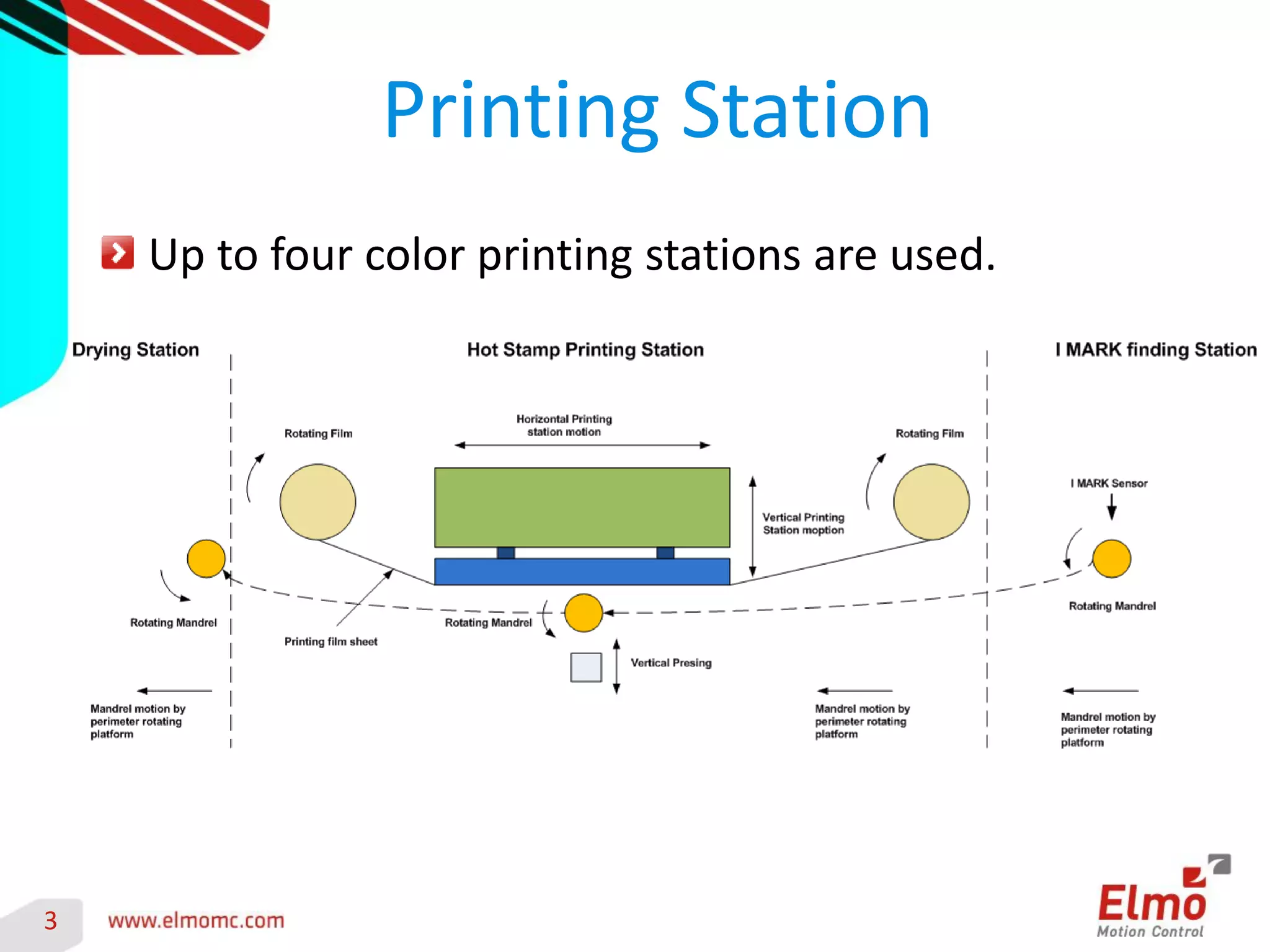

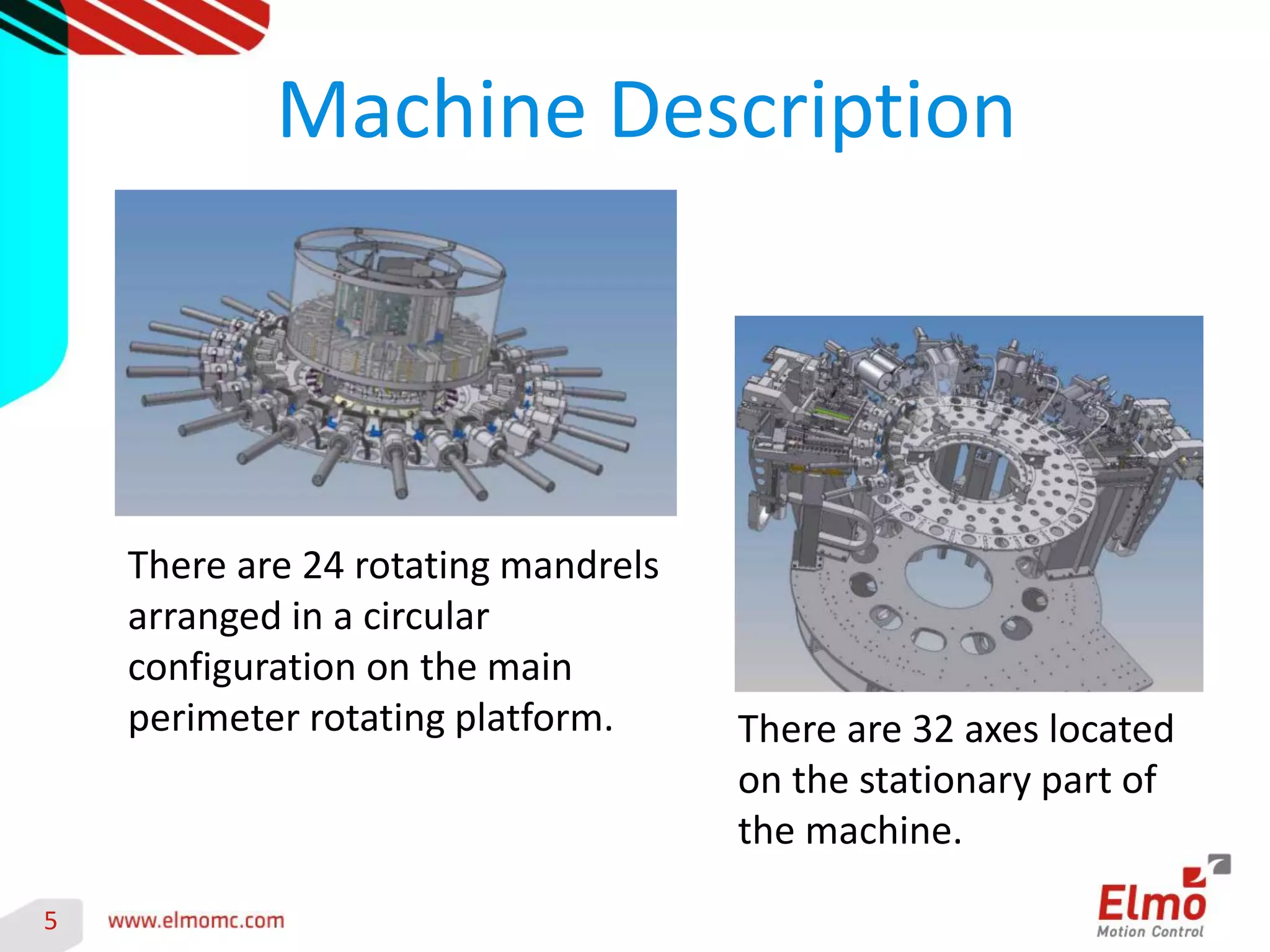

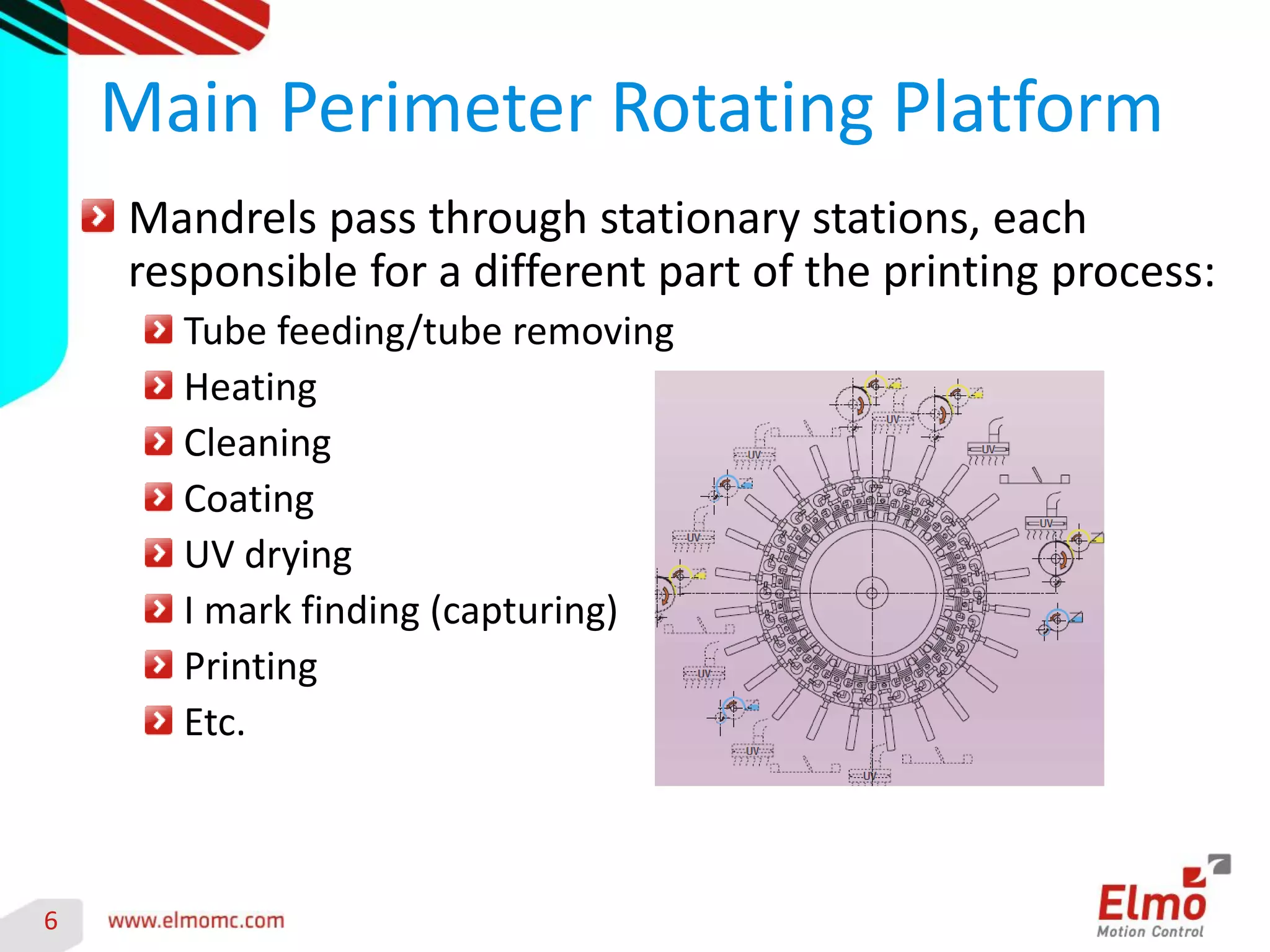

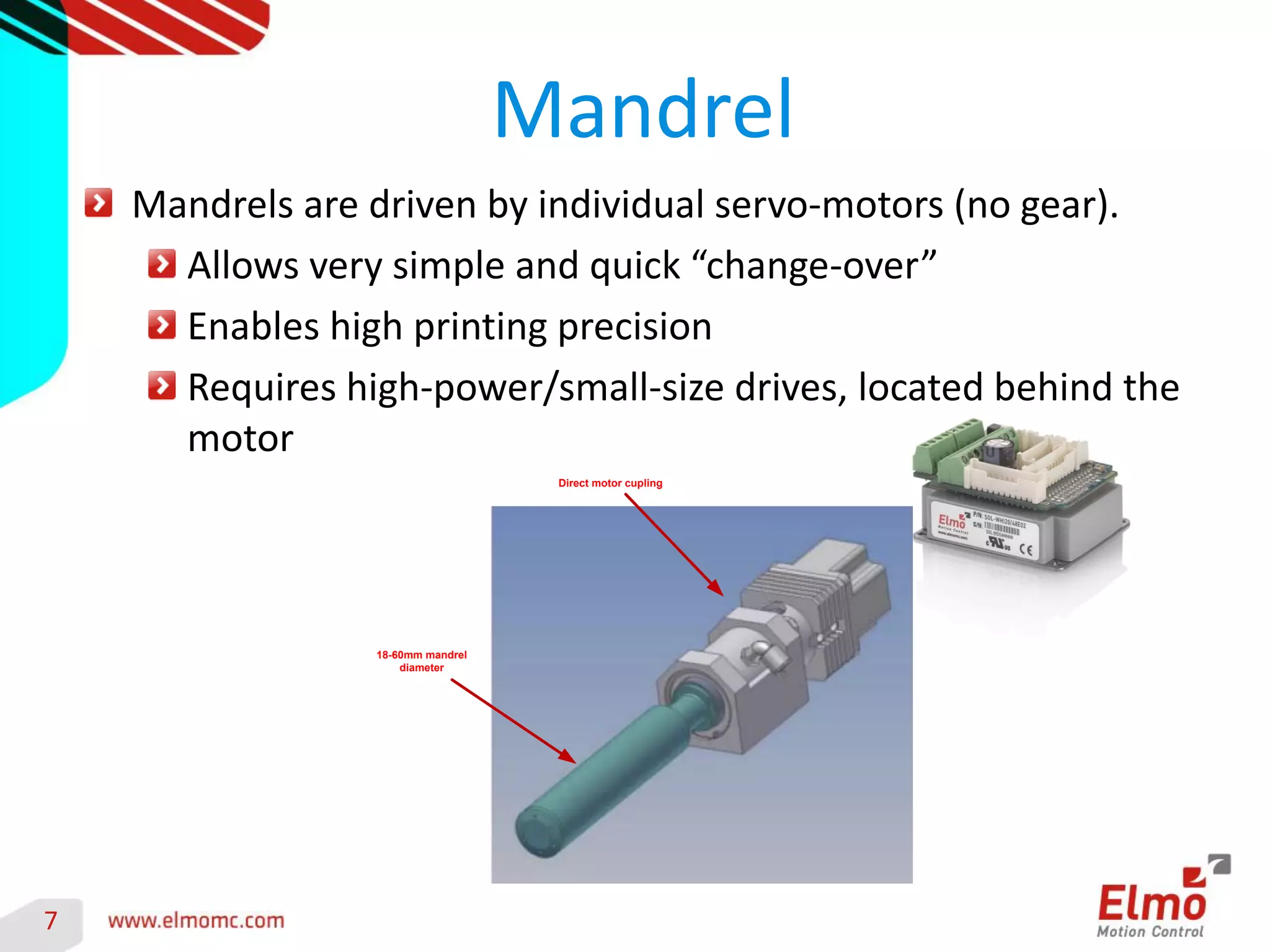

