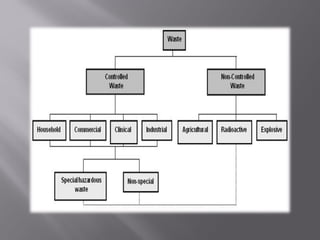

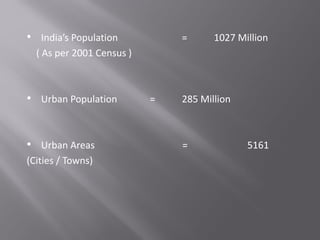

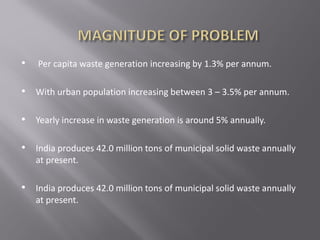

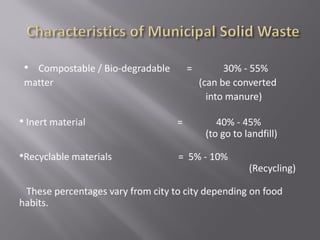

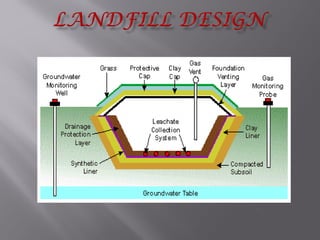

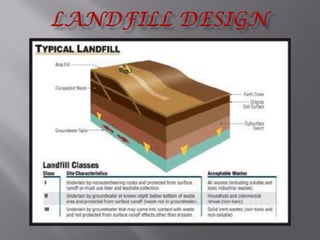

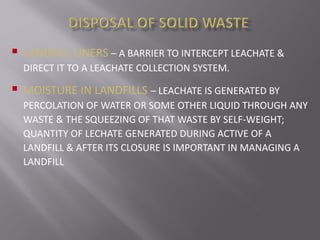

The document discusses various types of waste generated in India, including municipal solid waste, and highlights the increasing per capita waste generation and the inefficiencies in waste management systems. It covers the need for better waste segregation, recycling practices, and reduction strategies, as well as the environmental impacts associated with waste disposal and management techniques like landfilling. Furthermore, it emphasizes the importance of source reduction, community involvement, and modern waste management practices to mitigate the growing waste crisis.