angle ß for the setting. It should amount to 98° - 100°. Important: Ensure that the wheel lock is limited by the stop screws (1) and not by the cylinder stroke. Wheel angle stop adjustment The wheel stop angle is limited by the stop screws (1). - By operating on stop screws (1), set both steering angles to 82° - 2° - Check opposite angles - Check for adequate clearance between wheels and truck frame - Check that the wheel lock is not limited by the cylinder stroke Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) a a ß ß Right-hand bend Steering lock Left-hand bend a

- 8. 02 Steer Axle 06 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Stub axle king pin bearings Removal: Unscrew the three grease nipples (1) Remove screws (2) from lower and upper ends of king pin Remove washers (3 & 14), roll pins (6 & 13) as well as seals (5) Unscrew grub screw (10) Drive king pin (4) down, forcing out lower needle bearings (7) and seal (8) at the bottom of the king pin. Then drive out king pin into opposite direction. Drive out upper needle bearings (7) and seal (8) Remove stub axle (11) with thrust bearing (9) and shims (12) Installation: Pack bearings with grease. apply a smear of grease to the sealing lips of the seals before installation! Install needle bearings (7) andseals(8) into axle beam Install stub axle (11) with thrust bearing (9) into axle beam Grease shims (12) before installation. Compensate for any play by adding shims (12), making sure that the thickest shim is placed bearing end Install stub axle king pin (4), pressing it in at 8 kN max. Apply Loctite grade 243 to threads of grub screw (10) and install grub screw Install washers (3 & 14) with seals (5) Install roll pins (6 & 13) Install screws (2) Install grease nipples (1) Lubricate the stub axle with grease! Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24)

- 9. 02 Steer Axle 07 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Track rod and steer cylinder bearing at stub axle 1 = hex. hd. screw M10 x 35, secured with Loctite 243 2 = washer 3 = oil seal 4 = ball joint, press force: 4 kN max. 5 = roll pin 6 x 24 6 = completely screw in piston rod then screw but by one turn 7 = oil seal 8 = oil seal 9 = pin, press force: 8 kN max. Track rod bearing on steering bell crank 1 = circlip (retaining ring) 2 = pin, press into steering bell crank at 30 kN max. press into ball joint at 10 kN max. 3 = steering bell crank 4 = ball joint, press force: 4 kN max. 5 = V shaped rings 6 = washer Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24)

- 10. 02 Steer Axle 08 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Steer cylinder mounting at axle beam 1 = snap ring 2 = ball joint, press force: 2.6 kN 3 = roll pin 4 = hex. hd. bolt, secured with Loctite 243 5 = washer 6 = oil seal 7 = oil seal 8 = pin, press into ball joint at 9 kN max. press into axle beam at 68 kM max. Bell crank mounting 1 = locking ring 2 = washer / shims 3 = needle bearing 4 = pin, press into axle beam at 42 M max. 5 = grease nipple 6 = snap ring 7 = washer (must always be fitted) 8 = oil seal Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24)

- 11. 03 Power axle 01 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Contents Page Technical Data for Maintenance service 2 Power Axle / Description 3 Spur-type reduction gearbox / Sectional view 5 Power axle removal and installation 6 Wheel hub removal and installation 9 Half -shaft removal and installation 10

- 12. 03 Technical Data for Maintenance service 02 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Functional Group 03 Power axle type AE 40 - 02 Torque loadings frame/power axle MA = 1000Nm Torque loadings axle housing/gear reduction box MA= 295Nm End play toothed hollow shaft + 0.03 mm - 0.06 mm Torque loadings centring flange / wheel hub ZS M 8 x 16 10.9 MA=35 Nm Torque loadings oil drain plug MA = 70 Nm Torque loadings half shaft ZS M 12 x 35 10.9 MA = 120 Nrn Gearbox oil capacity: 9.5 litres checked with dipstick unscrewed and pushed in as far as it will go and then withdrawn again Grade of oil: SAE - 90 EP - 51512 Grade of grease lithium soap based grease with EP additive

- 13. 03 Power Axle 03 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Description The power axle consists of a double reduction spur-type gearbox(1)comprising differential assembly with two-bearing driving pinion, to which a D.C. electric motor (2) is flange mounted, as well as of,a long axle housing (3) and an axle housing which is an integral part of the gear case (1). The long axle housing (3) with the double reduction spur-type gearbox (1) are rigidly bolted to the frame and the mast pivots are bolted to the half-shaft housings. 1 = differential gear reduction box 2 = D.C. drive motor 3 = long half-shaft housing with cast-on brake backplate 4 = fixing screws 5 = short half-shaft housing / gearbox half with cast-on brake backplate 6 = mast pivots bolted to the half shaft housings

- 14. 03 04 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Power Axle Spur-type reduction gearbox with differential assembly

- 15. 03 Spur-type reduction gearbox with differential assembly 05 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) 1 Gear case 2 3 dowel pin 4 allen screw 5 tapered roller bearing 6 differential 7 gear 8 roll pin 9 hex hd bolt 10 shim 145 x 130 x 0.5 -0.9 11 twered roller bearing 12 gear with shaft 13 shim 160 x 85 x 0.5 -0.9 14 circlip 15 connector 16 sealing ring 17 oil drain plug 18 lid 19 plug 20 driving dog 21 chevron seal 22 tapered roller bearing 23 toothed hollow shaft 24 ‘O’ring 25 shim 75 x 65 x 0.5 -0.8 26 ‘O’ring 27 chevron seal 28 cover 29 spring washer 30 hex hd bolt M 8 x 20 8.8

