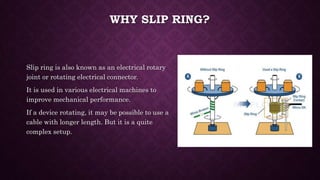

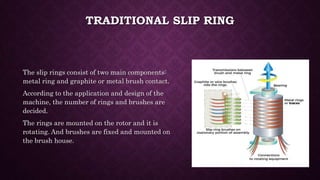

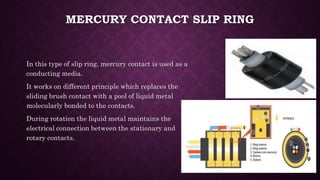

A slip ring is an electromechanical device that facilitates the transmission of power and electrical signals from a stationary to a rotating system, enhancing mechanical performance in various applications. There are several types of slip rings, including traditional, pancake, mercury contact, and wireless slip rings, each with unique designs and principles of operation. Key applications include wind turbines, intelligent lighting, medical equipment, and robotics.