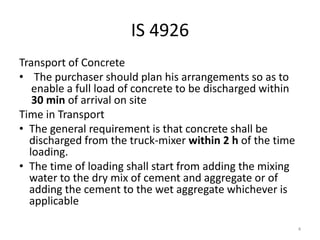

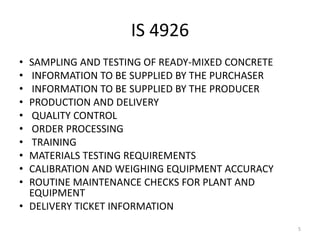

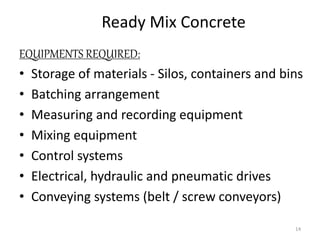

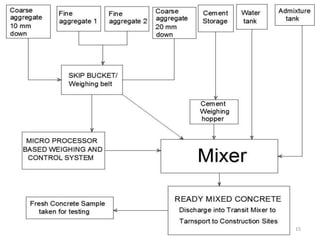

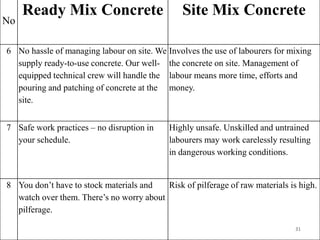

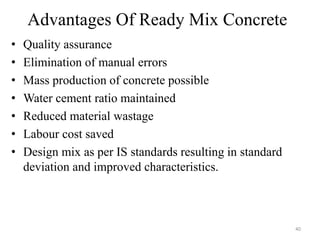

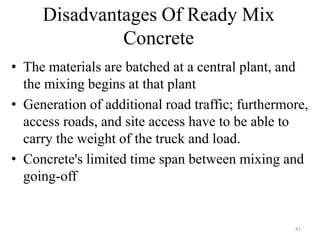

The document discusses the characteristics and benefits of ready-mix concrete (RMC), highlighting its convenience and quality in construction projects. It covers essential aspects such as transport requirements, raw materials, mixing processes, and the advantages and disadvantages of using RMC compared to site-mixed concrete. The document emphasizes the significance of planning and quality control in ensuring the effective use of RMC in various construction applications.