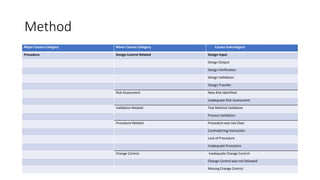

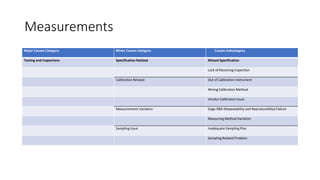

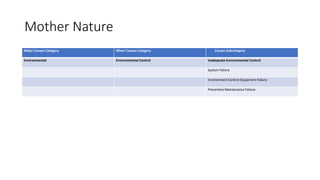

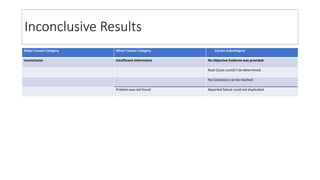

This document provides a standardized method for classifying the root causes of issues according to the "Six M's": Man, Machine, Method, Material, Measurement, and Mother Nature. It outlines major and minor cause categories for each of the Six M's. For example, under "Man" the major cause category is "Personnel Related" and minor categories include "Training Related" and "Procedure was not Followed." The goal is to standardize root cause reporting.