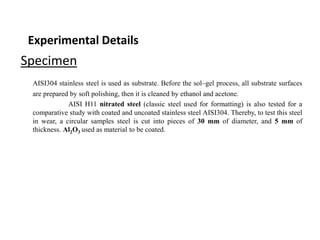

- Sol-gel coating was applied to stainless steel to improve its wear resistance. Alumina was deposited on AISI 304 stainless steel via dip coating and heat treatment.

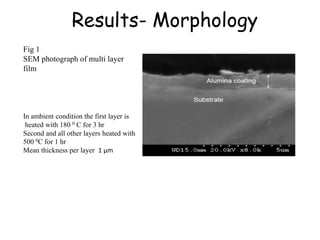

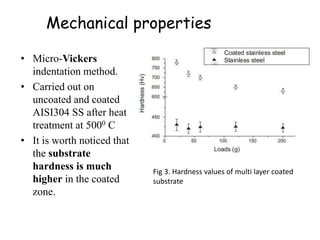

- Characterization found the coating was smooth, homogeneous, and compact with higher hardness than the uncoated steel. Alumina peaks were detected via EDX.

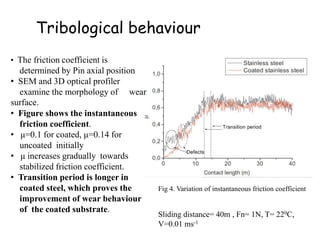

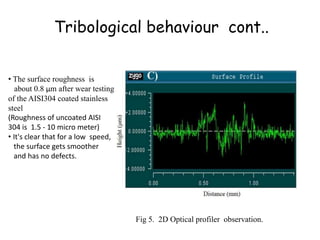

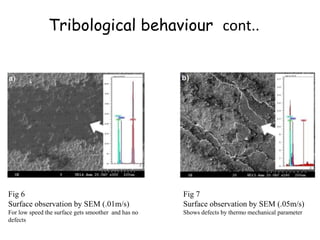

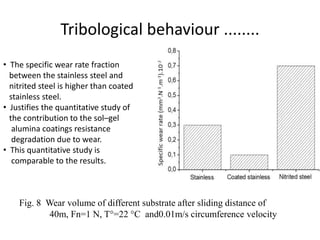

- Pin-on-disk tests showed the coated steel had lower friction coefficients and less wear than the uncoated steel. The coated surface remained smooth at low speeds with no defects, while uncoated steel roughness increased after wear.

![Reference

[1] B. Tlili, A.Barkaoui, M.Walock, Tribology and wear resistance of the stainless steel.

The sol–gel coating impact on the friction and damage; 102(2016)348–354

[2] S.M. Attia, Jue Wang, Guangming, Jun Shen, and Jianhua M A; Review on sol- gel

derived coatings: process, techniques and optical applications; vol 18 (2012) ,211-218

[3] M. Aparicio A. Jitanu G. Rodriguez A. Degnah K.Al-Marzoki J. Mosa L.C. klein;

Corrosion Protection of AISI 304 Stainless Steel with Melting Gel Coatings;

S0013-4686(2015)31068-9

[4] Ana F. Suzana, Elivelton A. Ferreira, Assis V. Benedetti, Hudson W.P. Carvalho, Celso V.

Santilli, Sandra H. Pulcinelli; Corrosion protection of chromium-coated steel by hybrid

sol-gel coatings; S0257-8972(2016)30358-9](https://image.slidesharecdn.com/seminar2-copy-180513072653/85/Sol-Gel-coating-20-320.jpg)