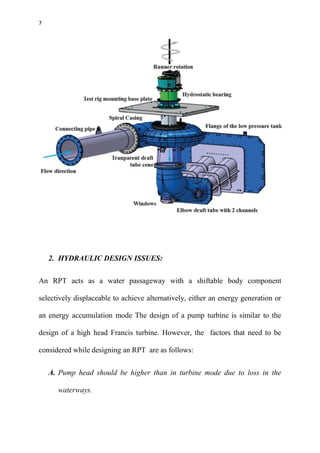

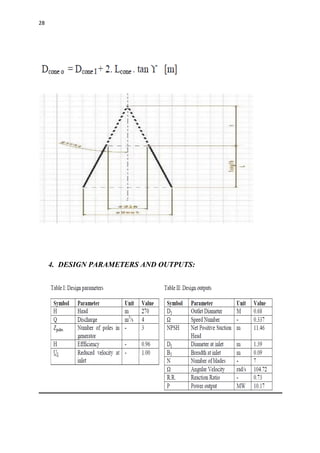

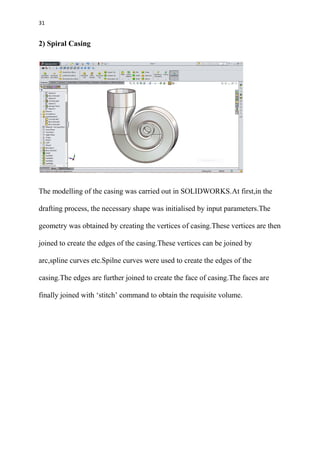

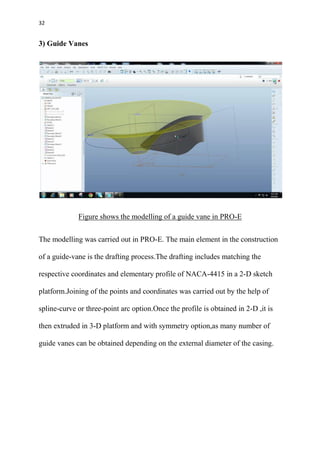

This document summarizes an undergraduate thesis on the design and analysis of a reversible pump turbine (RPT). The thesis was submitted by 8 students under the supervision of Dr. Subhas Chandra Rana. The thesis covers hydraulic design issues of RPTs including Euler's equation, stability, cavitation, and net positive suction head. It also describes the design process involving determining main dimensions, maximum efficiency point, and modeling the RPT housing using CAD software. Computational fluid dynamics analysis was performed to simulate the RPT in turbine mode.