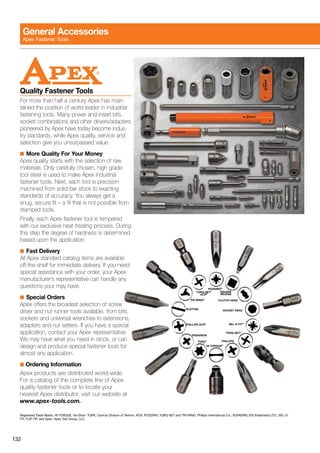

This document provides information about Apex Tool Group's power tool sales and service centers located around the world, including contact details for centers in Detroit, Houston, Seattle, Lexington, Los Angeles, York, Brazil, Canada, China, England, France, Germany, Hungary, and Mexico. It also lists the company's address and website.