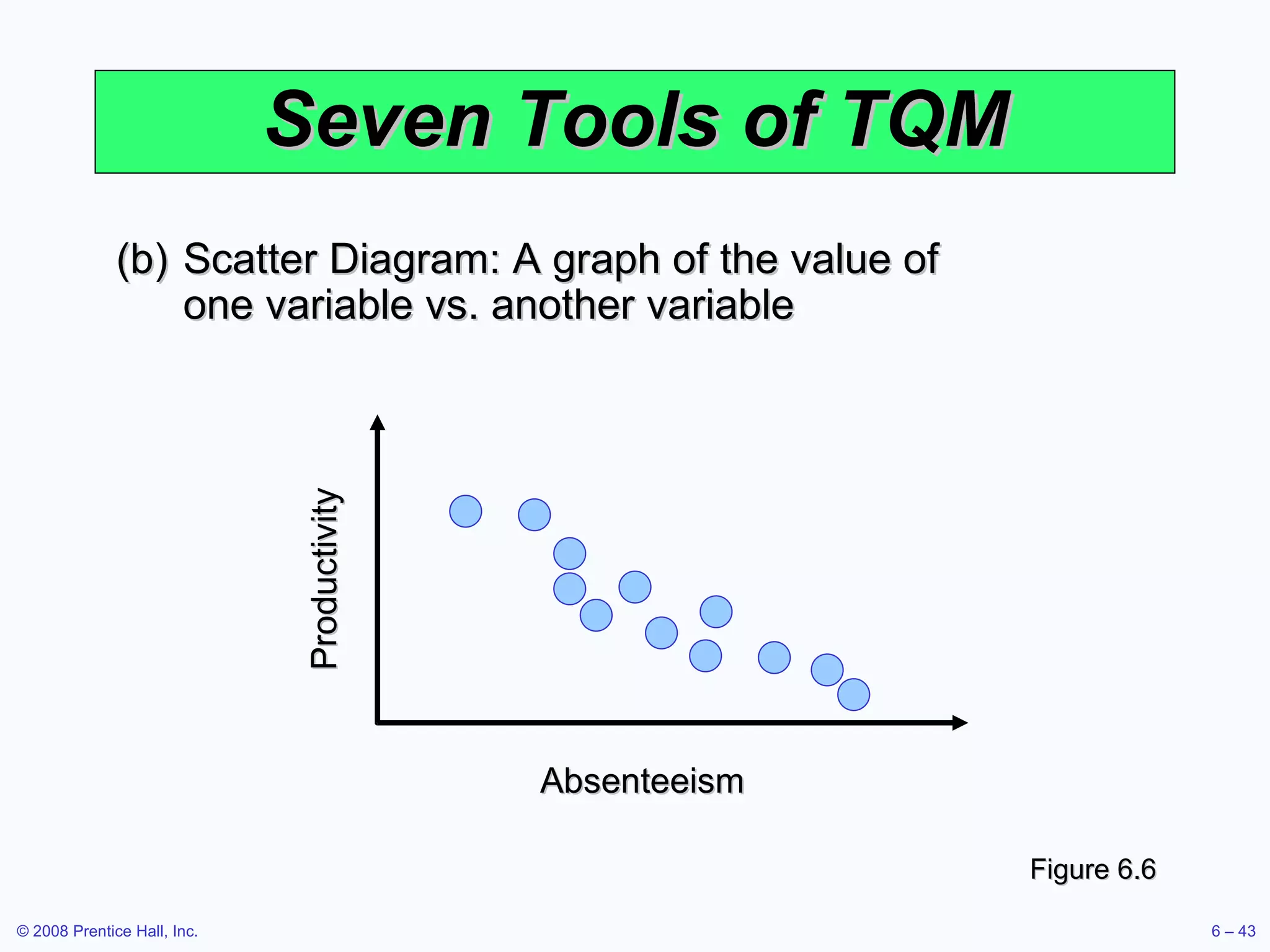

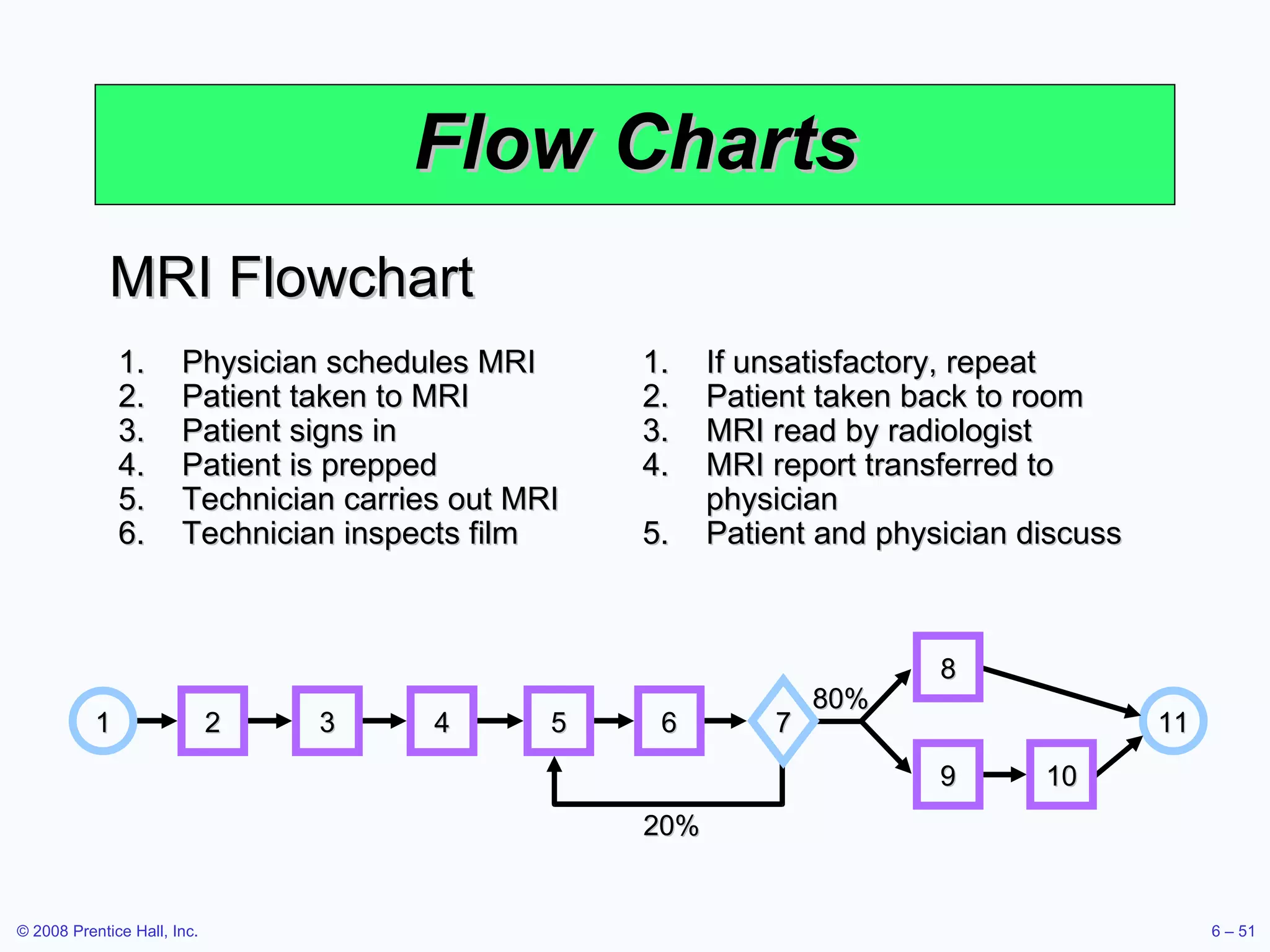

The document discusses key concepts in quality management including total quality management (TQM), Six Sigma, benchmarking, just-in-time (JIT) manufacturing, and tools for continuous improvement. It explains that quality supports business strategies, improves profitability through increased productivity and lower costs, and defines quality from different perspectives including user-based and manufacturing-based views. Key dimensions of quality and costs of quality are also summarized.