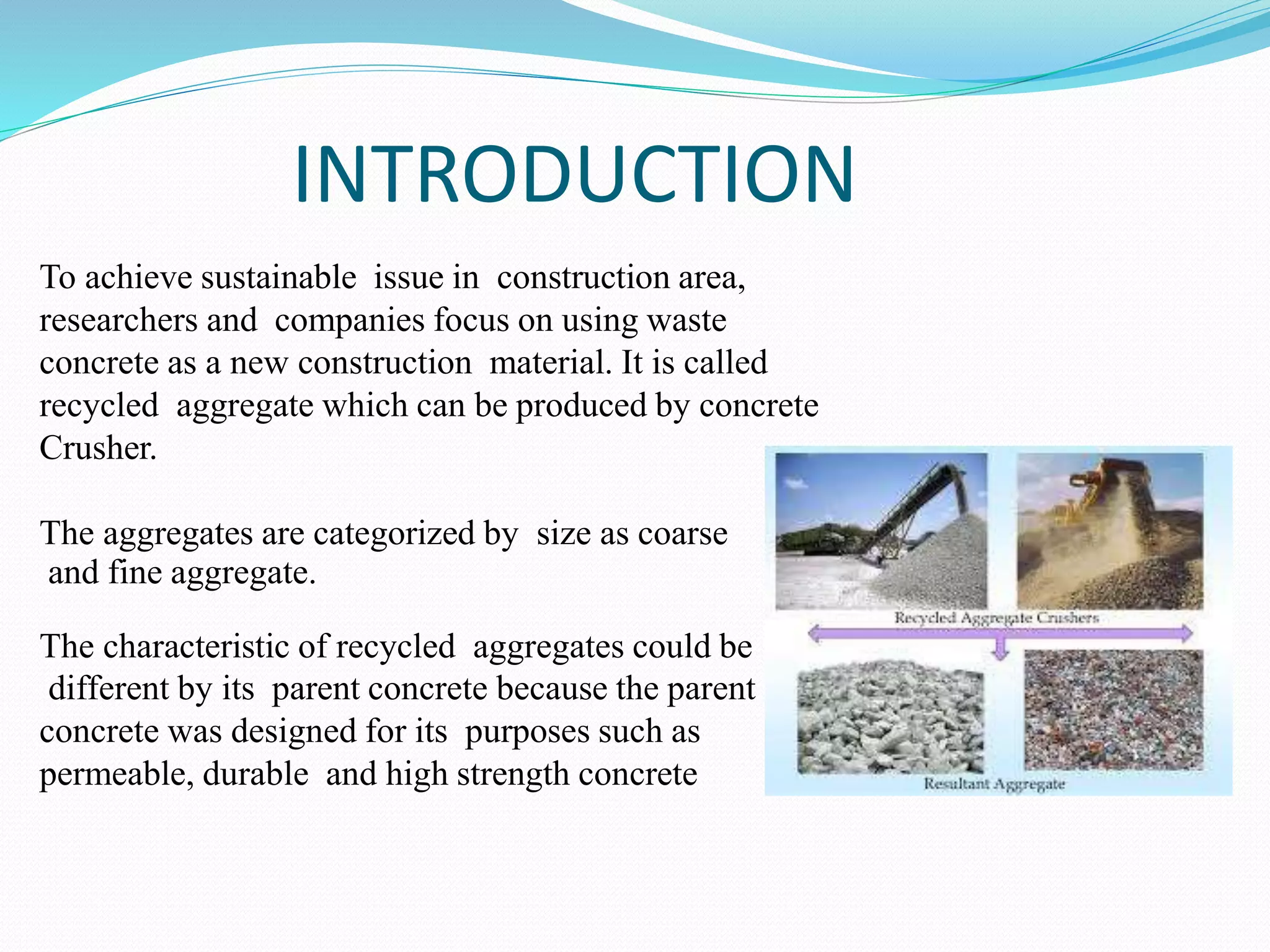

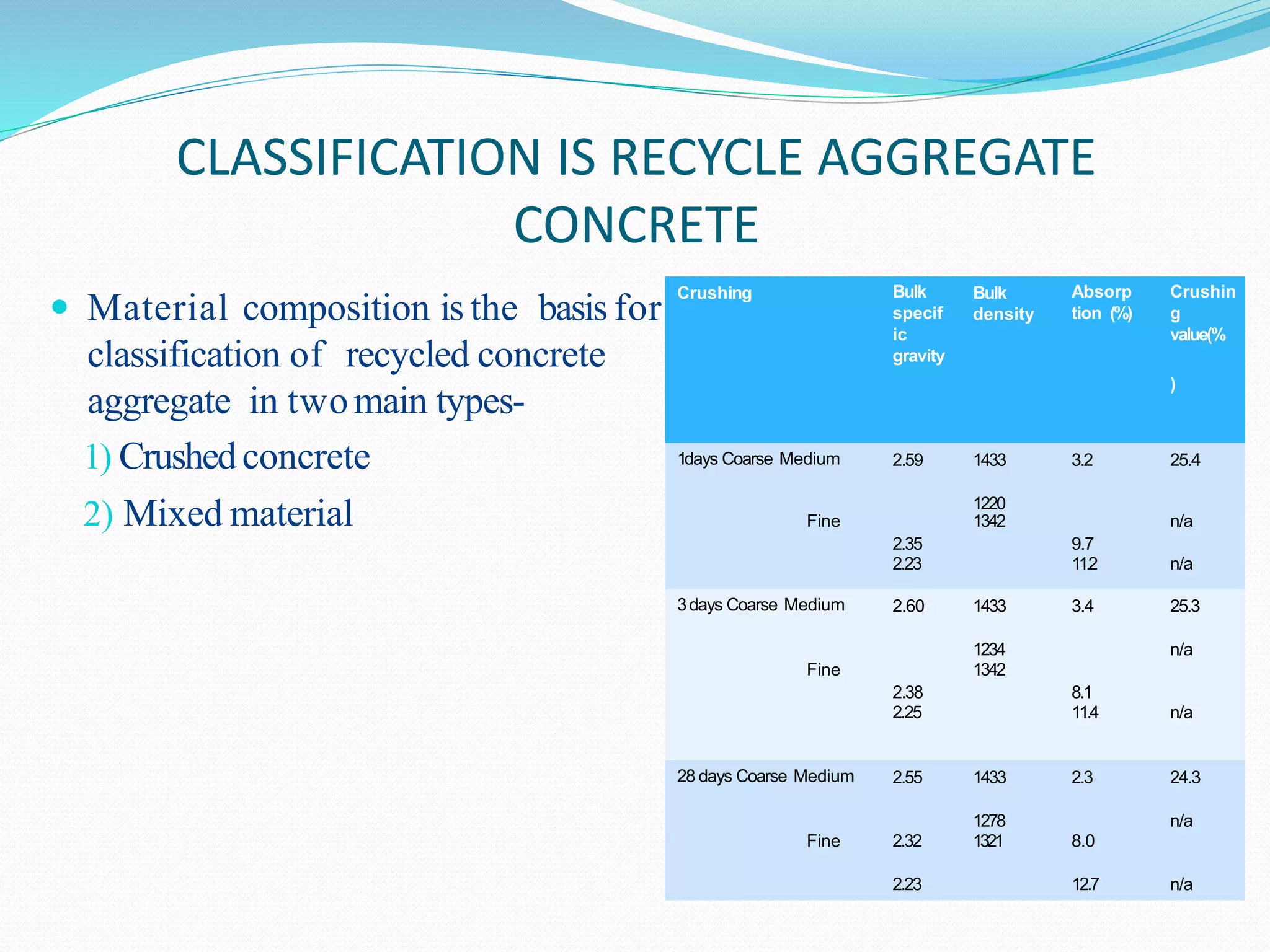

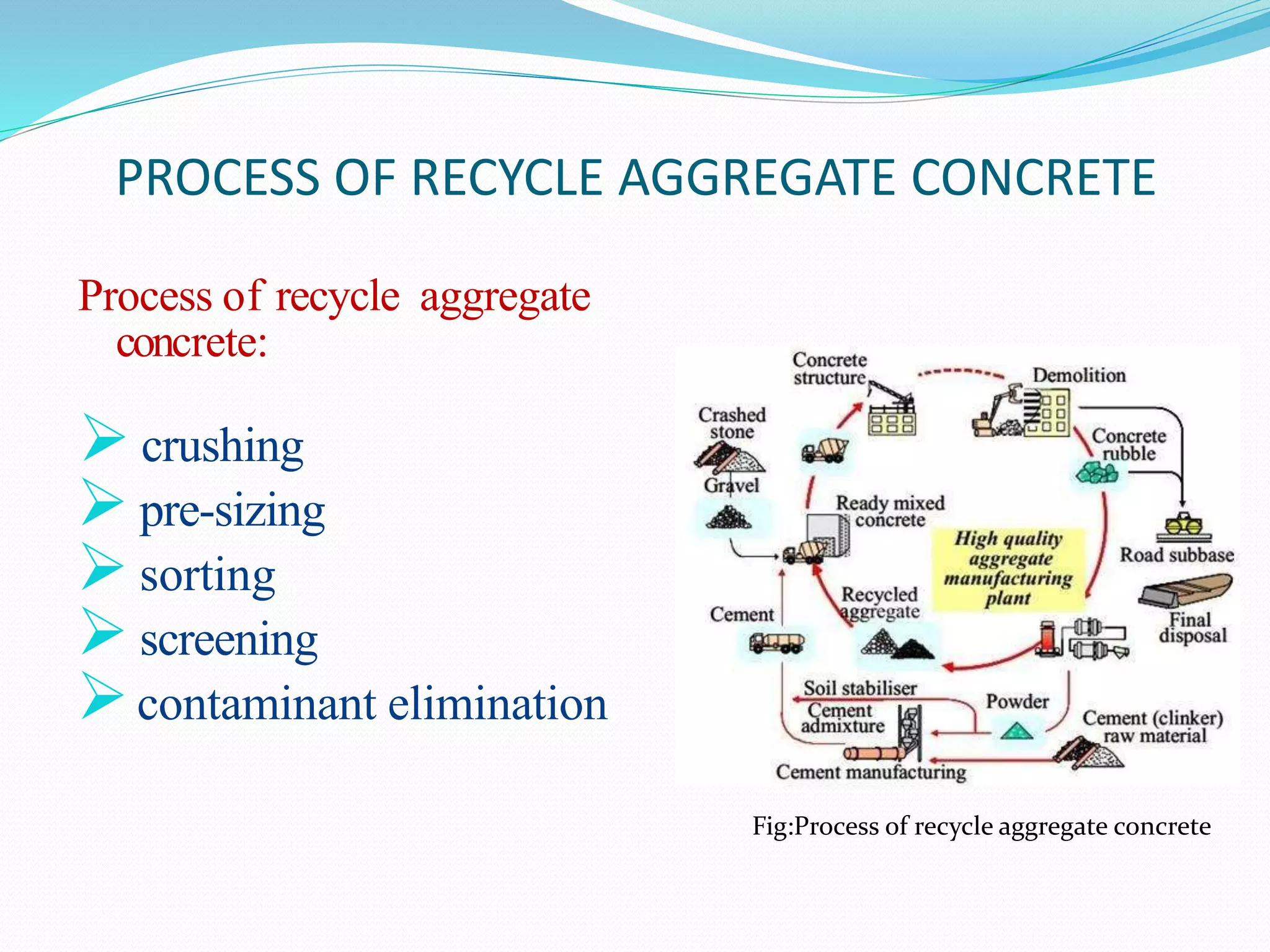

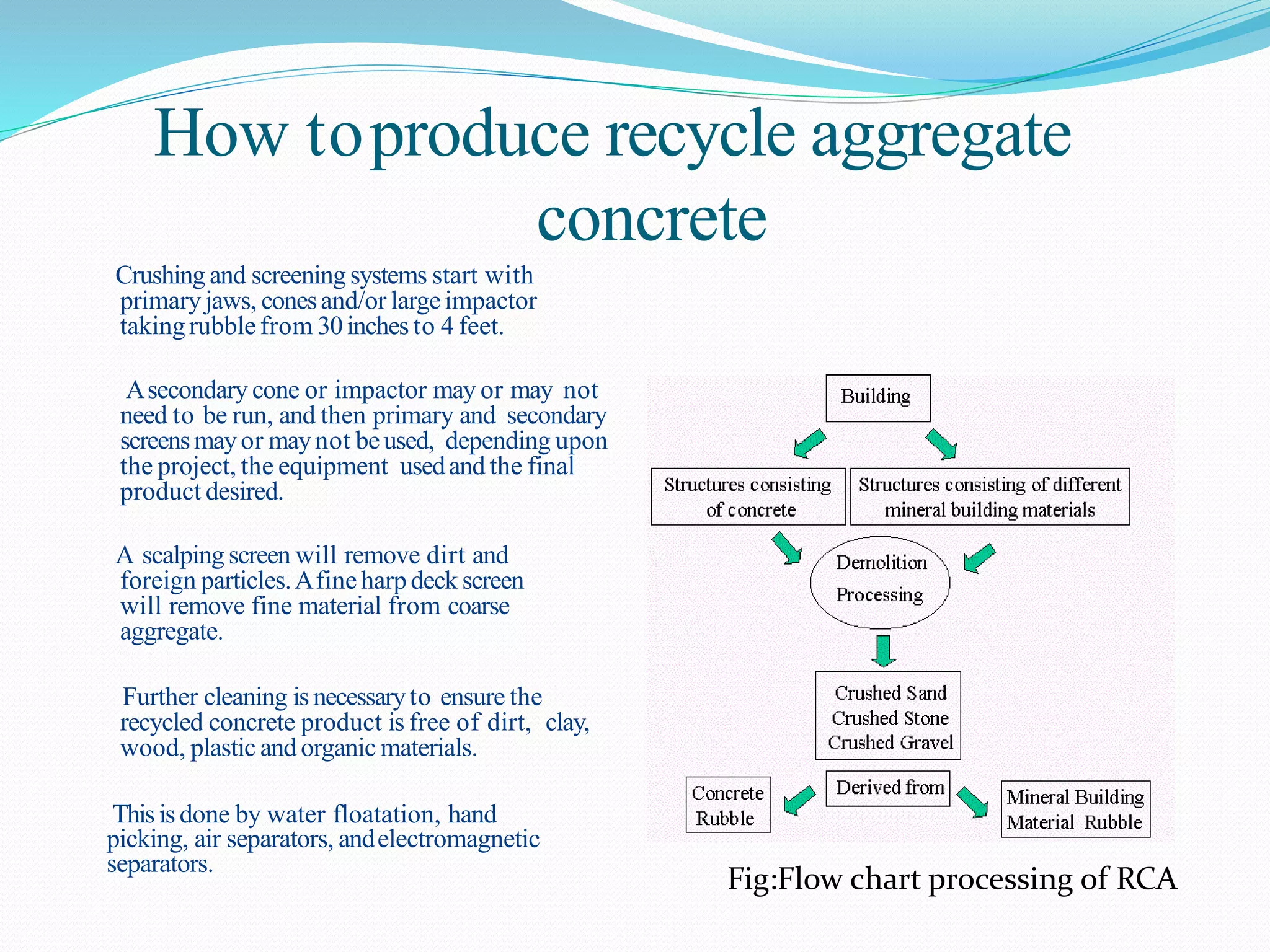