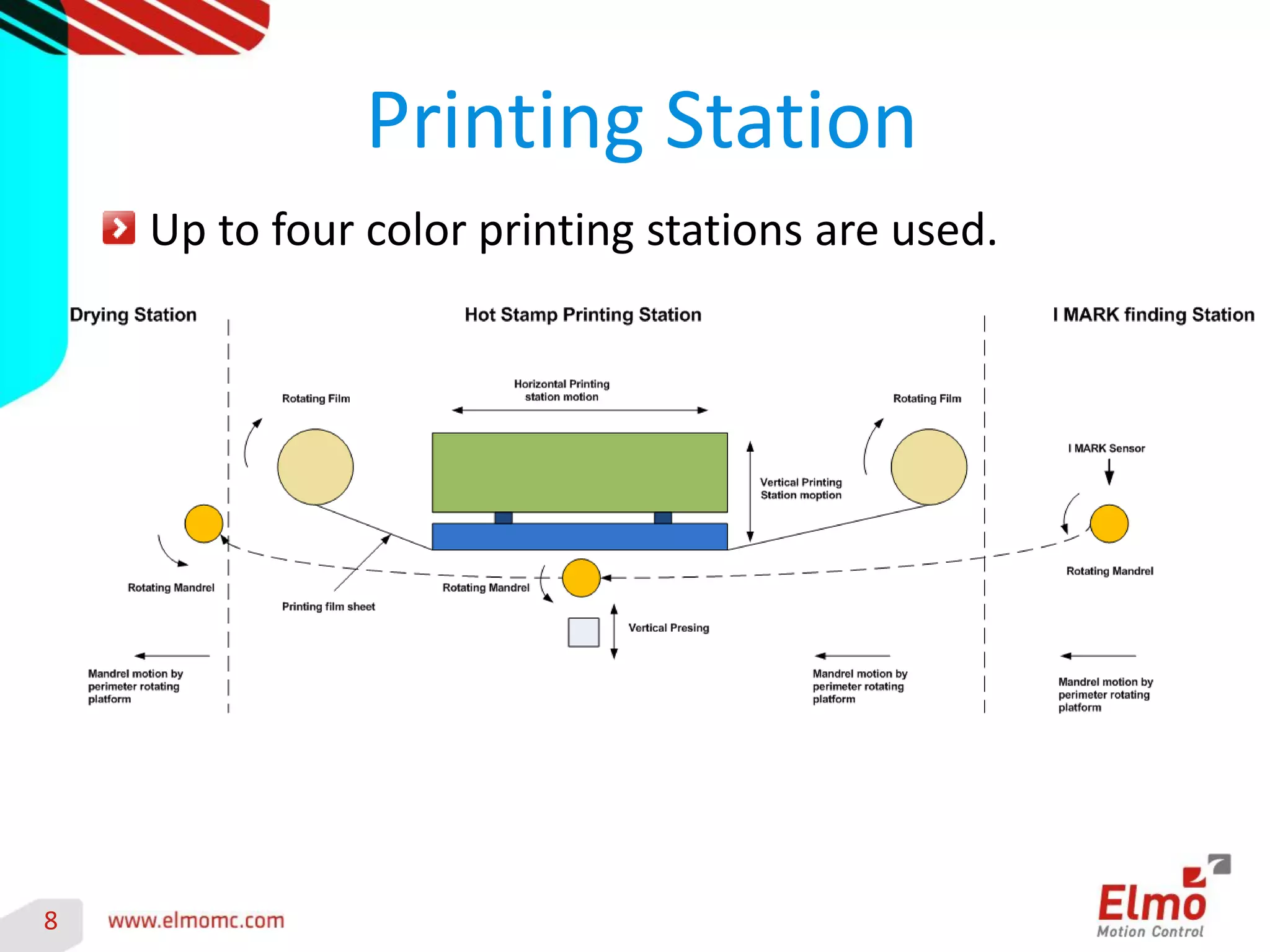

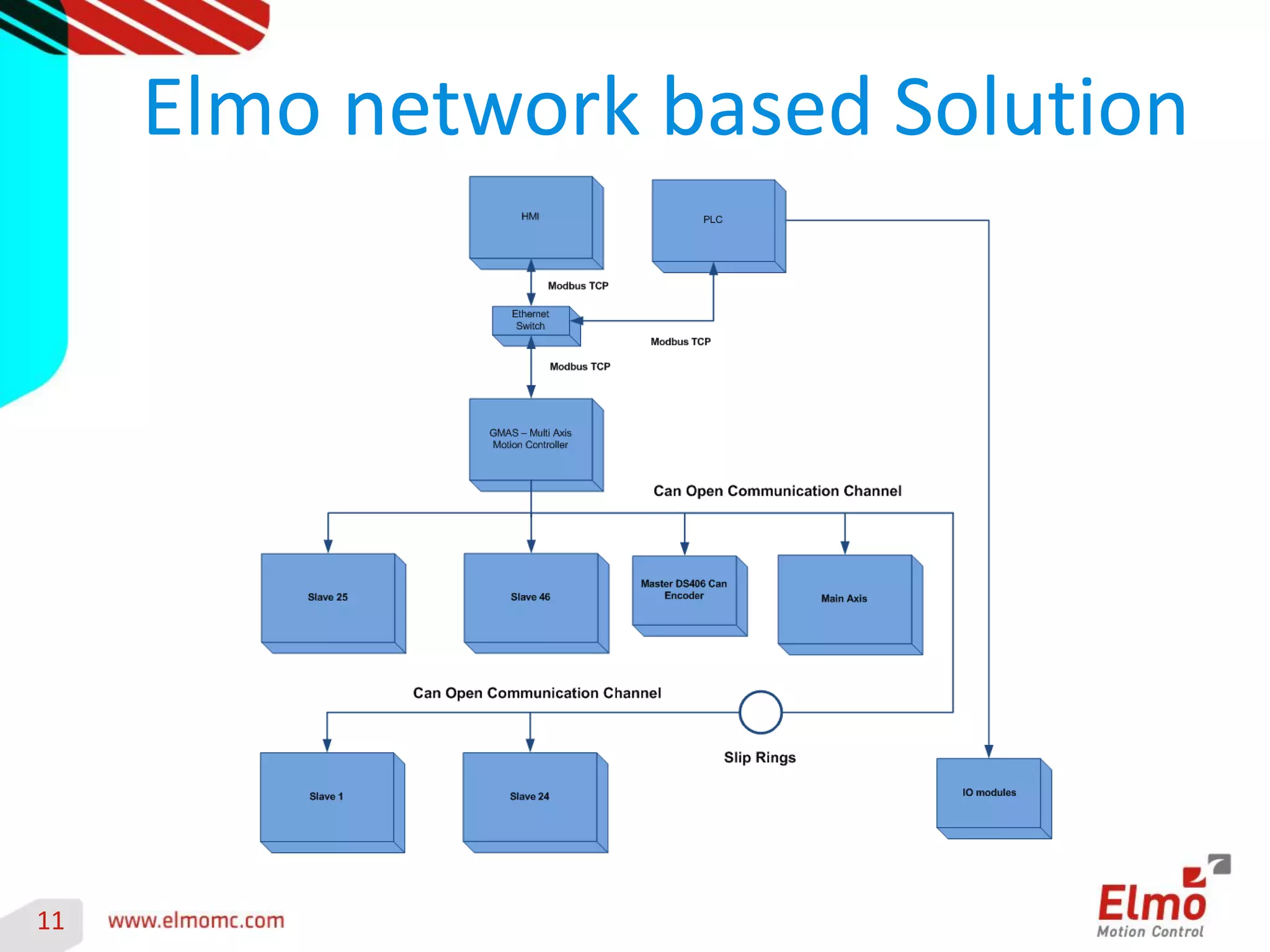

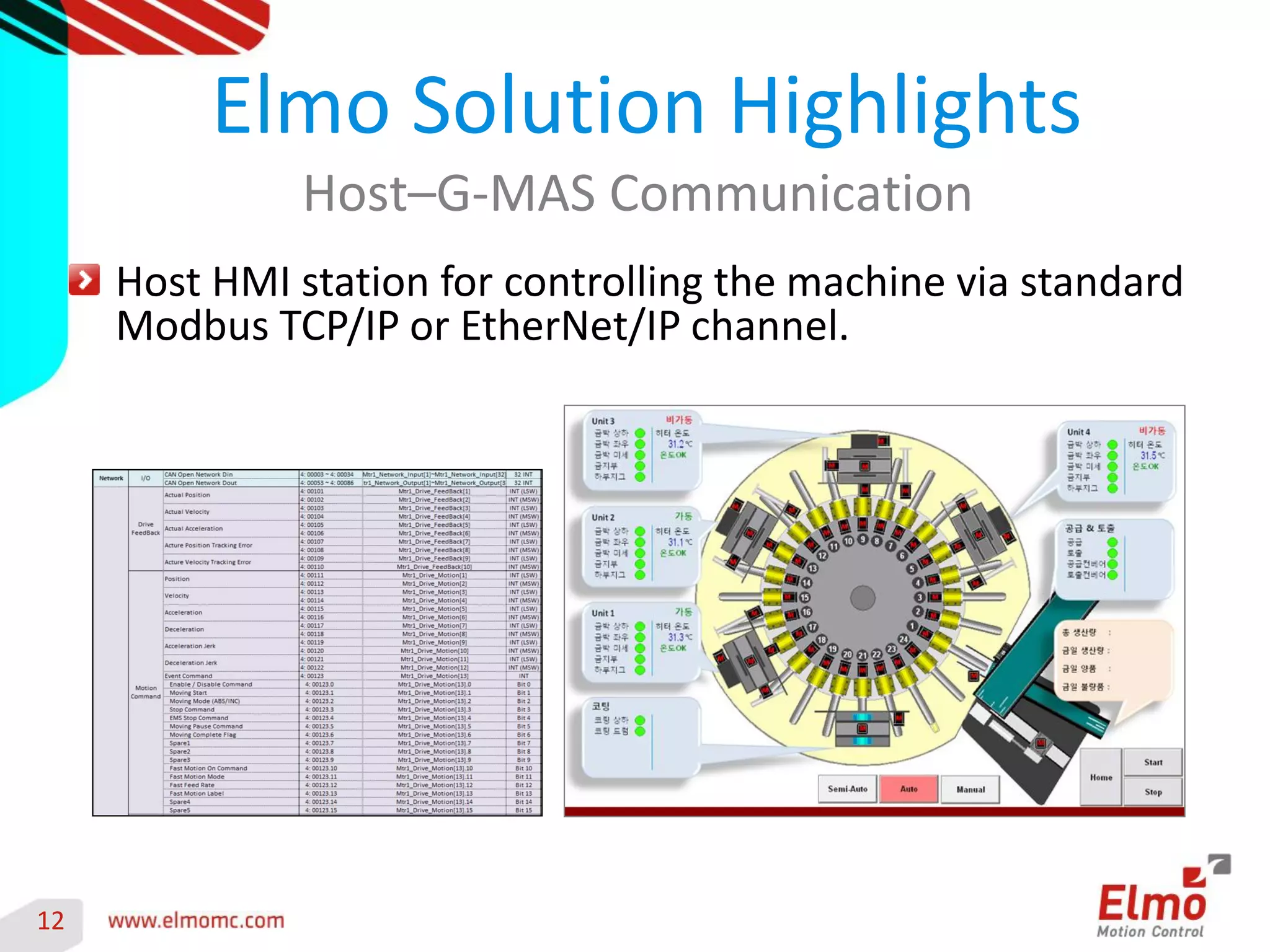

