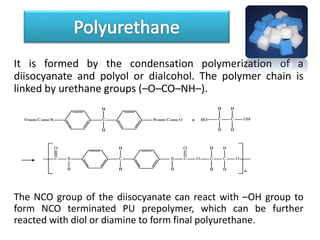

This document discusses starch-based polyurethanes. It begins by classifying polymers as either synthetic or natural. Common synthetic polymers are listed. Starch is introduced as a natural polymer extracted from plants. The document then explains how polyurethane is formed from diisocyanates and polyols. Several studies modifying starch to create biodegradable and renewable starch-based polyurethanes are summarized. These modifications improved properties like mechanical strength and decreased toxicity. Finally, applications of these starch-based polyurethanes are mentioned, such as in biomedical products, packaging and controlled fertilizer release.