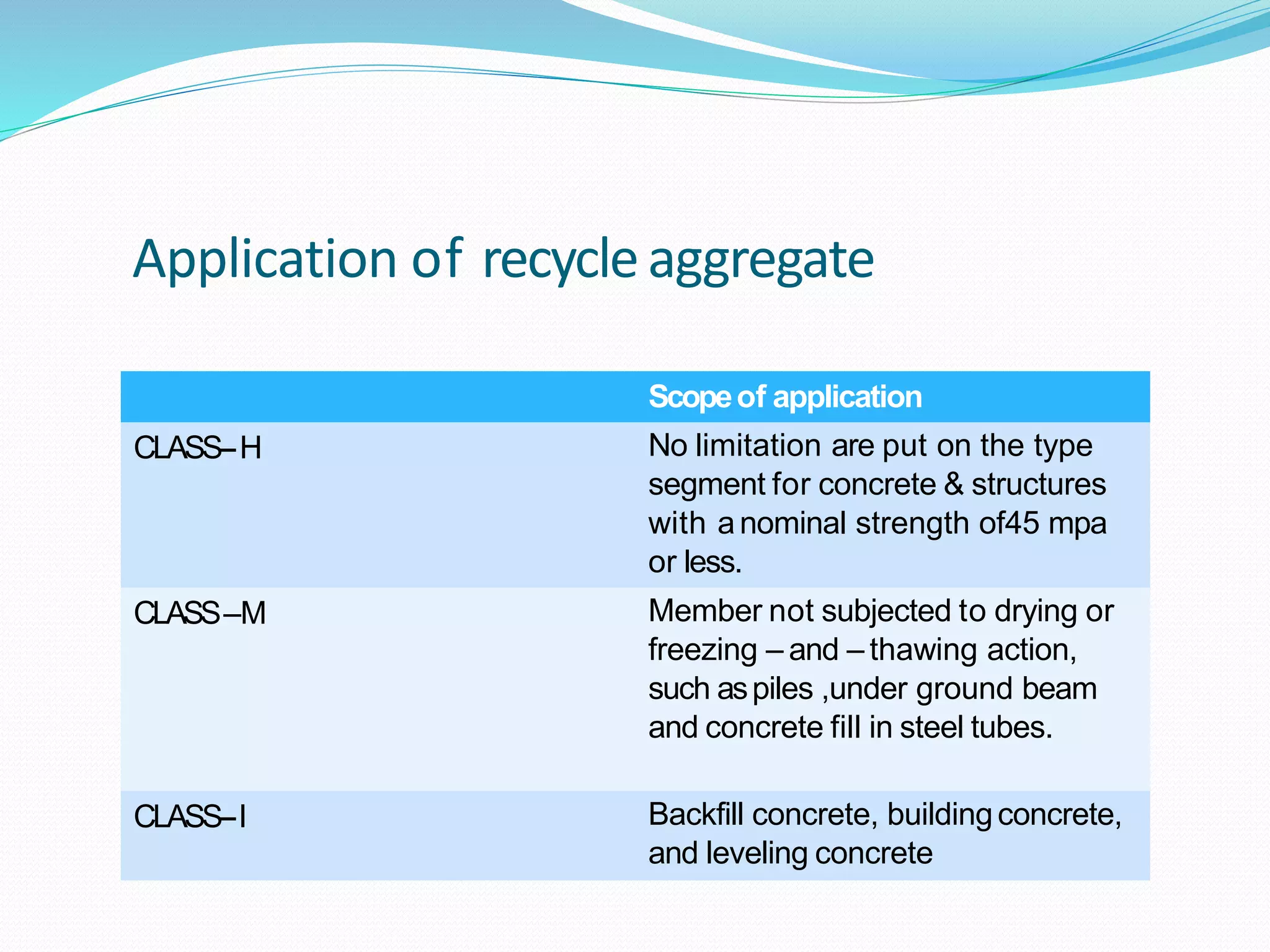

This document summarizes a study on recycled concrete aggregate conducted by G. Saichander, a 4th year civil engineering student. It discusses what recycled concrete aggregate is, its characteristics, classification, production process, uses, benefits, and disadvantages. Recycled concrete aggregate is produced from crushing waste concrete to achieve sustainable construction. It has properties like lower strength but can be used in applications like road base or sub-base to reduce costs and environmental impacts of virgin aggregate extraction and landfilling.