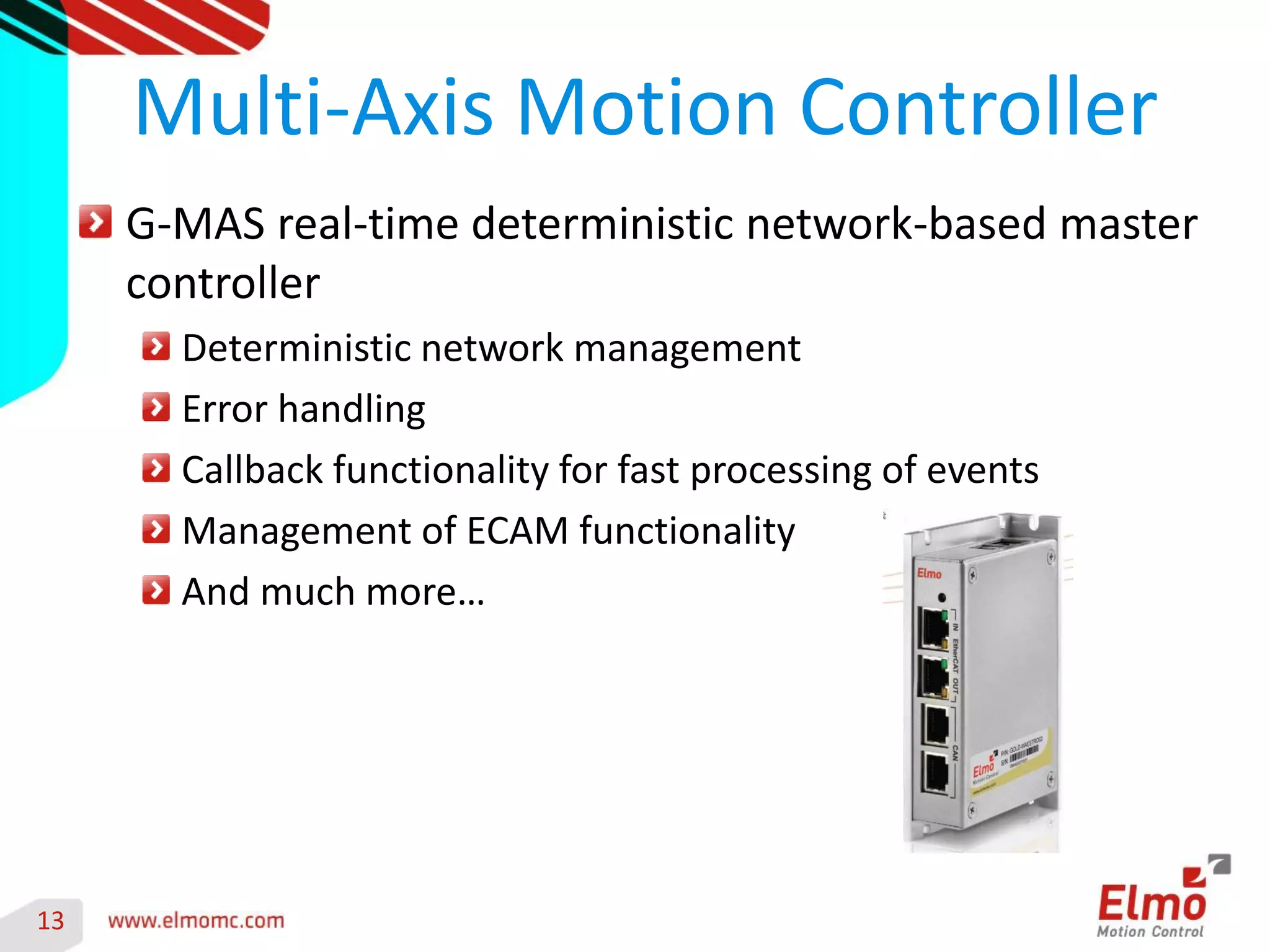

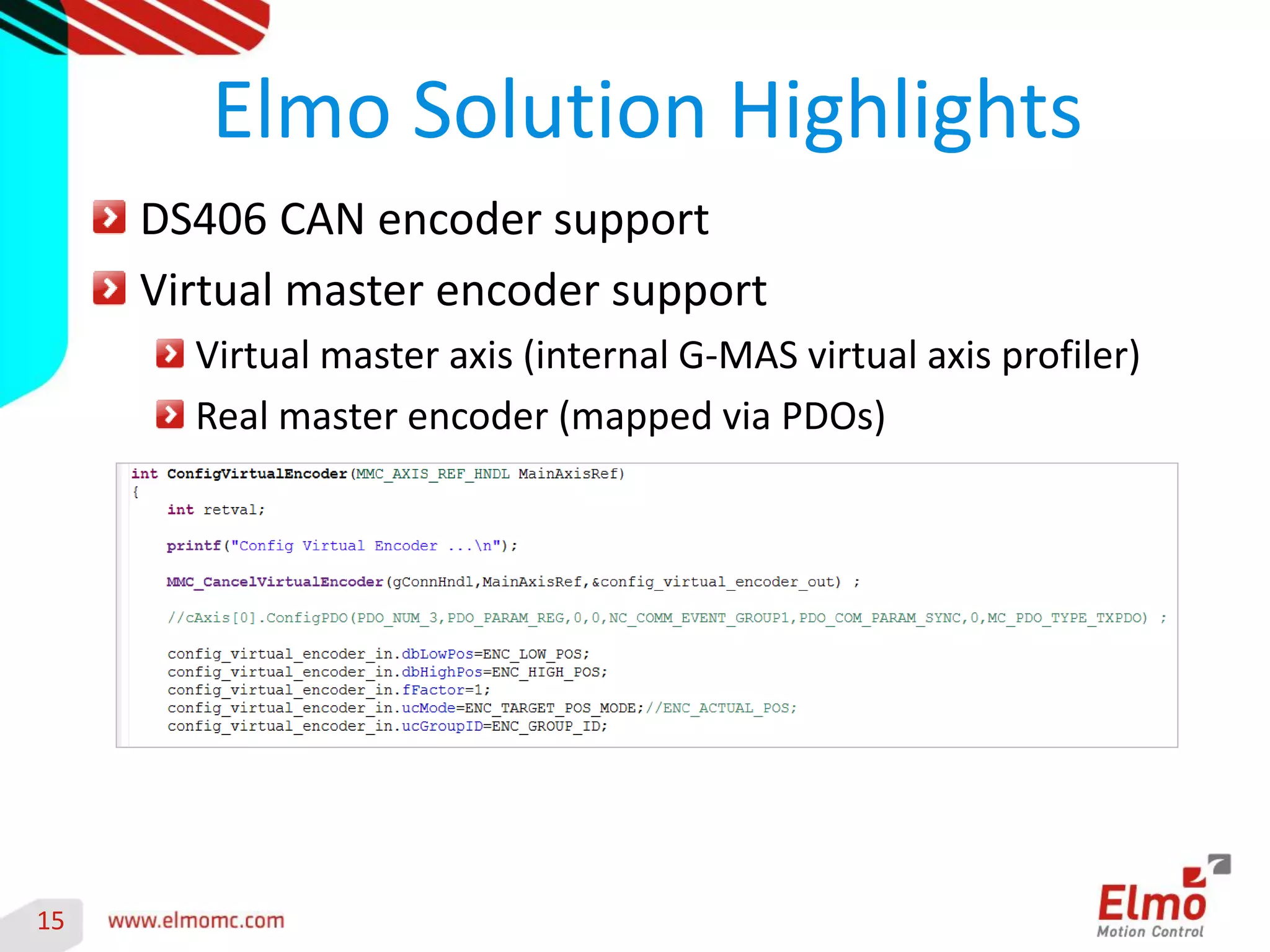

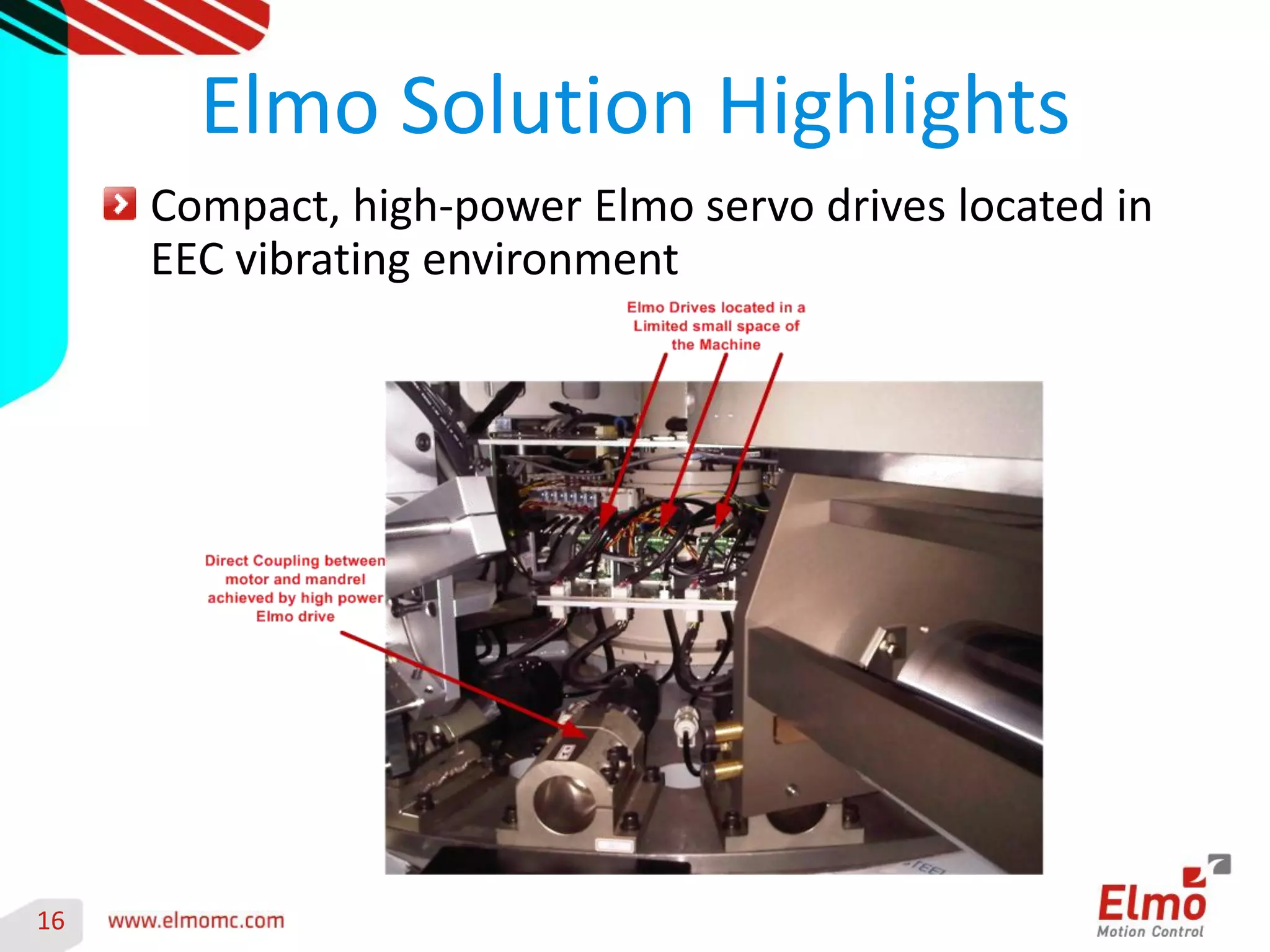

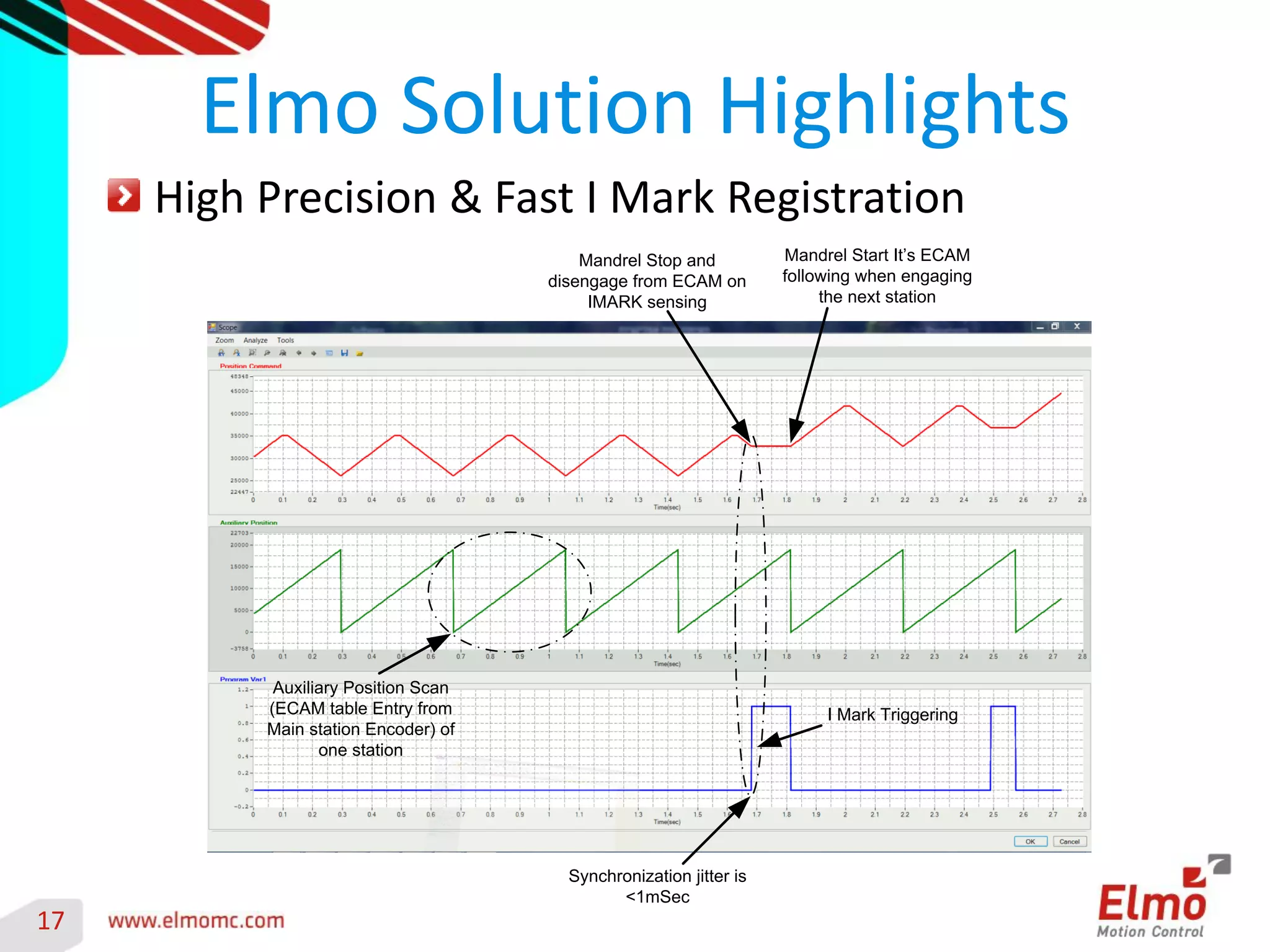

