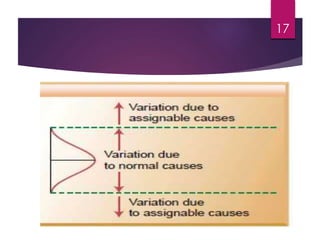

This document provides an overview of statistical quality control (SQC). It discusses that SQC uses statistical techniques to measure and evaluate quality, with the goal of determining if a production process is in control. The history and key figures who developed SQC are outlined, including Walter Shewhart who created control charts in the 1920s. Descriptive statistics, statistical process control, and acceptance sampling are presented as the main categories of SQC. Variations in quality are described as being either due to chance/common causes or assignable causes, with the latter needing to be identified and corrected.