Embed presentation

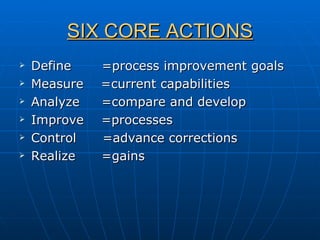

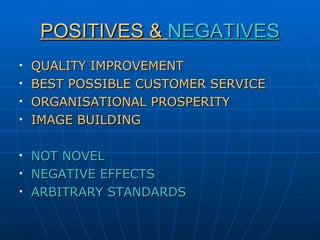

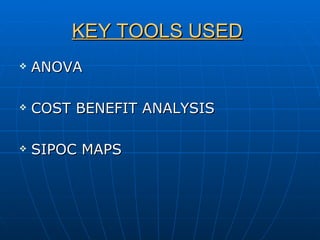

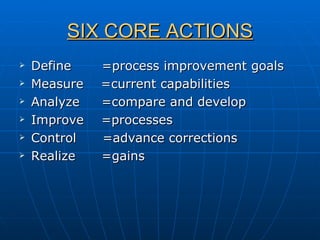

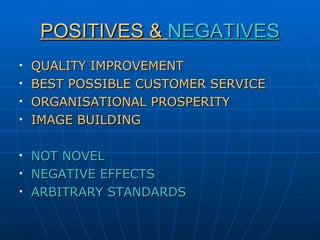

Six Sigma is a set of practices aimed at systematically improving processes to eliminate defects. It originated at Motorola in 1986, inspired by principles of total quality management and zero defects. Six Sigma aims for less than 3.4 defects per million opportunities through defining goals, measuring current performance, analyzing processes, improving processes, and controlling improvements. It uses a structure of executives, champions, master black belts, black belts, and others to implement projects using tools like ANOVA, cost-benefit analysis, and SIPOC maps. While enabling quality improvement and customer satisfaction, some criticize it for arbitrary standards and not being novel.