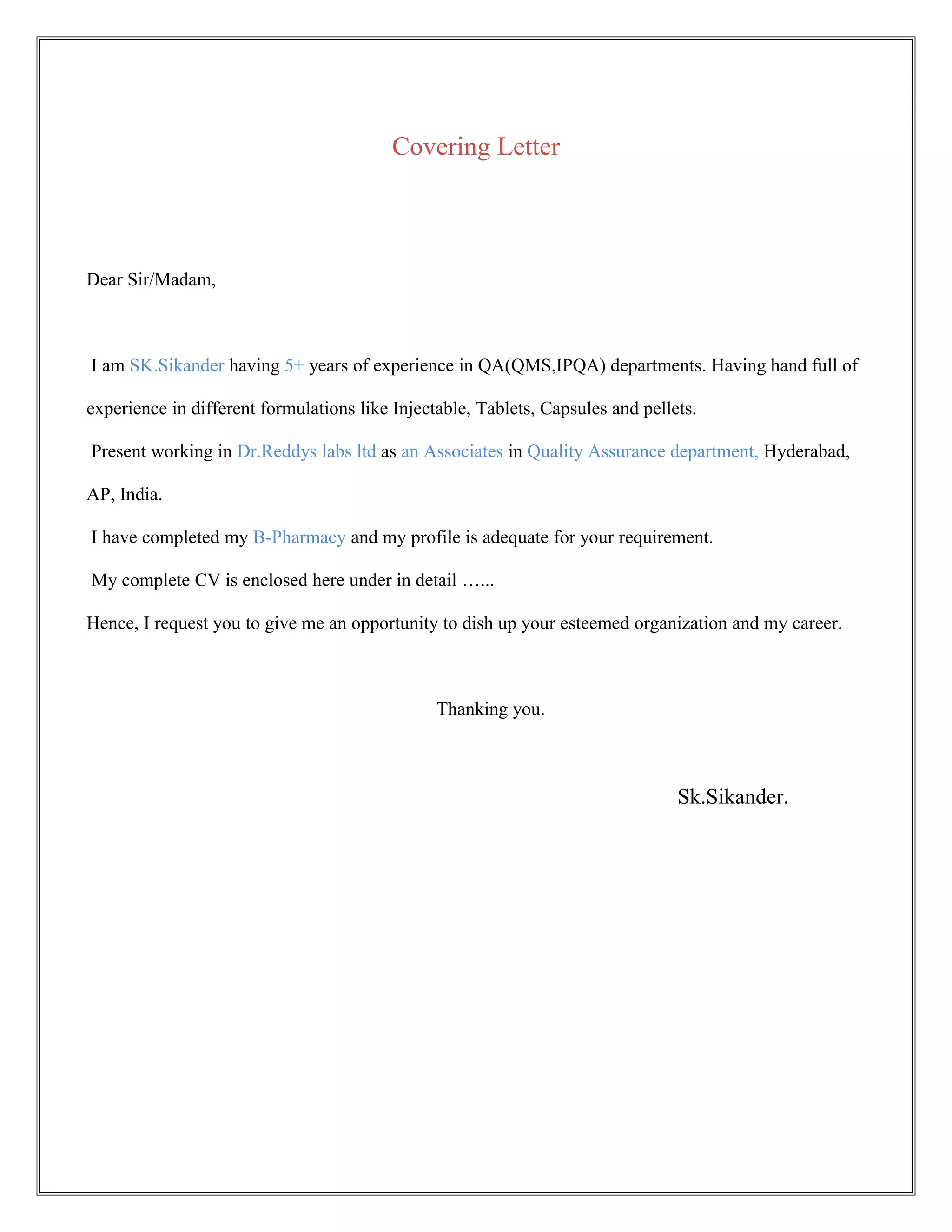

Sikander is applying for a new position and has over 5 years of experience in quality assurance for pharmaceutical formulations like injectables, tablets, capsules and pellets. He is currently working as an Associate in Quality Assurance at Dr. Reddy's Laboratories in Hyderabad, India. He has a B-Pharmacy degree and believes his qualifications are a good fit for the requirements of the new role. He has included his full CV for consideration and requests an opportunity to further his career with the company.