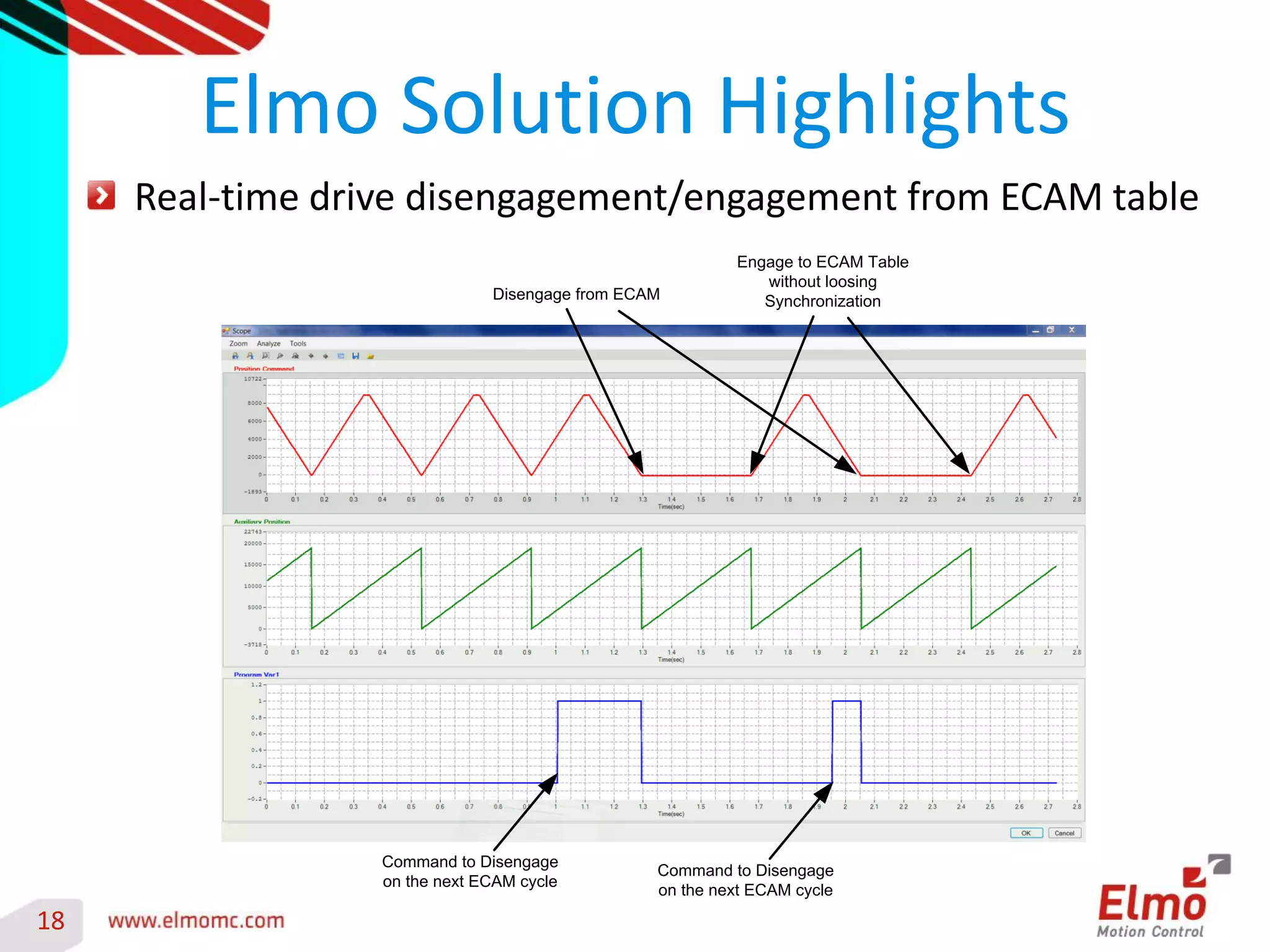

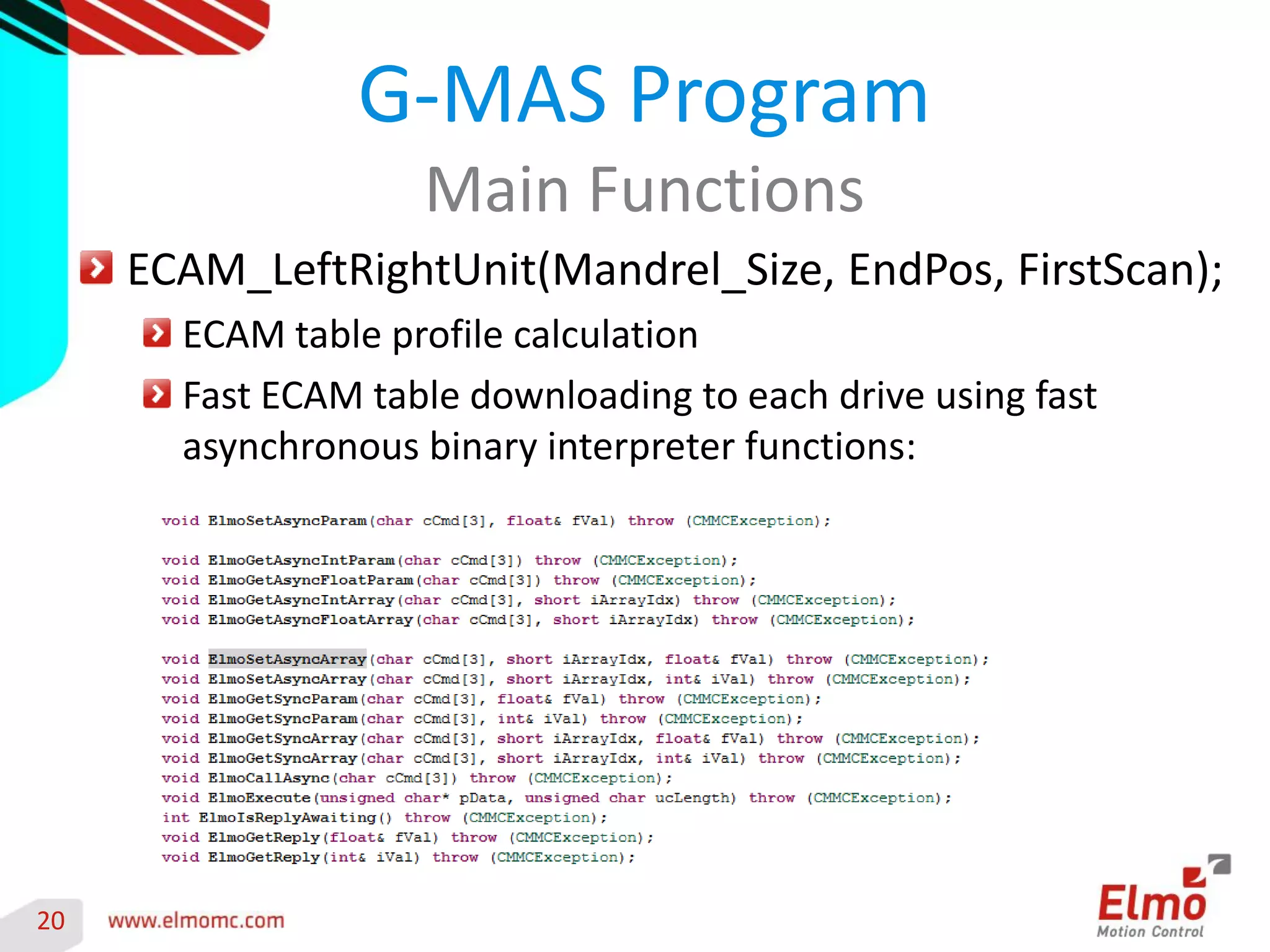

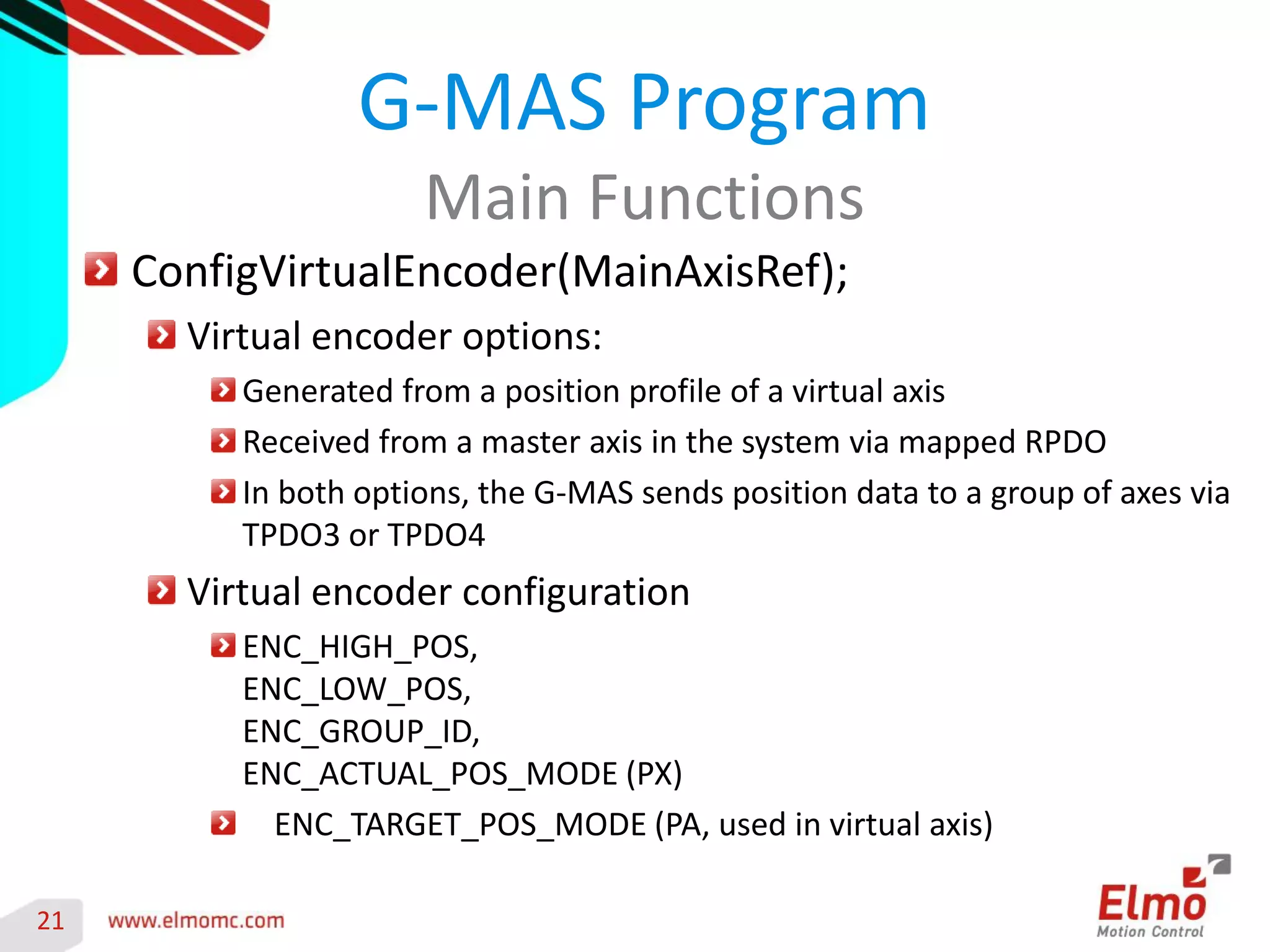

The document discusses an ecam-based motion control solution designed for various types of printing and textile machines, highlighting its application across multiple printing technologies and textile operations. It outlines the machine's architecture, which includes a rotating platform with servo-driven mandrels, and details the challenges and features of the Elmo network-based solution for high-performance synchronization and control. Additionally, it emphasizes the advanced motion control capabilities and benefits such as high throughput and precision in the operational environment of the machines.