- 16. 03 Power Axle 06 Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Power Axle removal Remove mast assembly Chock truck securely to prevent rolling Drain oil at oil drain plug (2), catch oil in pan Slacken wheelnuts Remove wheels Clearly mark the electric cables before disconnecting them from the drive motor Disconnect hydraulic brake lines at brake master cylinder Disconnect brake cables at the parking brake With sling around power axle attach chain to overhead hoist Remove mounting bolts (3) right and left Carefully manoeuvre the power axle clear of truck Power Axle mounting With the overhead hoist manoeuvre power axle into frame Insert the 16 mounting bolts with their 16 washers but do not tighten at this stage Torque all mounting bolts (3) to MA 1000 Nm Remove overhead hoist Reconnect drive motor cables Reconnect hydraulic brake lines to brake master cylinder Reconnect brake cables to parking brake Install wheels (see FG. 04) Install mast (see FG. 20) Checking oil level: Unscrew dipstick. push it in as far as it will go and then withdraw again (do not screw in for checking the oil level) Oil capacity: 9.5 litres Gearbox oil : SAE 90 EP - 51512 1 = oil filler neck with dipstick 2 = oil drain plug 3 = mounting bolts 4 = tension washers

- 17. 03 Power Axle 07 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Item Description 1 Spring washer DIN 137 2 Hex hd bolt M 8 x 20 8.8 MA = 23 Nm 3 Washer 4 Chevron seal A 45 x 62 x 8 P70 5 ‘0’ ring seal 37x2-P70 6 Tapered roller bearing 7 ‘0’ ring seal 74x3-P80 8 Lid 9 Allen screw M 12 x 50 - 10.9 MA = 120 Nm 10 Tapered roller bearing 11 Toothed hollow shaft Power from the drive motor is transmitted via a shaft with spline to the double reduction gears. The pinion shaft in gearbox is supported both sides on tapered roller bearings, and the sealing between drive motor and gearbox is with chevron seal.

- 18. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 19. 03 Power Axle 08 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Adj usting instructions for supporting the toothed hollow shaft on taper roller bearings 1. Assemble both taper roller bearings onto toothed hollow shaft. After that determine dimension W across taper roller bearing outer races. 2. Determine installation dimension „B“. 3. Determine centring collar length „C“ on cover. 4. Thickness of shims D = B - (minus) (A + C + 0.06 mm) 5. Add or remove shims as per actual dimension = „D“ + (plus) 0.03 mm (preload) up to - (minus) 0.06 mm (free play). 6. Assemble both taper roller bearings which must be repacked with grease up to half of the max. capacity In exceptional cases gearbox oil SAE 140 EP can be used as a substitute. 7. Using a fitting tool (mandrel), preassemble outer race of taper roller bearing (opposite the cover). 8. Install toothed hollow shaft. 9. Using a fitting tool, pre-assemble by around 20 mm outer race of taper roller bearing (cover side). 10. Install layer of shims as per para. 5, and by tightening the coverboltsevenlyin corner tocorner sequence bring taper roller bearing outer race into final position.

- 20. 03 Wheel hub 09 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Wheel hub removal - J ack up truck securely from the side the removal is performed or drain the oil from the reduction gearbox if both sides of the truck are chocked. - Remove the wheeinuts and withdraw the drive wheel. - Remove the half -shaft (6) - see page 9. - Remove the brake drum(1)after having first released the parking brake. - Remove the alien screws (7). - Remove the centring flange (8). - Remove hub (3). Wheel hub installation NOTE: If the wheel hub is not provided with wheel studs (2), press new studs into the wheel hub using a press. - Tap both outer races of the taper roller bearings (10 & 11) into the wheel hub. - Grease inner race of taper roller bearing (10) and insert it into wheel hub. - Press radial seal (12) into wheel hub. - Pack wheel hub with grease, and slide it on axle housing. - Grease inner race of taper roller bearing (9) and tap until properly seated. - Apply Loctite 572 to centring flange (8) and position it on the axle housing (centring occurs automatically on taper roller bearing), install alien screws (7) and tighten to specified torque. Torque loading: M A= 35 Nm - Refer to page 10 for half-shaft installation.

- 21. 03 Half -shaft removal and installation 10 STILL GmbH Stand: 6/2003 ( Ersatz für Stand: 8/1992 ) Workshop Manual R 7041 - 43, (R 7012/13 / 15/16 / 23/24) Half-shaft removal - J ack up truck securely from the side the removal is performed or drain the oil from the axle. - Remove wheeinuts. - Remove drive wheel. - Remove screws (1) securing half-shaft to hub. - Using two of the screws, pull half-shaft (3) from housing. Two appropriate tapholes exist in the shaft flange. - Carefully withdraw the half-shaft from the axle housing. Half-shaft installation - Install chevron type sealing ring (2). - Slide O-ring (4) on half -shaft. - Carefully install half-shaft (3) into axle housing and assemble it to bevel gear in differential. It may be necessary to drive it in with a hammer and a block of hardwood. - Bolt half-shaft (3) and wheel hub (5) firmly together. - Torque loading MA = 120 Nm - Follow same procedure for other halfshaf t.